Polyvinyl chloride (PVC) glove production device

A production device and glove technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve problems such as non-standardization of process equipment, unfixed production technology, and restrictions on industry technology upgrades, so as to improve the demoulding effect and solve the problem of PU shedding problem, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

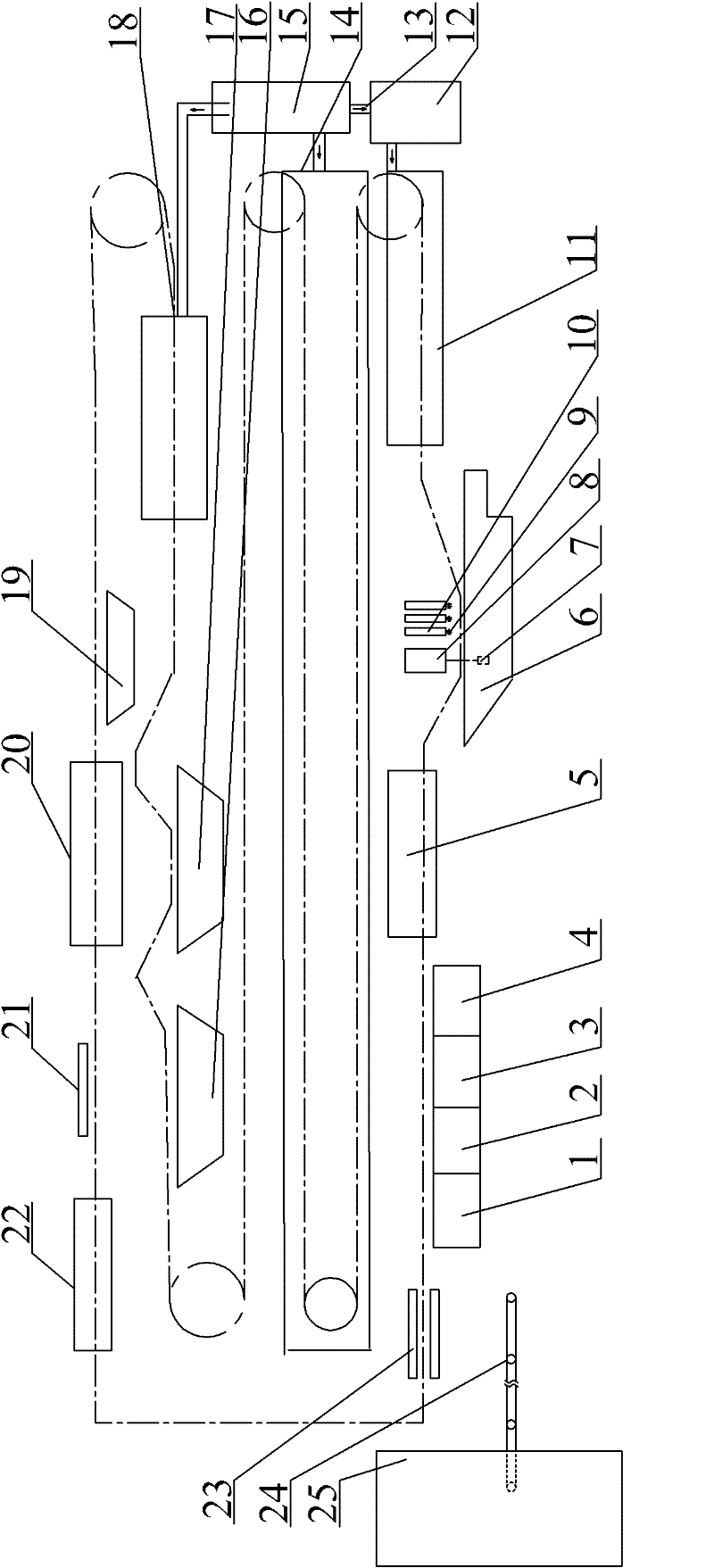

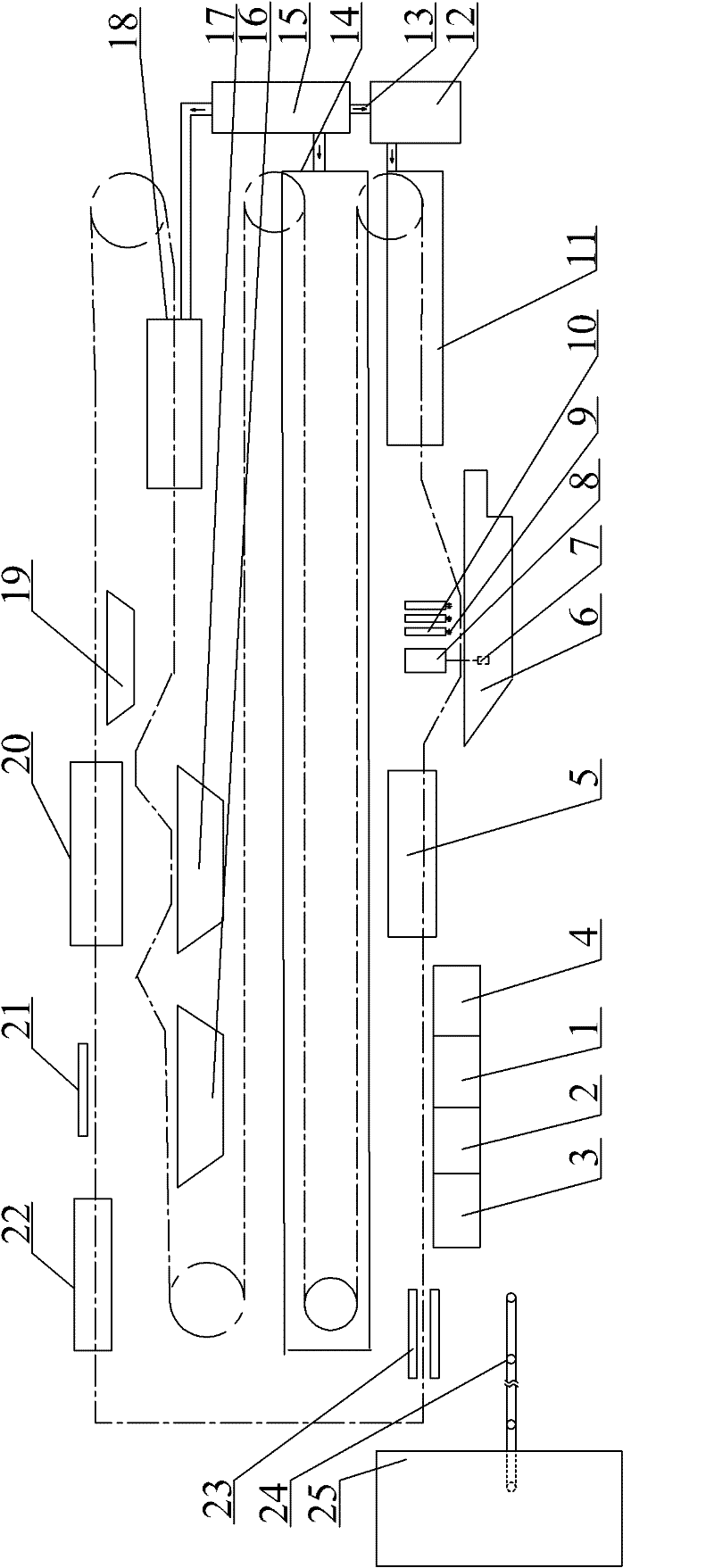

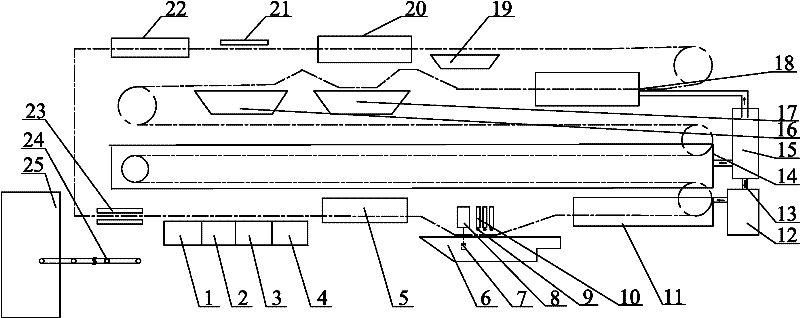

[0027] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0028] like figure 1 , 2 As shown, the PVC glove production device includes a hand mold track line and a glove production device. The dotted line shows the hand mold track line, and the solid line shows the glove production line. The hand mold track line is located above the glove production device. The glove production device Including sequentially arranged PVC material trough 6, PVC material dripping section 11, PVC plasticizing molding device 14, PU material trough 17, PU drying device 18, PVC glove curling device 21 and demoulding device 23, PVC plasticizing The molding device 14 and the PU drying device 18 are both connected to the heating boiler 15. A hand mold cleaning device and a hand mold drying device 5 are arranged between the demolding device 23 and the PVC hopper 6 in sequence, and the PVC hopper 6 is provided with a hand mold cleaning device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com