Catalyst sampler

A sampler and catalyst technology, applied in the direction of sampling devices, etc., can solve the problems of small sampling volume, non-continuous sampling, and poor universal applicability, and achieve the effects of increasing insertion depth, reducing sampling loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

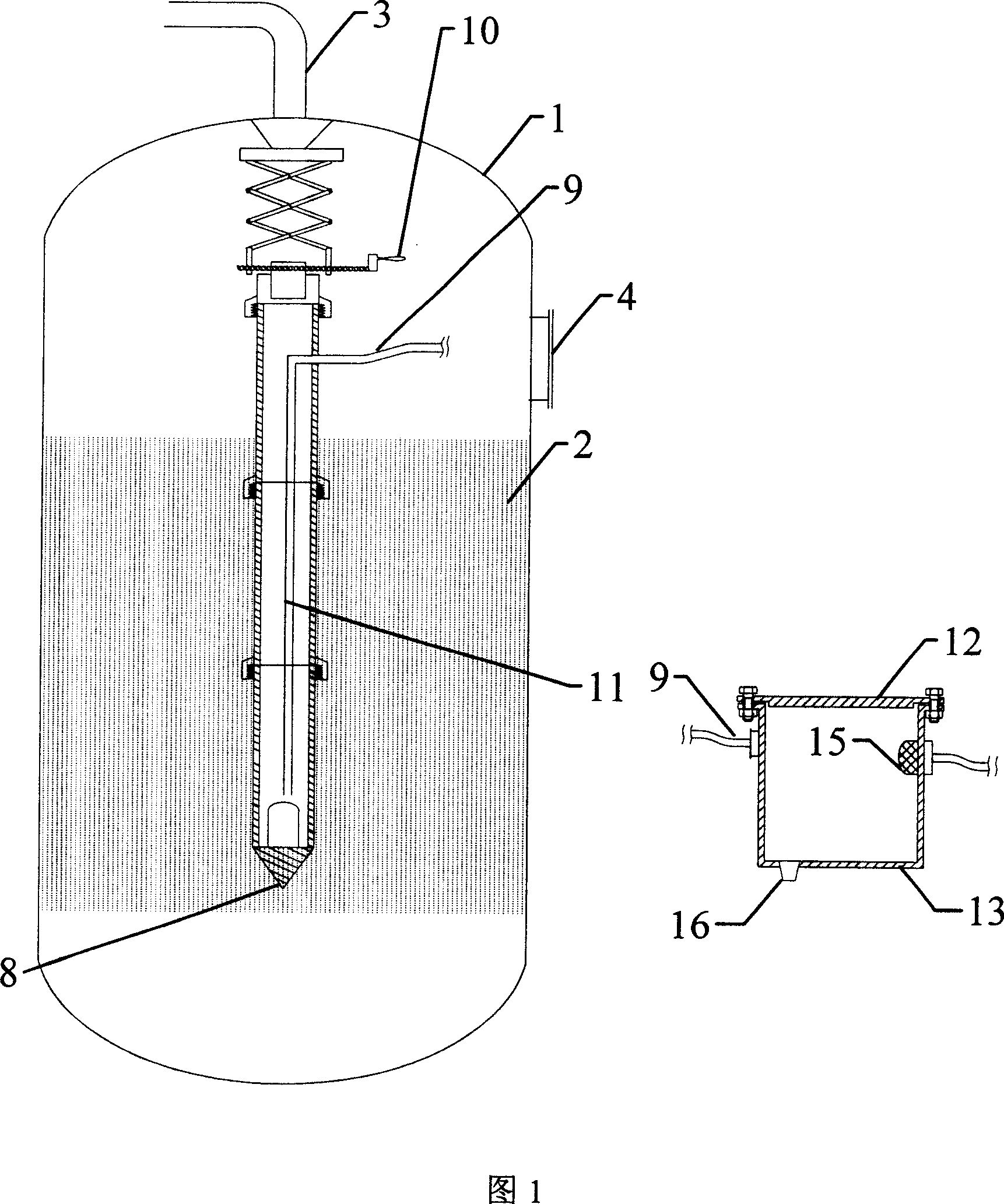

Embodiment 1

[0042] Catalyst sampling experiments were carried out in fixed bed reactors which had been operated industrially. Send 3 pipes of the sampling tube (made of metal), 3 pipes of the sample conduit (made of metal and plastic respectively), spiral lifter, hose and other components into the reactor through the manhole, and the catalyst is sampled. After assembly of the reactor, the catalyst in the catalyst bed was sampled. Driven by the screw jack, the sampling tube easily enters various depths of the catalyst bed. The catalyst bed is continuously sampled by opening the sampling hole, or by closing the sampling hole, that is, closing the sampling hole first, and then opening the sampling hole when the sampling tube reaches the required depth of the catalyst bed. Catalyst sampling at different depths, the catalyst sampling device of the present invention can accomplish the purpose of catalyst sampling. The sampler is inserted to a depth of up to 3 meters. When the sampling is fin...

