Connecting structure of aluminum electrolytic prebaked anode guide bar and steel jaw and preparation method thereof

A technology of prebaked anode and connection structure, which is applied in the field of connection structure between aluminum electrolytic prebaked anode guide rod and steel claw, which can solve the problems of increasing the repair cost of aluminum guide rod, easy fracture of aluminum-aluminum welding point, and high anode voltage loss, etc. problems, achieve the effect of reducing maintenance costs and use costs, small deformation, and reducing the rate of desoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

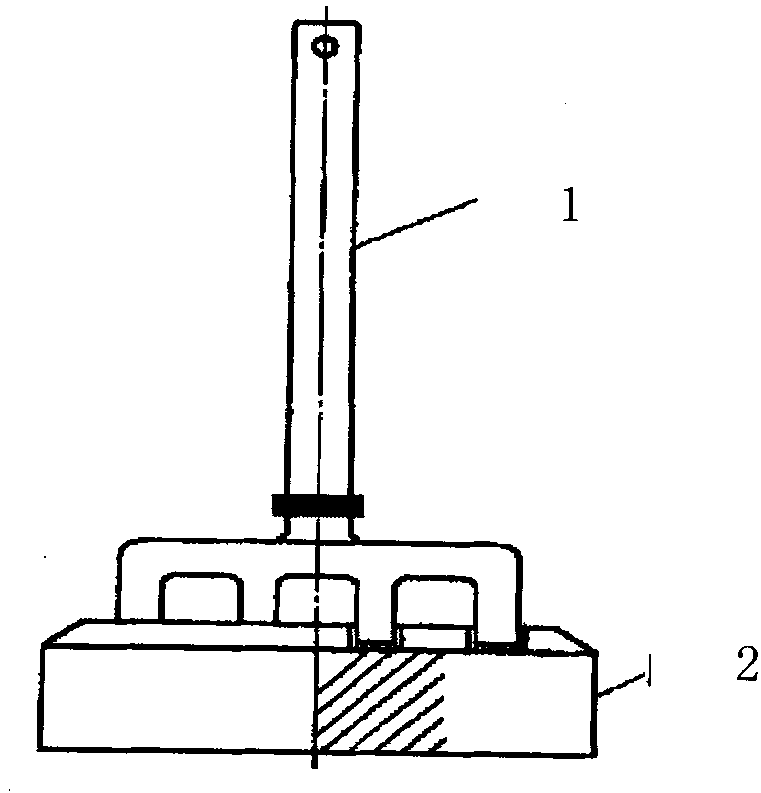

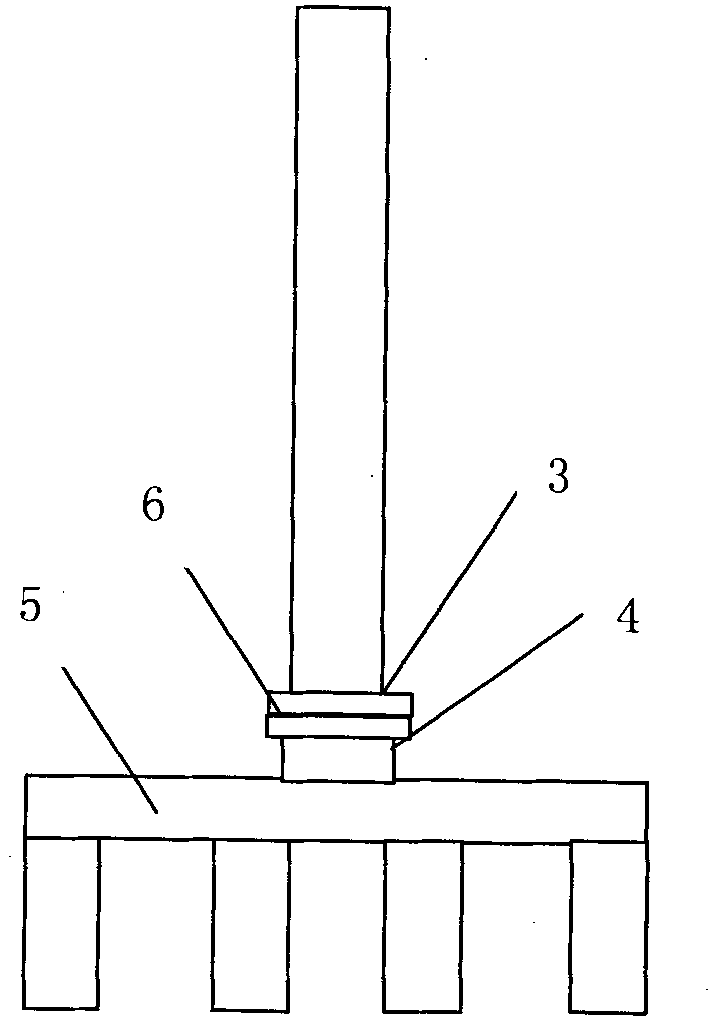

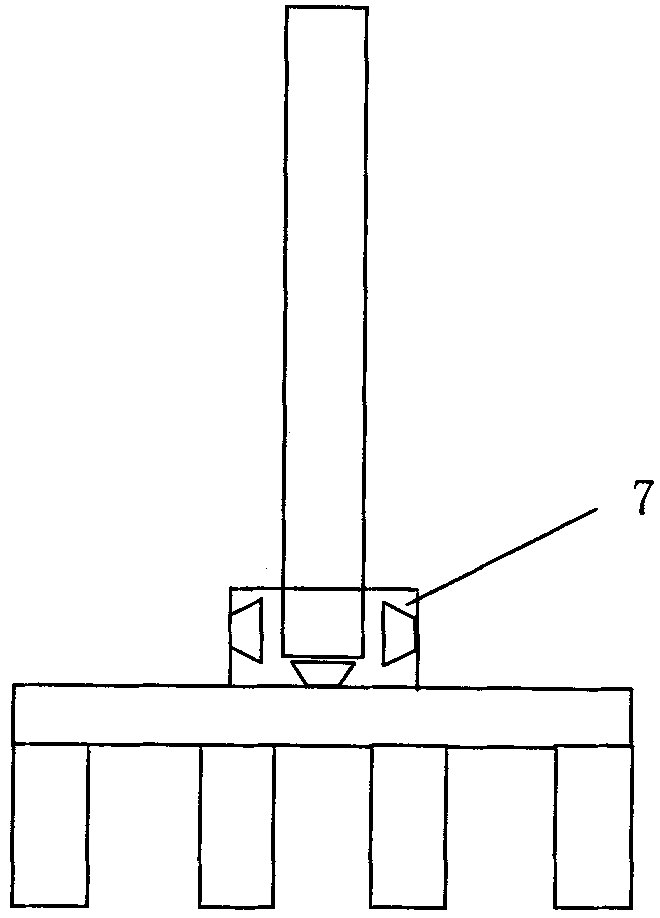

[0030] According to the thermal and physical properties of the metal phases, at a temperature of 750 to 800 ℃, use aluminum liquid or aluminum copper alloy liquid (copper accounts for 0.3%) to cast the steel claw hollow bucket (cast aluminum steel bucket), so that the guide rod and the steel The claws are connected as a whole. Such as Figure 4 As shown, the cast aluminum steel bucket has a protruding dovetail structure, and the aluminum guide rod casting head part has a dovetail groove: the lower part of the cast aluminum steel bucket is connected with the steel claws as a whole.

[0031] Specific production method:

[0032] 1. Clean and remove rust inside the steel bucket before aluminum casting;

[0033] 2. Coat a thin layer of rosin or solder paste on the inner wall of the steel bucket to prevent the inner wall of the steel bucket from being oxidized;

[0034] 3. Preheat the steel bucket and aluminum guide rod to 500~600℃ before casting aluminum;

[0035] 4. Heat aluminum or alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com