Aluminum chipping briquetting device

A kind of aluminum chip and basic technology, which is applied in the field of waste chip recycling and processing, can solve the problems of low pressing efficiency and production efficiency, reduced transportation efficiency, and infirmity, so as to improve pressing efficiency and transportation efficiency, reduce labor intensity, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

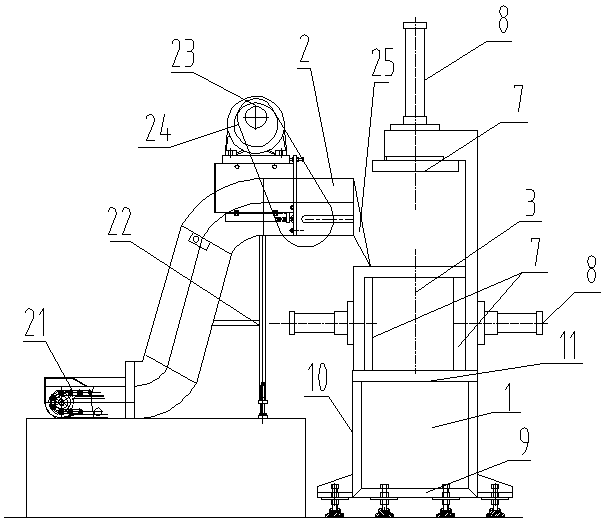

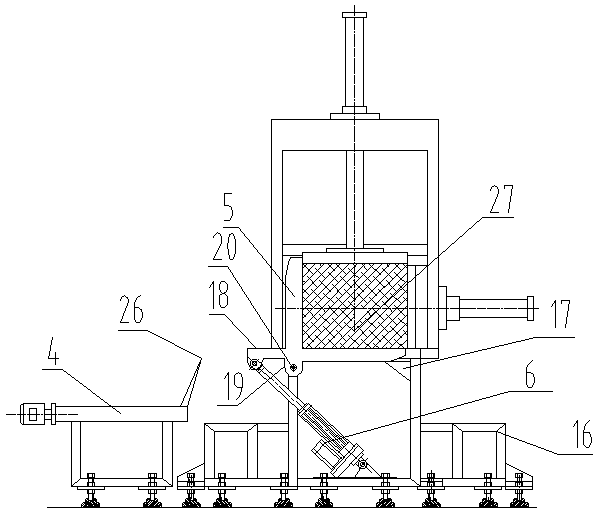

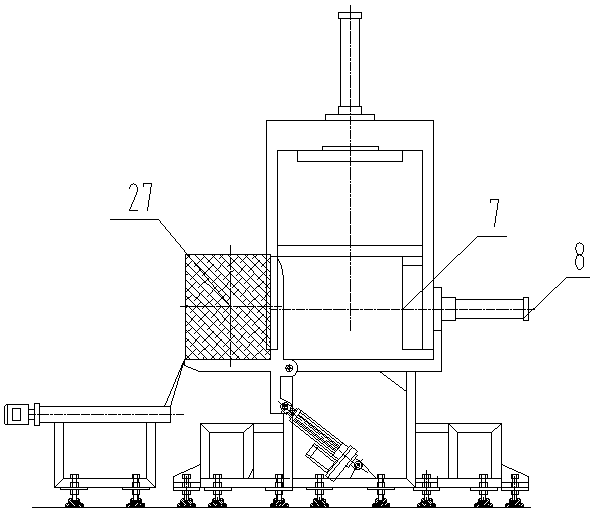

[0028] The following is attached with the manual Figure 1-5 Embodiment 1 of the present application is illustrated:

[0029] An aluminum chip briquetting device includes a basic frame 1, a feeding mechanism 2, a briquetting turning mechanism 3, and a transport mechanism 4.

[0030]The briquette turning mechanism 3 is fixedly arranged on the base frame 1, and the briquetting turning mechanism 3 includes an L-shaped briquetting turning frame 5, a turning drive assembly 6, 4 push plates 7, 4 pushing assemblies 8, and the pushing assembly 8 and The overturn drive assembly 6 can be a cylinder, a hydraulic cylinder or an electric cylinder, etc., one end of the overturn drive assembly 6 is fixed on the base frame 1 through a hinge shaft, and the other end is fixed on the L-shaped briquetting overturn frame 5 through a hinge shaft; the L-shaped briquetting block The overturning frame 5 comprises a bottom plate and a side plate at right angles, the L-shaped briquetting overturning fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com