Charging method and device for low pressure ceramic gas discharge tube

A gas discharge tube and gas filling device technology, which is applied in the direction of electric tube/lamp filling, etc., can solve the problems that the technical parameters of the discharge tube cannot be precisely controlled, the breakdown voltage Vs of the discharge tube varies greatly, and cannot be adjusted according to needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

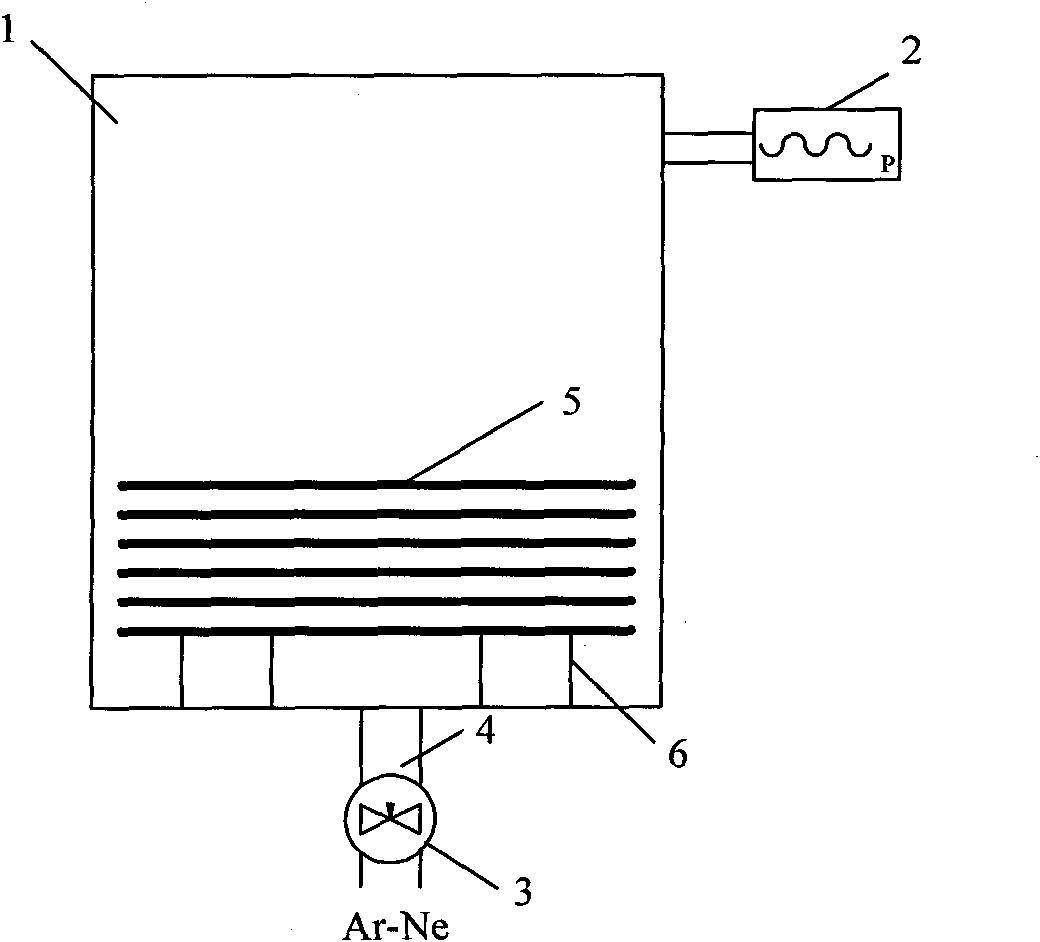

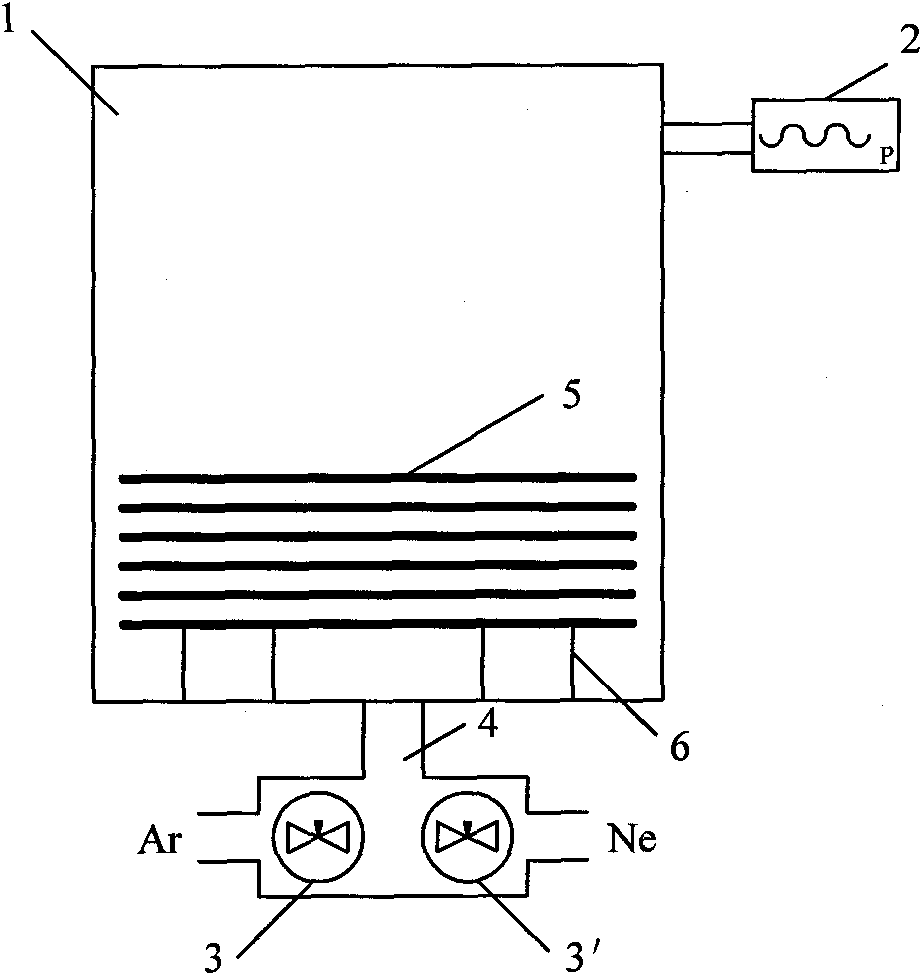

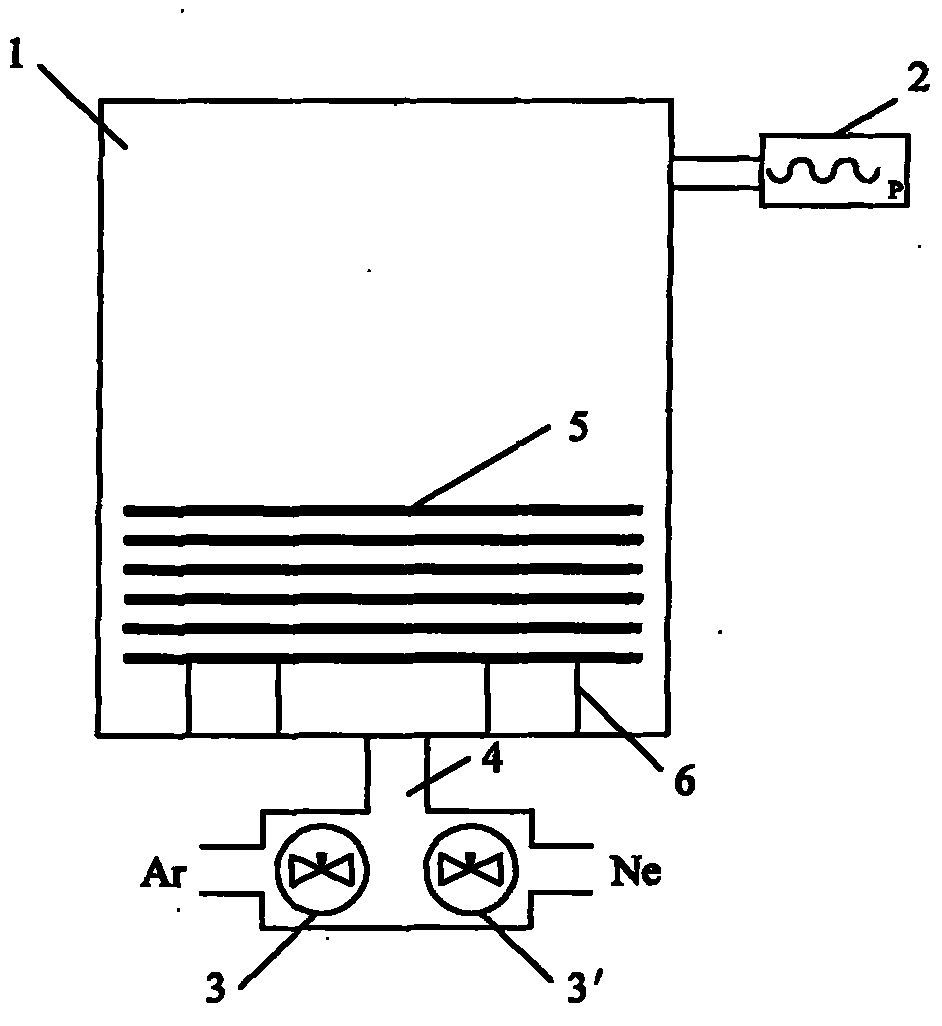

Embodiment 1

[0027] Manufacture of low-voltage ceramic diode gas discharge tube (model 2R55Φ5.5×6). Materials are prepared as follows:

[0028] Fe-Ni-Co alloy electrode: outer diameter D=Φ5.5, neck root diameter d=Φ3.9, total height H=2.8, neck height H 1 = 2.3,;

