Patents

Literature

68results about How to "Not easy to demould" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

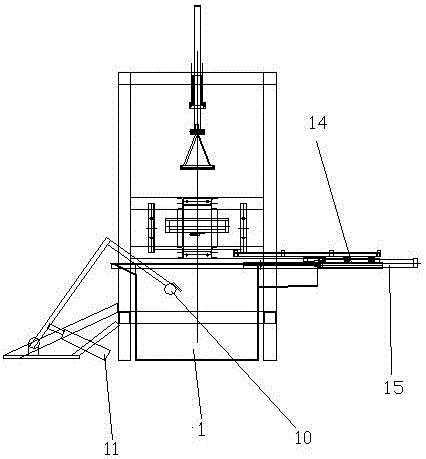

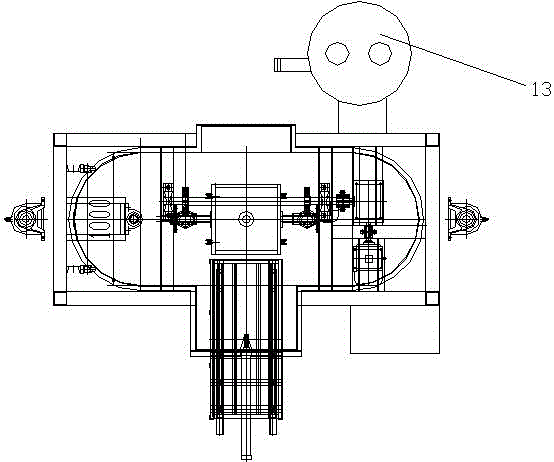

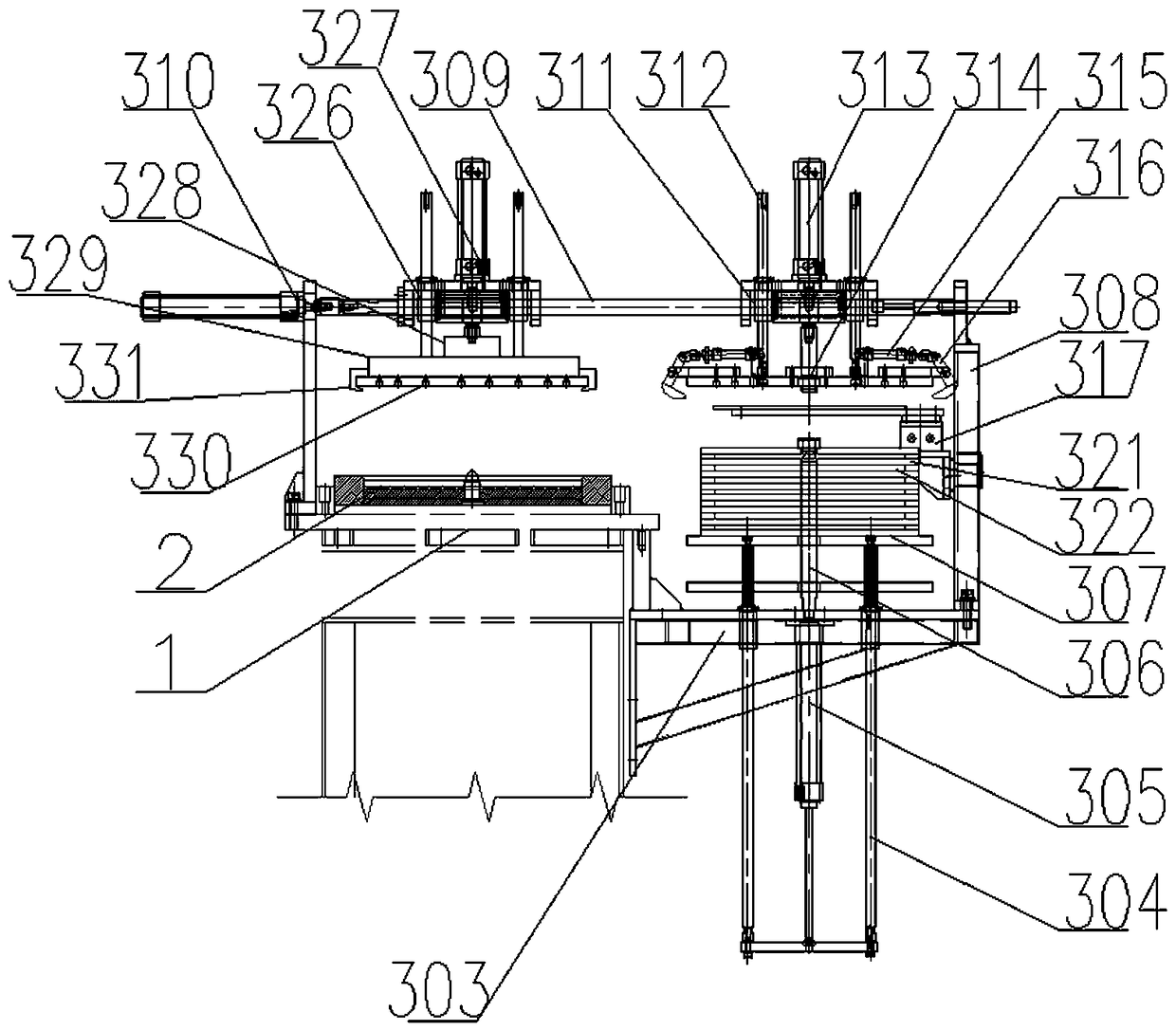

Full-automatic core shooter

ActiveCN105478684AQuality improvementIncrease exhaustMoulding machinesControl systemElectric machinery

