Large-rotary continuous feeding and waste discharging system

A material feeding and waste technology, applied in metal processing and other directions, can solve the problems of large floor space, increased operating costs of paper cutters, and increased costs, and achieve the effects of improving production efficiency, reducing idle running time, and realizing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

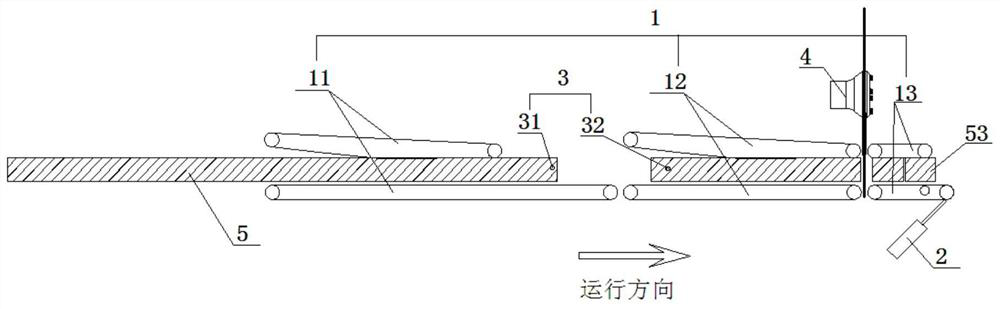

[0054] figure 1 It shows an implementation form of the present invention, a large-circle continuous feeding and waste discharge system, including:

[0055] The feeding and conveying system 1 includes a first clamping and conveying unit 11, a second clamping and conveying unit 12 and a third clamping and conveying unit 13 arranged in sequence along the feeding direction, and the clamping and conveying unit is composed of conveyor belts arranged up and down oppositely , the feeding conveying channel is formed between the upper and lower conveyor belts, and the horizontal linear feeding channel composed of the first feeding conveying channel, the second feeding conveying channel and the third feeding conveying channel corresponding to the three clamping conveying units respectively The lower conveyor belt of the third clamping and conveying unit allows one end to swing up and down, and a telescopic mechanism 2 is arranged below the third clamping and conveying unit to support the...

Embodiment 2

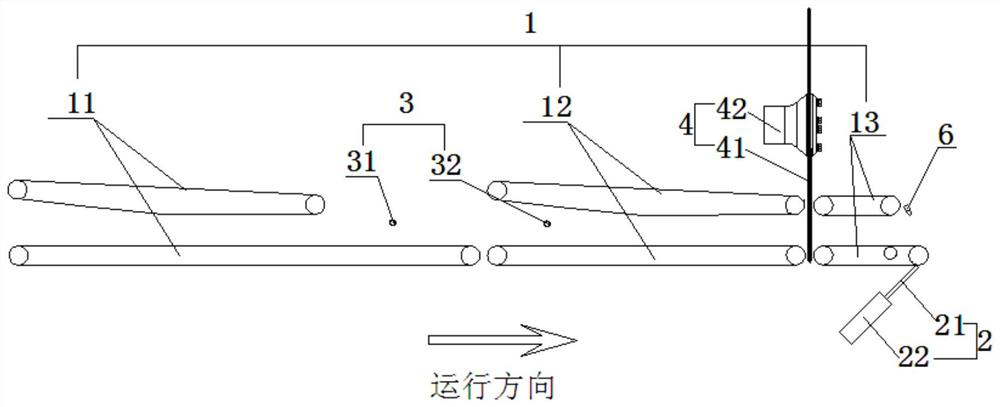

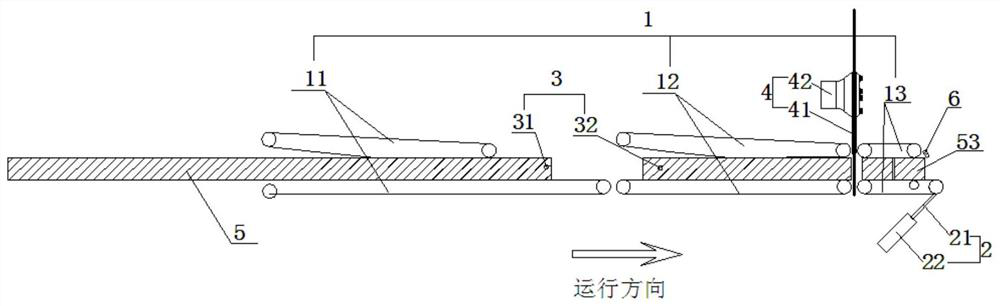

[0064] figure 2 It shows an implementation form of the present invention, a large-circle continuous feeding and waste discharge system, including:

[0065] The feeding and conveying system 1 includes a first clamping and conveying unit 11, a second clamping and conveying unit 12 and a third clamping and conveying unit 13 arranged in sequence along the feeding direction, and the clamping and conveying unit is composed of conveyor belts arranged up and down oppositely , the feeding conveying channel is formed between the upper and lower conveyor belts, and the horizontal linear feeding channel composed of the first feeding conveying channel, the second feeding conveying channel and the third feeding conveying channel corresponding to the three clamping conveying units respectively The lower conveyor belt of the third clamping and conveying unit allows one end to swing up and down, and a telescopic mechanism 2 is arranged below the third clamping and conveying unit to support th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com