Great current quick-speed turning on-off body

A high-current, bridge technology, applied in the field of high-current rapid disconnection, can solve the problems of high risk, high difficulty, loud vibration and noise, etc., and achieve the effect of reducing risk, using less medicine, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

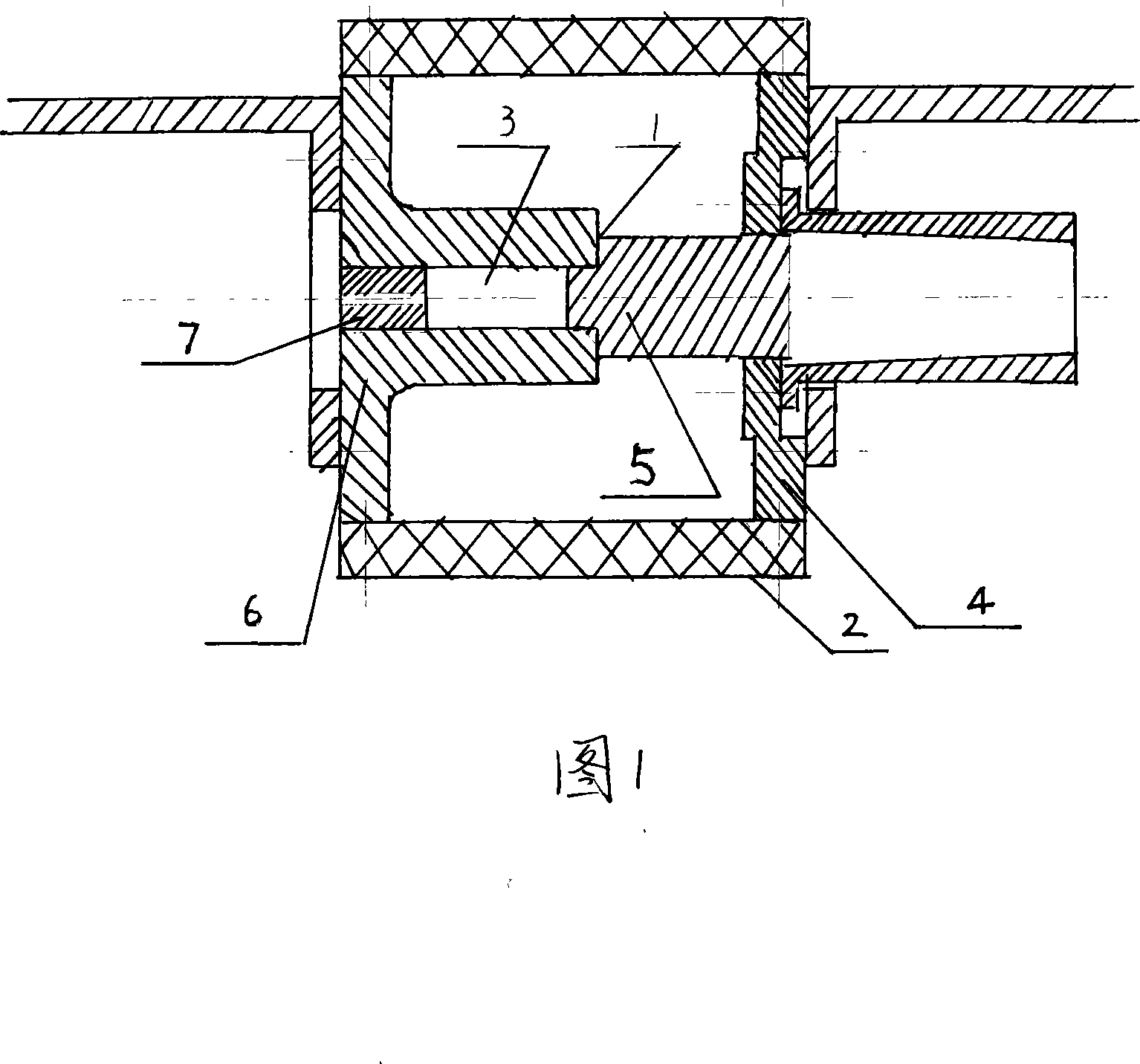

[0025] Referring to the accompanying drawings, the high-current quick-opening body, the two ends of the insulating sleeve 2 are respectively installed with the frying chamber end plate 6 and the container end plate 4 for connecting the circuit, and the frying cavity end plate 6 and the container end plate There is a cylinder in the middle of 4, and the front end of the cylinder of the end plate 6 of the blasting chamber is screwed with a plug 7, and there is a through hole for the lead wire of the explosive in the middle of the plug 7. There is a piston bridge body 5, the front end of the piston bridge body 5 has a cylinder inserted into the cylinder body of the end plate 6 of the frying chamber, the junction of the piston bridge body 5 and the end plate 6 of the frying chamber is connected by silver welding 1, and the piston bridge body 5 is connected to the plug 7 The part between is the blast chamber 3 filled with explosives, the rear end of the piston bridge body 5 is inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com