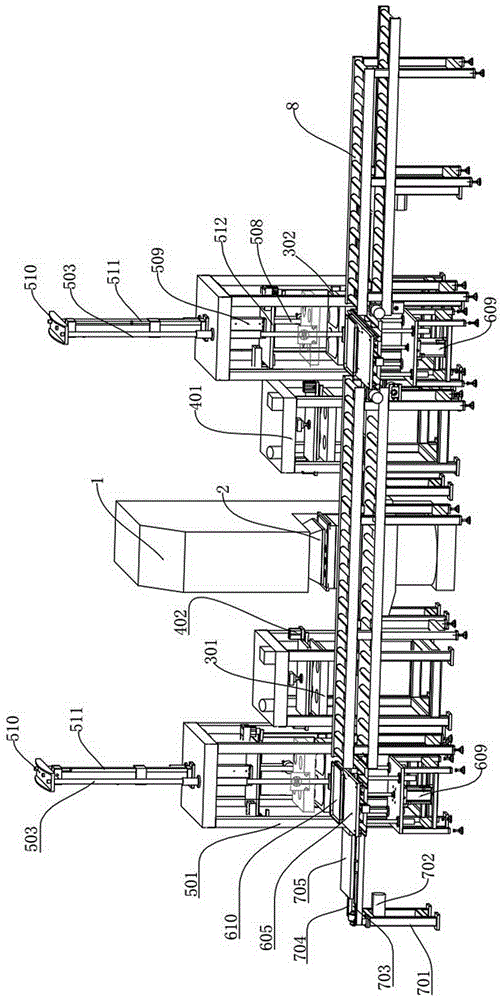

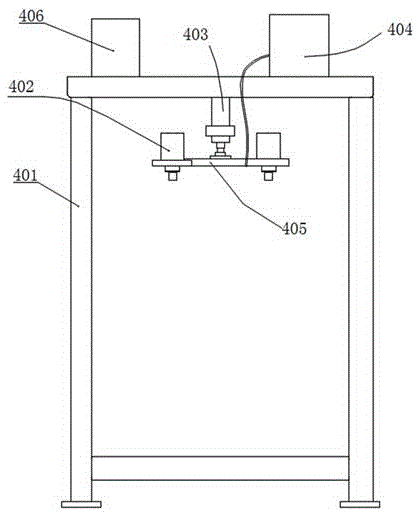

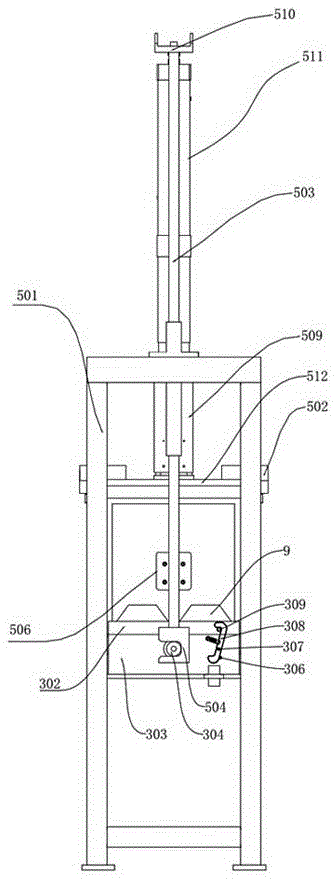

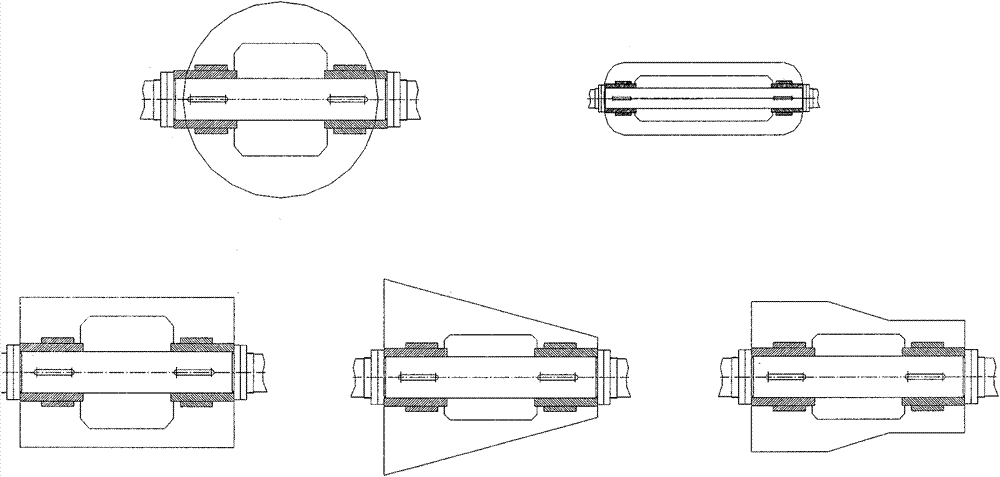

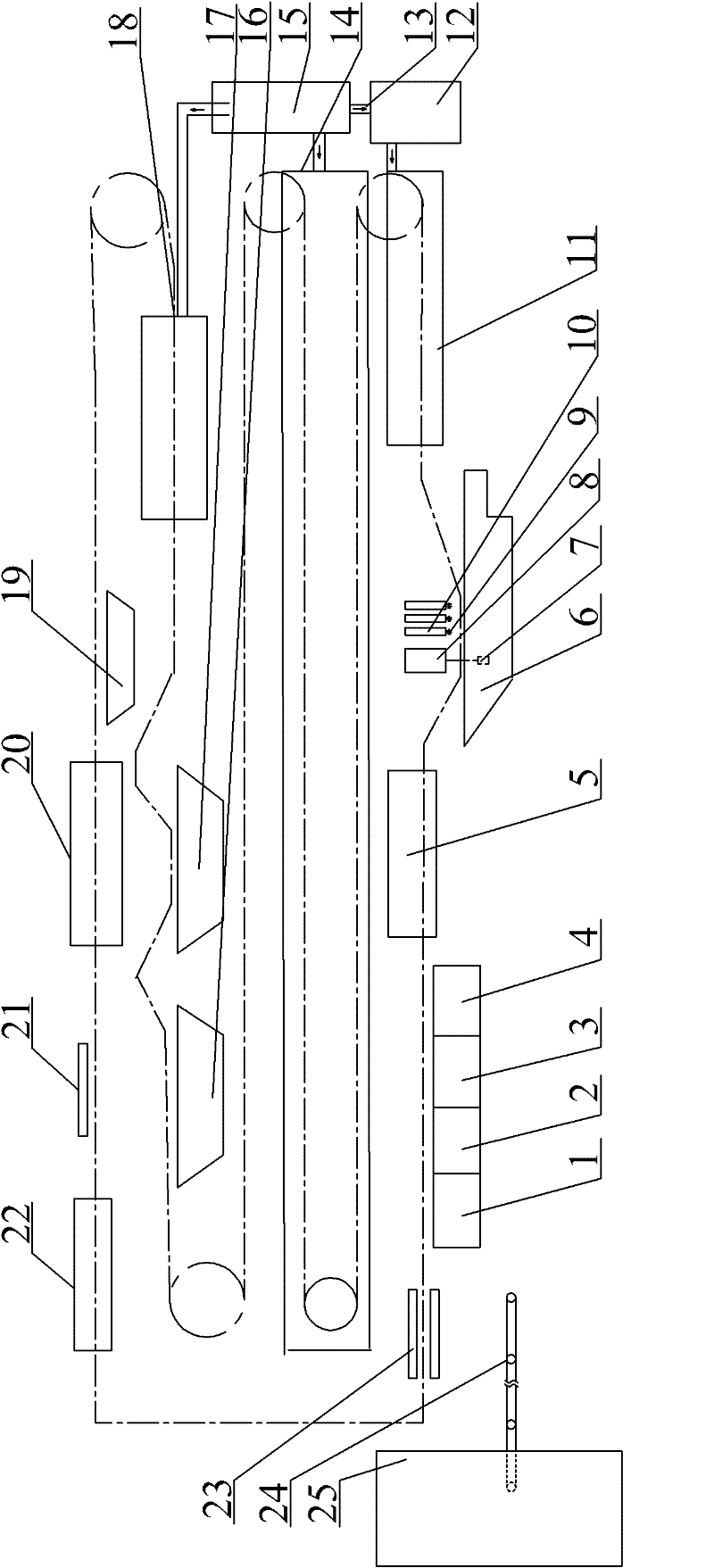

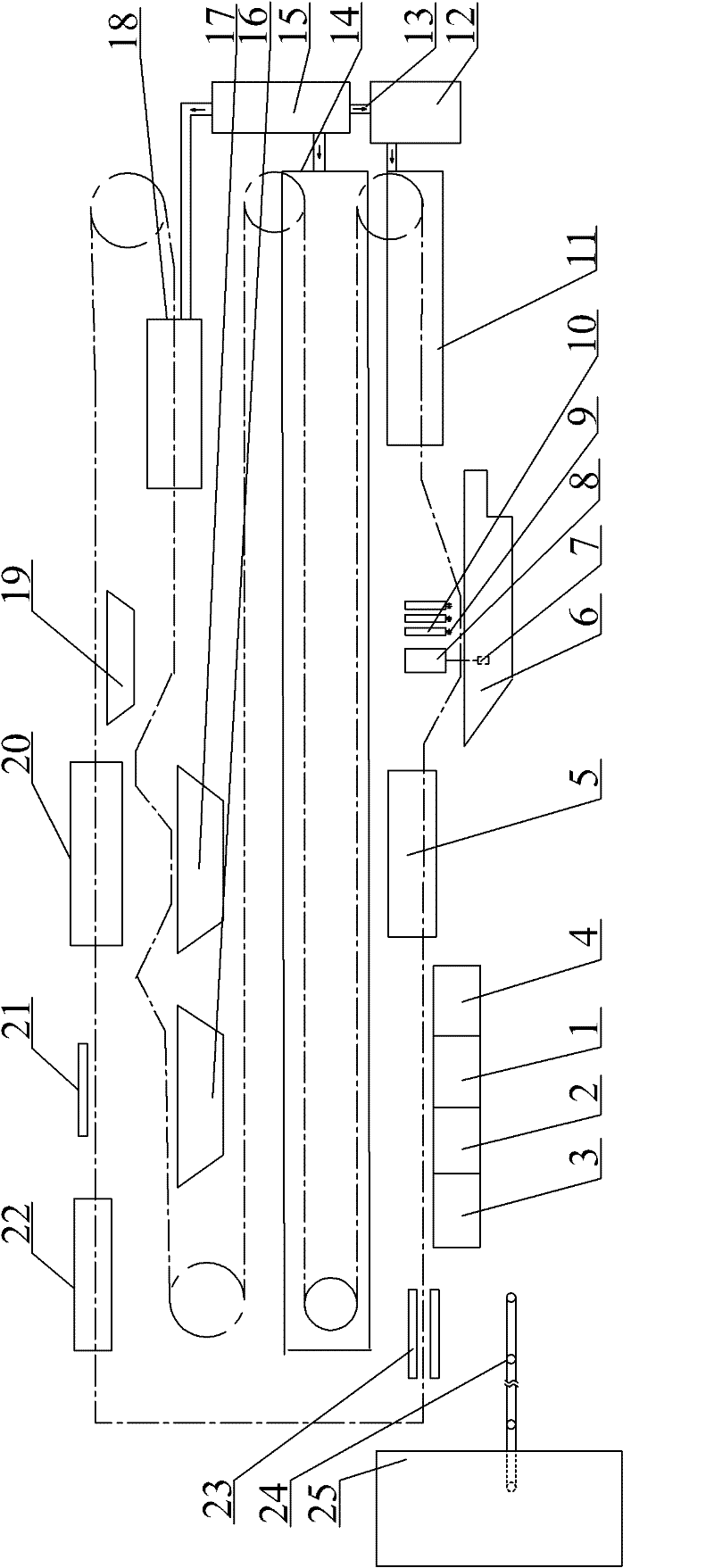

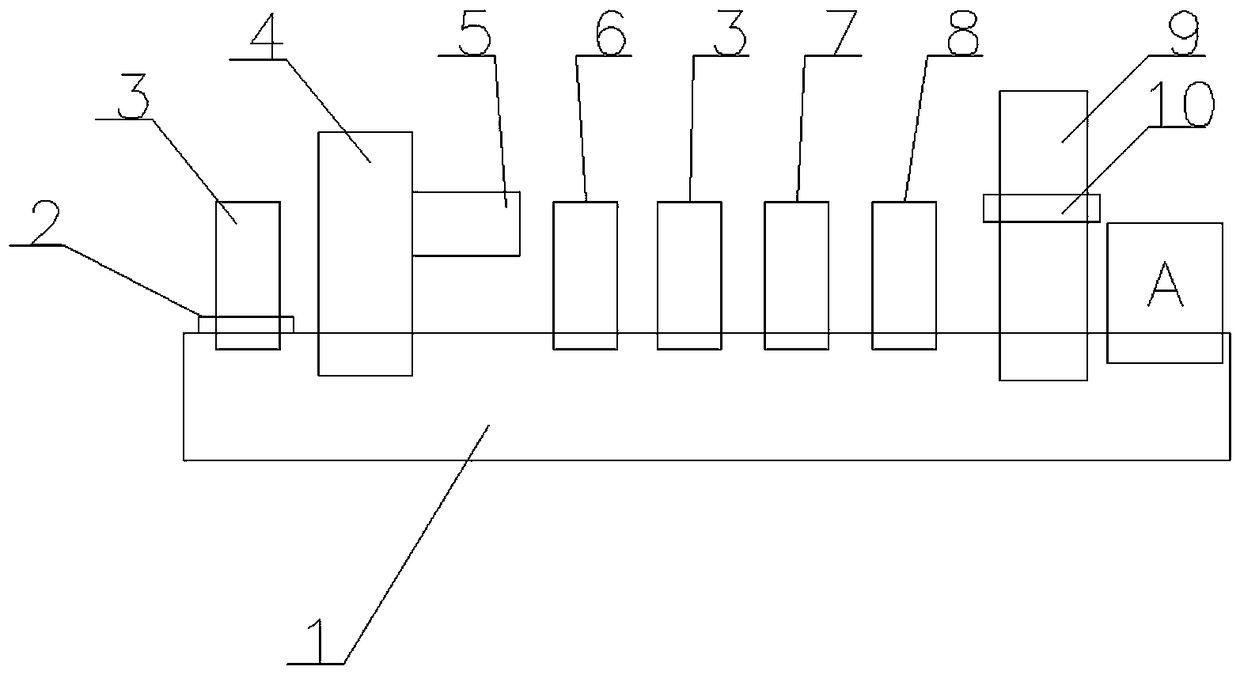

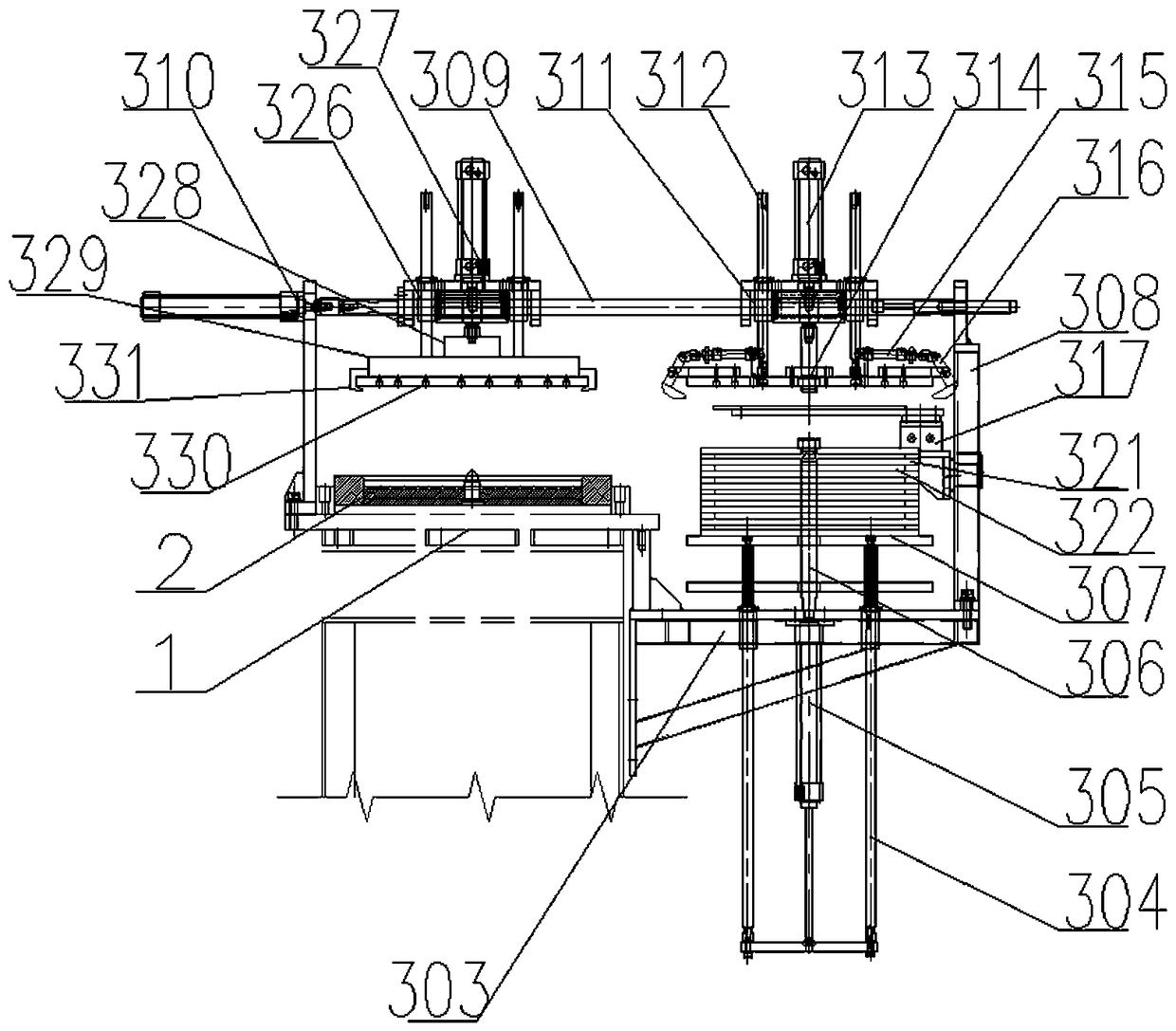

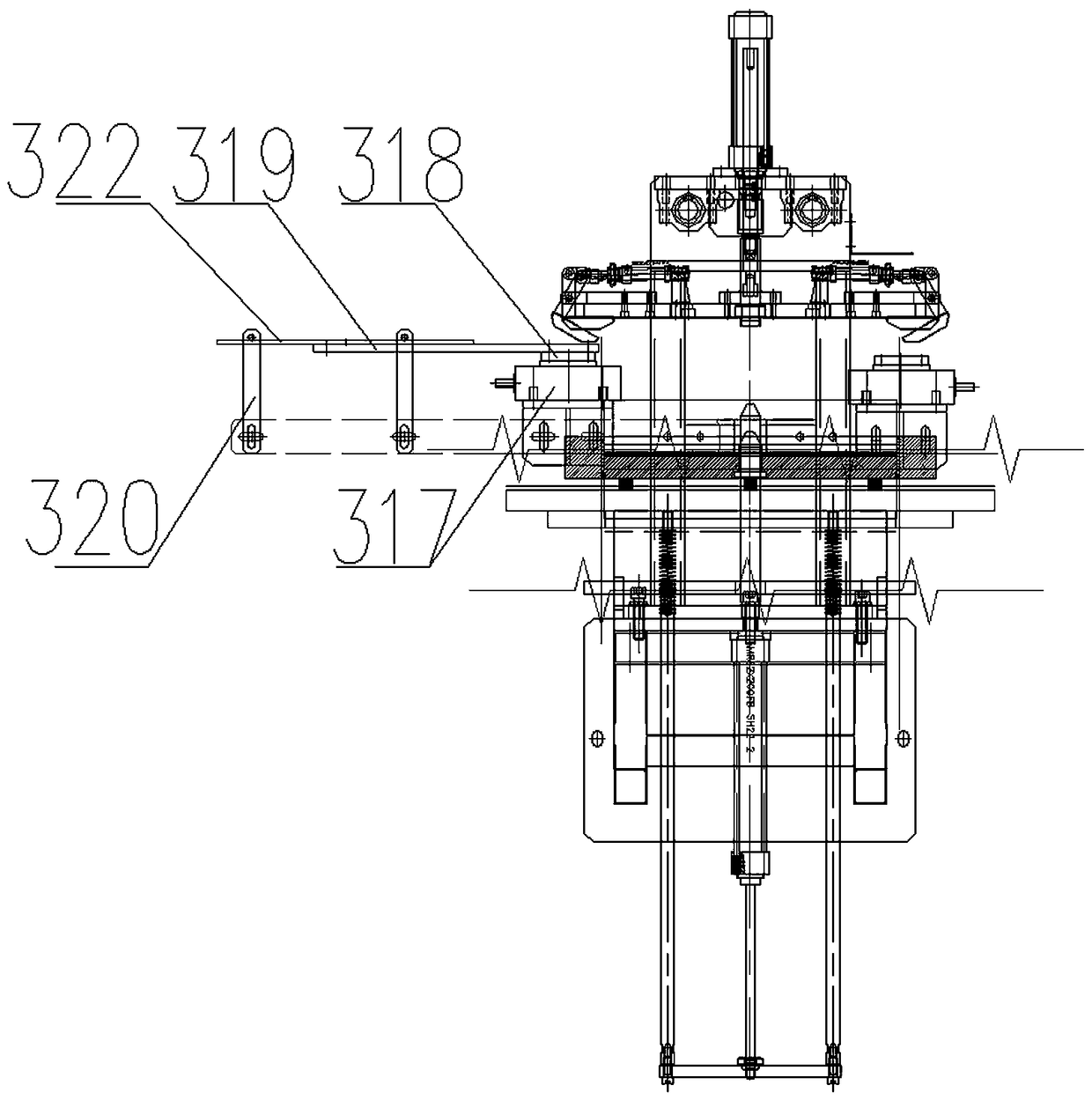

