Patents

Literature

61results about How to "Adapt to production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-permeability super black decorated base paper and preparation method thereof

ActiveCN103614949AImprove permeabilityImprove breathabilitySpecial paperPaper/cardboardTitaniumWet strength

The invention relates to high-permeability super black decorated base paper and a preparation method of the high-permeability super black decorated base paper, and belongs to the technical field of decoration base paper. The preparation method is characterized by comprising the following steps: taking pulp mixed from bleached softwood pulp and bleached hardwood pulp according to the mass ratio of 1:(3.6-4.4) as a main raw material; reducing the beating degree of bleached wood pulp to 32 SR, enabling the mass concentration to reach 4%, and then pumping into a repulping pond for later use; directly adding a black pigment to the repulping pond, wholly substituting kaoline for titanium dioxide to prepare the decorated base paper with a black and shiny color, the fluorescent whiteness of 6%-8%, the basis weight of 70-90g / m<2>, the ash content of 10%-15%, the wet strength of 6.5-9N, the dry strength of 35-50N, the water absorption of 20-35mm / 10 minutes and the air permeability of 15-20s / 100ml. The high-permeability super black decorated base paper disclosed by the invention has the advantages of uniformity in coloring, good covering power, high air permeability, low basis weight and high paper output ratio; a processed decorating plate is high in stereoscopic impression, pure and bright in color and luster, green and environmental-friendly without white patterns.

Owner:ZIBO OU MU SPECIAL PAPER

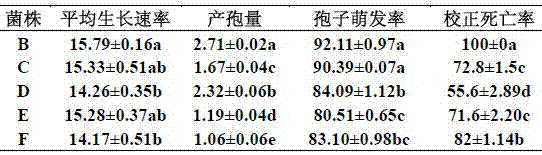

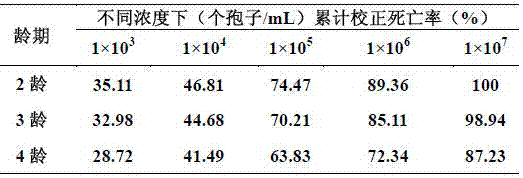

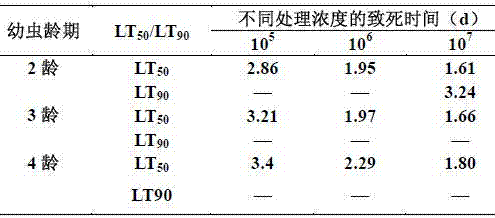

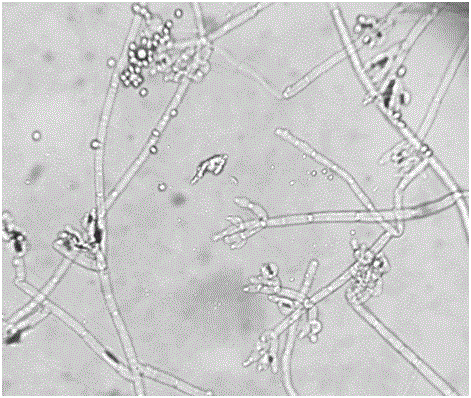

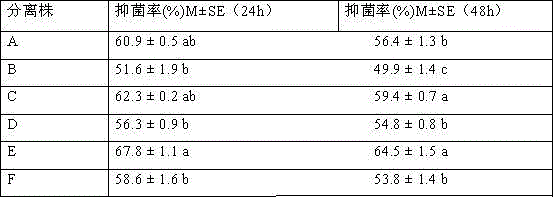

Fungi Imperficti strain and uses thereof

InactiveCN101343614AAdapt to production requirementsNo pollution in the processBiocideFungiBiotechnologyPlutella

The invention discloses paecilomyces javanicus strain and the application thereof. The strain adopts paecilomyces javanicus IJ-N2, the strain is preserved in the China Center for Type Culture Collection on tenth of June in 2008 with a CCTCC No of M208085. The strain is wild strain obtained through separating a plutella xylostella body naturally infested by entomogenous fungous from Nonggang Natural Forest Reserve Areas in Guangxi, the paecilomyces javanicus strain is obtained through the wild strain being back inoculated to the plutella xylostella body for rejuvenation, and depurative strain is obtained through the monospore separating operation being performed to the strain. The paecilomyces javanicus strain has strong infestation and insecticidal effect to aleyrodids, solenopsis invicta buren, spodoptera litura, aphid and plutella xylostella according to long-term infection biology study and indoor bioassay.

Owner:GUANGDONG XINJINGXIANG BIOLOGICAL ENG CO LTD

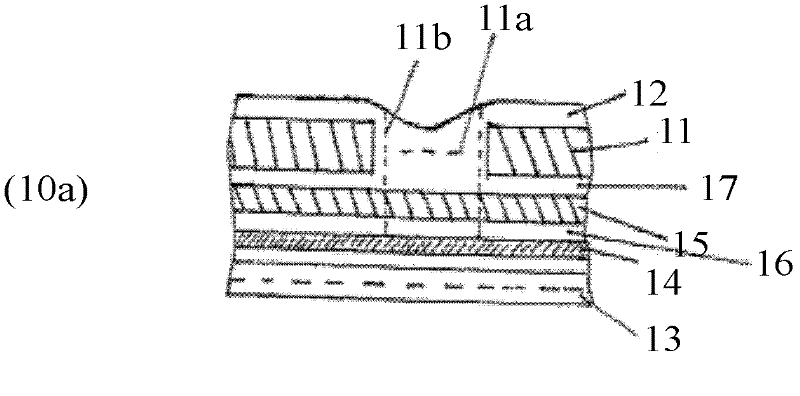

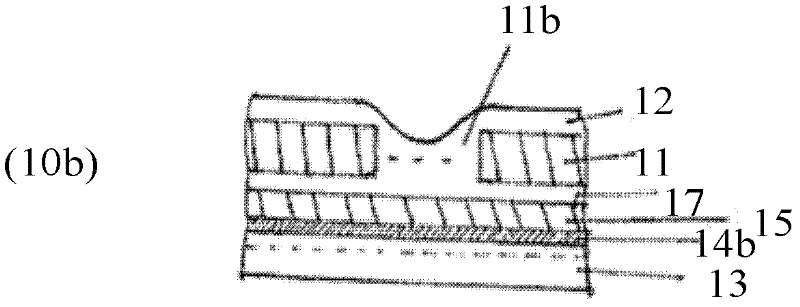

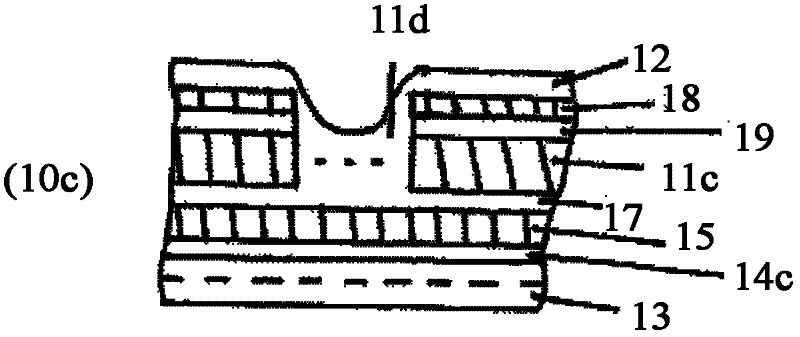

Robust packaging laminate, method for manufacturing of the packaging laminate and packaging container produced therefrom

ActiveCN102470626ARaise the possibilityAdapt to production requirementsSynthetic resin layered productsLaminationCardboardPolymer science

A packaging laminate (10a) comprising a core layer of paper or carton (11) with through -going holes, openings or slits (11a), a first layer of heat sealable thermoplastic material applied on the outermost side of the packaging laminate (10a), a second layer of heat sealable thermoplastic material (13) applied on the other, innermost side of the packaging laminate (10a), one or more barrier layers (14) applied between the core layer (11) and the innermost thermoplastic layer (13), the thermoplastic material (12,13) and barrier layers (14) all being laminated to each other within the regions of said holes (Ha) to form a membrane of barrier and thermoplastic material layers. A method for manufacturing of the packaging laminate and a packaging container that is made from the packaging laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

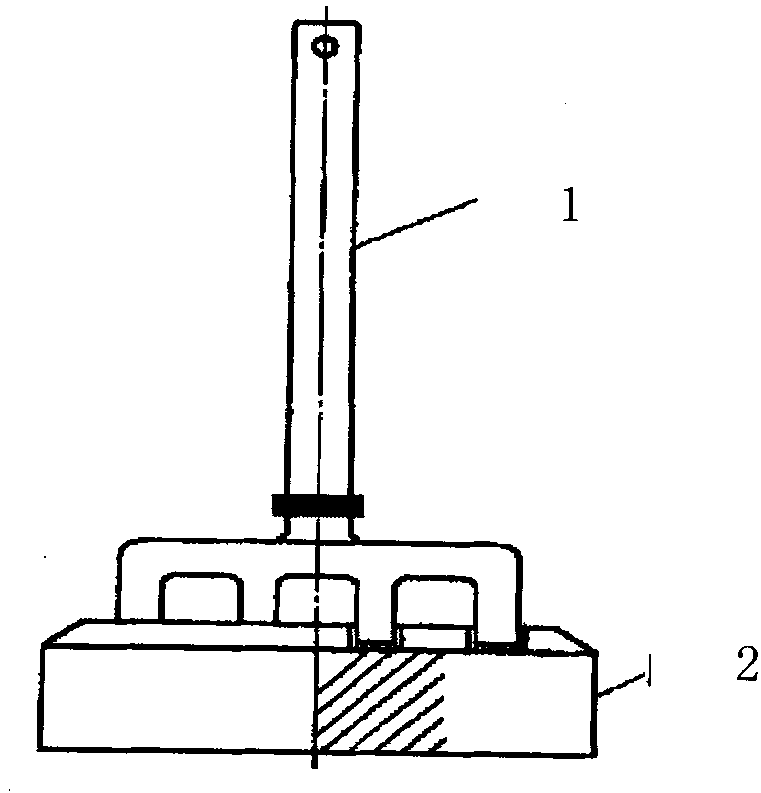

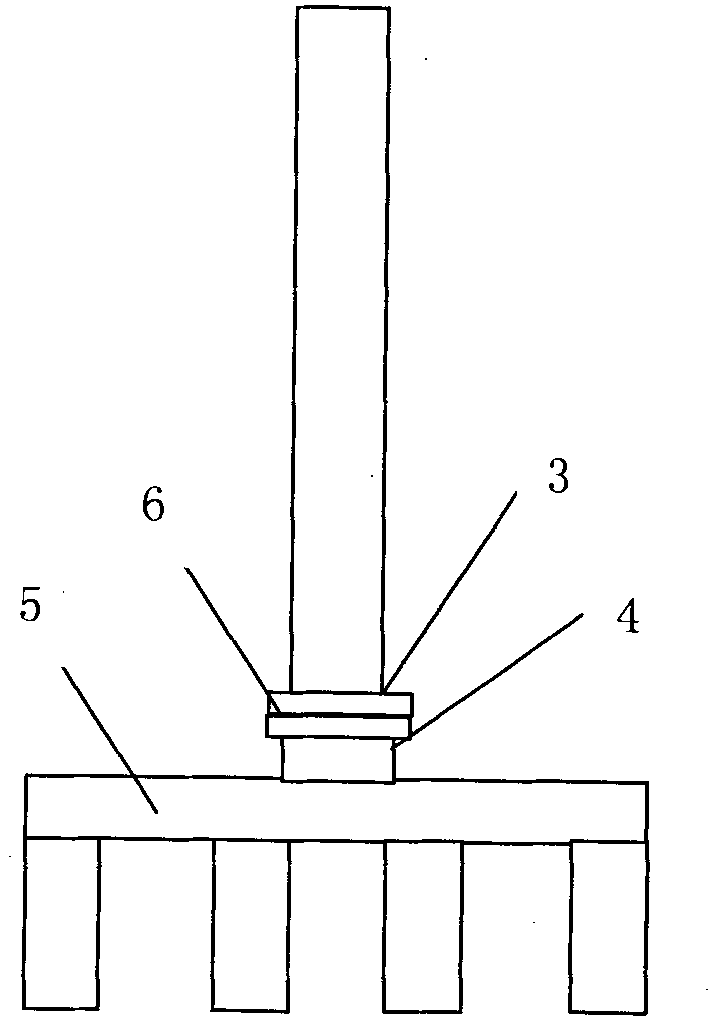

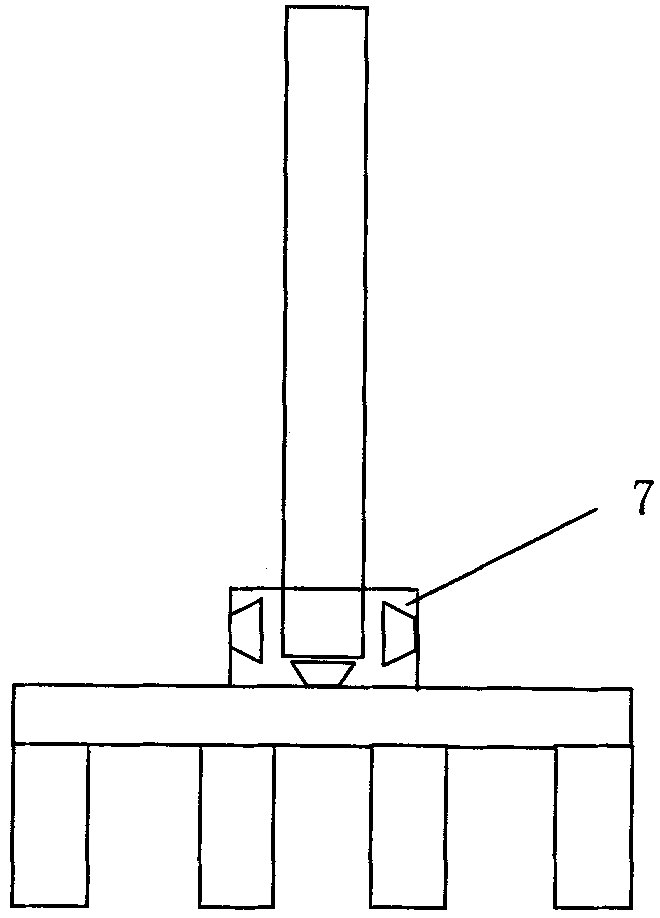

Connecting structure of aluminum electrolytic prebaked anode guide bar and steel jaw and preparation method thereof

The invention discloses a connecting structure of an aluminum electrolytic prebaked anode guide bar and a steel jaw and a preparation method thereof. The connecting structure of the aluminum electrolytic prebaked anode guide bar and the steel jaw ensures that the guide bar and the steel jaw are connected into a whole by pouring a steel jaw hollow hopper with aluminum liquid or aluminum-copper alloy liquid with the temperature of 750-800DEG C at the temperature of 500-600DEG C. A connecting method of the aluminum electrolytic prebaked anode guide bar and the steel jaw has strong reliability and reduces the voltage loss of an anode steel jaw by about 10-20mv by fully utilizing good conductive performance of aluminum; and an aluminum-steel interface alloy layer has stable bonding, high strength and little deformation, thereby greatly reducing the desoldering rate of aluminum-aluminum soldering points and burst soldering points of the aluminum guide bar, effectively prolonging the service life of the anode guide bar and reducing the maintenance fees and the using cost.

