Temperature uniformity control system for multi-temperature zone of large plate vacuum annealing furnace and control method thereof

A vacuum annealing furnace and control system technology, which is applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of multiple heating temperature zones, low temperature control accuracy, inconsistent detection and control, etc., and achieve convenient and intelligent operation High degree, improve the effect of temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

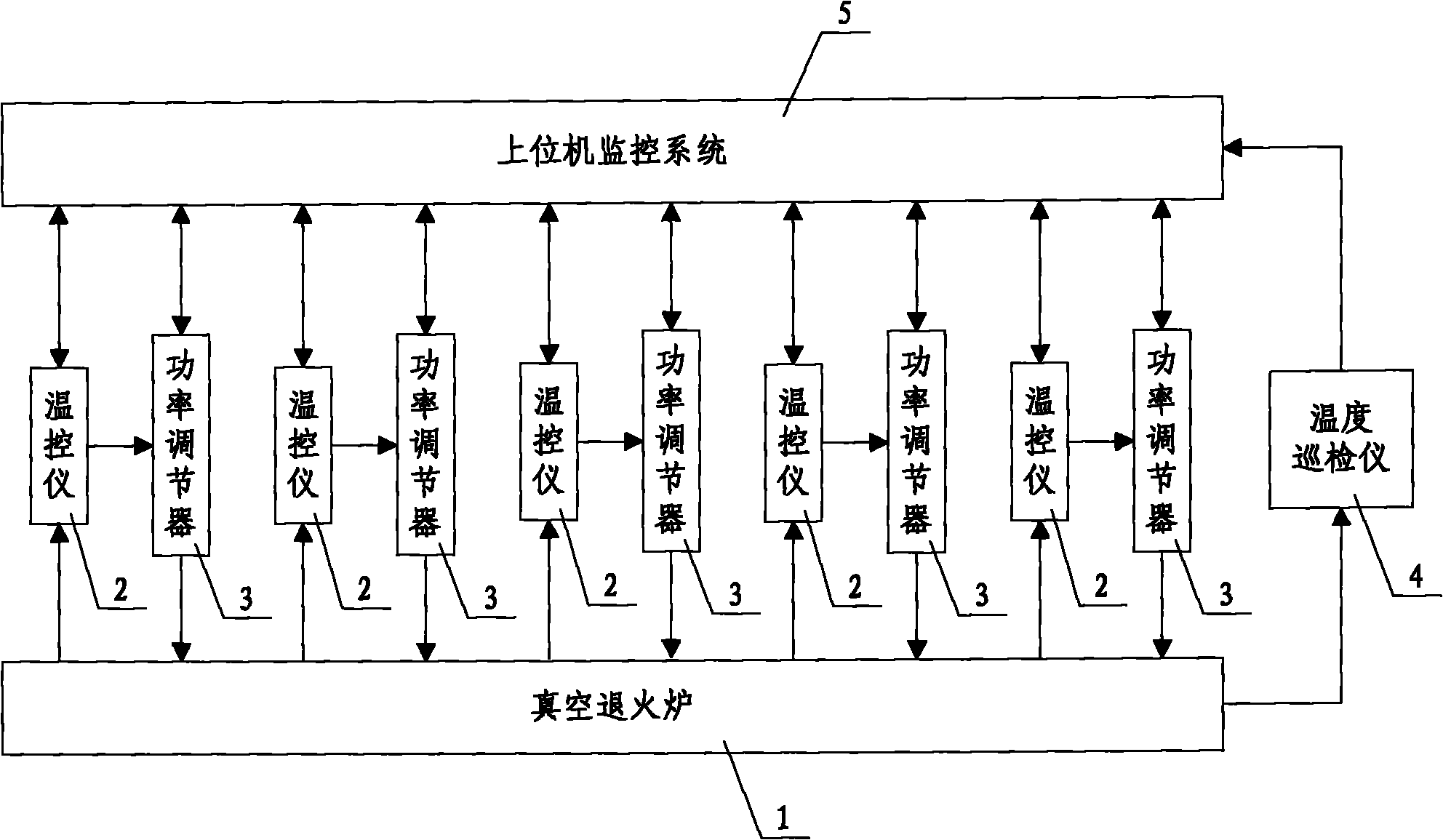

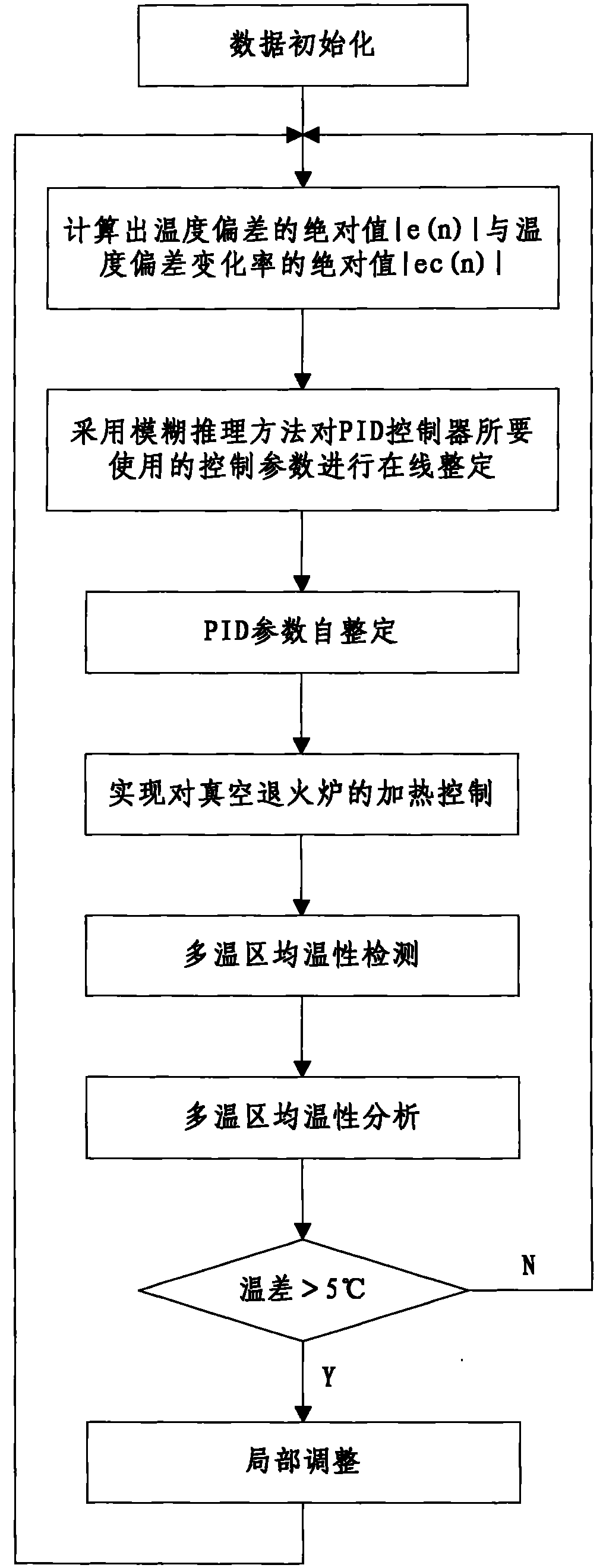

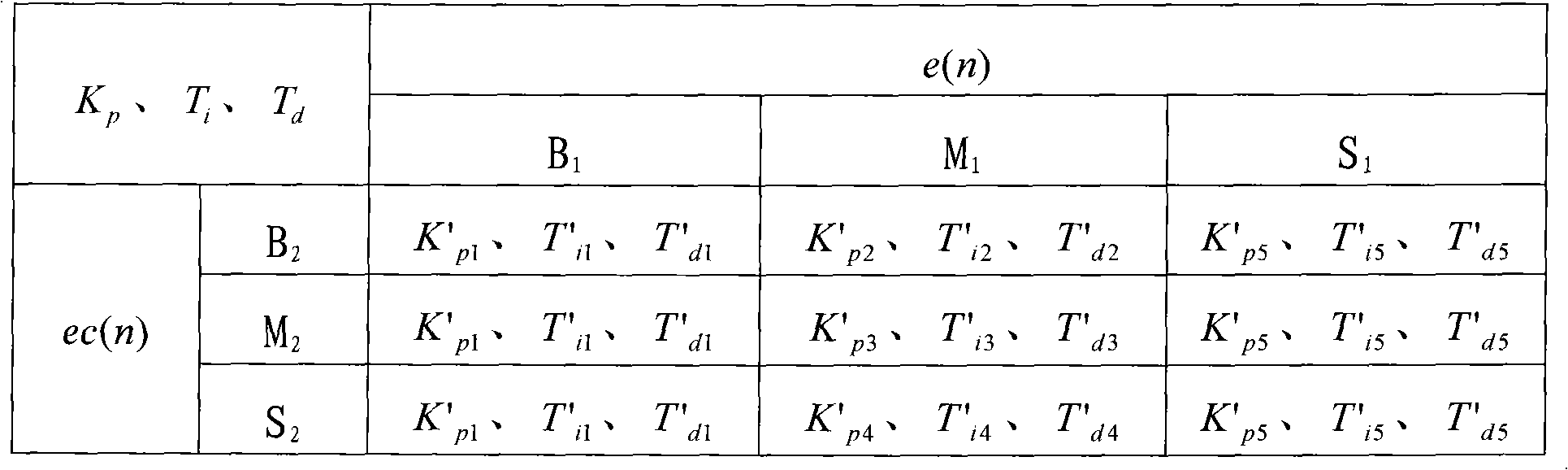

[0044] Such as figure 1 As shown, the large plate vacuum annealing furnace multi-temperature zone temperature uniformity control system of the present invention includes correspondingly connecting with multiple heating zones of the vacuum annealing furnace 1 and controlling the heating temperature in each heating zone of the vacuum annealing furnace 1 A plurality of temperature controllers 2 to be controlled, a plurality of power regulators respectively connected to a plurality of temperature controllers 2 and correspondingly connected to a plurality of heating zones of the vacuum annealing furnace 1 and to adjust the heating power of the vacuum annealing furnace 1 3. The uniform temperature inspection instrument 4 connected to the multiple heating zones of the vacuum annealing furnace 1 and detecting the temperature of each heating zone of the vacuum annealing furnace 1, and the multiple temperature controllers 2 and multiple powers through the RS485 bus The regulator 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com