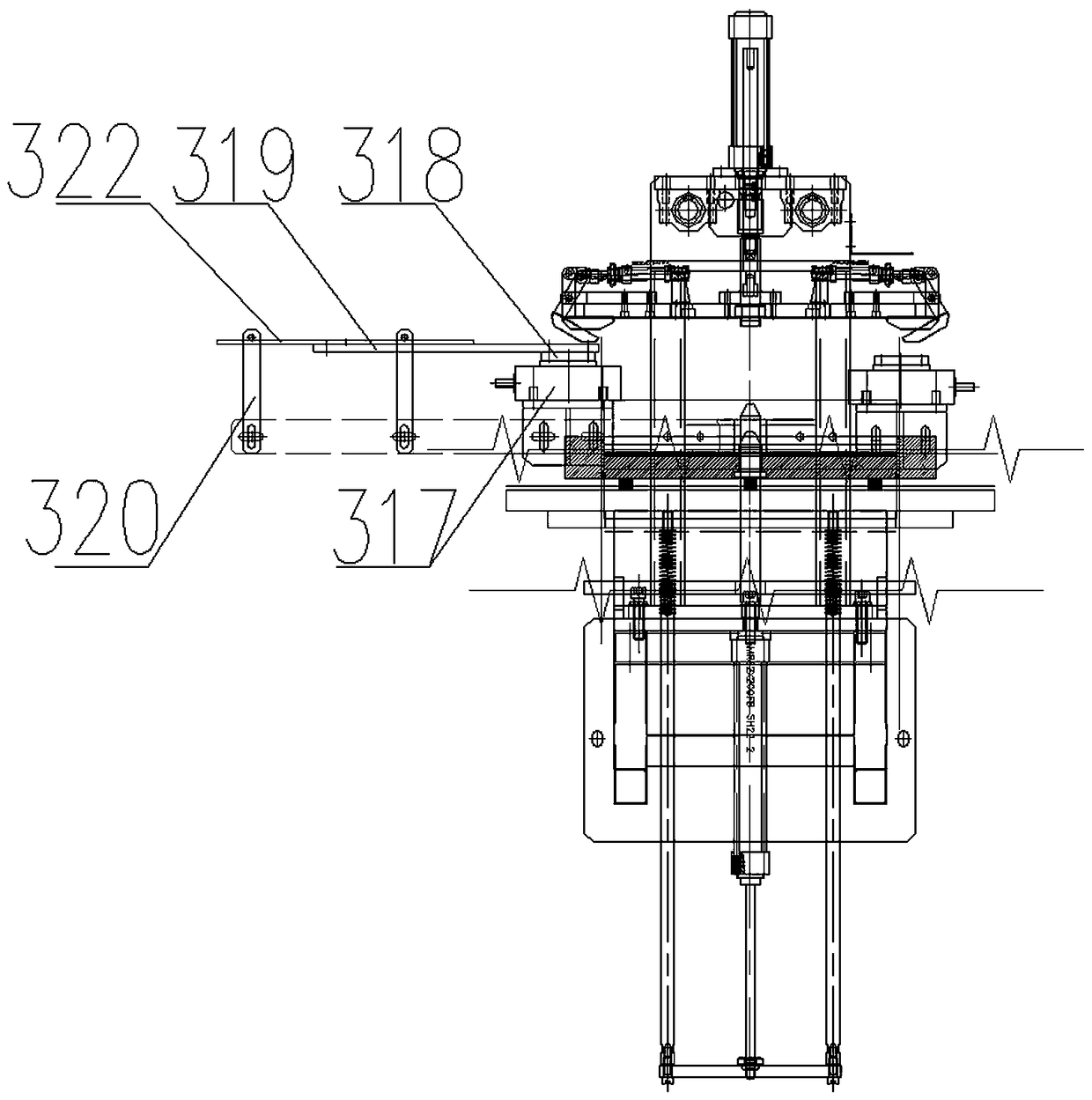

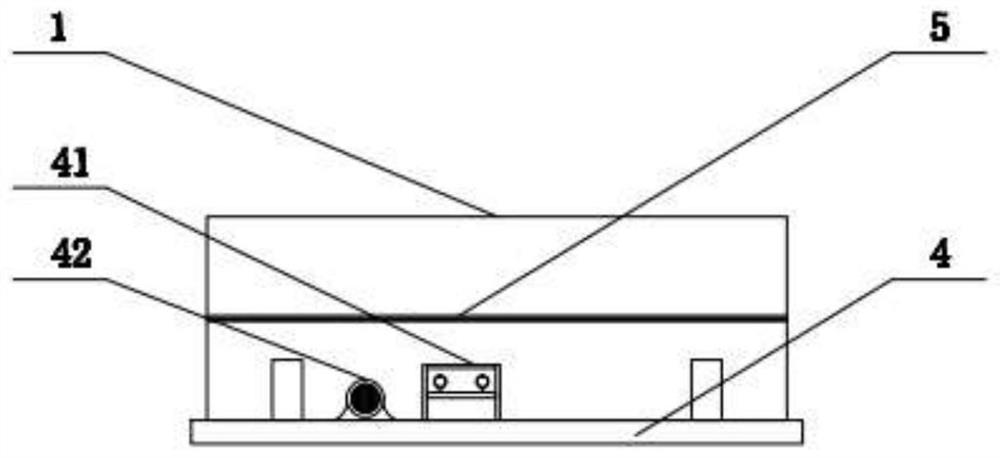

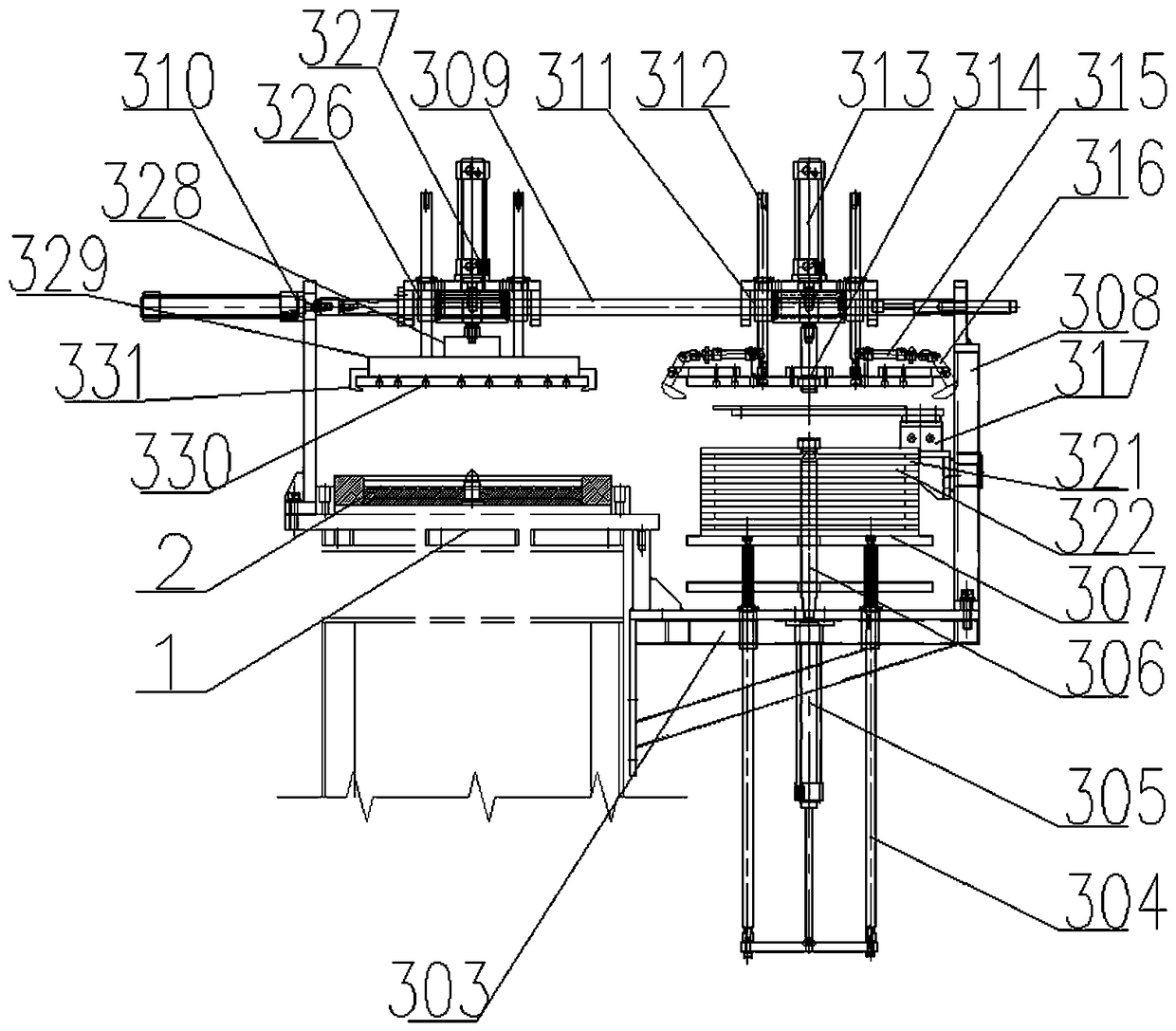

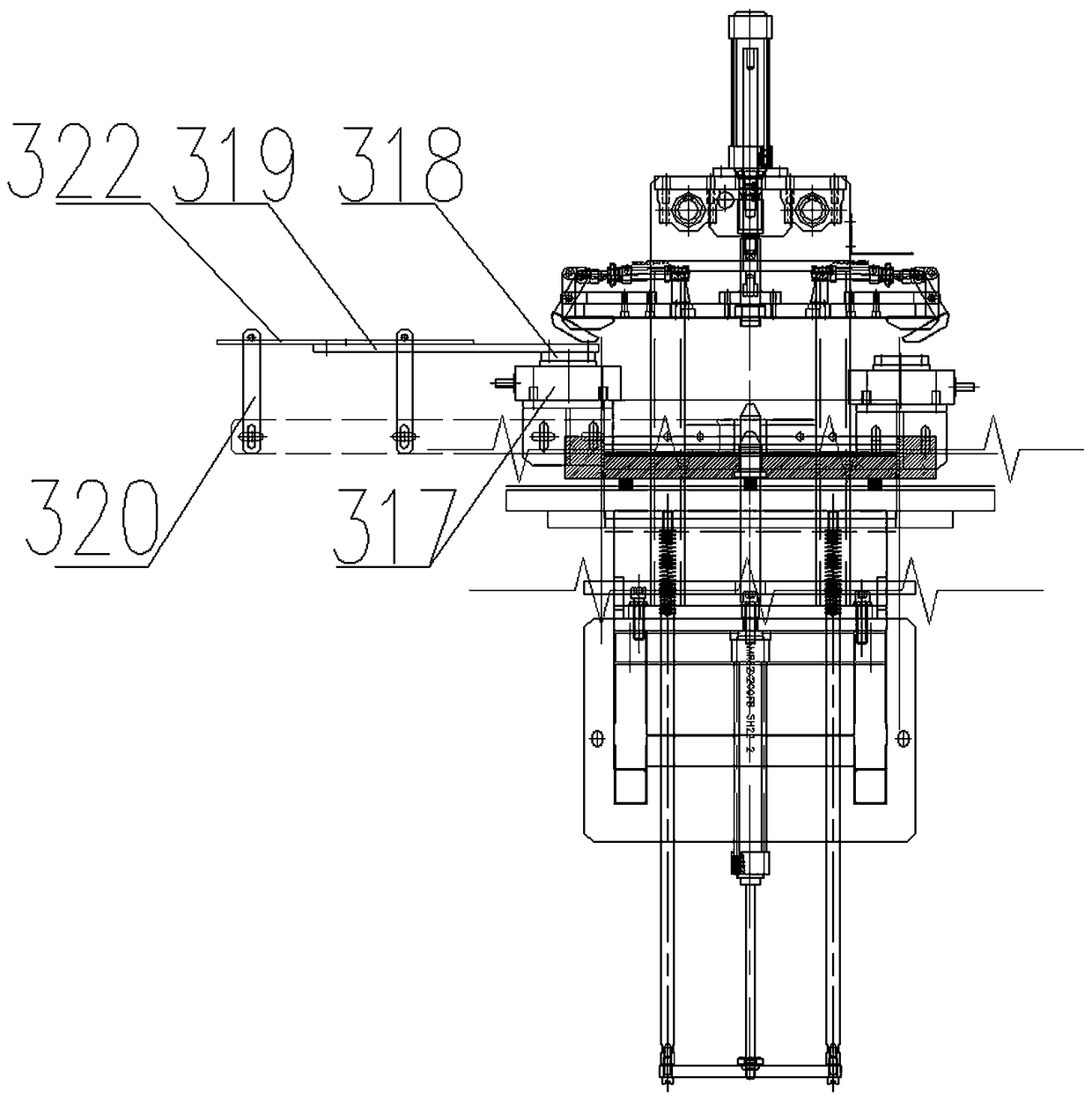

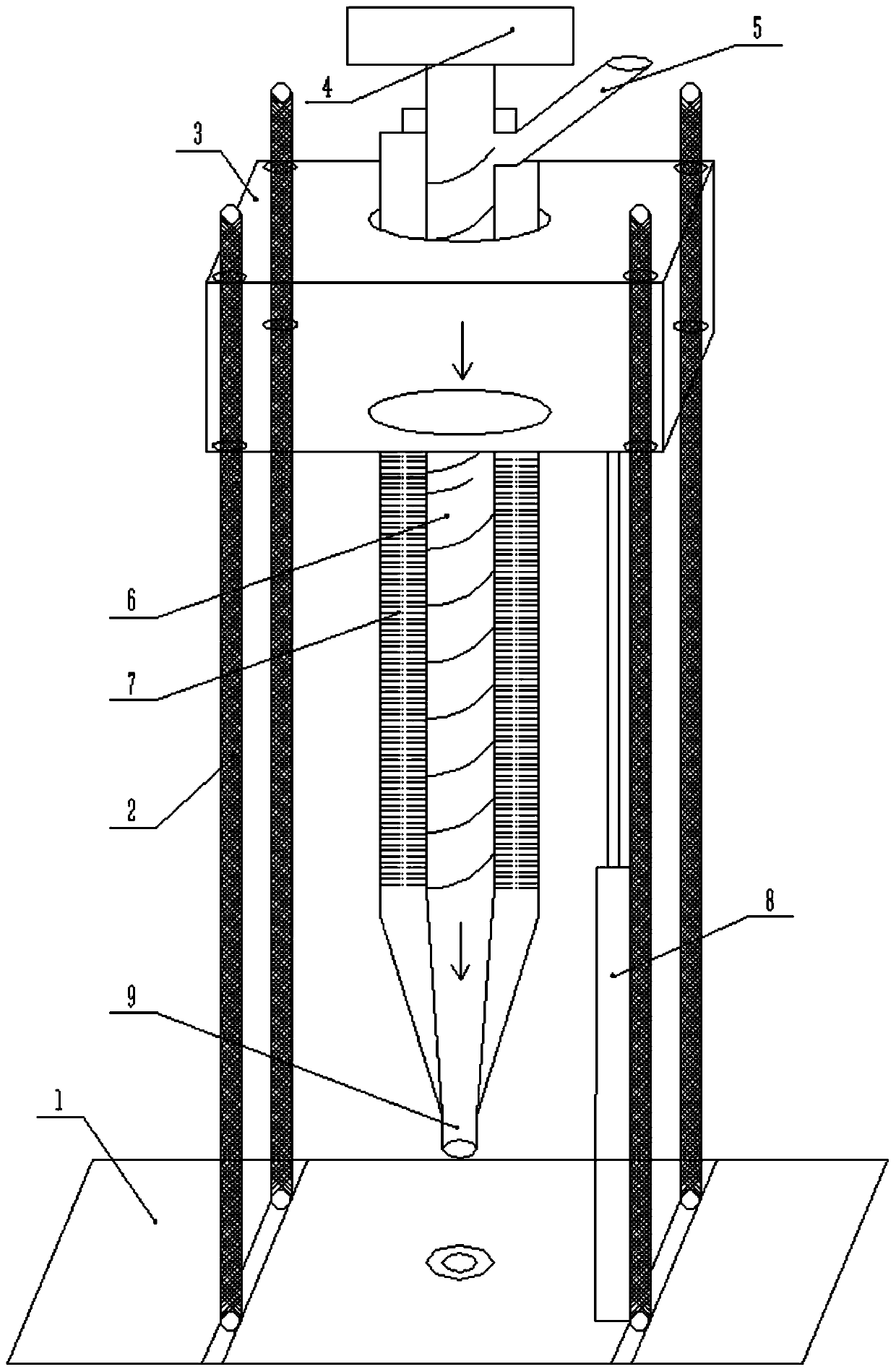

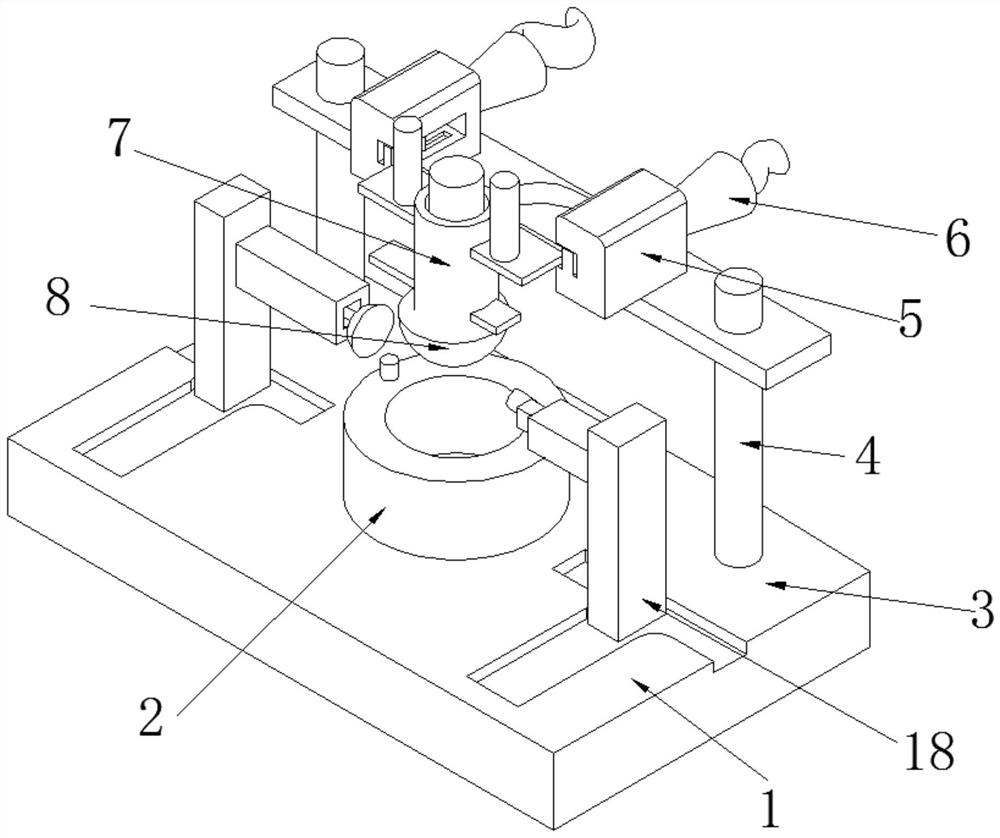

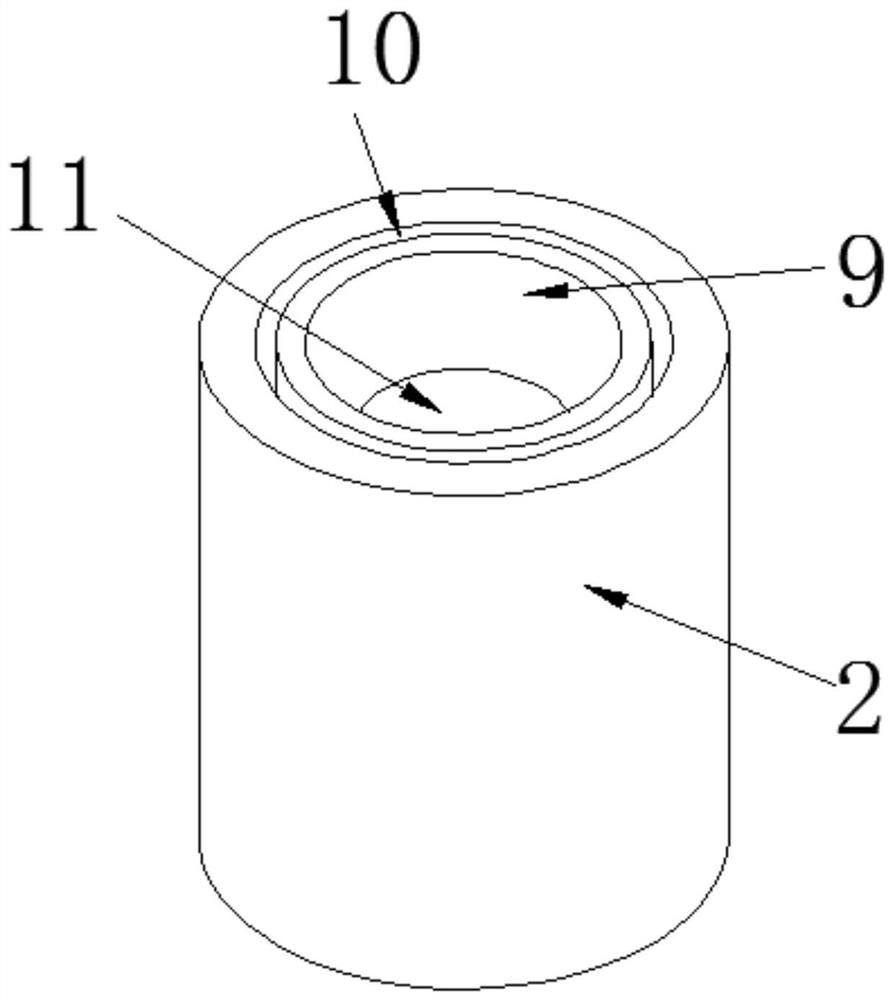

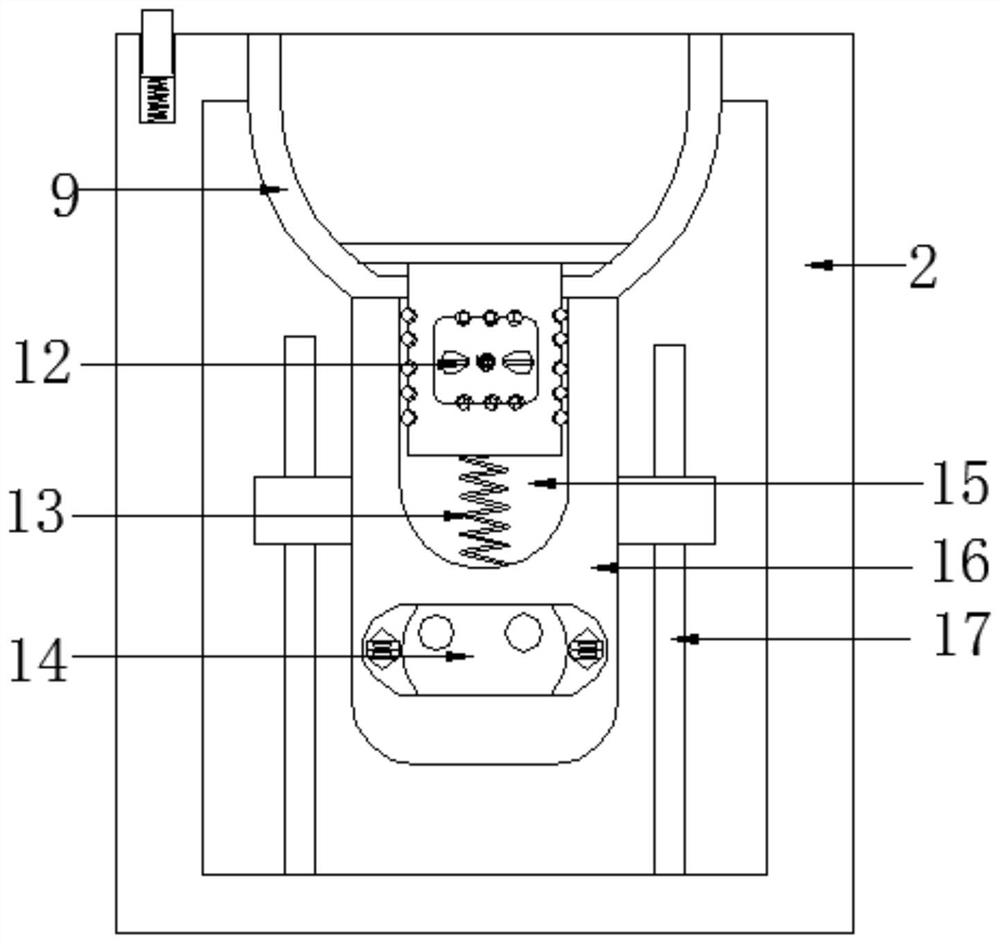

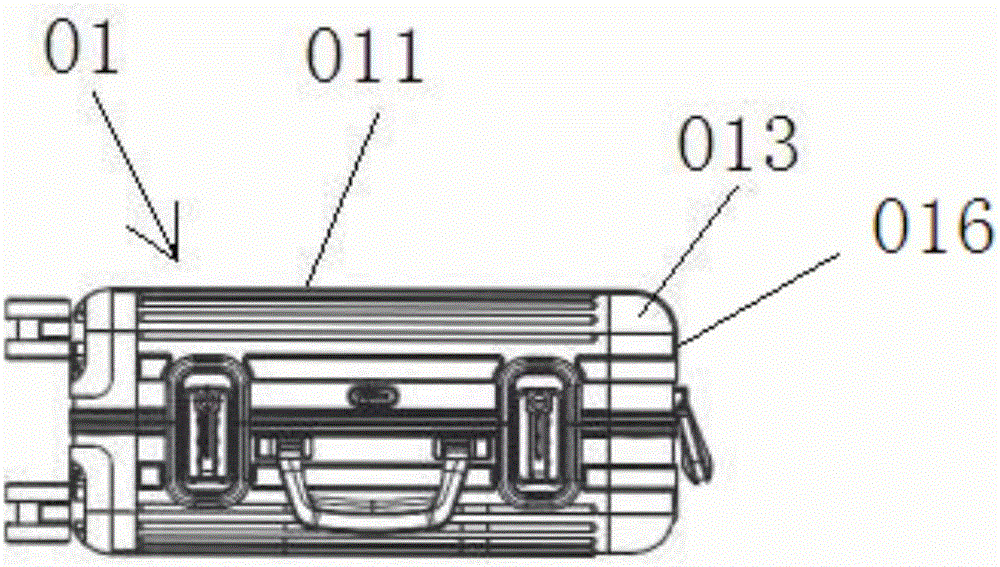