Owner:YUNNAN ALUMINUM

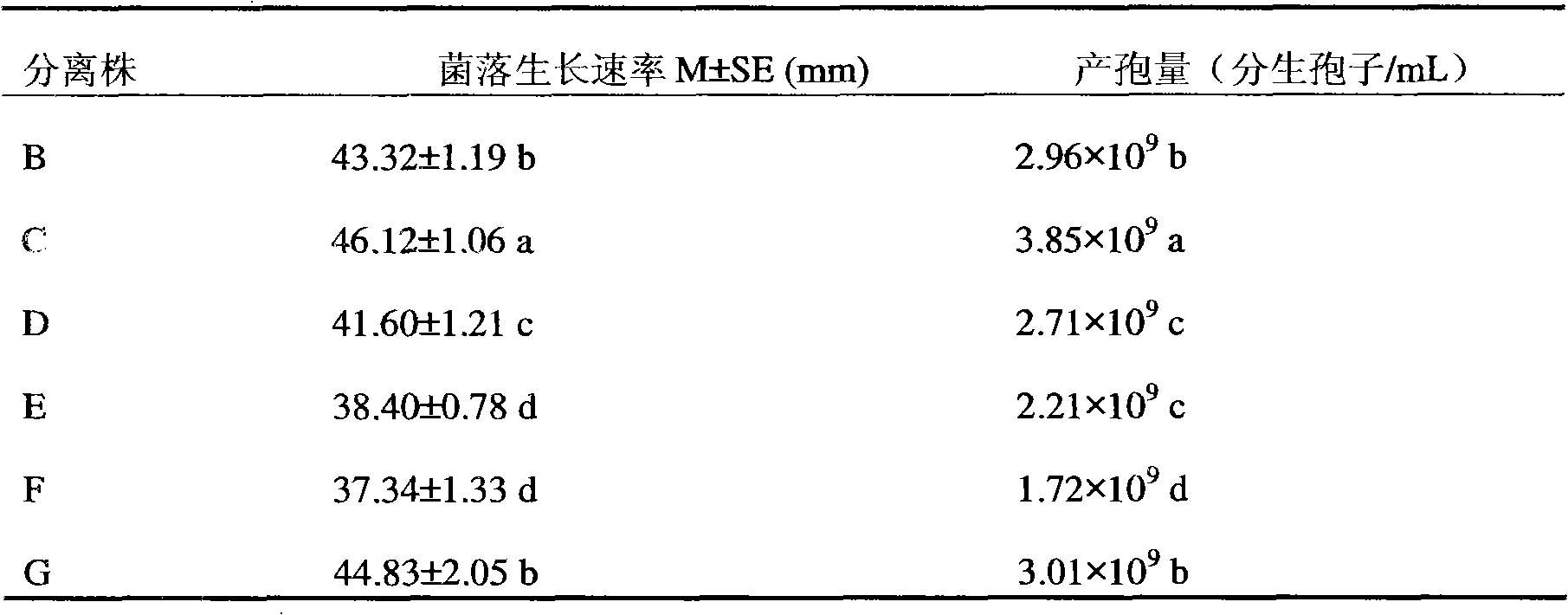

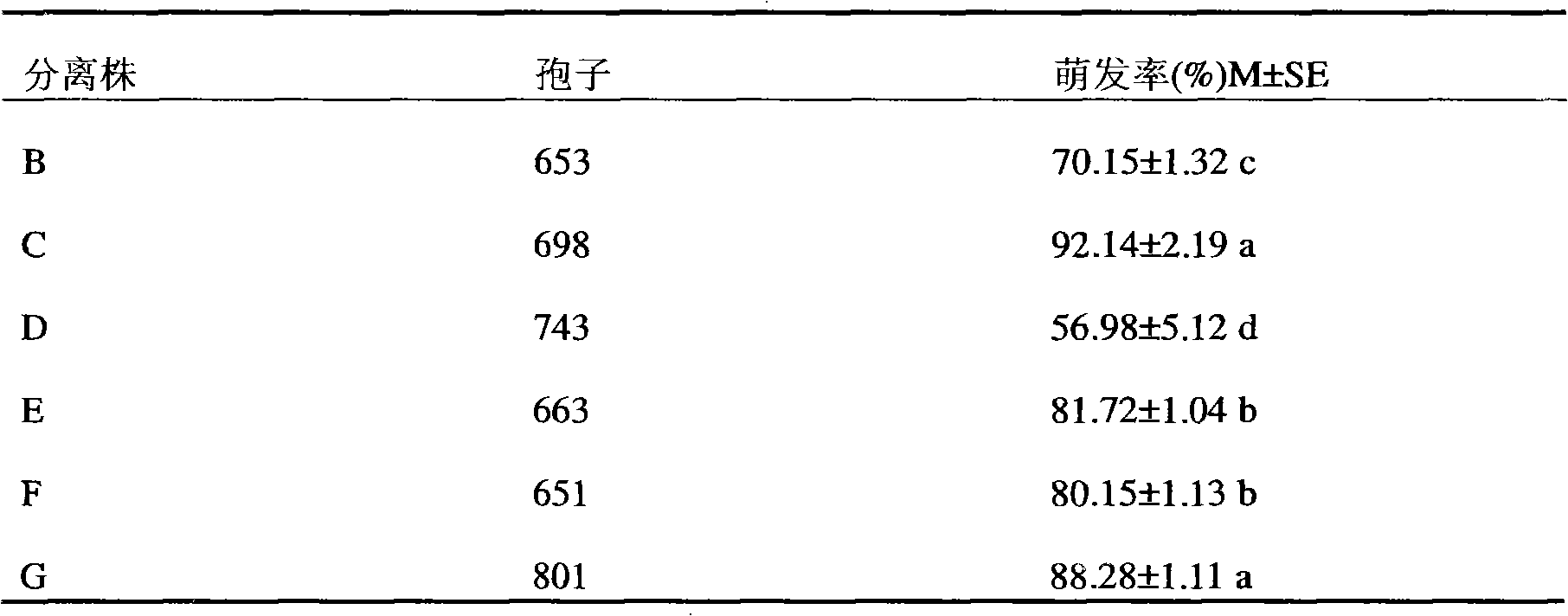

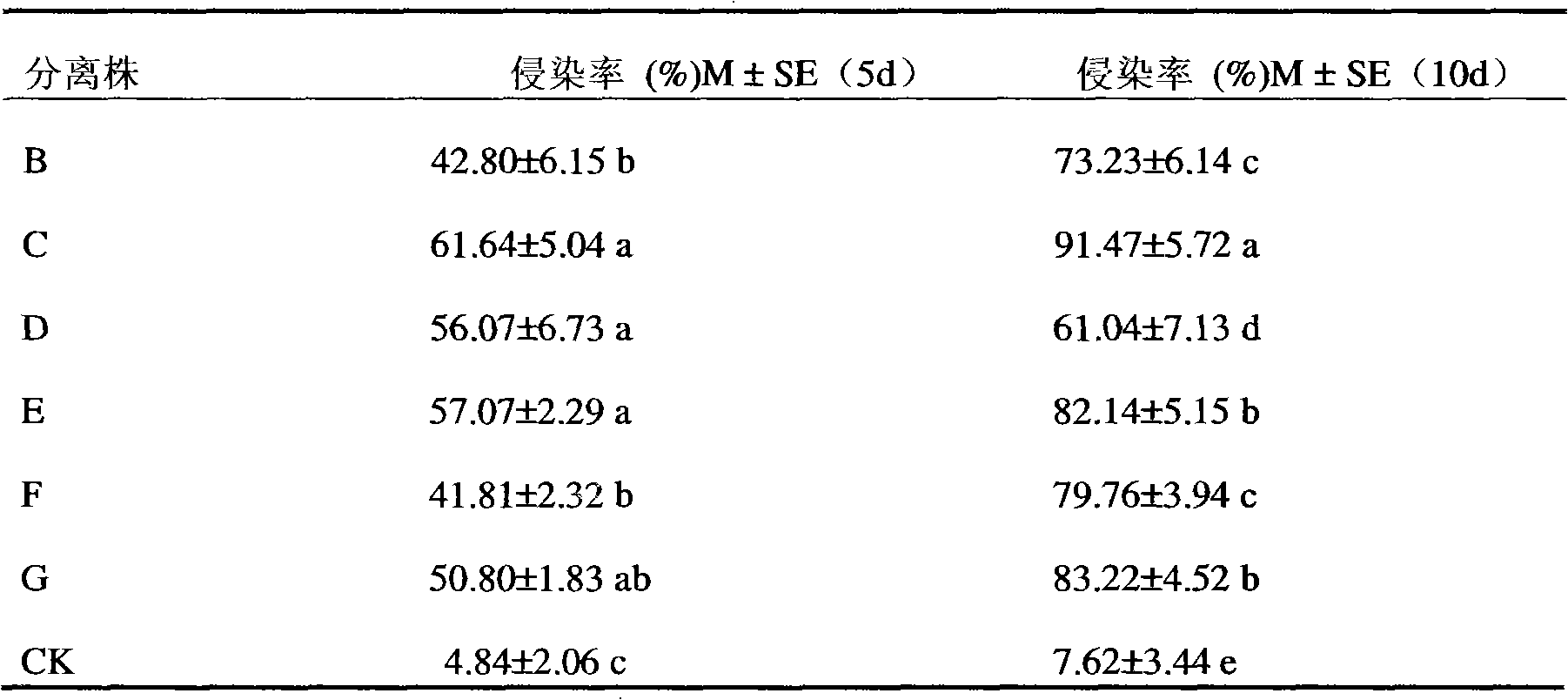

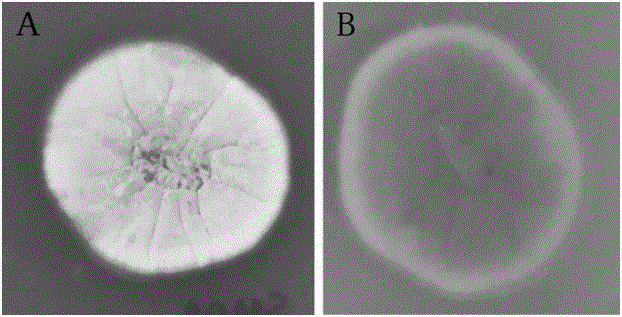

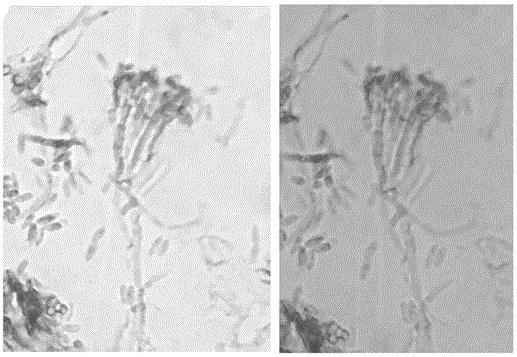

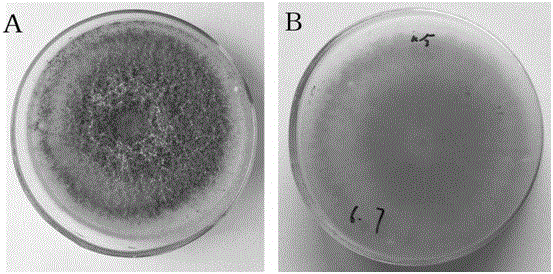

Aschersonia aleyrodis strain and uses thereof

InactiveCN101182467AAdapt to production requirementsNo pollution in the processBiocideFungiArthropod mouthpartsSpore

The invention discloses an aschersonia aleyrodis strain and the application of the strain. The aschersonia aleyrodis strain is a wild strain separated from bemisia tabaci body in Guangzhou area, which is naturally infected by worm living fungus. The wild strain is multi-planted on the bemisia tabaci body for the rejuvenation, so that the aschersonia aleyrodis strain is obtained; the purified strain is obtained through single spore isolation. The paecilomyces fumosoroseus strain is AA01-N8; the preservation number of the strain is CCTCC No: M207087; the strain is stored in China Center for Type Culture Collection on 27 June, 2007. Through a long term of infectious biology research and the indoor biology testing, the aschersonia aleyrodis has strong infectious and killing effects for a plurality of sucking mouth parts insects, such as the white fly and the cotton worm etc.

Owner:SOUTH CHINA AGRI UNIV

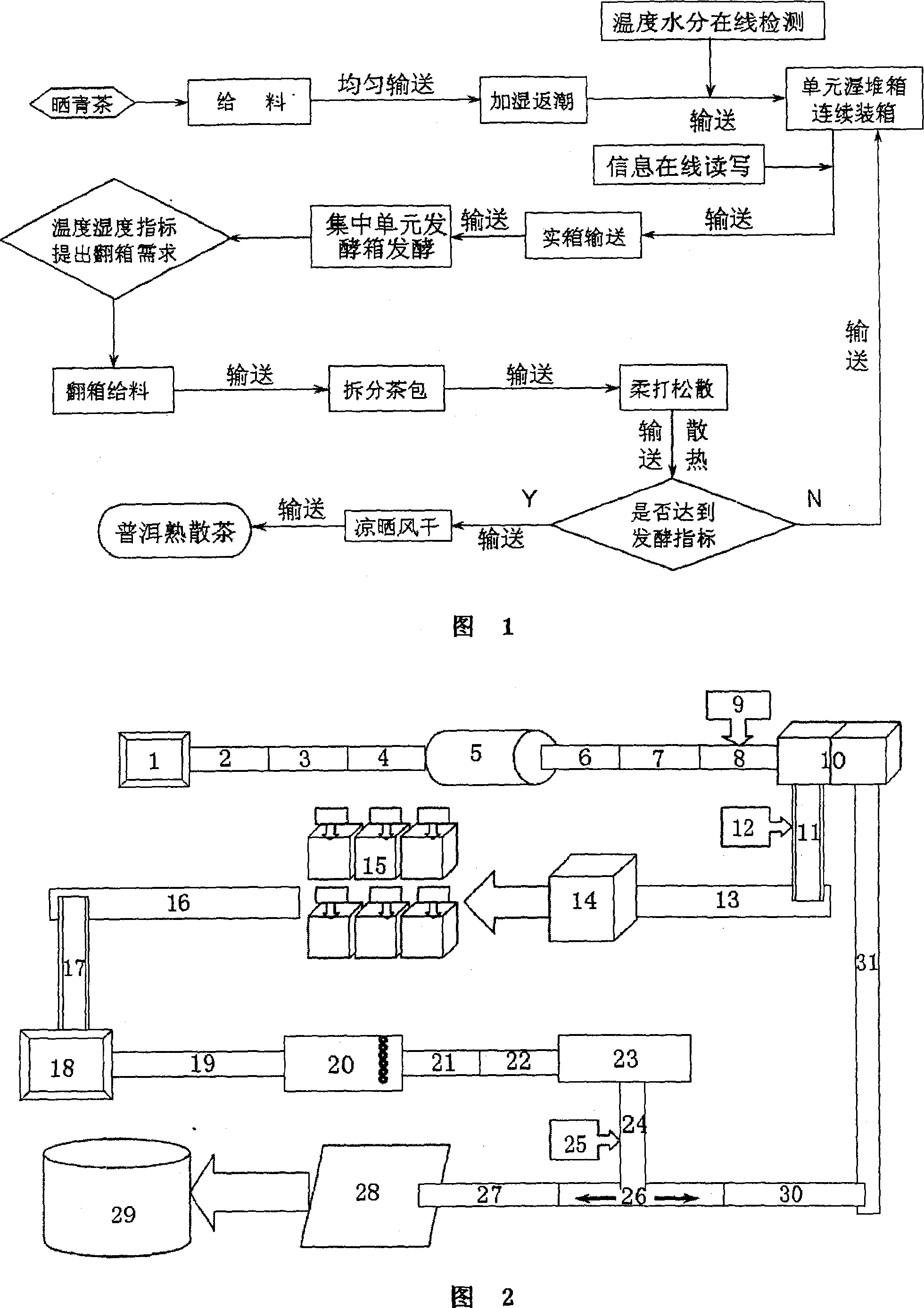

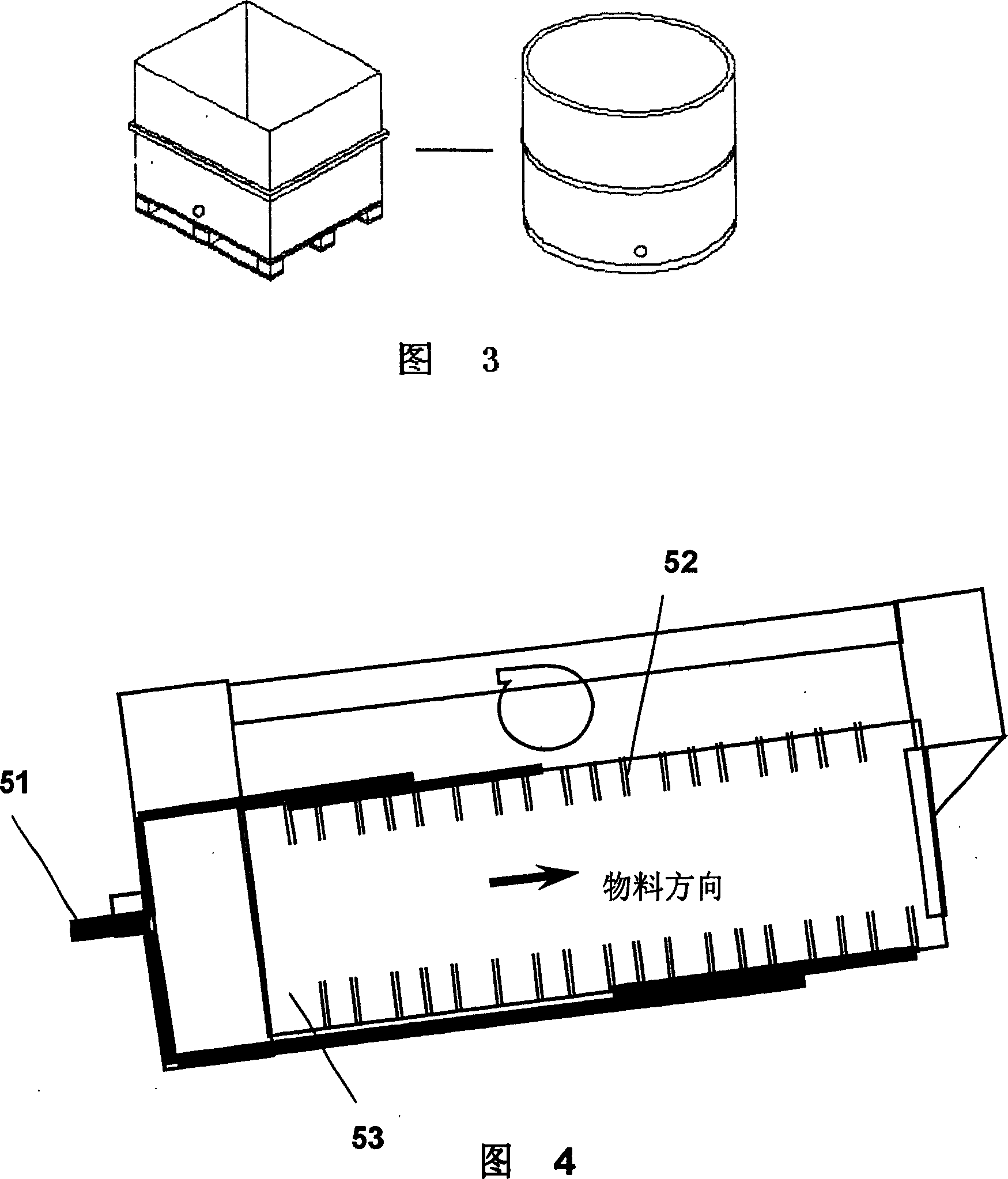

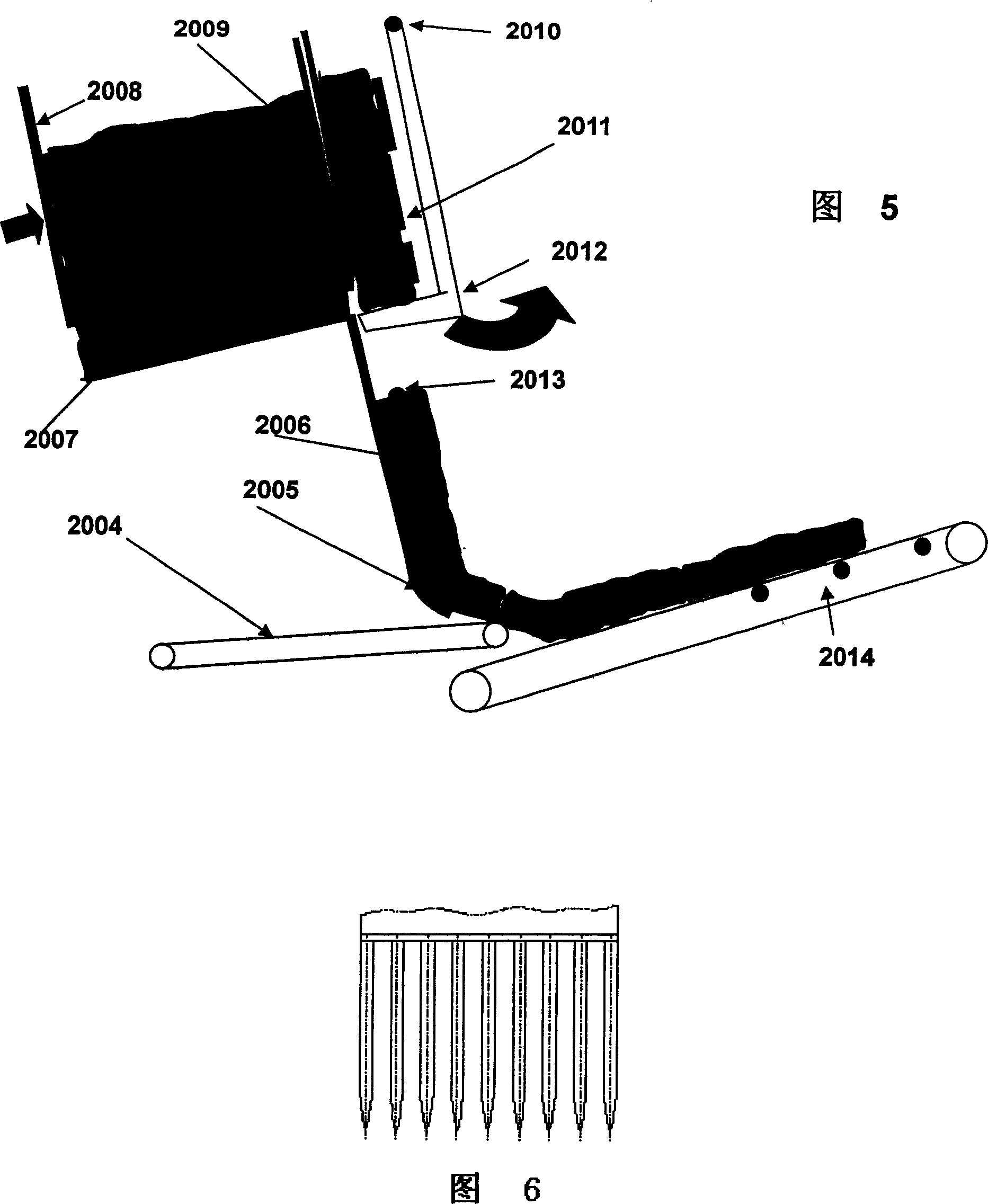

Automatic production technology for pu'er ripe tea

InactiveCN101142949AFlexible settingsAdapt to production requirementsPre-extraction tea treatmentClimate change adaptationAutomatic controlControl system

The invention discloses an automatic production process of pu-er ripe tea, which comprises the following procedures: material feeding, humidification moistening, packaging, real box transportation, fermentation, extraction and overturning box, resolution of tea package, flexible beating and loosening, sunning and air drying, loose pu-er ripe tea packaging, etc. the whole process of the invention can be automatically controlled by a central control system, index of each procedure can be set up flexibly and controlled effectively by the system, moreover, the invention has high degree of automation and can meet the manufacturing requirement of large-scale pu-er tea enterprise of information, digitalization, large scale and flexibility. Considering the cost, automation level of the invention can be reduced and the mainframe equipment can be used alone while supported by little manual work, therefore, the invention also can upgrade shortcoming of the prior pu-er tea production process and promote healthy and stable growth of the Yunnan pu-er tea industry.

Owner:冉文学

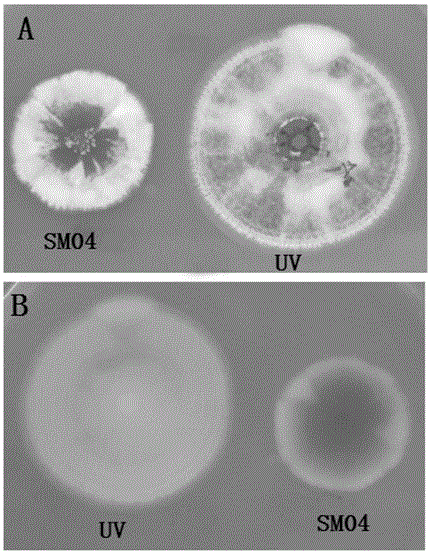

Anti-ultraviolet high-toxicity meterhizium anisopliae mutant strain MaUV-1 and application thereof

ActiveCN106434362AStrong infestation and insecticidal effectImprove efficiencyBiocideFungiBiological testWild strain

The invention discloses an anti-ultraviolet high-toxicity meterhizium anisopliae mutant strain MaUV-1 and application thereof. The meterhizium anisopliae mutant strain MaUV-1 is obtained due to ultraviolet mutation screening of wild metarhizium anisopliae. The strain is preserved in the China Center for Type Culture Collection in May 6th, 2016, and the preservation number is CCTCC NO:M 2016250. Through infection biological study and indoor biological test, the meterhizium anisopliae mutant strain MaUV-1 has a strong infection insect killing effect on pests like insecticide-resistant plutella xylostella and solenopsis invicta, and is high in anti-ultraviolet capacity. Compared with a wild strain, toxicity of the mutant strain which is stable in inheritance to plutella xylostella is improved by 75%, toxicity to solenopsis invicta is improved by 39-78%, and the anti-ultraviolet capacity is improved by 70-189%.

