Inner cone type temperature equalizing target heat pipe blackbody

A heat pipe and cone technology, applied in the field of radiation temperature measurement, can solve the problems of difficult insertion depth of thermocouples or platinum resistances, difficult temperature gradients to meet design requirements, difficult target surfaces and standard devices, etc., to improve heating efficiency and The effect of heating speed, reducing thermal conductivity error, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

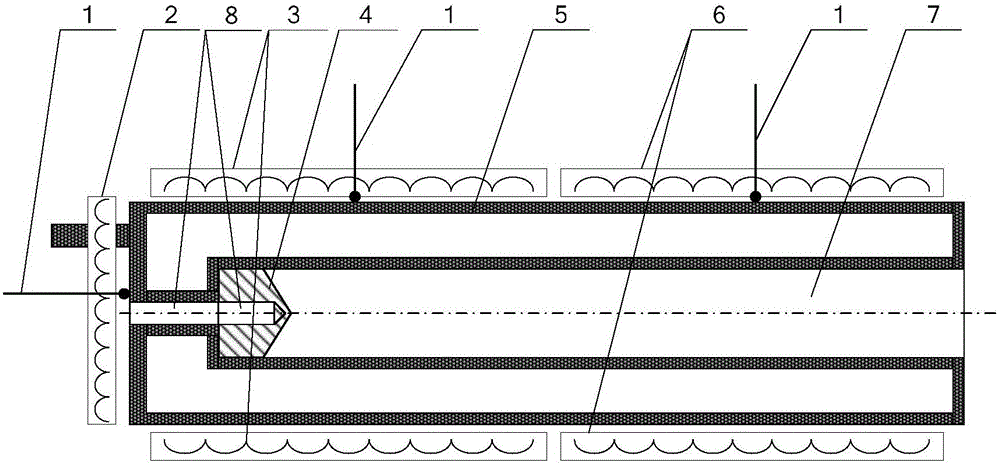

[0019] Such as figure 1 Shown is a schematic diagram of the black body structure of an inner cone type uniform temperature target heat pipe. The black body cavity 7 is integrated with the heat pipe 5. The inner wall of the heat pipe 5 is the black body cavity 7. Conical temperature equalizing target 4, the bottom of the inner conical temperature equalizing target 4 is punched as a reference temperature sensor jack 8, heat pipe 5 is heated in three stages, and the temperature control sensor 1 of each stage is installed on the outer wall of heat pipe 5. In this embodiment, the inner conical temperature uniform target 4 is fixed on the heat pipe 5 by welding, and the temperature control sensor 1 is installed on the outer wall of the heat pipe 5 by fastening a spring ring.

[0020] For the above-mentioned inner cone-type uniform temperature target heat pipe blackbody, the geometric shape of the blackbody cavity 7 is specially designed, that is, its length-to-diameter ratio must re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com