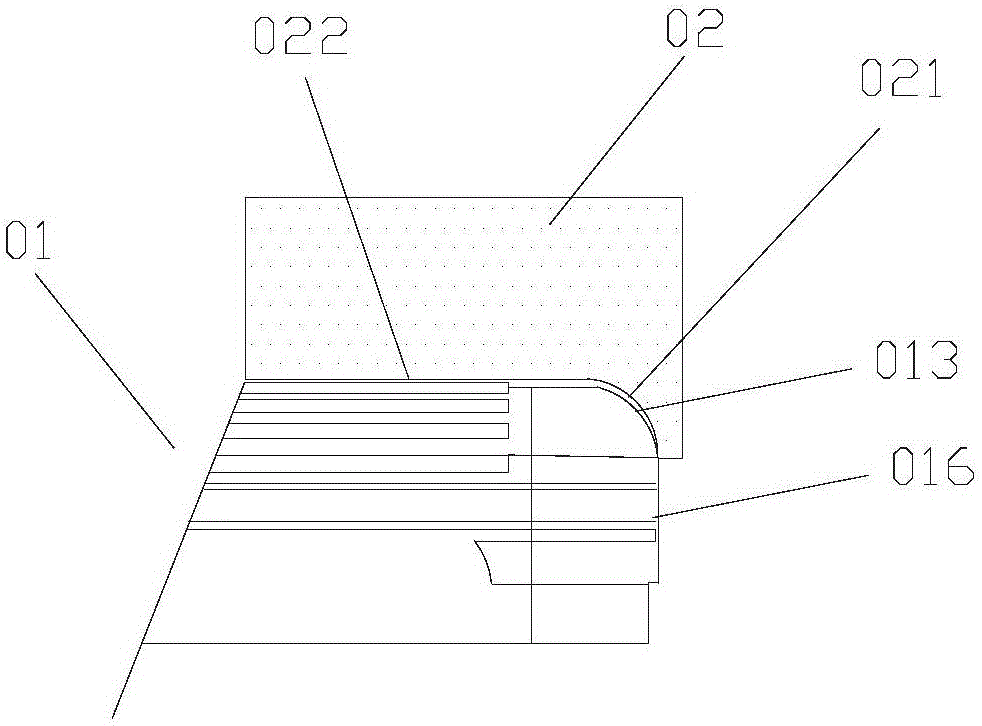

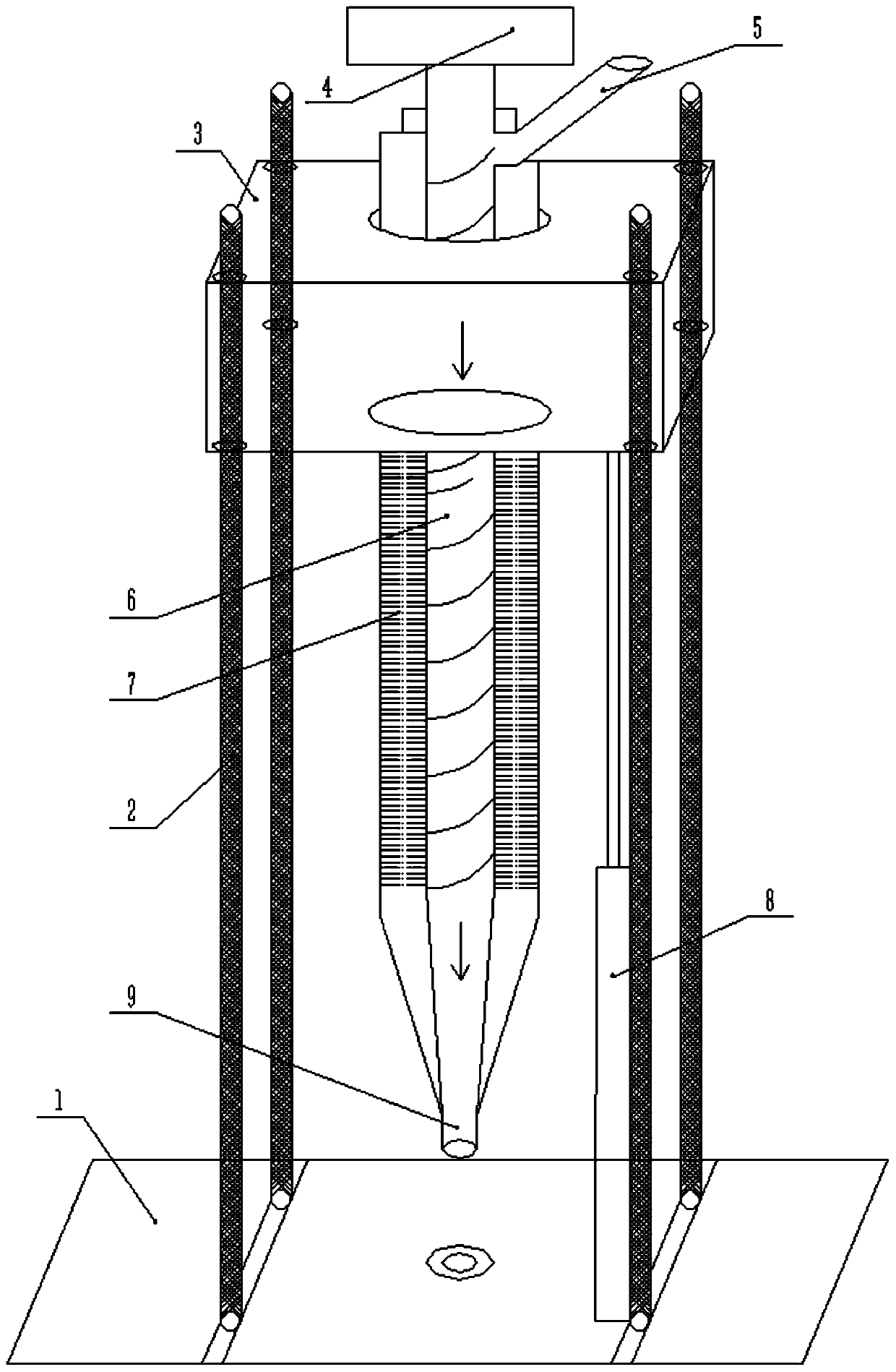

The invention relates to a full-automatic core shooter. The full-automatic core shooter comprises a die and a core shooting device shooting core sand into the die. The die is divided into an upper die body, a middle die body and a lower die body. Buckle mechanisms controlling the middle die body and the lower die body to be opened and closed are arranged on the two opposite side faces of the die. The full-automatic core shooter further comprises a solidifying device, a die stripping device, a moving device, a material receiving device and a PLC control system. The solidifying device comprises a solidifying rack, a blowing mechanism and a die splitting mechanism. The die stripping device comprises a die stripping rack, a lifting mechanism lifting the die, an overturning mechanism overturning the lifted die, and an ejecting mechanism enabling a mold core in the die to be stripped. The moving device is driven by a servo motor, and the die is accurately positioned or horizontally reciprocates at the stations of the core shooting device, the solidifying device and the die striping device. The material receiving device is used for automatically conveying the mold core obtained in the die stripping device. The PLC control system controls drive motors and air cylinders in the core shooting device, the solidifying device, the die stripping device, the moving device and the material receiving device so as to achieve automatic running.