Owner:SOUTH CHINA AGRI UNIV

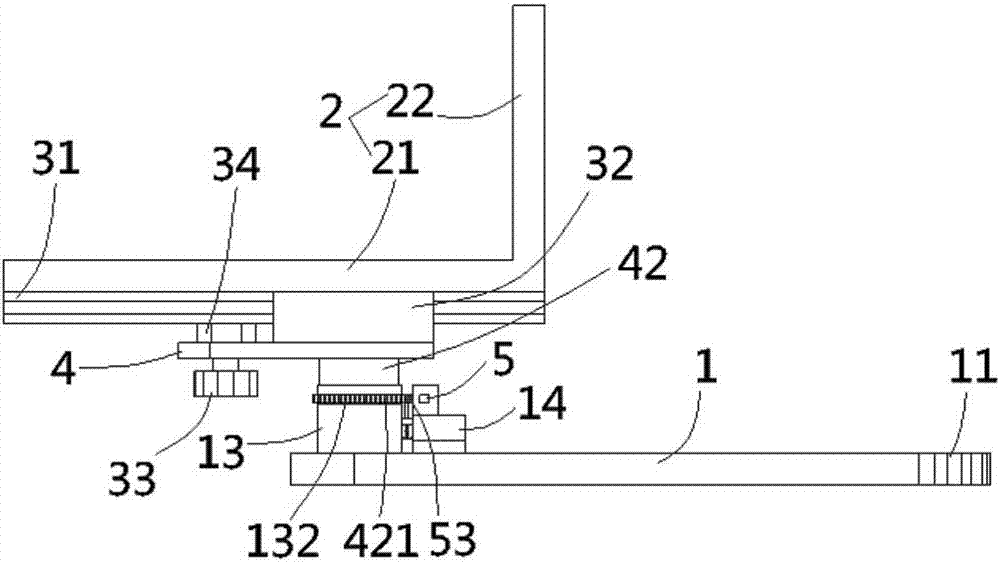

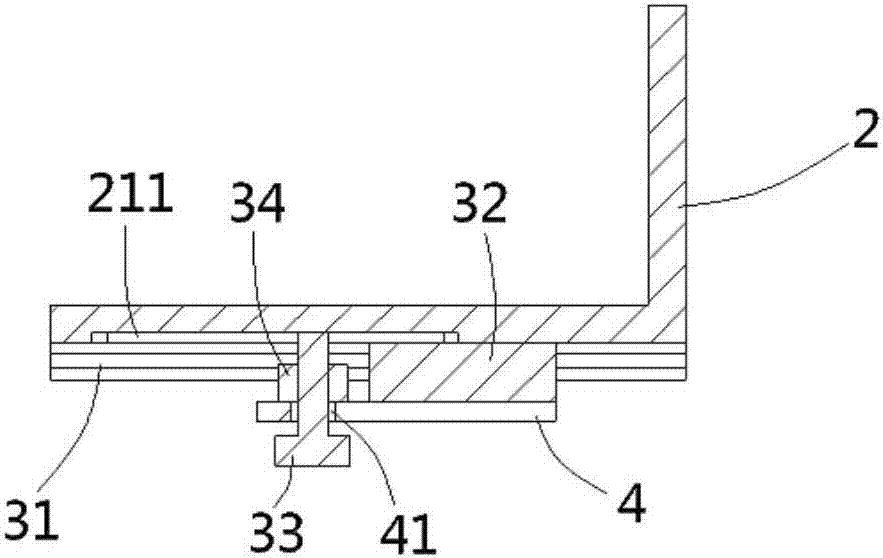

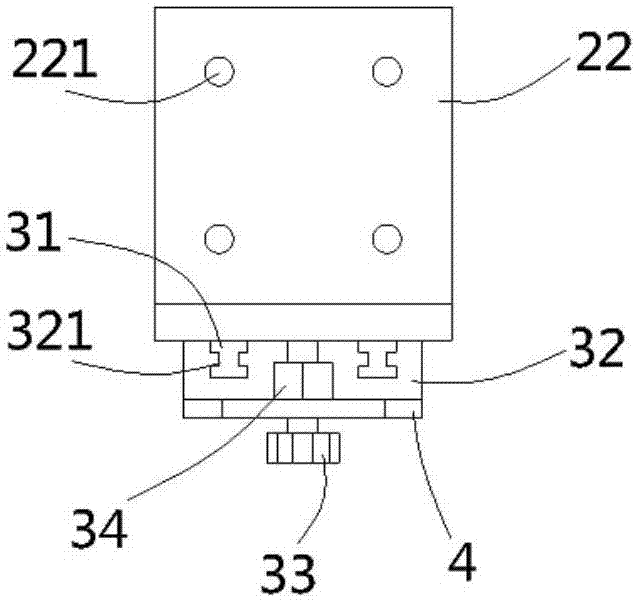

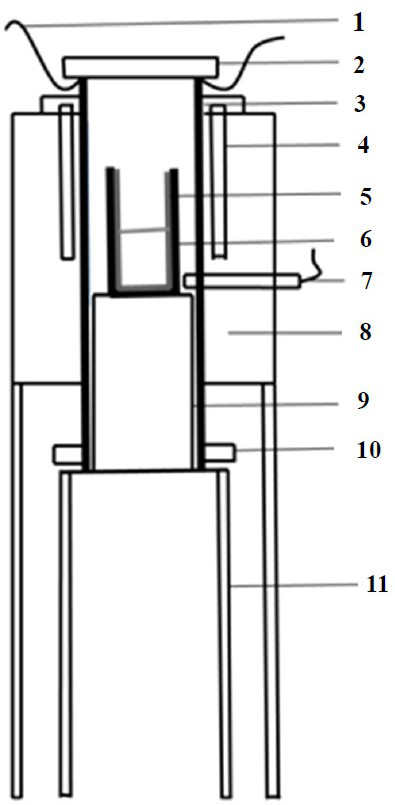

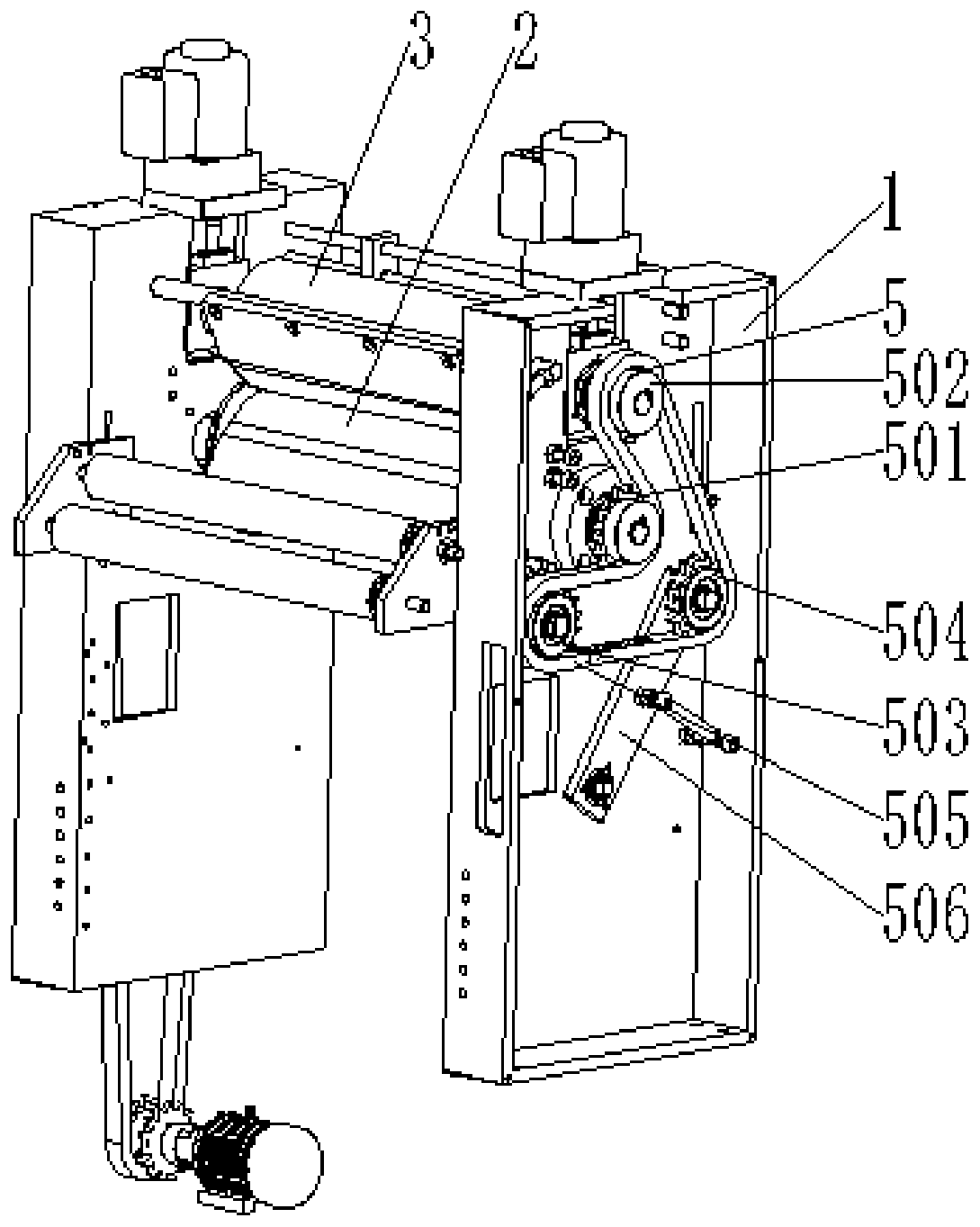

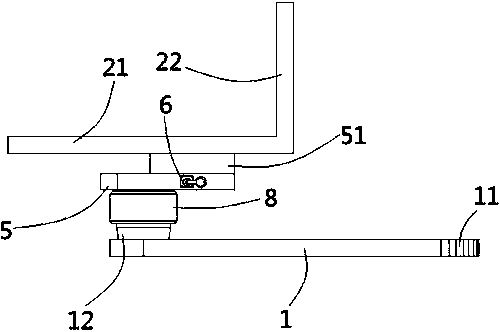

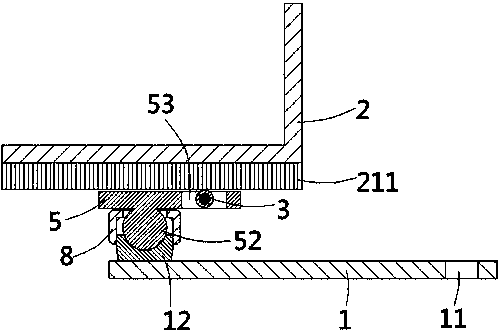

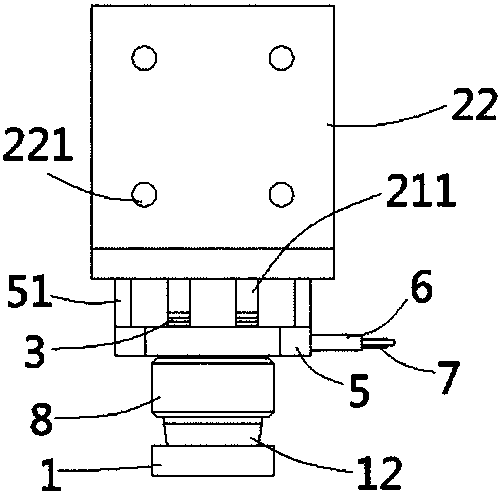

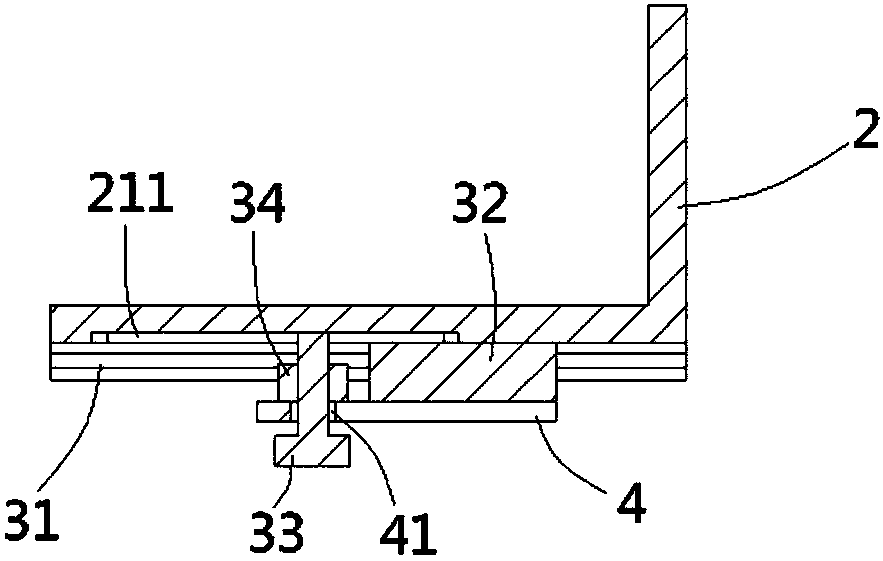

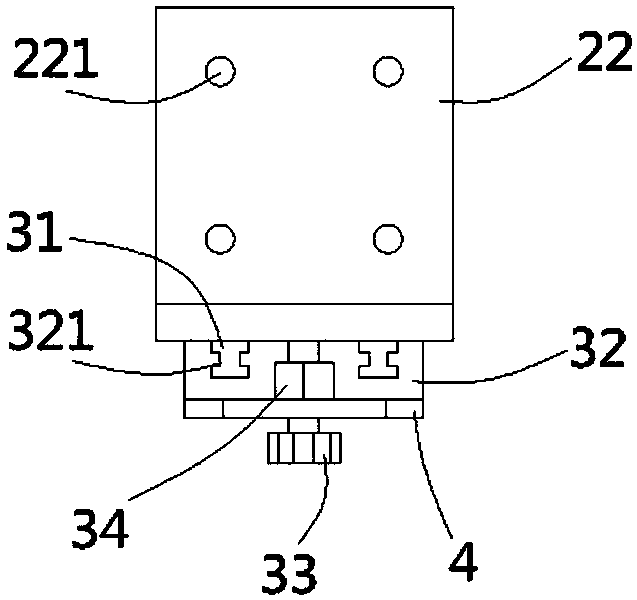

Regulating type industrial support for automated equipment

ActiveCN106870908ARealize multi-angle adjustmentAdapt to production requirementsStands/trestlesEngineeringSlide plate

Owner:ZHEJIANG KAIBO PRESSURE VESSEL

Compound desinsection primary agent and pesticide consisting of verticillium lecanii and abamectin

InactiveCN101513192AAdapt to the natural ecological environmentReduce dosageBiocideAnimal repellantsArthropod mouthpartsPlant Louses

The invention discloses a compound desinsection primary agent and a pesticide consisting of verticillium lecanii and abamectin. The primary agent is a mixture of the verticillium lecanii and the abamectin, wherein, the mass ratio between the verticillium lecanii and the abamectin is 100:0.1-0.5; through long-term infection biological study and interior biological assay, the verticillium lecanii has strong infection desinsection effect on a plurality of pests, the sucking pest in particular. The compound pesticide consisting of verticillium lecanii and abamectin of the invention has good effect in preventing and controlling pests such as trialeurodes vaporariorum westwood, bemisa babaci, plant louse, diamond back moth, thrips palmi karny and the like, and has certain effect in controlling mite pests.

Owner:SOUTH CHINA AGRI UNIV

Compound desinsection primary agent and pesticide consisting of verticillium lecanii and beta-cypermethrin

InactiveCN101513193AReduce dosageReduce pesticide residuesBiocideAnimal repellantsArthropod mouthpartsAlpha cypermethrin

The invention discloses a compound desinsection primary agent and pesticide consisting of verticillium lecanii and beta-cypermethrin. The primary agent is a mixture of the verticillium lecanii and the alpha cypermethrin, wherein, the mass ratio between the verticillium lecanii and the alpha cypermethrin is 100:5-50; while the pesticide consists of a primary agent and a secondary agent, according to mass percent, the primary agent accounts for 5-50%, and the secondary agent 50-95%. Through long-term infection biological study and interior biological assay, the verticillium lecanii has strong infection desinsection effect on a plurality of pests, the sucking pests in particular. The compound pesticide consisting of the verticillium lecanii and the beta-cypermethrin of the invention has good effect in preventing and controlling pests such as white fly, plant louse, diamond back moth and the like.