[0029] Porcelain tube: outer diameter D = Φ5.5, inner diameter d = Φ4.0, height H = 4.95, 4 drawn carbon lines; electronic powder model: K203.5, distance between two electrodes 0.35 (the above alloy electrode and porcelain tube are Commercially available products, all in millimeters).

[0030] The inflation conditions are as follows: Ne-Ar mixed gas is charged, in which the number of molecules of Ar is 1.9%, and the pressure value indicated by the precision pressure gauge is -0.078MPa.

[0031] Since the initial value of the precision pressure gauge is -0.1MPa, when only Ne is charged, the Ne pressure value displayed on the precision pressure gauge 2 is calculated by the following formula: -0.078+[-0.1-(-0.078)] ×1.9%, the o...

Embodiment 2

[0039] On the basis of Example 1, only the number of molecules occupied by Ar was changed to 2.4%, and the other process conditions were unchanged, and the production was carried out. Randomly sample 14 products to test and record their Vs value. The test data is shown in the table below: (unit V)

[0040]

[0041] It can be seen from the above table that under the gas-filling conditions of Example 2, when the number of Ar molecules in the mixed gas accounts for 2.4%, a diode discharge tube with a very low DC breakdown voltage Vs can be manufactured.

Embodiment 3

[0043] On the basis of Example 2, only the serial number of the electronic powder was changed to D18K, and the other conditions remained unchanged, and the production was carried out. Randomly sample 14 products to test and record their Vs value. The test data is shown in the table below: (unit V)

[0044]

[0045] It can be seen from the above table that although the type of electronic powder has been changed compared with Example 2, a diode discharge tube with a very low DC breakdown voltage Vs can still be manufactured under the same gas filling conditions. Therefore, the inflation method of the present invention is not affected by the type of electronic powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com