Automatic stacking device for aluminum profile finished products

An automatic stacking and aluminum profile technology, which is applied to the stacking, transportation and packaging of objects, can solve the problems of ordinary machinery that cannot be stacked neatly and save space, cannot complete blanking, and manpower is not timely, so as to improve production efficiency and production safety, reduce labor costs, and reduce the effect of stacking space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

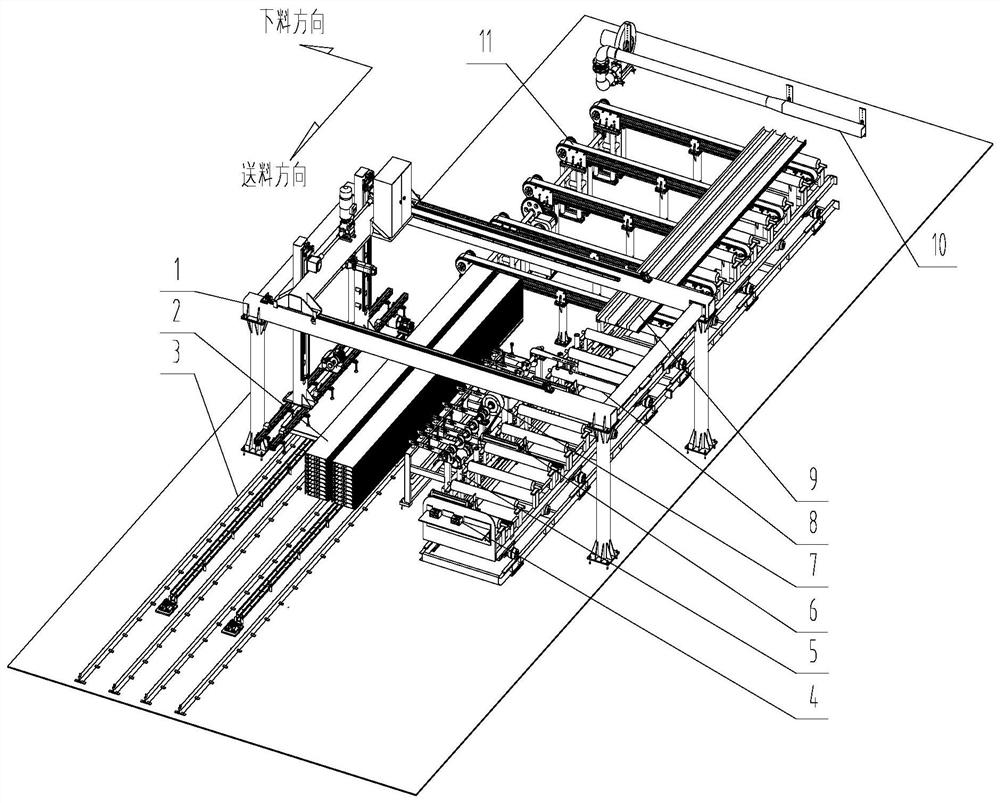

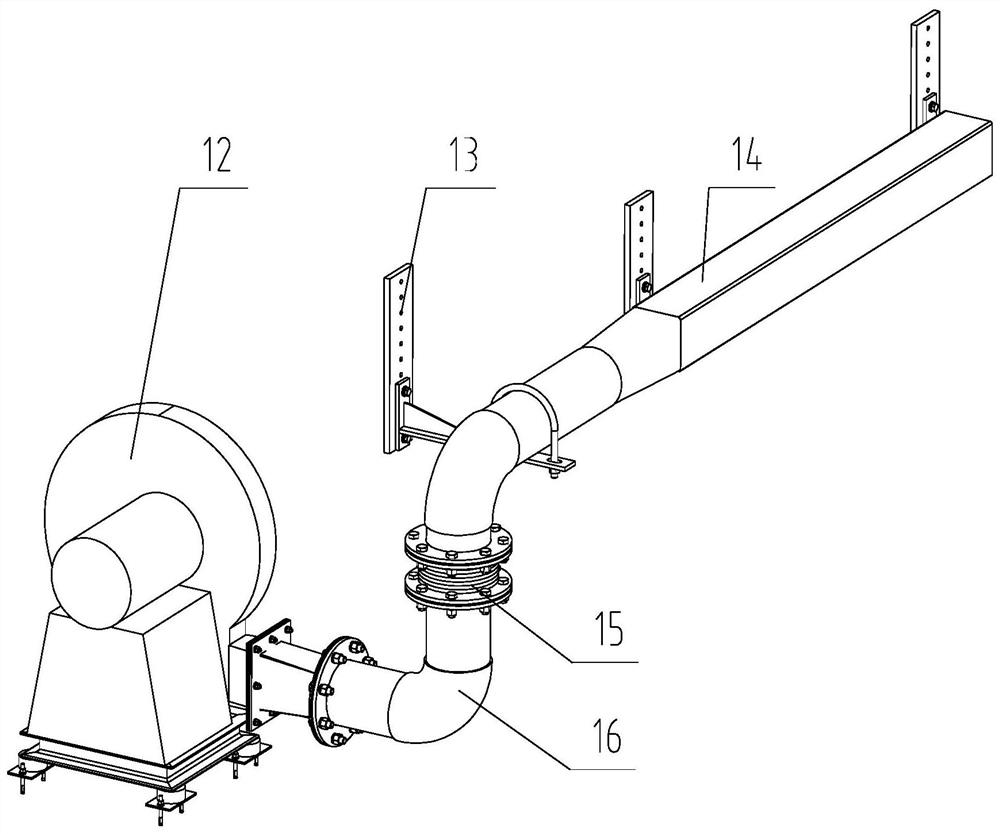

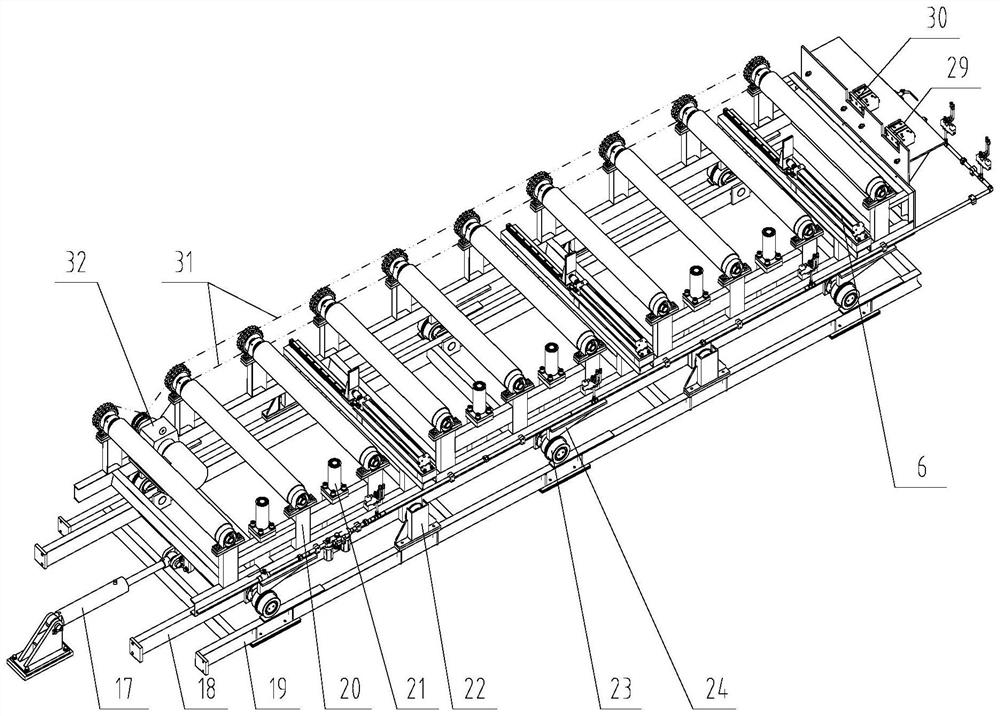

[0051] An automatic stacking device for finished aluminum profiles, adopting a fully automatic control method, including a control system, and a conveying device 8 connected to the control system, a manipulator 1, a material transporting device 3, a material turning device 7, a purging device 10 and a material picking device Device 11; the purge device 10 is set at the outlet of the finished saw to blow off the sawdust on the profile 9; the conveying device 8 is arranged on the side of the outlet of the finished saw to transport the profile 9 after sawing; the conveying device 3 is located at the conveying device 8 is far away from one end of finished product saw and is arranged in parallel with it; Manipulator 1 comprises the gantry frame 47 that straddles delivery device 8 and material delivery device 3 and the manipulator body that is arranged on the gantry frame 47; Material turning device 7 is arranged on material delivery device 3 and Between the conveying devices 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com