Owner:SOUTH CHINA AGRI UNIV

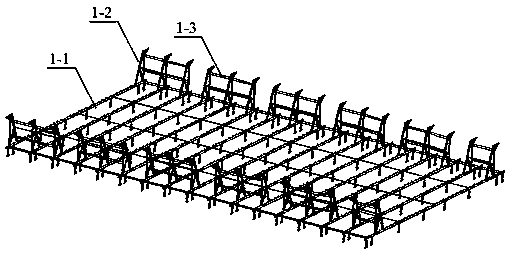

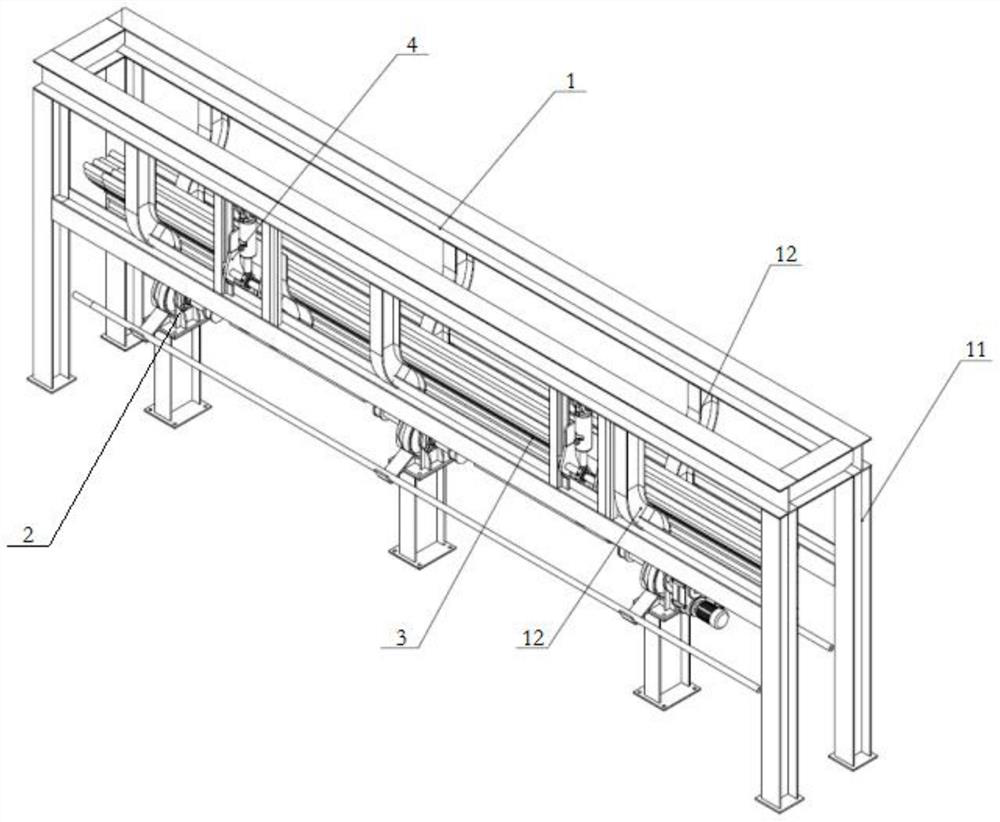

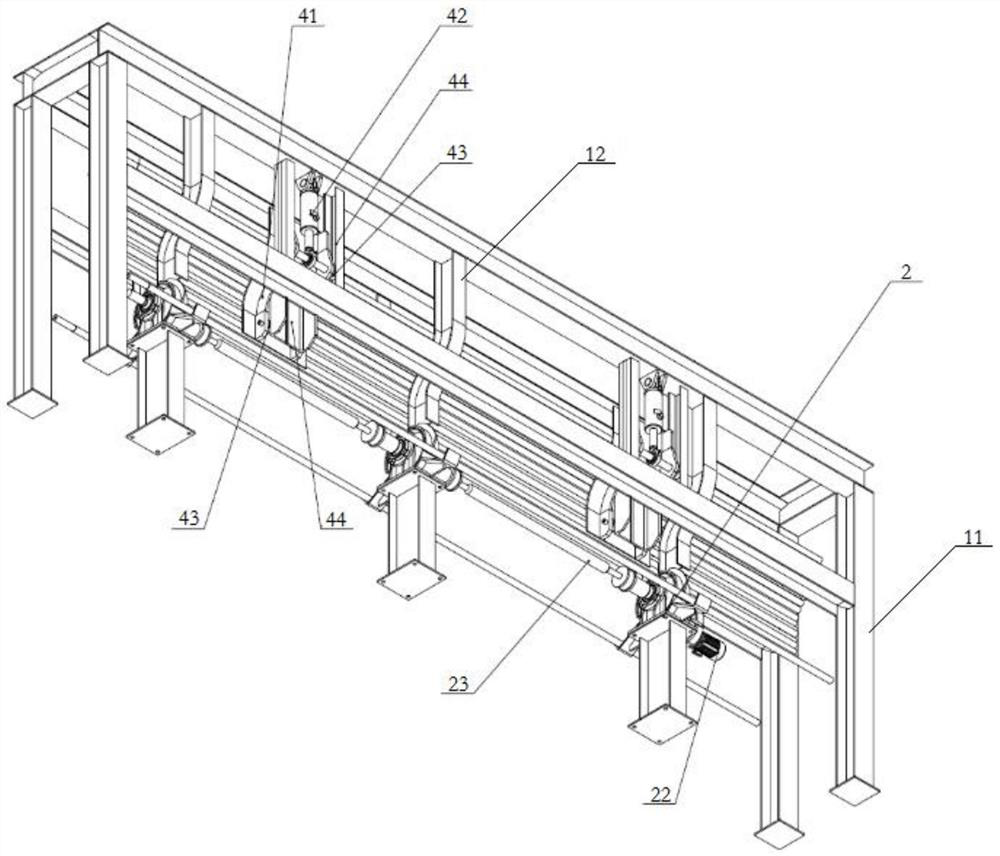

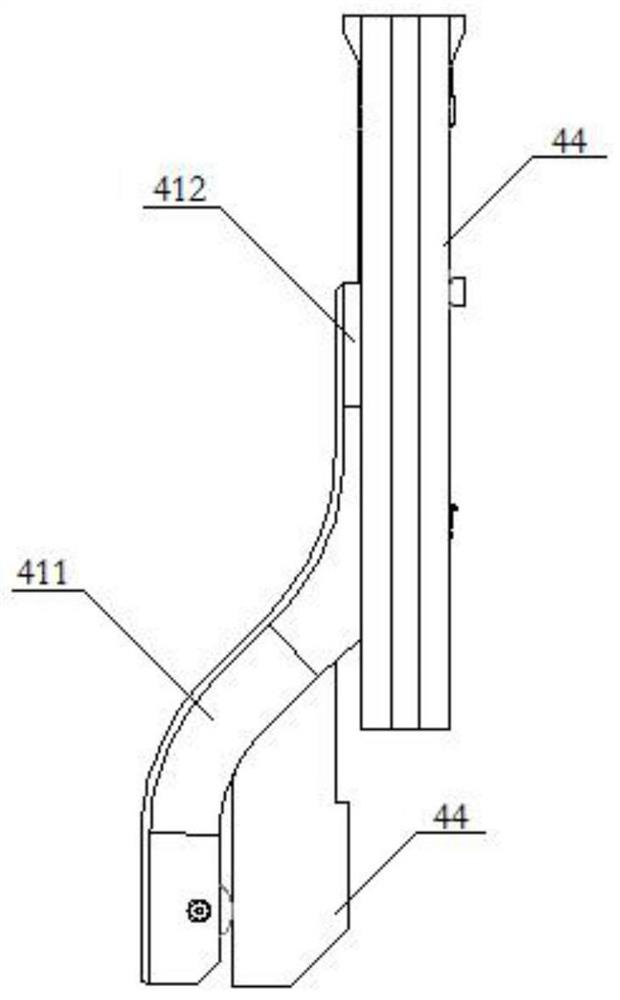

Large section steel box beam amplitude-selection matching structure and manufacturing method

PendingCN107794834AGuaranteed accuracyGuaranteed production qualityBridge erection/assemblyManufacturing qualityStructural engineering

The invention relates to a large section steel box beam amplitude-selection matching structure and a manufacturing method. The large section steel box beam amplitude-selection matching structure and the manufacturing method can adapt to the width change of a steel box beam and can also guarantee smooth conducting of total assembly of the steel box beam and the manufacturing quality. Inclined struts of a steel box beam total assembly jig frame are designed to be that three of the inclined struts serve as a set, and the inclined struts in each set are connected to be an overall inclined strut frame through tie rods. The lower ends of every three inclined struts at the lower ends of the two corresponding inclined strut frames are connected with cross beams correspondingly. Anti-overturning sliding devices are arranged on the positions, at the bottoms of the inclined struts, of the cross beams, and meanwhile pin locking devices are arranged at the bottoms of the inclined struts. The largesection steel box beam amplitude-selection matching structure and the manufacturing method have the advantages that a bran-new large section steel box beam amplitude-selection matching manufacturing technology is formed and can meet the manufacturing requirement of the variable-width steel box beam, the precision of matching manufacturing of the steel box beam is guaranteed, and the manufacturingquality of the steel box beam can also be guaranteed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Isaria fumosorosea

InactiveCN103756913AGood control effectLow lethal concentrationFungiMicroorganism based processesBiotechnologySporeling

The invention discloses an isaria fumosorosea. The isaria fumosorosea is a wild strain obtained from a coptotermes body naturally soaked in entomogenous fungi in a separating manner from the national nature conservation area of Jiulianshan in Jiangxi province. The wild strain is grafted back to the coptotermes body so as to be rejuvenated, thereby obtaining the isaria fumosorosea. A purification strain is obtained by performing monospore separation on the isaria fumosorosea. The purification strain is an isaria fumosorosea SCAU-IFCF02 which is collected in CCTCC (China Center for Type Culture Collection) on November 1st, 2013 and has the collection number of CCTCCNO:M2013526. According to a long-term infection biology study and indoor bioassay, the isaria fumosorosea has very strong application potential for the biological prevention and control of diamond black moths and coptotermes.

Owner:SOUTH CHINA AGRI UNIV

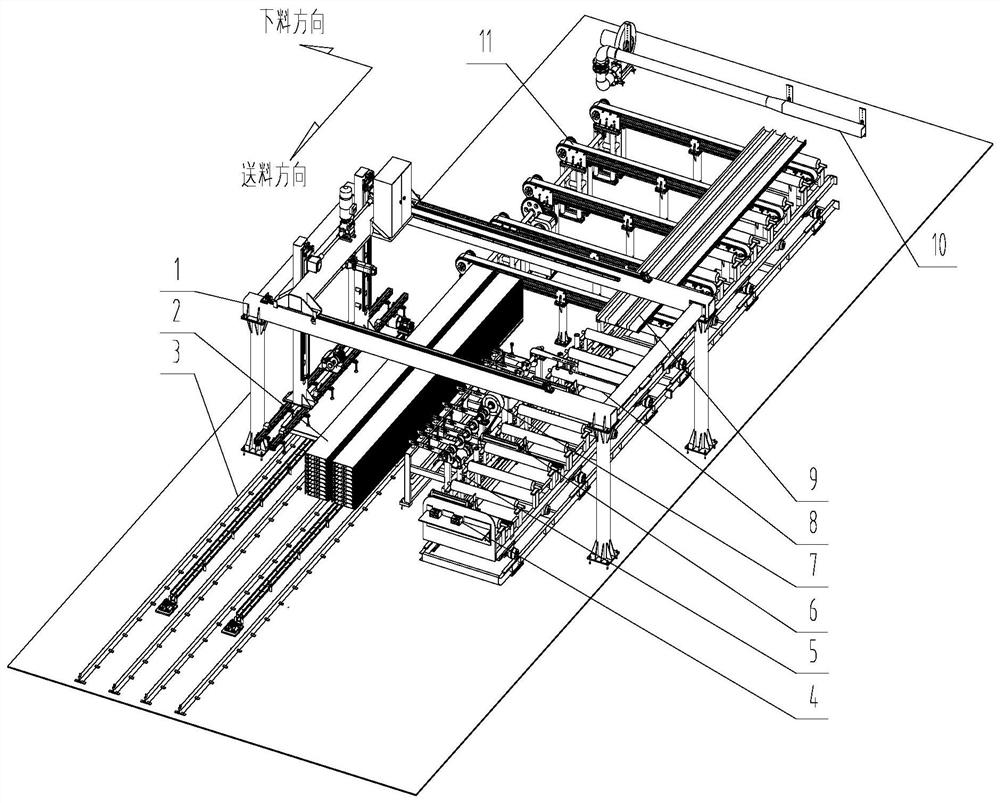

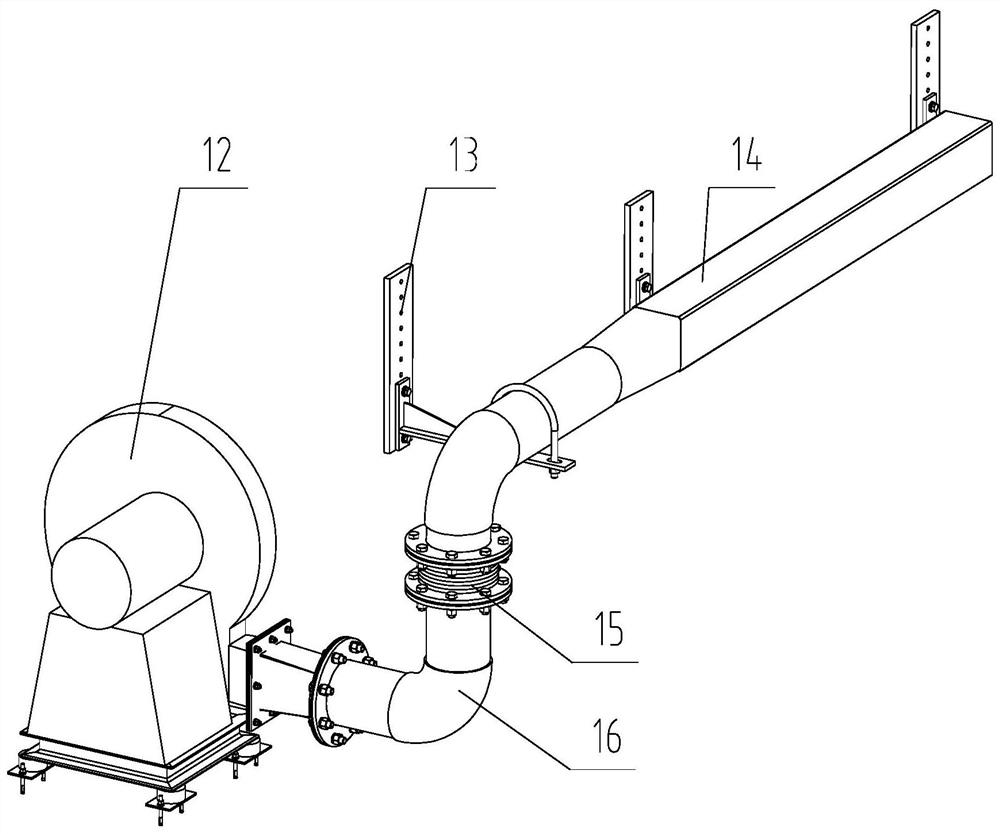

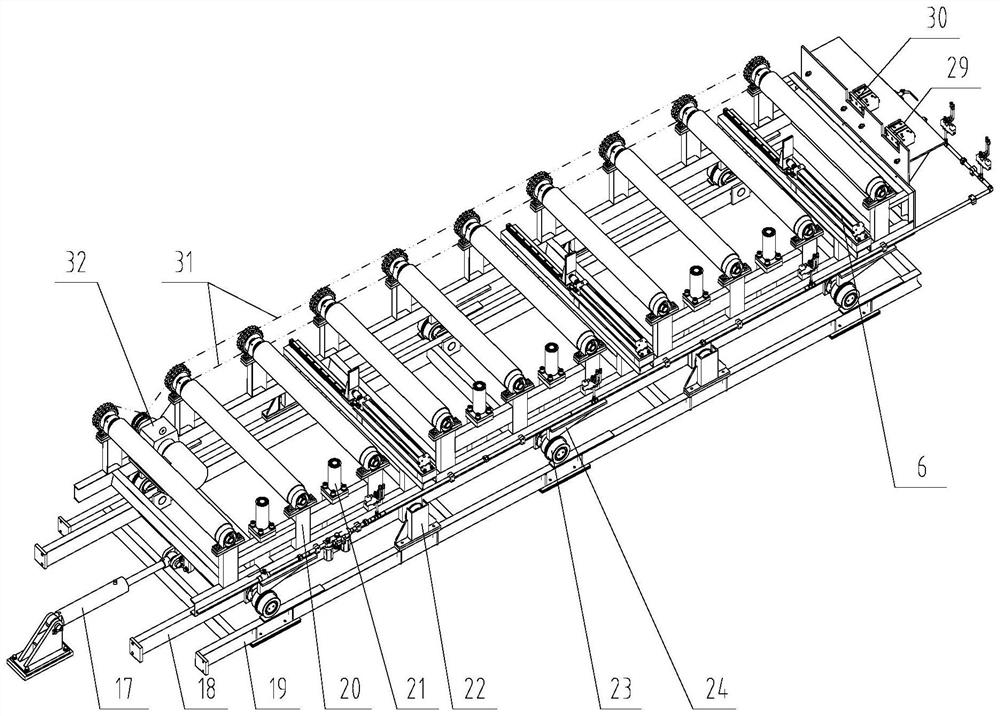

Automatic stacking device for aluminum profile finished products

InactiveCN112390018ARealize upside-down interspersed stackingSave stack spaceStacking articlesRobot handControl system

The invention relates to an automatic stacking device for aluminum profile finished products, and belongs to the technical field of mechanical equipment. The automatic stacking device comprises a control system, a conveying device, a mechanical arm, a material conveying device and a material turning device, wherein the conveying device, the mechanical arm, the material conveying device and the material turning device are connected with the control system. The conveying device is arranged on one side of a discharging port of a finished product saw so as to convey sawn profiles. The material conveying device is located at the end, away from the finished product saw, of the conveying device and is parallel to the conveying device. The mechanical arm comprises a portal frame stretching acrossthe conveying device and the material conveying device and a mechanical arm body arranged on the portal frame. The material turning device is arranged between the material conveying device and the conveying device and can grab and turn over profiles located on the conveying device. The mechanical arm body can grab profiles located on the conveying device and the material turning device according to the manner set by the control system and place the profiles onto the material conveying device so as to complete stacking of the profiles. Through cooperation of the mechanical arm and the materialturning device, inverted alternate stacking of irregular-section profiles is achieved, and the stacking space is greatly reduced.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

Trichoderma harzianum strain Th-N5 resisting carbendazim and application of trichoderma harzianum strain Th-N5

ActiveCN106282029AReduce usageSolve the problem of pesticide residuesBiocideFungiDiseaseHigh resistance

The invention discloses a trichoderma harzianum strain Th-N5 resisting carbendazim and application of the trichoderma harzianum strain Th-N5. The trichoderma harzianum strain Th-N5 is preserved at China Center for Type Culture Collection on May 6, 2016, and the preservation number is CCTCC NO. M2016251. By virtue of the study of infection biology and indoor bioassay, the strain has good effect for preventing Sclerote disease of mulberry fruit; and the strain has relatively high resistance to the chemical pesticide Carbendazim. The strain is cooperated with a low dosage of carbendazim, the Sclerote disease of mulberry fruit can be thoroughly controlled, the use amount of the chemical pesticide is greatly reduced, and the pesticide residue problem in the mulberry fruits can be solved. The strain is a local strain in China and is not introduced from foreign countries, thereby being adaptive to the local natural environment. In addition, the trichoderma harzinum is a biocontrol fungus, and is used as a living body biological pesticide, the tridoderma harzinum has a brand new acting mechanism different from the existing chemical insecticide, is pollution-free to the environment, has no residue and adapts to the production requirement of the organic food.

