Radiating structure for outer-rotor direct-current brushless motor

A brushless DC technology with a heat dissipation structure, which is applied to electric components, electrical components, electromechanical devices, etc., can solve the problems of insufficient heat dissipation effect of electronic components of DC electronic control circuit boards, affecting the normal working state and life of electronic components, etc. Excellent effect, material cost saving, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

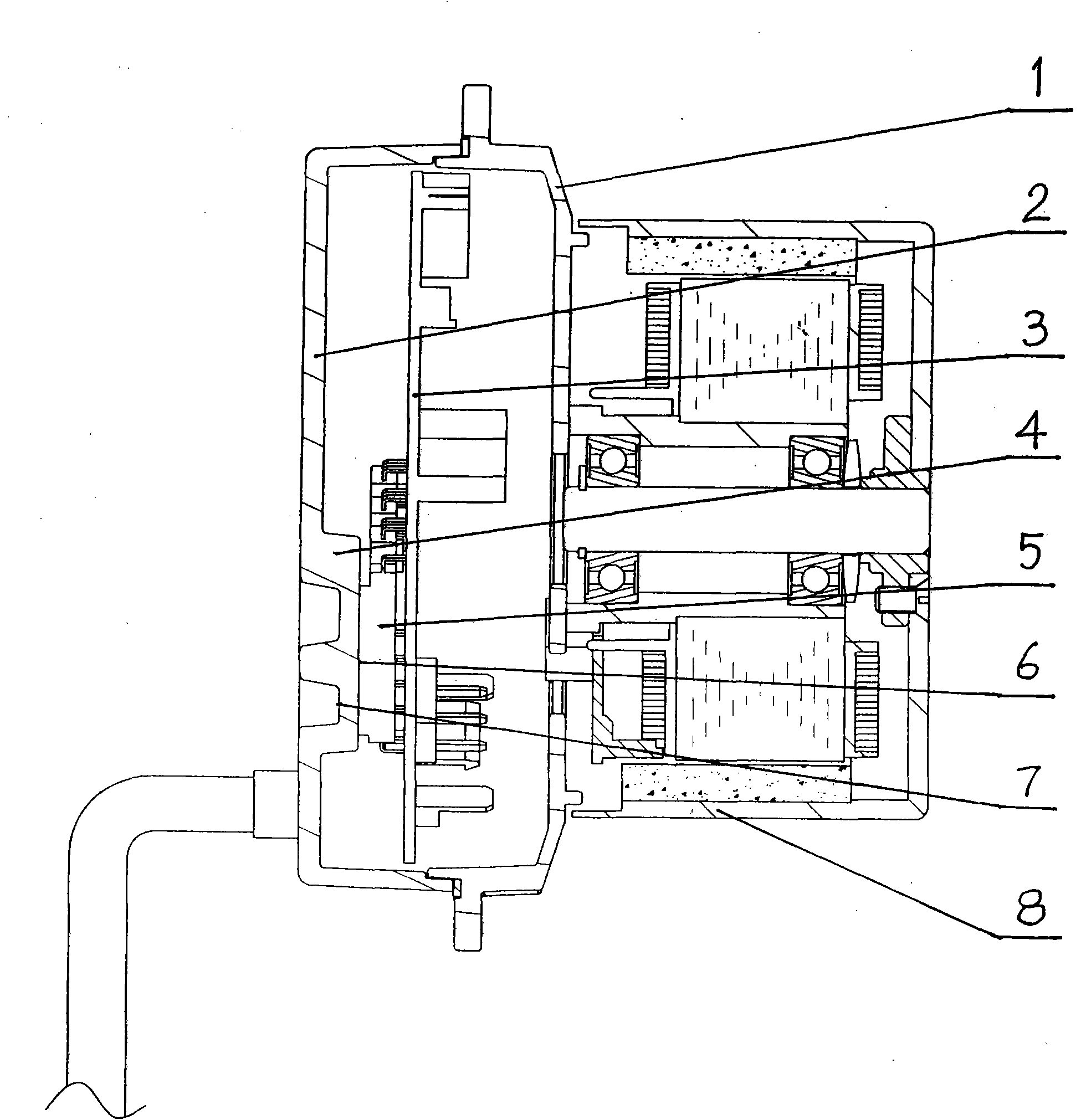

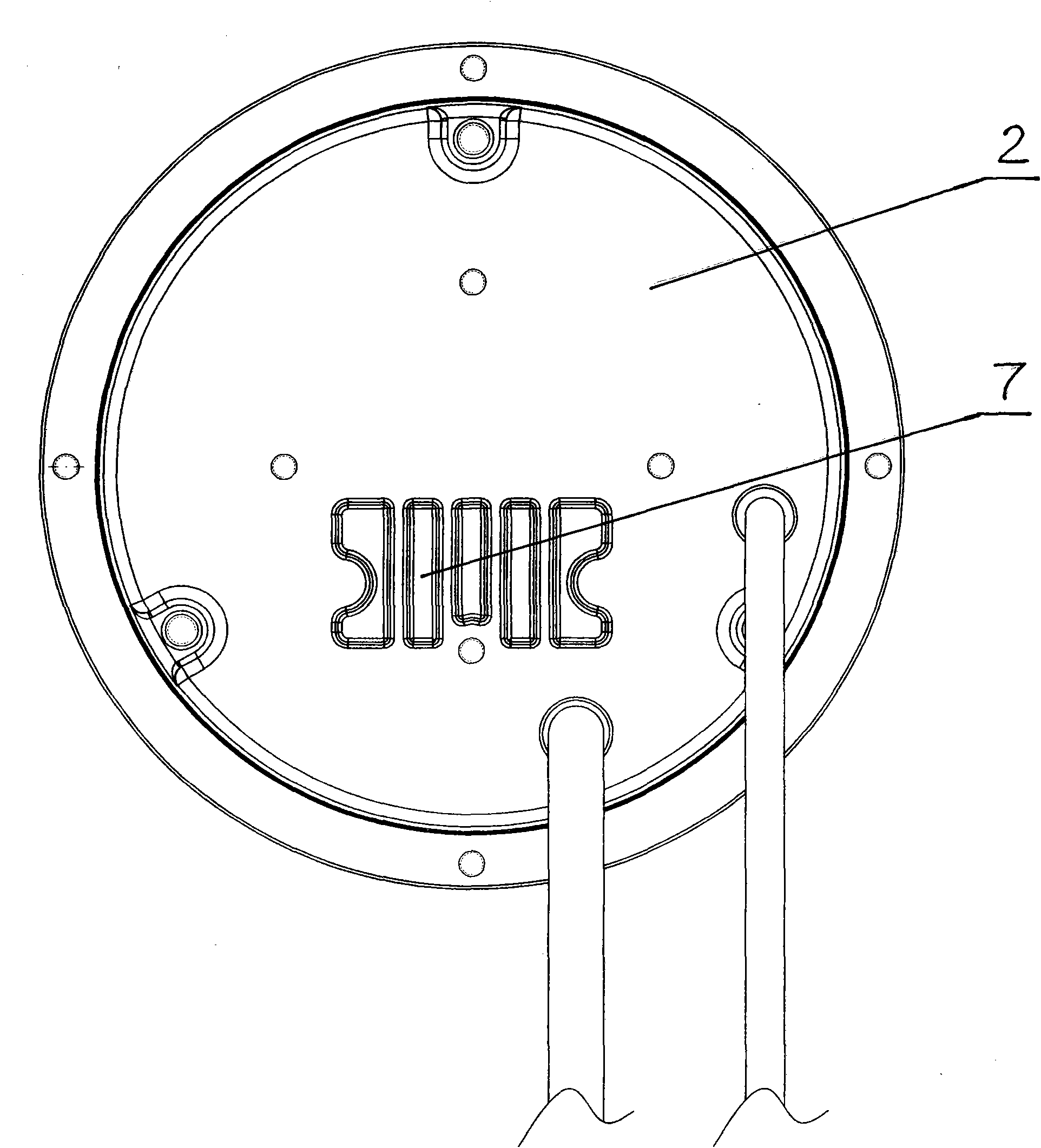

[0007] Visit figure 1 with figure 2 , The present invention includes a stator bearing bracket 1, a DC electronic control circuit board 3 with electronic components 5, a stator protection end cover 2 and an outer rotor assembly 8. The inner wall of the stator protection end cover 2 is integrally formed with a boss 4, a boss 4 The plane is in close contact with the heat dissipation plane 6 of the electronic component 5 on the DC electronic control circuit board 3 in an insulated manner, and a groove 7 is formed on the outer wall of the stator protection end cover 2 at a position corresponding to the boss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com