Robust packaging laminate, method for manufacturing of the packaging laminate and packaging container produced therefrom

一种包装层压材料、层压材料的技术,应用在层压装置、包装、层压等方向,能够解决打开包装的能力限制、磨损、无法干净地切割等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

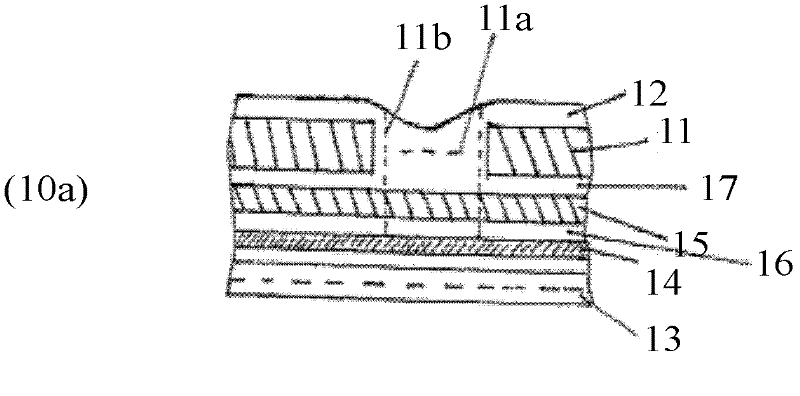

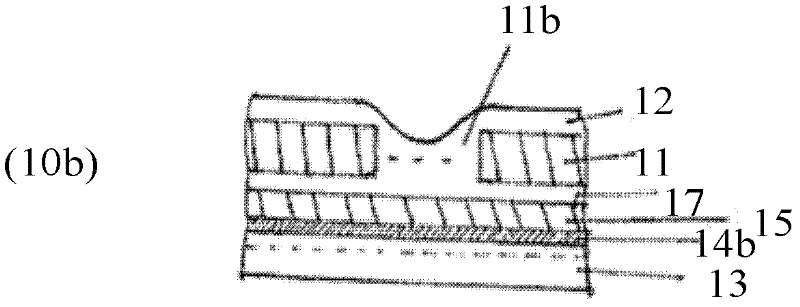

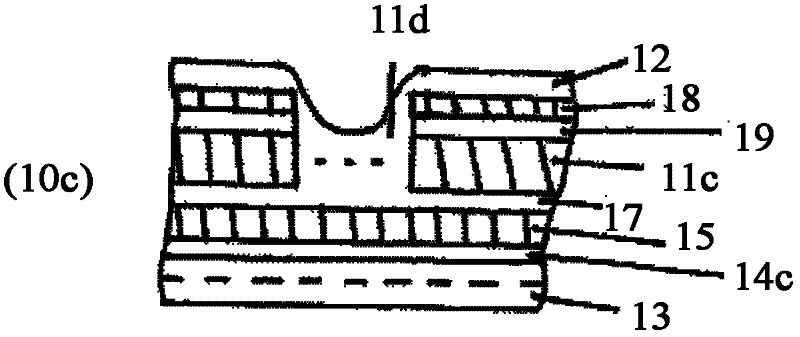

[0048] refer to Figure 1a The packaging laminate 10a of the present invention comprises a core layer 11 which is a settable rigid but foldable paperboard or cardboard. The core layer has through-holes, openings or slots 11a for mounting opening devices on packs produced from the packaging laminate. On the side of the core layer 11 which belongs to the outer side of the package produced by lamination, that is to say the side facing outwards away from the filled food product, a first outer heat-sealable thermoplastic layer 12 is applied, which faces towards the core layer side. Liquid and moisture isolation is also provided. The coating weight of the outer thermoplastic layer is about 10-20, preferably 12-18 g / m 2 , in particular polyethylene such as low density polyethylene (LDPE) may be used.

[0049] The core layer 11 is laminated on its inner side facing the inside of the package produced from the laminate to an additional stabilizing paper layer 15 . The stabilizing pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com