Owner:SOUTH CHINA AGRI UNIV

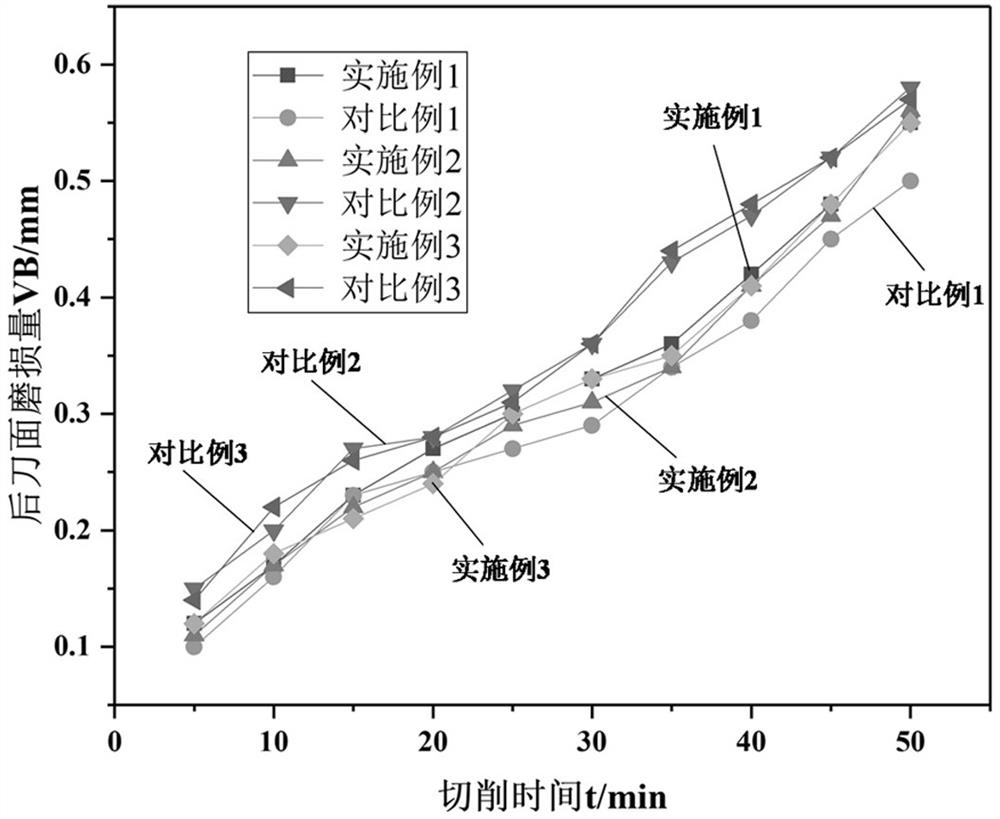

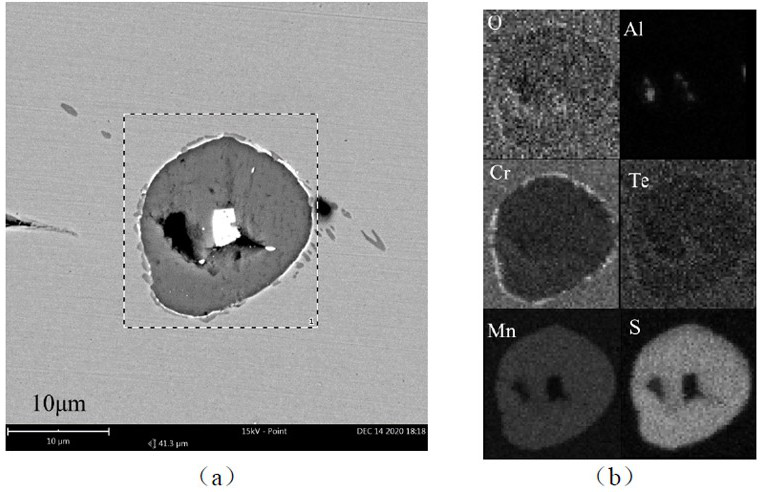

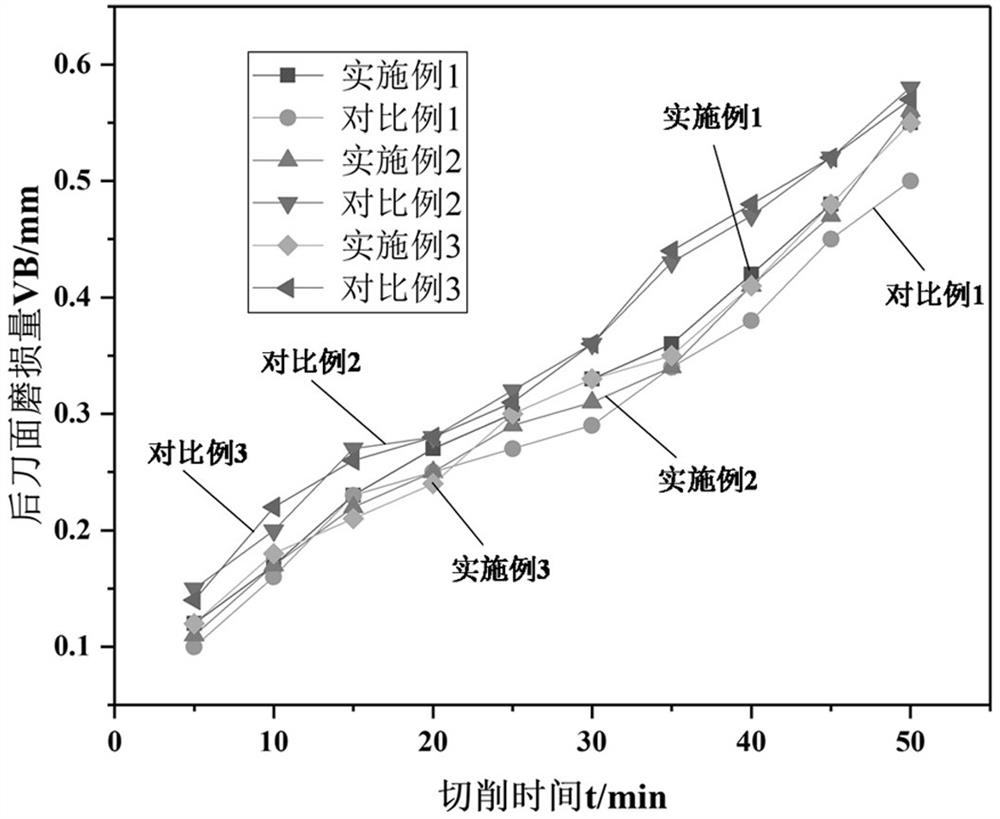

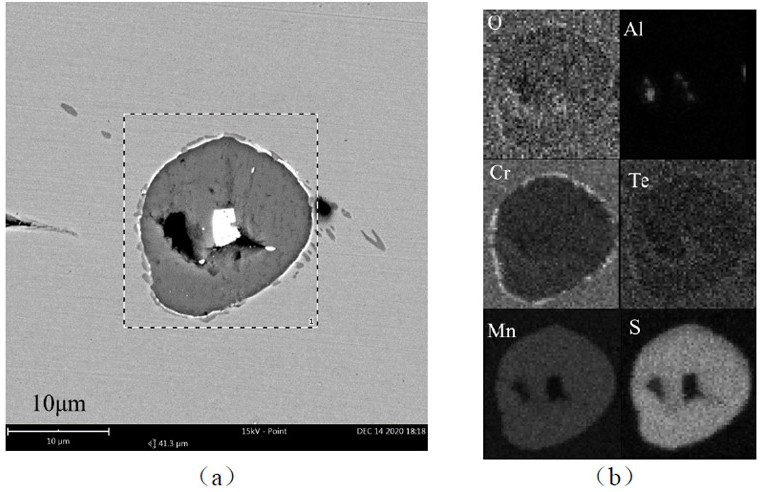

Free-cutting corrosion-resistant steel and preparation method thereof

The invention relates to free-cutting corrosion-resistant steel and a preparation method thereof. The free-cutting corrosion-resistant steel comprises the following components in percentage by mass: 0.015 to 0.024 percent of C; 0.4 to 0.5 percent of Si; 1.2 to 1.3 percent of Mn; 0.24 to 0.3 percent of S; 0.02 to 0.03 percent of P; 1.5 to 1.75 percent of Mo; 19 to 20 percent of Cr; 0.03 to 0.08 percent of Ca; 0.01 to 0.02 percent of Mg; 0.02 to 0.05 percent of Al; 0.012 to 0.03 percent of Te; and the balance Fe and impurities. The method comprises the following steps of uniformly mixing free-cutting steel, a ferrochrome mixture and slag charge, and completely melting at high temperature to obtain a melt; and adding tellurium into the melt, conducting heat preservation treatment, and cooling to obtain the free-cutting corrosion-resistant steel. The free-cutting corrosion-resistant steel disclosed by the invention has the optimal component proportion, and has the comprehensive optimal free-cutting performance and corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

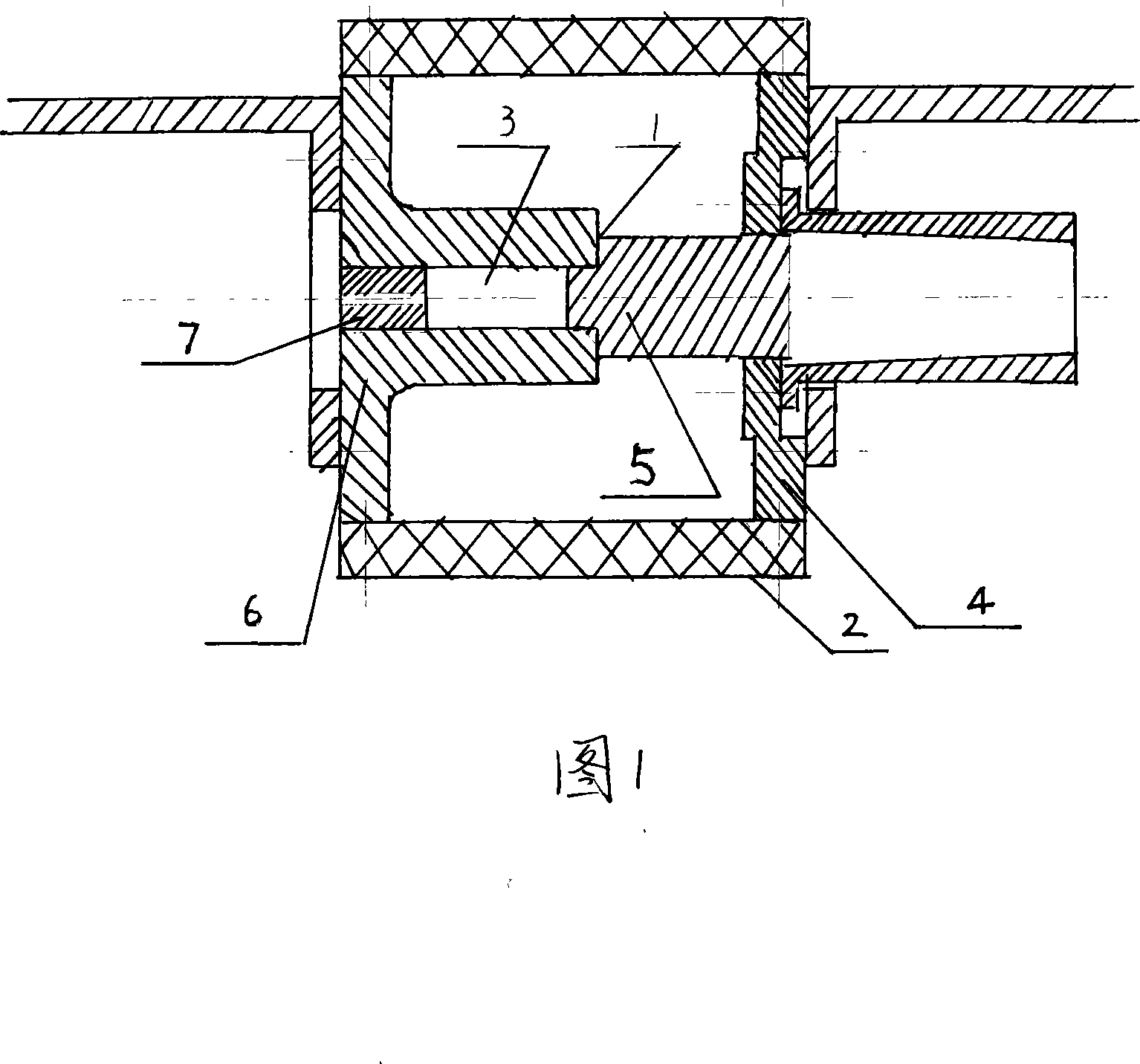

Great current quick-speed turning on-off body

InactiveCN101178993AReduce riskReduce hidden dangersHeating/cooling contact switchesSwitches with electrothermal releaseControl signalEngineering

The invention discloses a high-current quick-opening body, which is characterized in that the two ends of the insulating sleeve are respectively installed with an end plate of an explosion chamber and an end plate of a storage chamber for connecting to a circuit, and the end plate of the explosion chamber and the end plate of the storage chamber are respectively installed. There is a cylinder in the middle of the end plate, and the front end of the cylinder of the end plate of the blasting chamber is screwed with a plug, and there is a through hole for the lead wire of the explosive in the middle of the plug, and there is a piston bridge between the end plate of the blasting chamber and the cylinder of the end plate of the storage chamber. , the front end of the piston bridge body is connected to the cylinder body of the end plate of the blast chamber, the part between the piston bridge body and the blockage is an explosion chamber filled with explosives, and the rear end of the piston bridge body is inserted into the cylinder body of the end plate of the storage bin, The rear end of the barrel of the storage end plate is a tapered inner hole, which does not allow the piston bridge body to pass through. When the invention is detonated under the action of a control signal, the accuracy rate is high, the amount of explosive is small, and the risk of explosion is small.

Owner:HEFEI NANNAN POWER EQUIP CO LTD

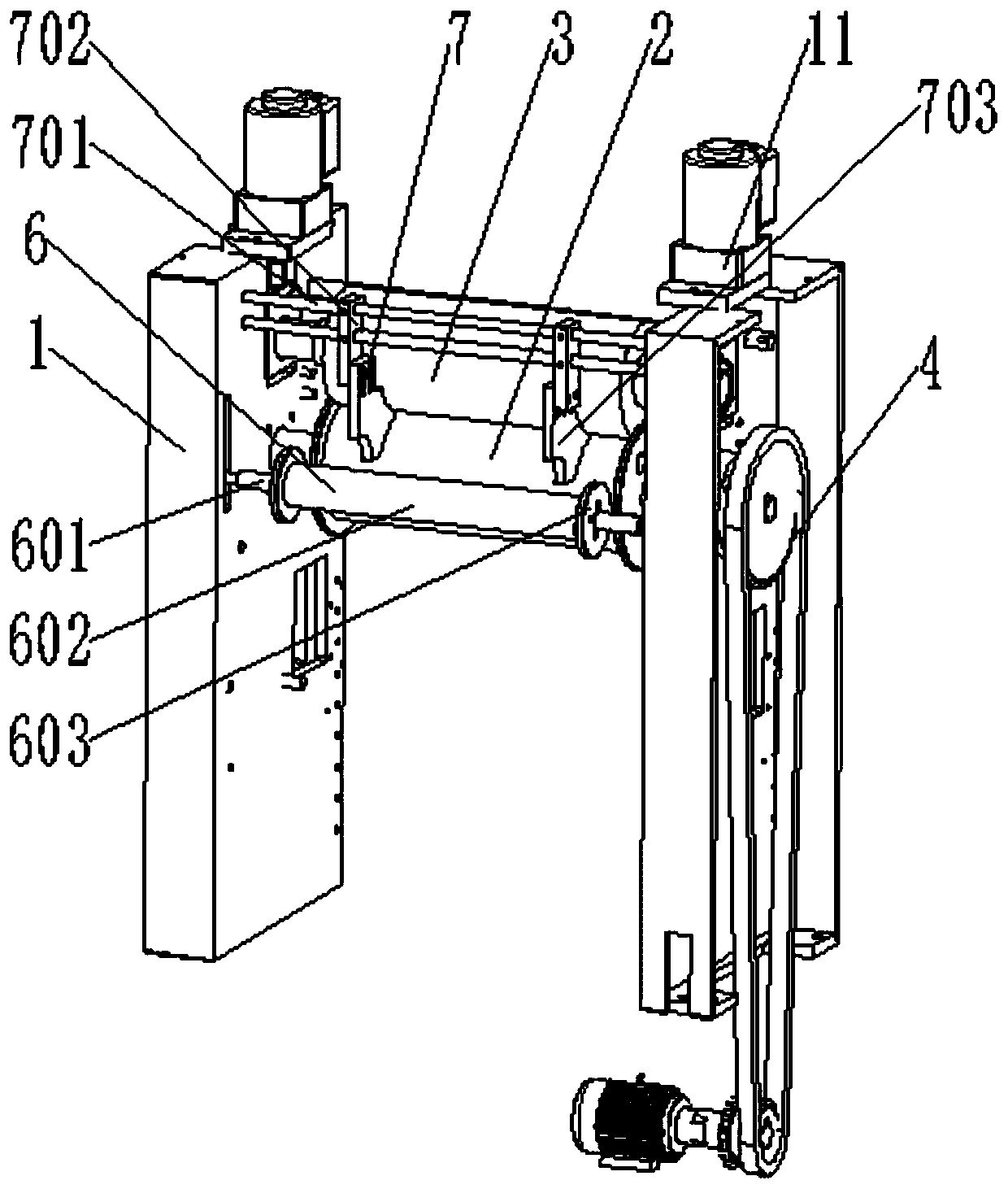

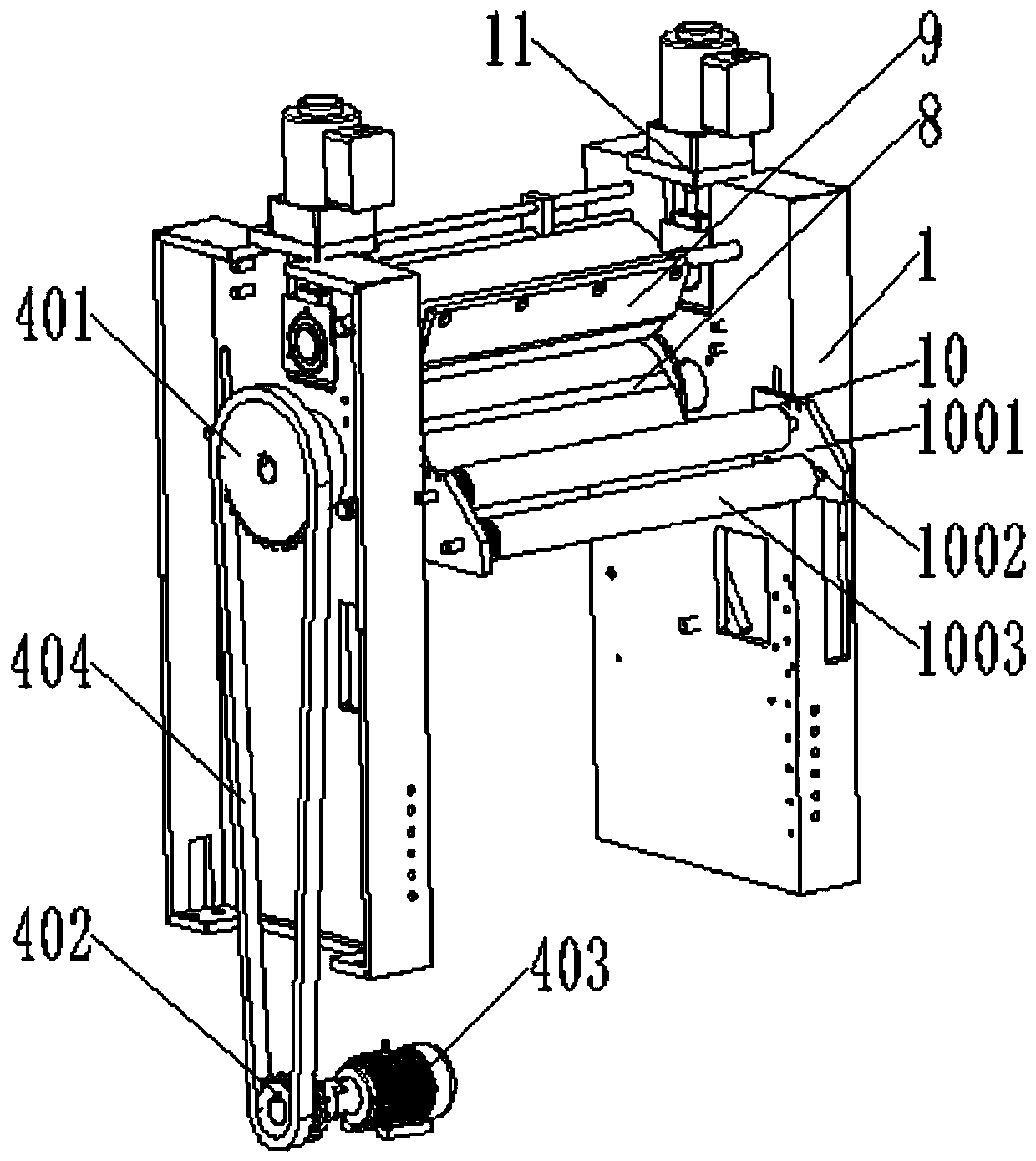

Calender for producing fresh wet noodles

InactiveCN110547307ACompact structureImprove production efficiencyDough-sheeters/rolling-machines/rolling-pinsPulp and paper industry

The invention discloses a calender for producing fresh wet noodles, and relates to the technical field of fresh wet noodle production equipment. The calender includes racks arranged at the two sides of a calender body, an upper roller and a lower roller are arranged between the racks, a drive mechanism is connected to one end of the lower roller, a transmission mechanism is arranged between the other end of the lower roller and one end of the upper roller, a noodle input support assembly is arranged at the front end of the lower roller, a limit plate assembly is mounted at the front end of theupper roller, a lower roller slicing knife assembly and an upper roller slicing knife assembly are arranged at the rear side of the lower roller and the rear side of the upper roller respectively, anoodle output support assembly is arranged between the racks and behind the lower roller, and upper roller distance adjustment mechanisms are arranged at the upper sides of the racks. By adopting thecalender for producing the fresh wet noodles, through a servo motor assembly, the gap between the press rollers can be automatically and accurately adjusted, the press rollers synchronously rotate oppositely, the noodle calendering thickness can be corrected in real time, and therefore the calender meets different thickness requirements for the fresh wet noodles.