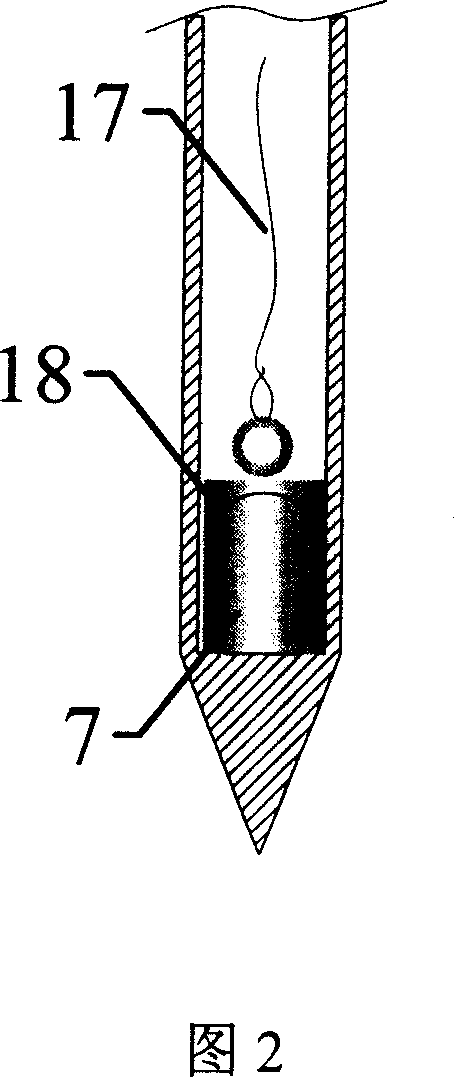

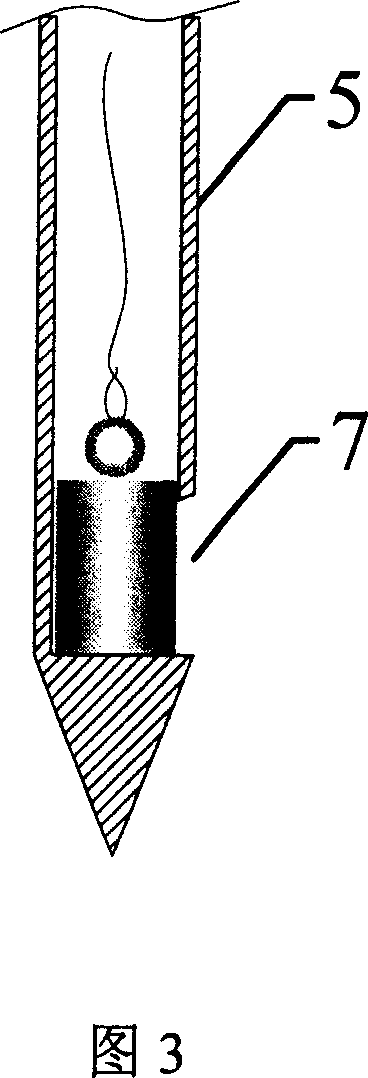

Embodiment 2

[0044] Catalyst sampling experiments were carried out in fixed bed reactors which had been operated industrially. Send 3 pipes of the sampling tube (made of metal), 3 pipes of the sample conduit (made of metal and plastic respectively), spiral lifter, hose and other components into the reactor through the manhole, and the catalyst is sampled. After assembly of the reactor, the catalyst in the catalyst bed was sampled. The effect of the screw propeller installed on the top of the sampling pipe 5 is mainly investigated. Practical applications have found that when the catalyst bed compaction is not serious and the catalyst bed is relatively loose, using the equal-diameter spiral propeller 19 can insert the sampler at a faster speed; , using the conical screw propeller 20, the sampler can be easily inserted into the catalyst bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com