Method for producing powdery monoammonium phosphate of T-shaped pulveriser

A technology of monoammonium phosphate and pulverizer, applied in phosphate, phosphorus oxyacid, grain treatment, etc., can solve the problems of polluting the environment, ash leakage from fans, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

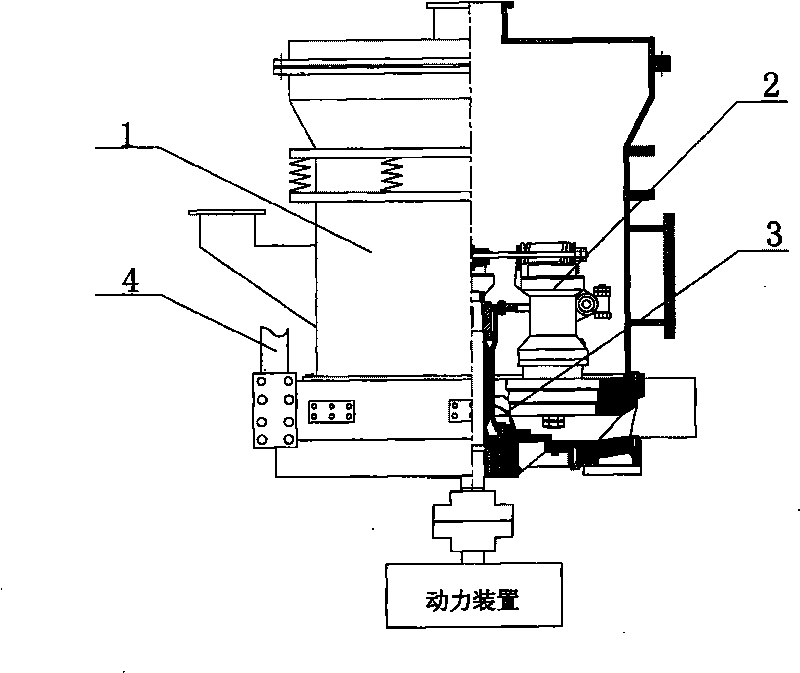

[0020] The equipment for producing powdered monoammonium phosphate consists of feeder, mill, powder classifier, two cyclone powder collectors, fan, bag filter and connecting pipeline. Among them, the mill is the MTM160T medium-speed mill. The complete set of equipment is manufactured and provided by Shanghai Xizhi Electric Power Equipment Co., Ltd. The maximum design capacity is 9-13t / h, and the power of the main engine motor is 132kw. Originally designed and manufactured for metallurgy, mine grinding ore and other materials with high hardness, it can grind ore of HRC13.

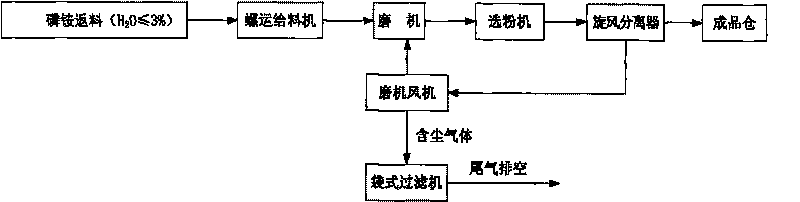

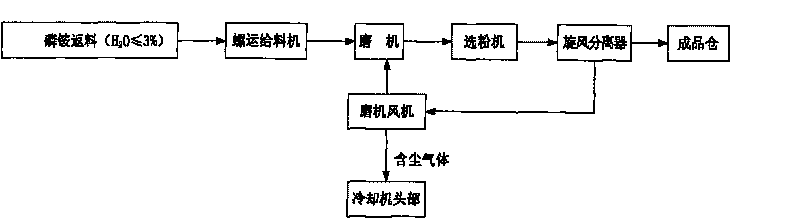

[0021] Such as figure 1 As shown, the ammonium phosphate return material is evenly sent to the lower air duct of the main engine by the screw feeder with frequency conversion speed regulation, and enters the grinding chamber with the wind, and the ammonium phosphate entering the grinding chamber is between the grinding roller and the grinding ring. Grinding, the ground powder is brought to the classifier by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com