Corrugated board creasing wheel and creasing wheel device

A corrugated cardboard and wire crimping wheel technology, applied in the direction of mechanical processing/deformation, can solve the problems of poor folding resistance, uneven folding and flapping, and achieve the effect of reducing costs, avoiding line bursting, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

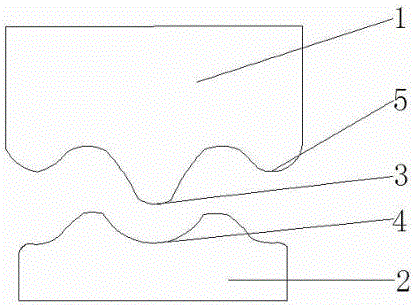

[0022] refer to figure 1 , a seven-layer paper corrugated cardboard creasing wheel, including an upper creasing wheel 1 and a lower creasing wheel 2, the upper creasing wheel 1 has a downward middle protrusion 3 in the middle of the bottom, and secondary protrusions 5 on both sides of the middle protrusion 3 , the upper crimping wheel 1 presents a three-convex shape, and the bottom crimping wheel 2 has a groove 4 in the center of the top. When the upper crimping wheel and the lower crimping wheel rotate, the middle protrusion 3, the auxiliary protrusion 5 and the groove are correspondingly engaged. The middle protrusion 3 of the upper crimping wheel 1, the auxiliary protrusions 5 on both sides and the groove 4 of the lower crimping wheel 2 are smooth curved surfaces; wherein, the height of the middle protrusion 3 is 5mm, and the height of the auxiliary protrusions 4 on both sides The height is 2mm, and the groove surface width of the groove 5 of the lower crimping wheel is 20m...

Embodiment 2

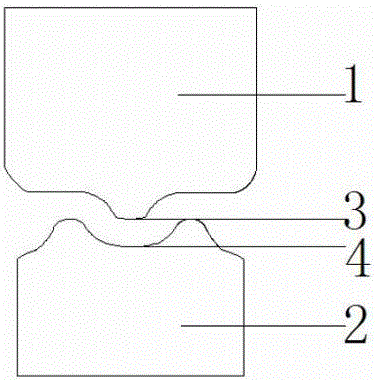

[0026] refer to figure 2 , a five-layer paper corrugated cardboard crimping wheel, including an upper crimping wheel 1 and a lower crimping wheel 2, the upper crimping wheel 1 has a downward middle protrusion 3 in the middle of the bottom, presenting a single convex shape, and the lower crimping wheel 2 There is a groove 4 in the center of the top. When the upper crimping wheel 1 and the lower crimping wheel 2 rotate, the middle protrusion 3 and the groove 4 are correspondingly engaged; the middle protrusion 3 of the upper crimping wheel 1 and the lower crimping wheel 2 The groove 4 is a smooth curved surface; wherein, the height of the middle protrusion 3 is 4mm, and the groove surface width of the groove 5 of the lower crimping wheel is 16mm.

[0027] A corrugated paper crimping wheel device, comprising a base frame, an upper crimping wheel shaft and a lower crimping wheel shaft installed on the base frame, and the above-mentioned upper creasing wheel and lower crimping whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com