Owner:WUHAN POLYTECHNIC UNIVERSITY

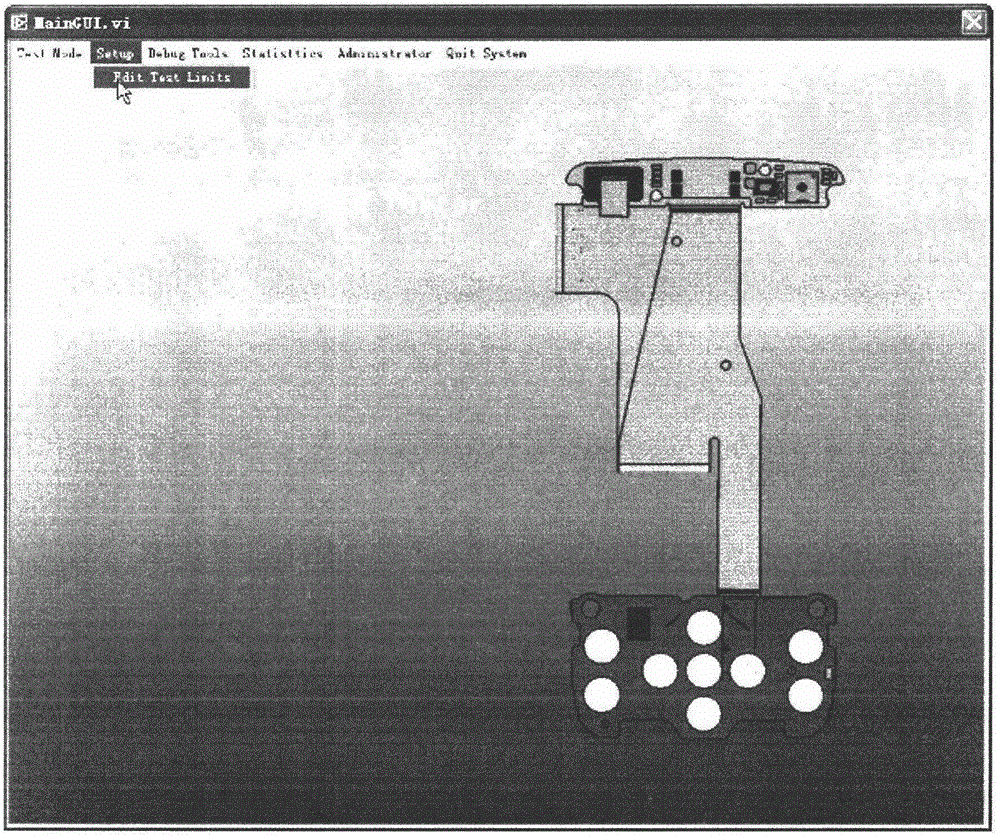

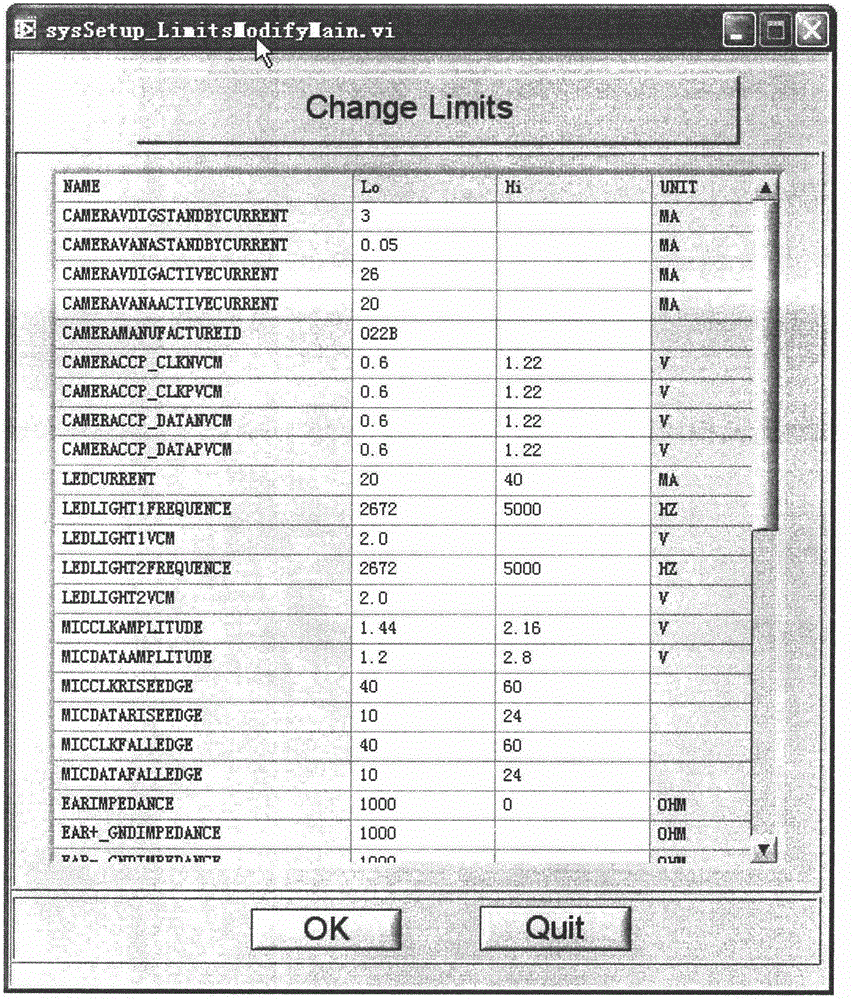

Multi-angle camera adjusting bracket for industrial production line

InactiveCN109027638AAvoid interferenceRealize multi-angle adjustmentStands/trestlesSlide platePulp and paper industry

The invention discloses a multi-angle camera adjusting bracket for an industrial production line. The multi-angle camera adjusting bracket comprises a supporting beam. An L-shaped camera bracket bodyis arranged at one end of the supporting beam and composed of a horizontal part and a vertical part. A rack is formed on the lower end face of the horizontal part. The lower end of the rack is connected with a rotating gear in a meshing mode. The rotating gear is fixed to a rotating shaft in inserted and sleeving modes. The rotating shaft is hinged to a sliding plate. One end of the rotating shaftpenetrates out of the side wall of the sliding plate. A limiting air cylinder is fixed to the position, one side of the rotating shaft, of the side wall of the sliding plate. A limiting shaft is fixed to a piston rod of the limiting air cylinder. A limiting hole matched with the limiting shaft is formed in the side wall of the rotating shaft. A spherical inserting head is formed in the middle ofthe lower end face of one side of the sliding plate. The inserting head is sleeved with a thread sleeve in an inserted mode. A support is formed at one end of the supporting beam. A spherical concavehole is formed in the upper end face of the support. The inserting head of the sliding plate is connected into the concave hole in an inserted mode. According to the multi-angle camera adjusting bracket, an industrial camera can be adjusted in a multi-angle mode, and thus the production requirements are met.

Owner:杜磊

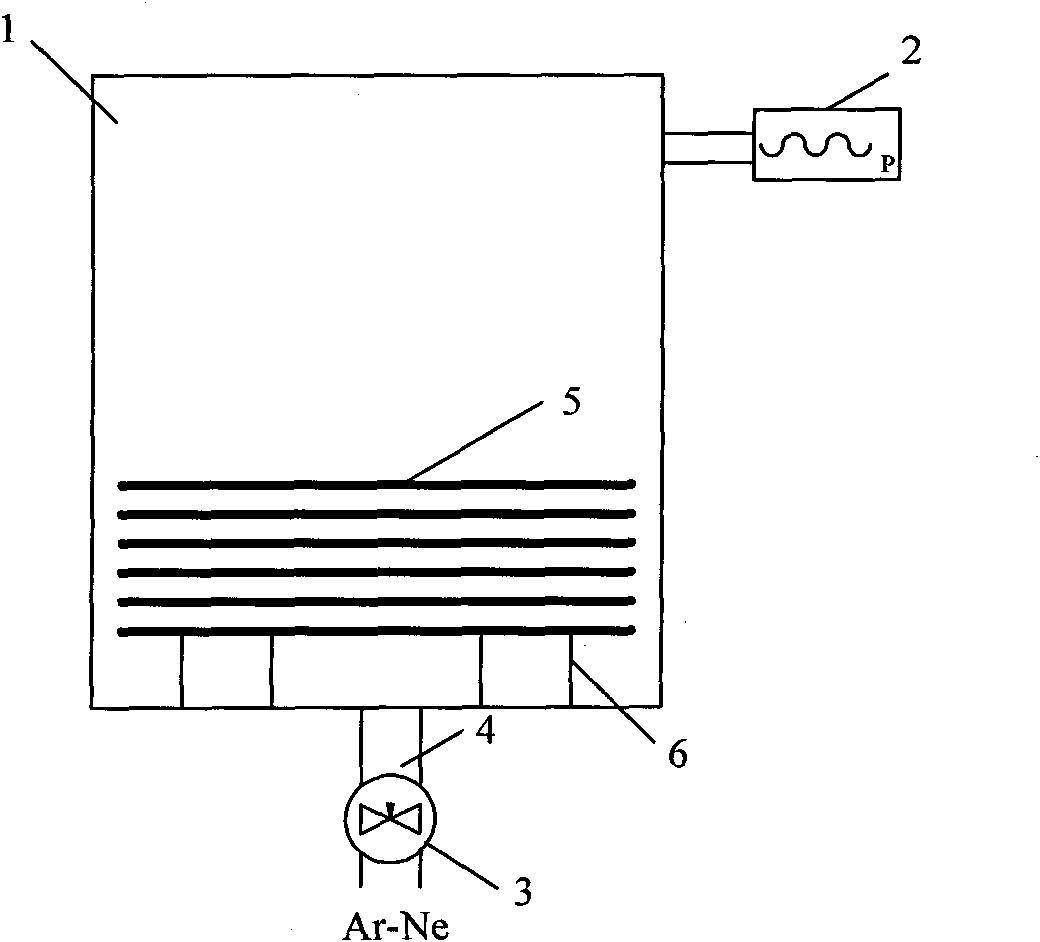

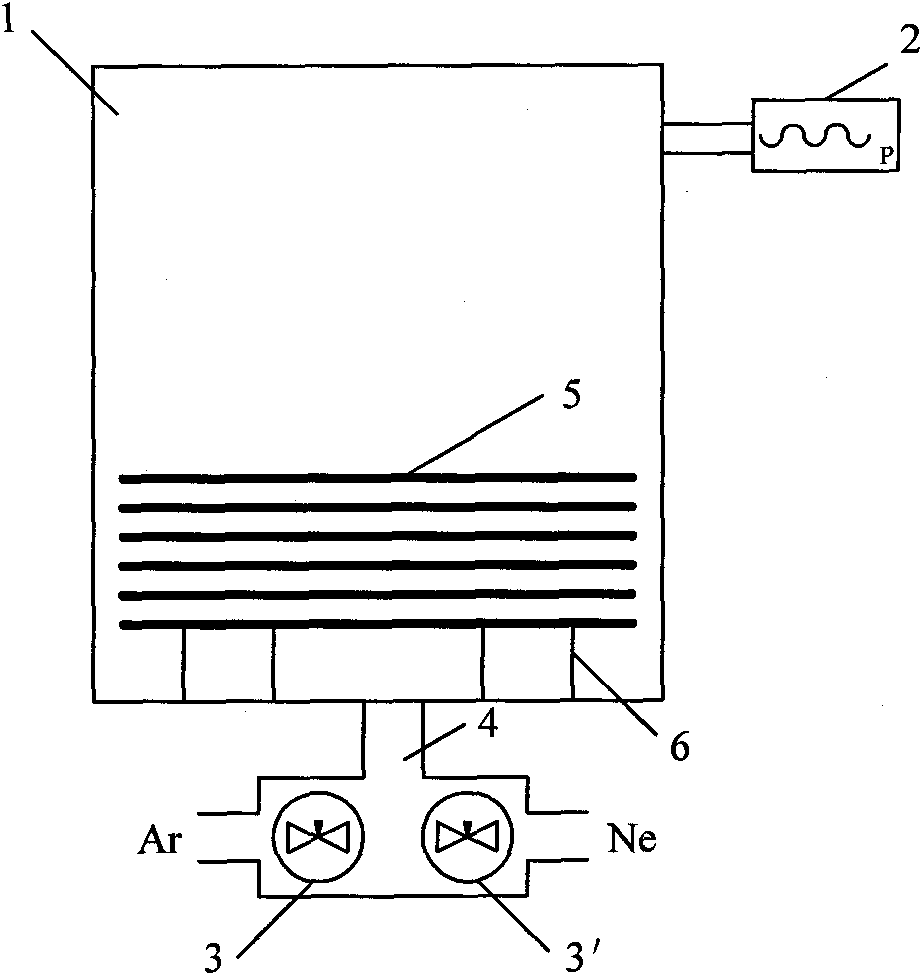

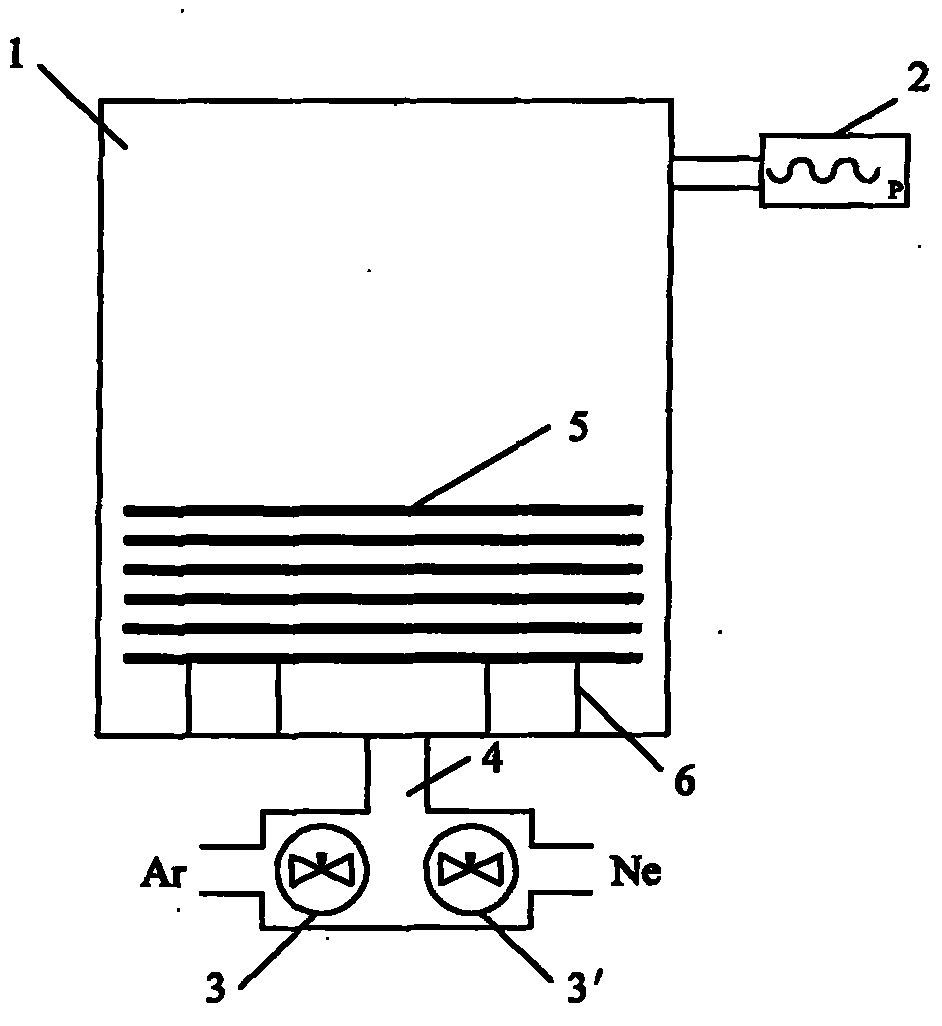

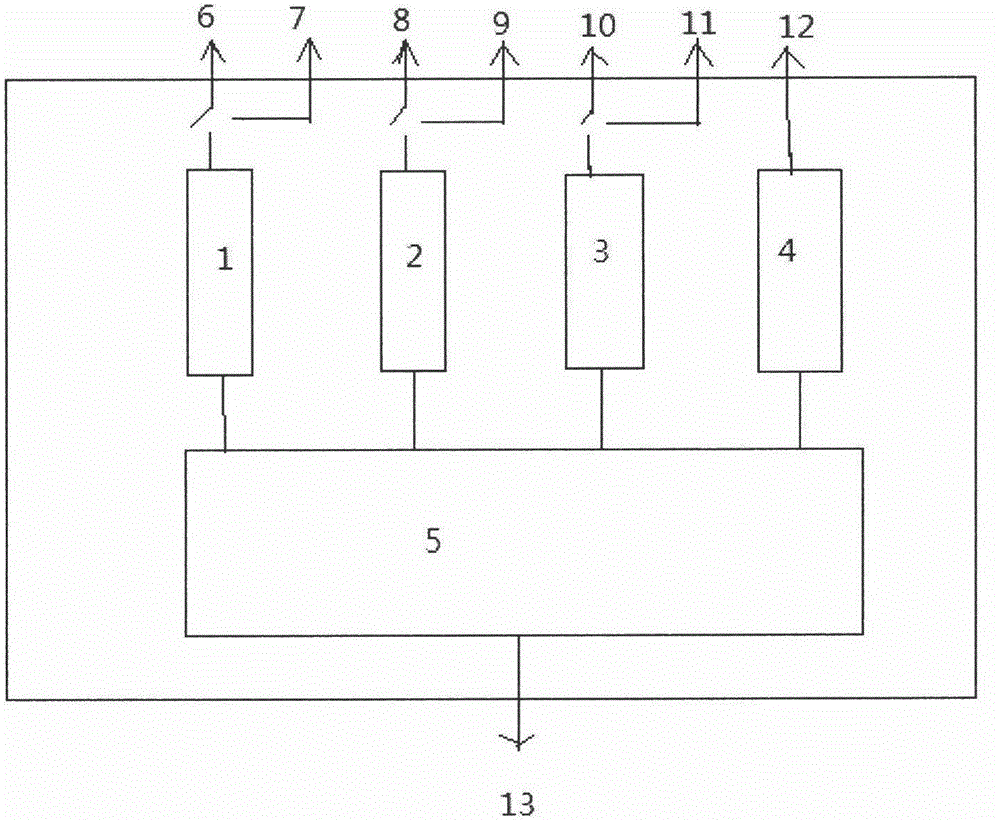

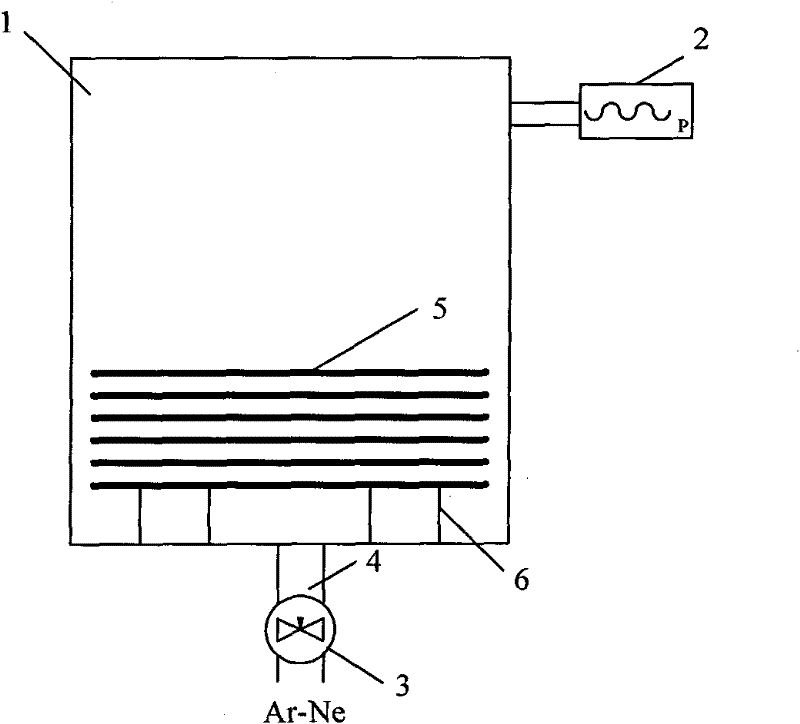

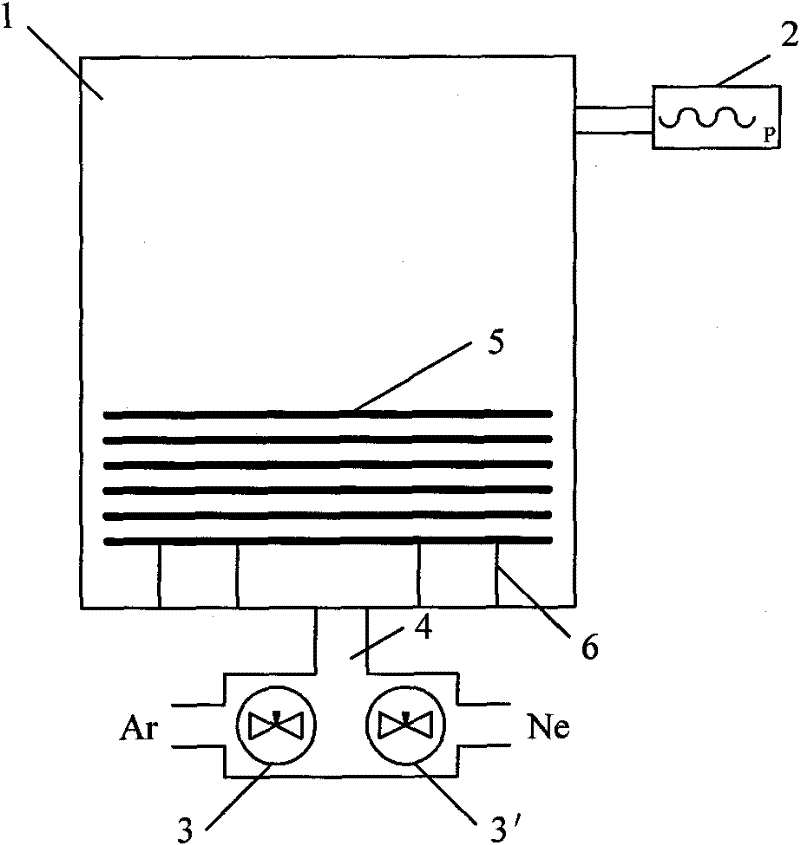

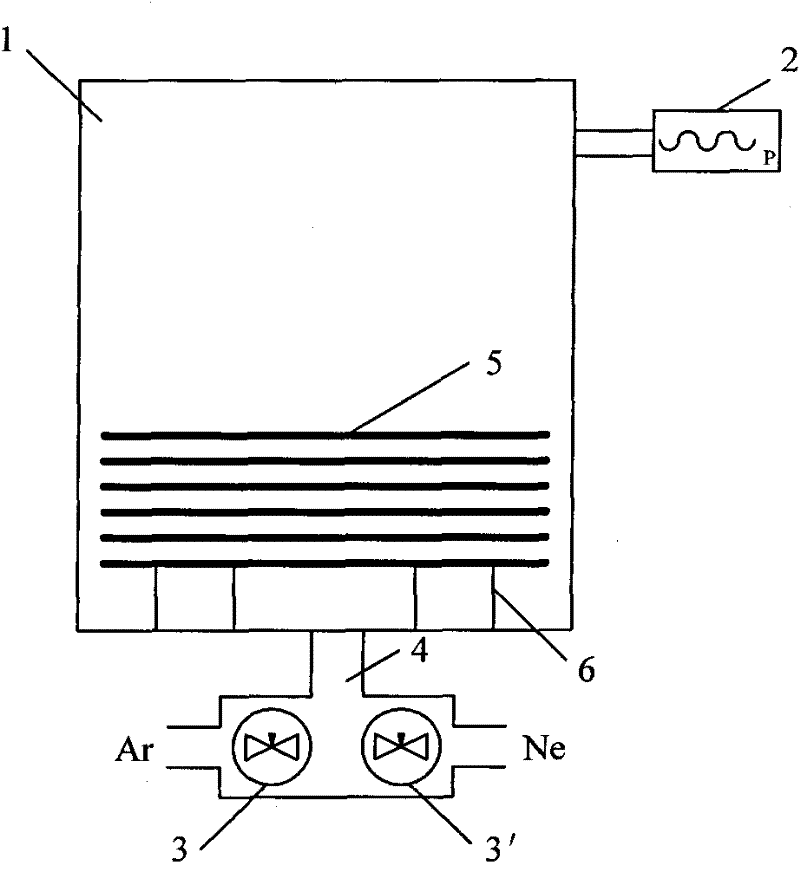

Charging method and device for low pressure ceramic gas discharge tube

InactiveCN101794698AEasy to manufactureHigh specification pass rateTube/lamp vessel fillingIonizationMixed gas

