Crane underframe

A crane and underframe technology, applied in the field of cranes, can solve the problems of high cost of automobile cranes, unsuitable for long-term use, etc., and achieve the effects of compact structure, low construction site requirements, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

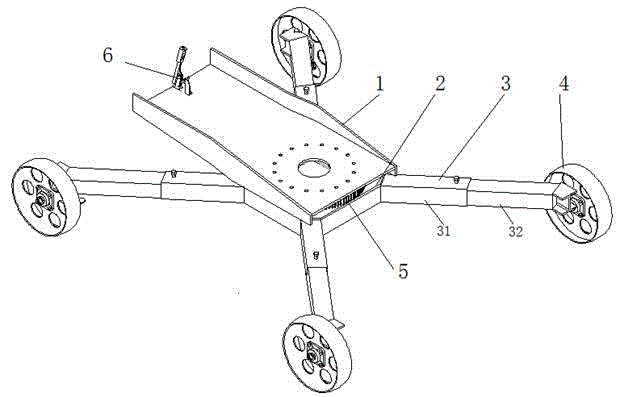

[0017] like figure 1 As shown, the crane underframe of the present invention includes a turntable 1, a base 2, a slewing bearing 5 installed between the turntable 1 and the base 2, a support leg 3 fixed on the base 2, and a support leg 3 installed at the end of the support leg 3. The walking wheel 4 and the slewing bearing 5 have an inner ring and an outer ring with teeth. The slewing table 1 can rotate freely relative to the base 2 around the slewing bearing 5. The bottom frame can move with the support legs 3 and the walking wheel 4 to realize the change of the position of lifting heavy objects. .

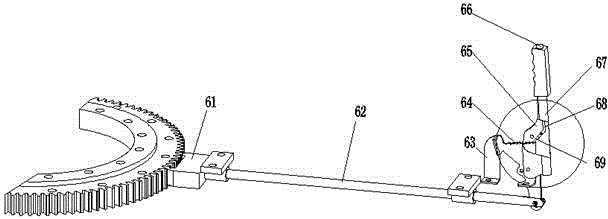

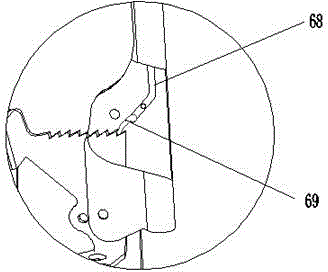

[0018] like figure 2 , image 3 As shown, the rotary locking mechanism 6 on the chassis is composed of a U-shaped fork 61, a lever 62, a locking handle 67 and a limit stop 63. The U-shaped fork 61 is fixedly connected to one end of the lever 62, and the lever 62 The other end is connected with the locking handle 67 by a rotating pair, the lever 62 is connected with the turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com