The invention discloses a charging method for a low pressure ceramic gas discharge tube, comprising the following steps of: respectively introducing two single gases with different ionization potentials into a hearth of a vacuum sealing weld furnace for mixing according to the molecule quantity; enabling the mixed gas to enter a discharge tube to be sealed and welded, which is arranged in the hearth; and finally sealing and welding an electrode with a ceramic tube of the discharge tube. The two single gases are neon gas and argon gas, wherein the molecular weight of the argon gas accounts for 1.0-2.5 percent. A charging device for the low pressure ceramic gas discharge tube comprises a heating and vacuum sealing and welding system, a precise pressure gauge connected with the heating and vacuum sealing and welding system and two parallel charging valves, wherein gas outlets of the two charging valves are respectively connected with charging ports of the heating and vacuum sealing and welding weld system. The invention enables the ratios of the two mixed gases to be adjusted according to the requirement and can realize precise control on technical parameters of the discharge tube. The low pressure ceramic gas discharge tube produced according to the mixture ratio of the two mixed gases can achieve lower direct current breakdown voltage.

Owner:WUXI CHAOYUAN ELECTRONICS

Method for controlling program-controlled equipment in centralized way

ActiveCN104932467AQuick switchAdapt to the requirements of small batch and multi-variety productionProgramme total factory controlProduction linePersonalization

The invention discloses a method for controlling program-controlled equipment in a centralized way, relates to a method for centralized remote control, and specifically relates to a method for program-controlled equipment. Hardware and software are used to simulate the human-computer interaction operation process of equipment. Switching and setting of an automatic process are realized under the condition of not reforming or upgrading the equipment. Therefore, investment on existing equipment is protected, a flexible production line is achieved, and a way is opened for personalized production modes. The method is applicable to small-batch and multi-variety production.

Owner:李二文

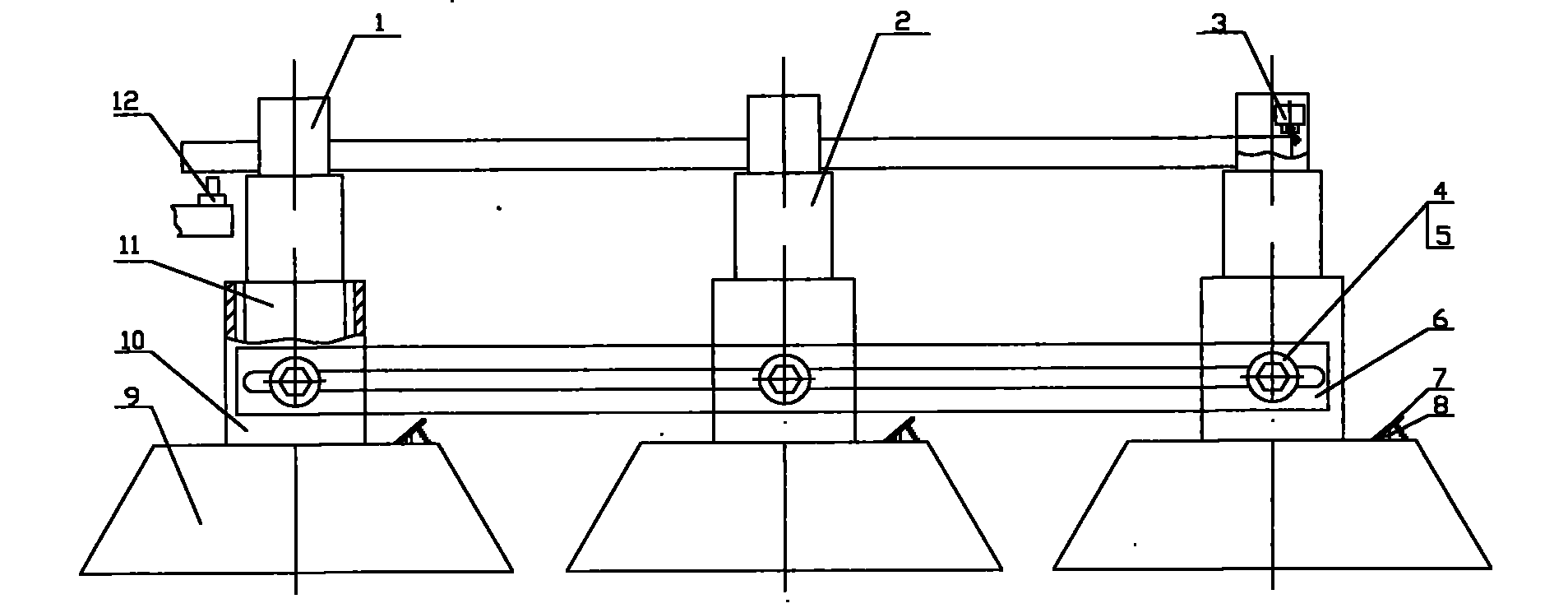

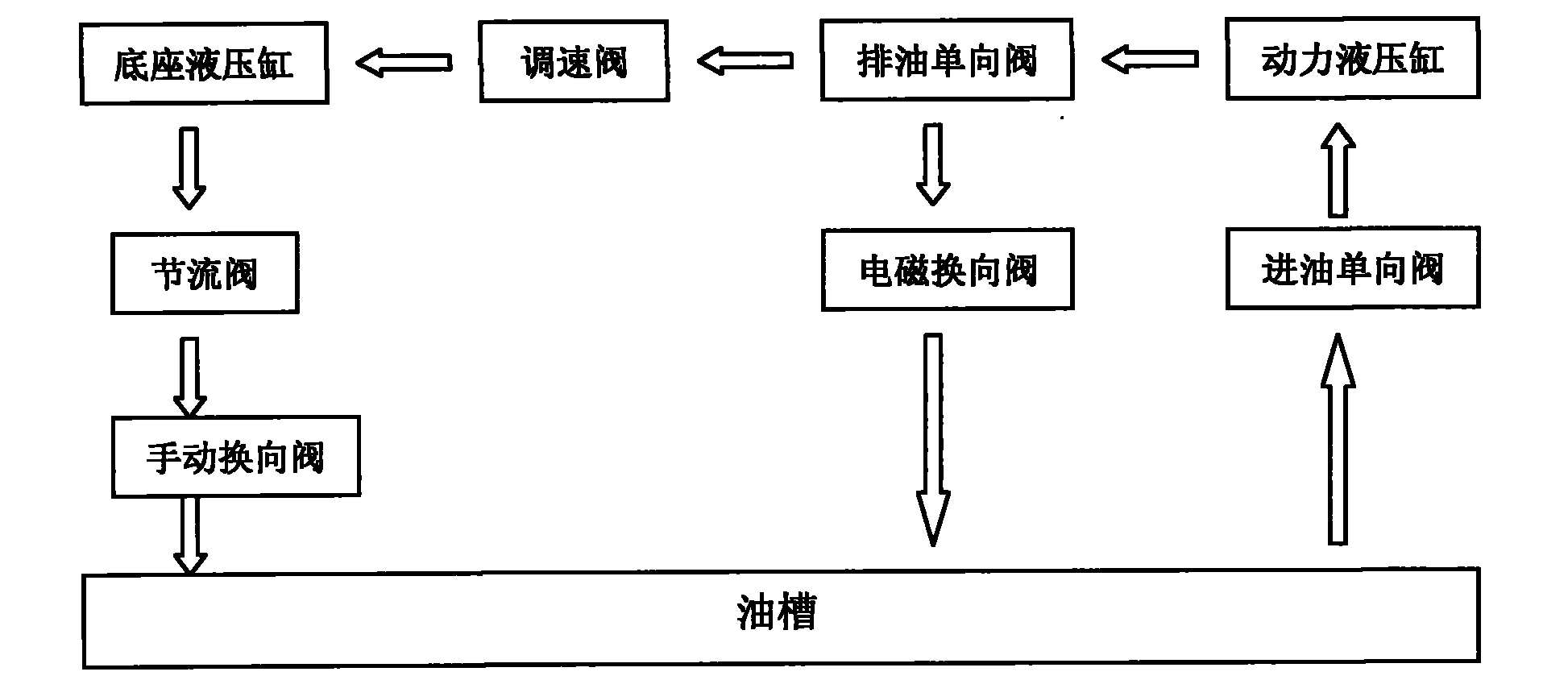

Spiral duct machine support frame

InactiveCN103722046AWarranty Strength RequirementsAdapt to production requirementsEngineeringScrew thread

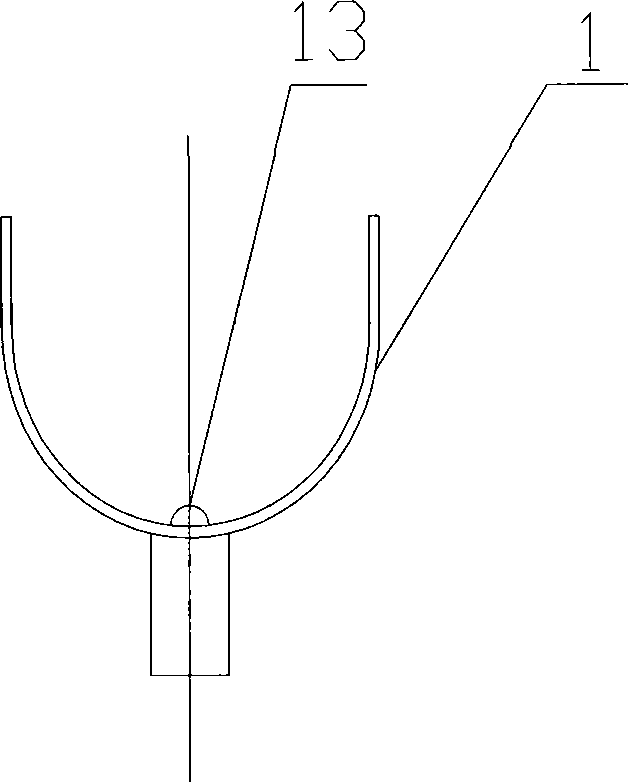

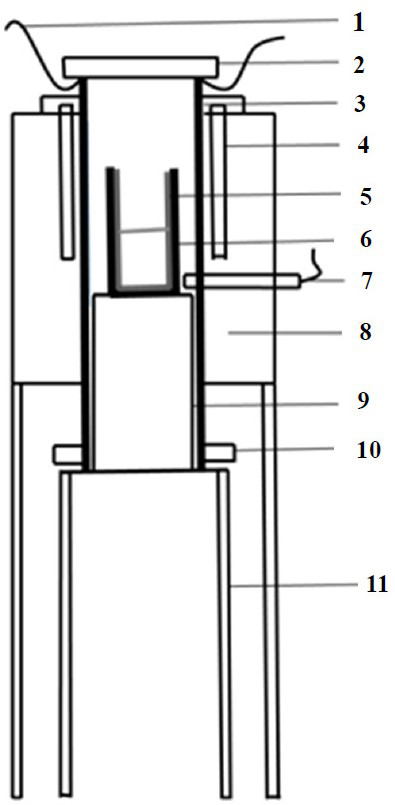

The invention provides a spiral duct machine support frame, and aims to provide a device can adjust the longitudinal and transverse movement of each support frame and can realize automatic spiral duct cutting. The support frame device is composed of U-shaped frames, lifting pipes, bases, rail steel, pedals, a travel switch and a cutting machine. The pedals drive the execution parts lifting pipes through hydraulic systems in the bases, and the lifting pipes drive the U-shaped frames to rise. When the U-shaped frames reach preset positions, contact switches on the U-shaped frames touch a spiral duct, the U-shaped frames stop rising, and an electromagnetic directional valve is opened. When the U-shaped frames descend, the electromagnetic directional valve is closed, a hand-directional valve is opened, and at the same time a throttle valve is adjusted so as to make the U-shaped frames descend to desired locations slowly. The number and interval of the support frame can be adjusted according to the length of the processed spiral duct pipe and the support frame strength requirement, and the support frame is fixed with screws and gaskets through the rail steel, the bases and threaded holes on positioning pipes. And when the front end of the spiral duct touches the travel switch, the cutting machine cuts off the spiral duct.

Owner:江苏启星新型材料科技有限公司 +1

A kind of free-cutting corrosion-resistant steel and preparation method thereof

The invention relates to a free-cutting corrosion-resistant steel and a preparation method thereof. The free-cutting corrosion-resistant steel contains components in mass percentage: C, 0.015-0.024%; Si, 0.4-0.5%; Mn, 1.2-1.3%; S, 0.24-0.3%; P, 0.02-0.03% ; Mo, 1.5-1.75%; Cr, 19-20%; Ca, 0.03-0.08%; Mg, 0.01-0.02%; Al, 0.02-0.05%; Te, 0.012-0.03%; the balance is Fe and impurities. The method comprises the following steps: mixing free-cutting steel, chromium-ferro mixed material and slag material, and completely melting at high temperature to obtain molten material; adding tellurium to the molten material, heat preservation treatment, and cooling to obtain easy-cutting corrosion-resistant steel. The free-cutting corrosion-resistant steel in the invention has the best composition ratio, and has the best comprehensive free-cutting performance and corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

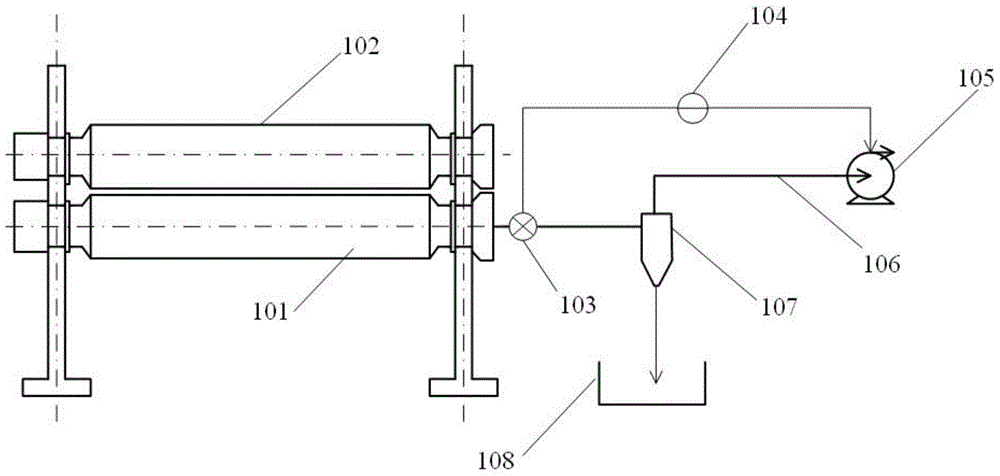

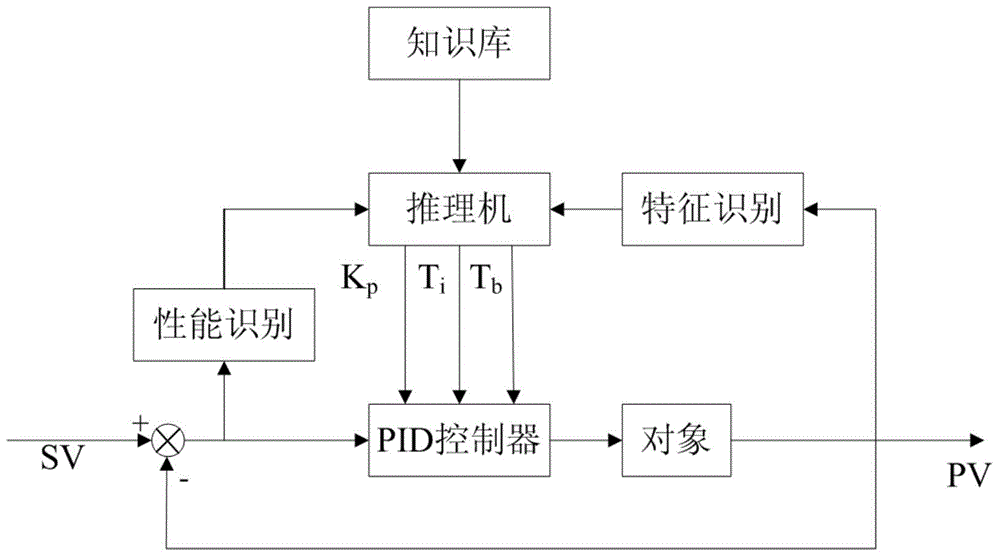

A vacuum press system for wet tanning

ActiveCN103895251BReduce DMF residuesImprove dehydration efficiencyPressesControl signalPulp and paper industry

The invention provides a vacuum pressing system for wet method tanning. The vacuum pressing system comprises a vacuum pressing device, a compression roller device, a pressure transmitter, a pressure adjuster, a water ring vacuum pump, a vacuum pipeline and an air-water separator. The water ring vacuum pump is communicated with the air-water separator through the vacuum pipeline, the air-water separator is communicated with a vacuum box outlet pipeline of the vacuum pressing device, the pressure transmitter is used for measuring the vacuum degree of the interior of the vacuum pressing device, the water ring vacuum pump is controlled by a PID controller, and the pressure adjuster transmits control signals to the PID controller to control the rotating speed of the water ring vacuum pump according to vacuum degree signals, measured by the pressure transmitter, of the interior of the vacuum pressing device. The vacuum pressing system for wet method tanning is used for increasing the DMF and water extraction rate of PU synthetic leather in the water processing process, the DMF residual quantity of the PU synthetic leather can be quickly reduced, water extraction efficiency of the vacuum pressing system is improved, and energy consumption generated in the drying process is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

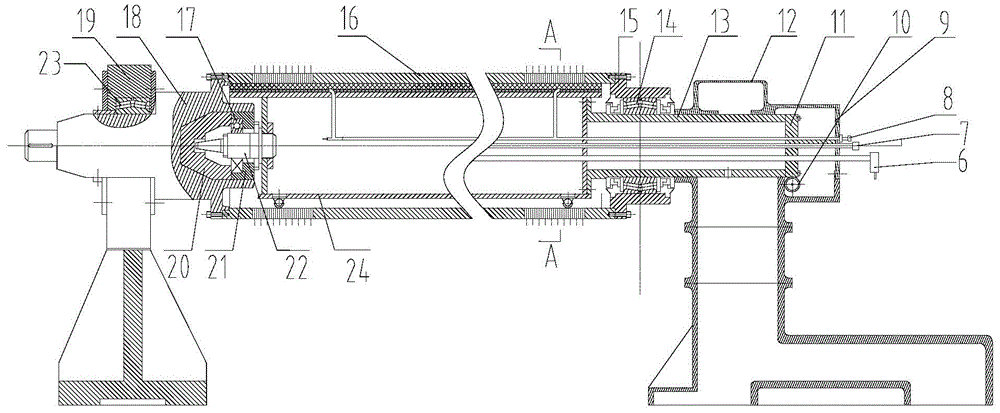

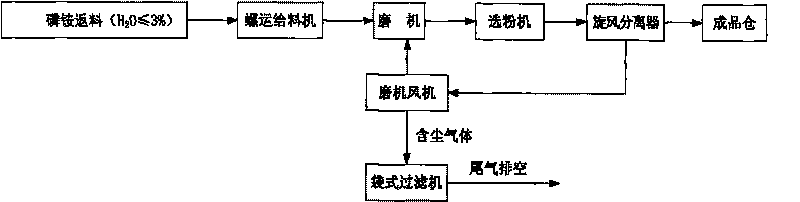

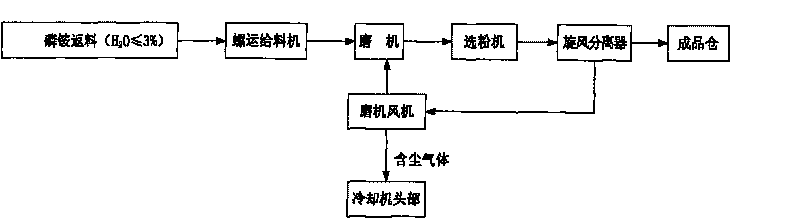

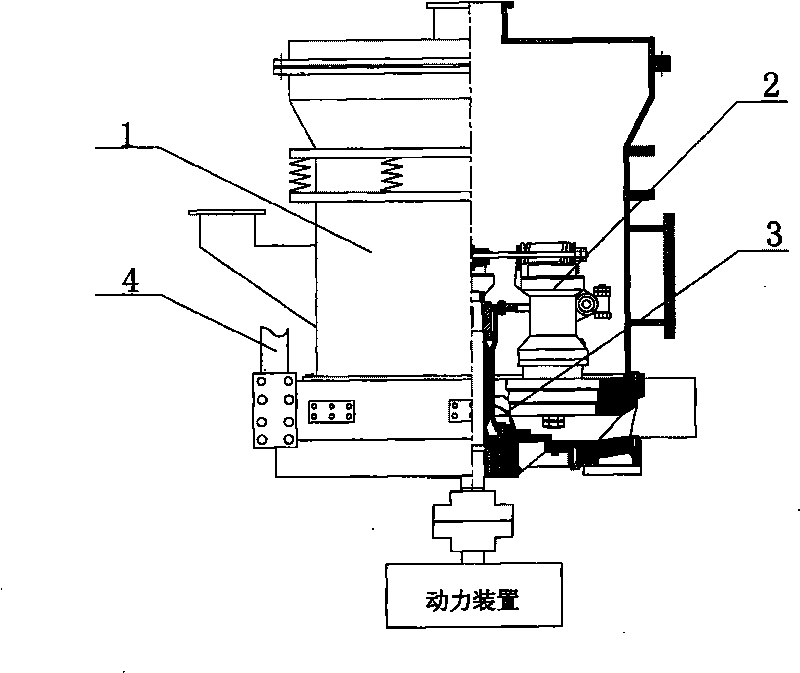

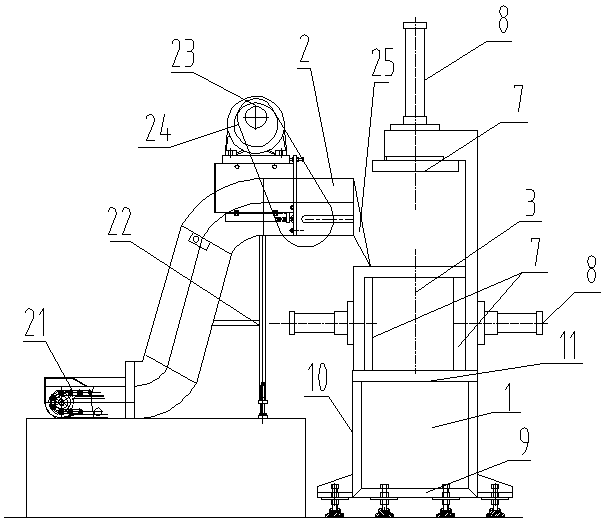

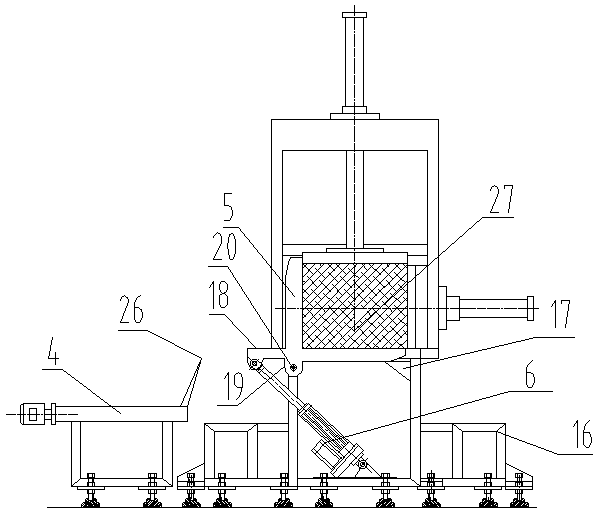

Method for producing powdery monoammonium phosphate of T-shaped pulveriser

InactiveCN101708831AAdapt to crushing needsAdapt to production requirementsPhosphatesGrain treatmentsOperating environmentFineness

The invention discloses a method for producing powdery monoammonium phosphate by a T-shaped pulveriser. The method comprises the following steps: taking the T-shaped pulveriser as a base, alternately removing three grinding rollers, setting a rear elevation angle of a perching knife in front of and corresponding to each grinding roller into 15-30 degrees; meanwhile, for improving operating environment, removing original matched bag type dust remover of the T-shaped pulveriser, and connecting a wind pipe to the cooling head part of a monoammonium phosphate device to lead air exhauster of the grinding machine to a dust remover of a cooling machine. The method applies the T-shaped pulveriser to the production of the powdery monoammonium phosphate for the first time, which not only obviously increases the output of the monoammonium phosphate, but also greatly improves presentation quality. The product has no hollow grains, low moisture and can not be agglomerated completely, the fineness is obviously improved; and moreover, the method greatly saves the maintaining and checking expense of the grinding machine and has a good application prospect.

Owner:云南云天化股份有限公司三环分公司

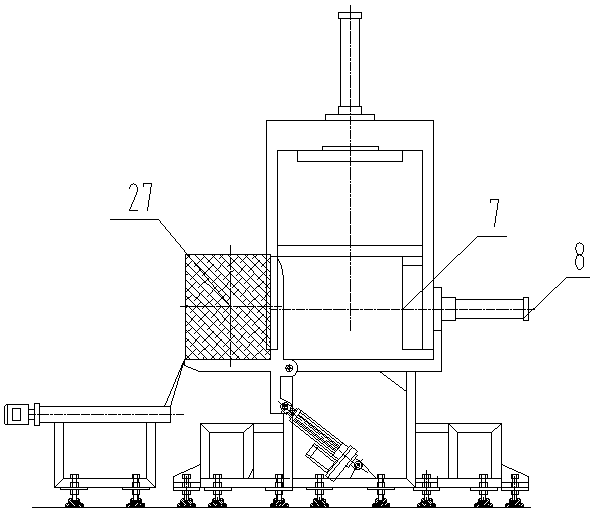

Aluminum chipping briquetting device

The invention belongs to the technical field of waste chipping recycling treatment, and particularly relates to an aluminum chipping briquetting device. The aluminum chipping briquetting device comprises a basic frame, a feeding mechanism, a briquetting turning mechanism and a transporting mechanism, and the briquetting turning mechanism comprises four push plates for compacting aluminum chippings. The immobility for pressing aluminum blocks can be improved, and scattering is not prone to happening in the transportation process. In addition, the device is simple in operation, the turning mechanism is used for turning the briquetted aluminum blocks to the transporting mechanism, the labor intensity of workers can be reduced, the pressing efficiency and transportation efficiency are improved, the aluminum chipping briquetting device adapts to the production requirements of the production line, and the production efficiency is improved.

Owner:CITIC DICASTAL

Iron chisel supply unit and blast furnace taphole drilling device

PendingCN112760437AImprove fluencyIncrease storage capacityBlast furnace componentsBlast furnace detailsMining engineeringChisel

The invention relates to an iron chisel supply unit. The iron chisel supply unit comprises chisel storage hoppers and iron chisel taking mechanisms, wherein the chisel storage hoppers comprises material bearing grooves with the wide upper portions and the narrow lower portions and discharging sections connected to the bottom ends of the material bearing grooves, discharging channels are formed in the discharging sections, and the width of the discharging channels is smaller than twice of the diameter of iron chisels; the iron chisel taking mechanisms are arranged at the outlet ends of the discharging channels. In addition, the invention further relates to a blast furnace taphole drilling device. The blast furnace taphole drilling device comprises a taphole drilling machine, the iron chisel supply unit and a chisel replacing unit used for installing the supplied iron chisels on the taphole drilling machine. According to the iron chisel supply unit and the blast furnace taphole drilling device, chisel storage hoppers are adopted for storing the iron chisels used for blast furnace production, the chisel storage hoppers are designed to comprise the material bearing grooves and the discharging sections, and the material bearing grooves are of the structure with the wide upper portion and the narrow lower portion, so that the storage amount of the iron chisels can be effectively increased; the width of the discharging channels is designed to be smaller than the twice of the diameter of the iron chisels, so that one-by-one discharging of the iron chisels can be ensured, and the chisel replacement operation is facilitated.

Owner:WISDRI ENG & RES INC LTD

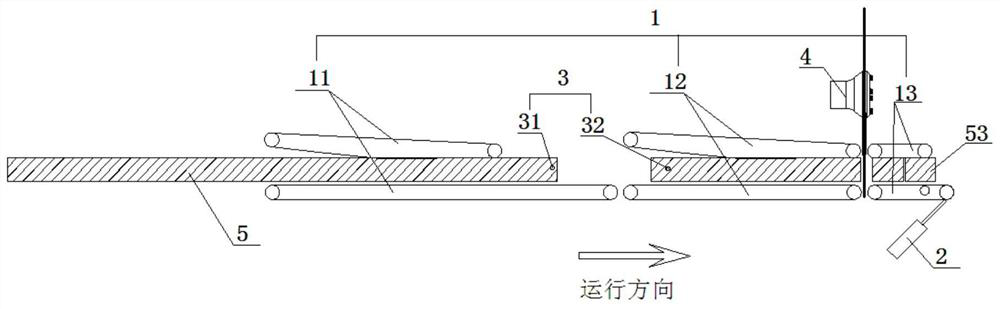

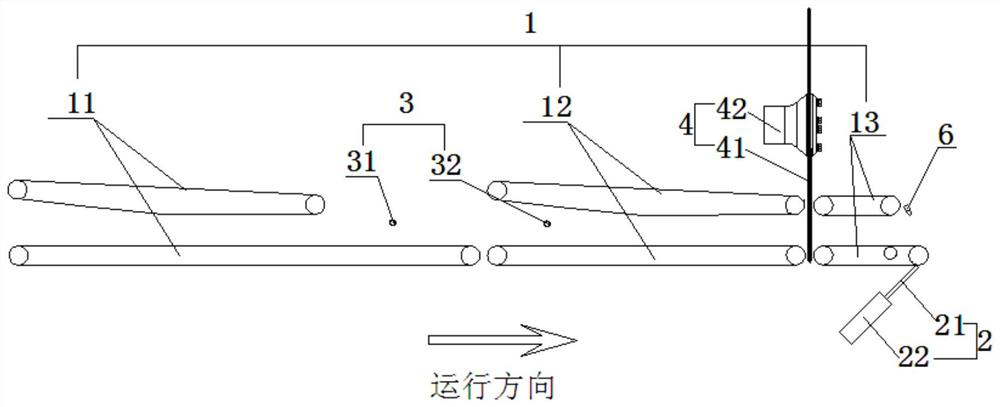

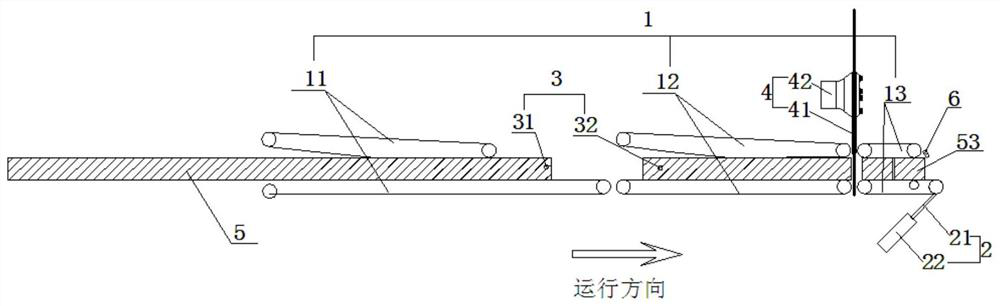

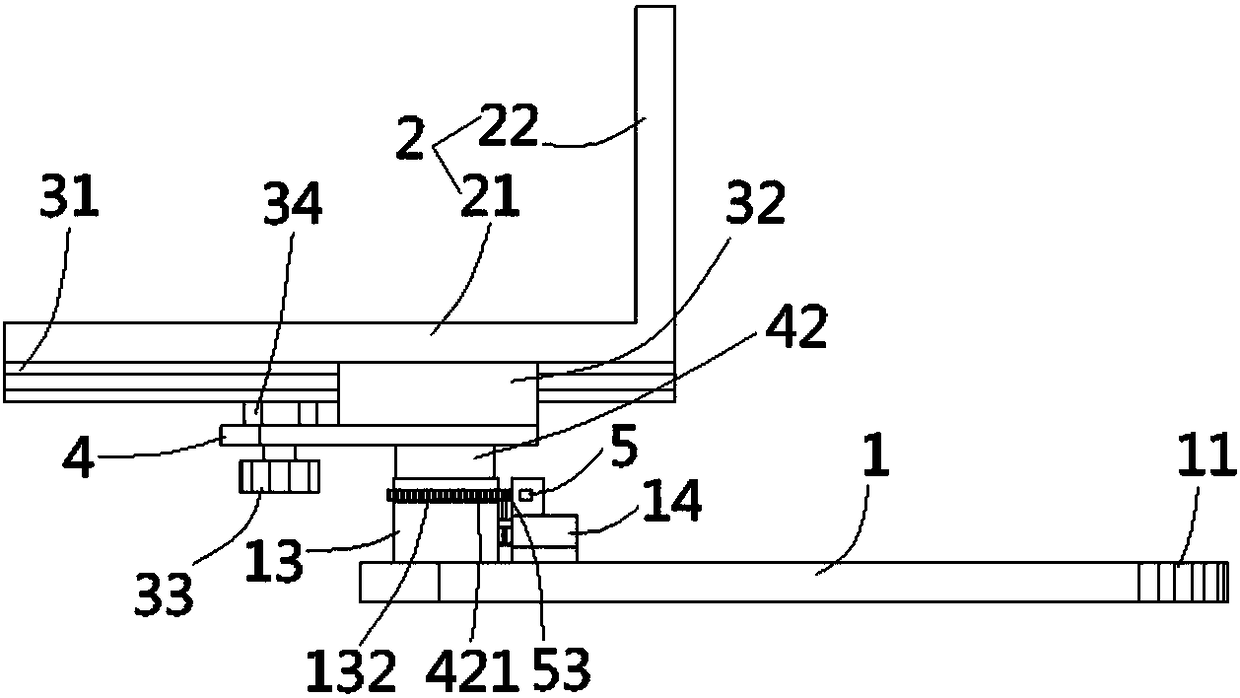

Large-rotary continuous feeding and waste discharging system

PendingCN112428323AReduce idle timeIncrease productivityMetal working apparatusPaper cutProcess engineering

The invention discloses a large-rotary continuous feeding and waste discharging system. The large-rotary continuous feeding and waste discharging system comprises a feeding conveying system, detectionswitches, a rotary cutter set and a control system, wherein the detection switches comprise a first detection switch and a second detection switch so as to respectively detect the positions of the paper head and the paper tail; the rotary cutter set is arranged between a second clamping and conveying unit and a third clamping and conveying unit and used for cutting long-strip paper materials; andthe control system controls the first clamping and conveying unit to operate in an accelerated mode to shorten the distance between the long-strip paper materials at the two ends according to detection signals of the detection switches, then the control system accelerates the cutting frequency of the rotary cutter set to rapidly cut the paper tails and the paper heads of the long-strip paper materials, and finally, a telescopic mechanism is controlled to stretch out and draw back to discharge the paper tails and paper heads. Compared with a traditional paper cutting machine, the large-rotarycontinuous feeding and waste discharging system has the advantages that the head, the tail and finished products of paper are continuously cut off, and the production efficiency is greatly improved.

Owner:柳州市卓信自动化设备有限公司

Compound desinsection primary agent and pesticide consisting of verticillium lecanii and imidacloprid

InactiveCN101513191BAdapt to the natural ecological environmentReduce dosageBiocideAnimal repellantsArthropod mouthpartsPlant Louses

The invention discloses a compound desinsection primary agent and pesticide consisting of verticillium lecanii and imidacloprid. The primary agent is a mixture of the verticillium lecanii and the imidacloprid, wherein, the mass ratio between the verticillium lecanii and the imidacloprid is 100: 5-50; while the pesticide consists of a primary agent and a secondary agent, according to mass percent,the primary main agent accounts for 5-50%, and the secondary agent 50-95%. Through long-term infection biological study and interior biological assay, the verticillium lecanii has strong infection desinsection effect on a plurality of pests, the sucking pest in particular. The compound pesticide consisting of verticillium lecanii and imidacloprid of the invention has good effect in preventing andcontrolling pests such as white fly, plant louse, diamond back moth and the like.

Owner:SOUTH CHINA AGRI UNIV

An adjustable industrial support for automation equipment

ActiveCN106870908BAchieve positioningRealize multi-angle adjustmentStands/trestlesEngineeringSlide plate

Owner:ZHEJIANG KAIBO PRESSURE VESSEL

Charging method and device for low pressure ceramic gas discharge tube

InactiveCN101794698BEasy to manufactureHigh specification pass rateTube/lamp vessel fillingIonizationMixed gas

The invention discloses a charging method for a low pressure ceramic gas discharge tube, comprising the following steps of: respectively introducing two single gases with different ionization potentials into a hearth of a vacuum sealing weld furnace for mixing according to the molecule quantity; enabling the mixed gas to enter a discharge tube to be sealed and welded, which is arranged in the hearth; and finally sealing and welding an electrode with a ceramic tube of the discharge tube. The two single gases are neon gas and argon gas, wherein the molecular weight of the argon gas accounts for1.0-2.5 percent. A charging device for the low pressure ceramic gas discharge tube comprises a heating and vacuum sealing and welding system, a precise pressure gauge connected with the heating and vacuum sealing and welding system and two parallel charging valves, wherein gas outlets of the two charging valves are respectively connected with charging ports of the heating and vacuum sealing and welding weld system. The invention enables the ratios of the two mixed gases to be adjusted according to the requirement and can realize precise control on technical parameters of the discharge tube. The low pressure ceramic gas discharge tube produced according to the mixture ratio of the two mixed gases can achieve lower direct current breakdown voltage.

Owner:WUXI CHAOYUAN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com