Owner:JINAN BIOMAX PRECISION MACHINERY CO LTD

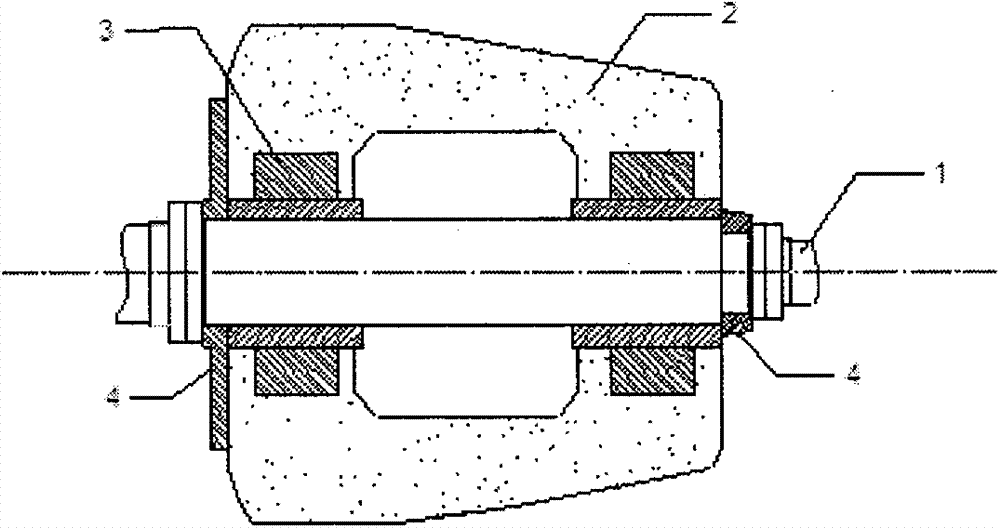

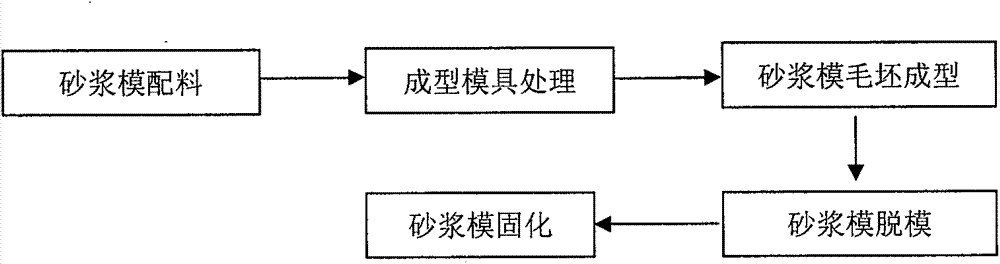

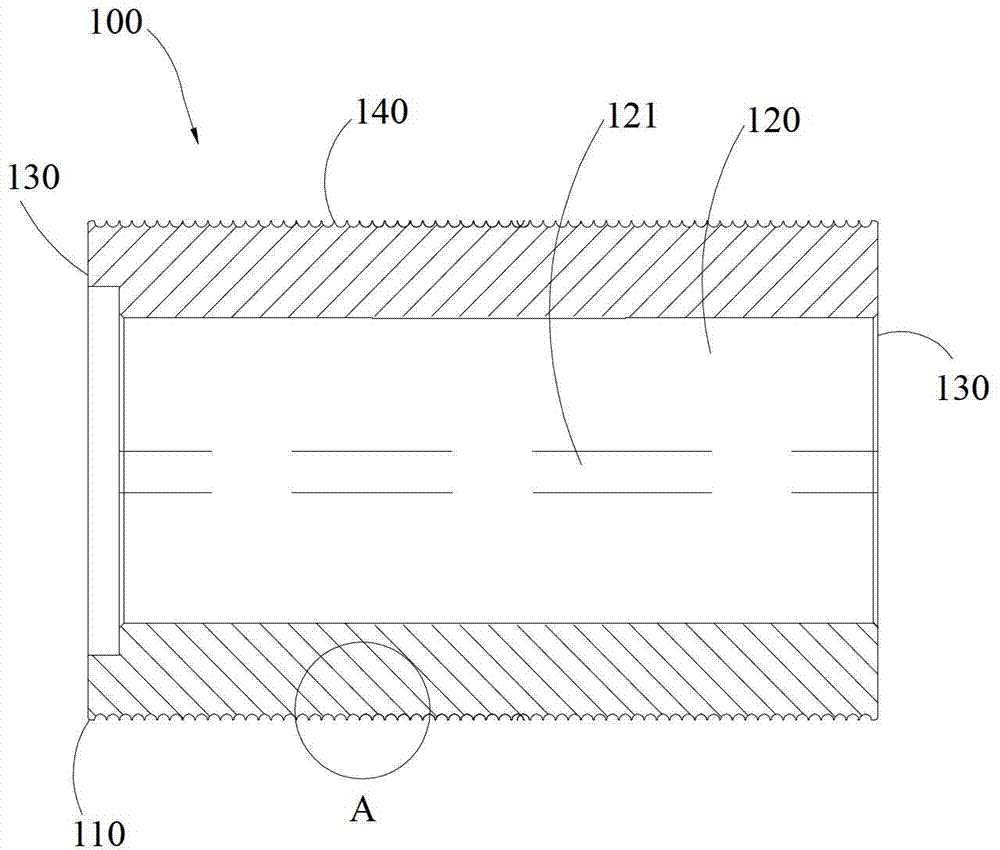

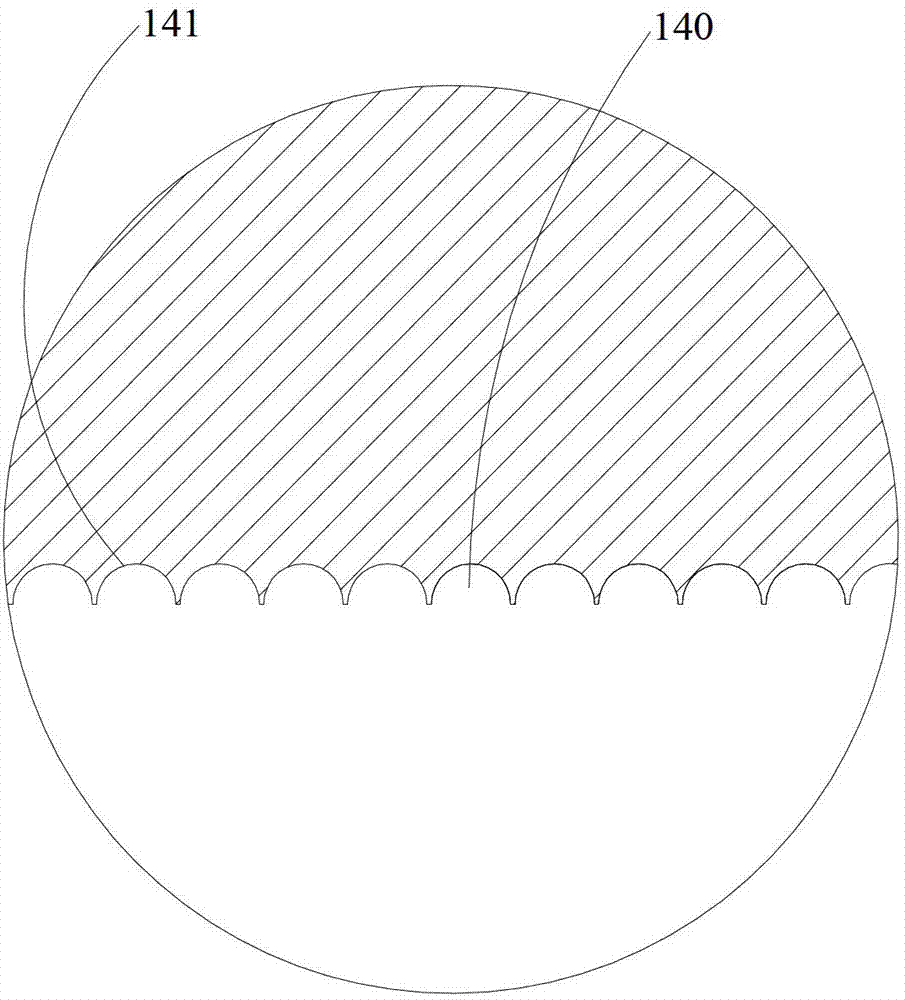

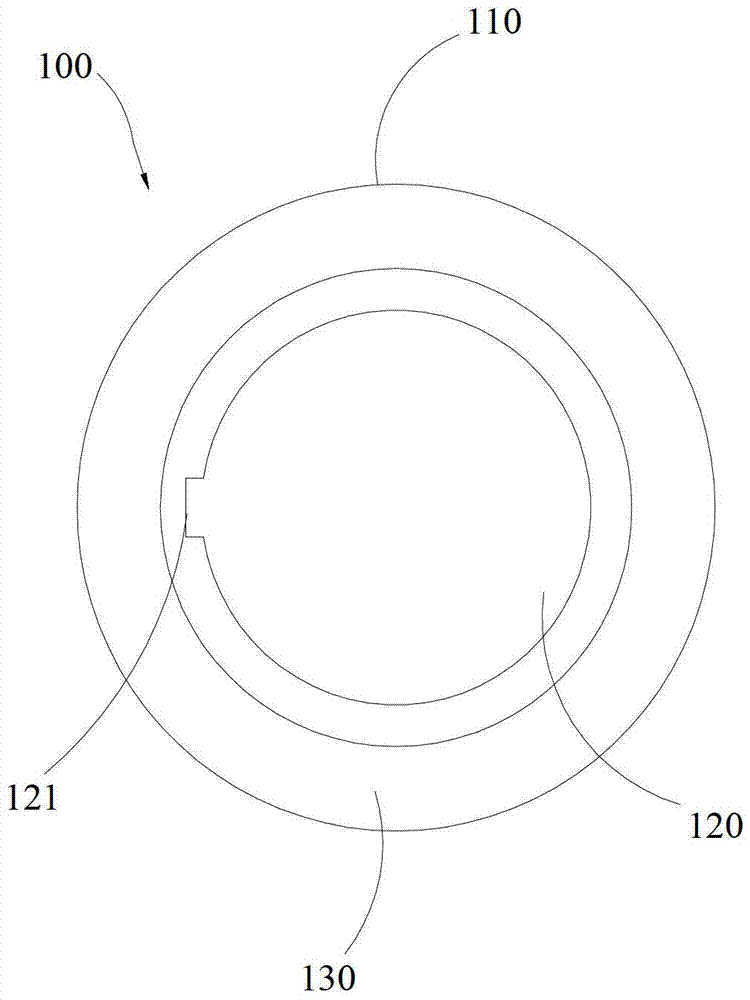

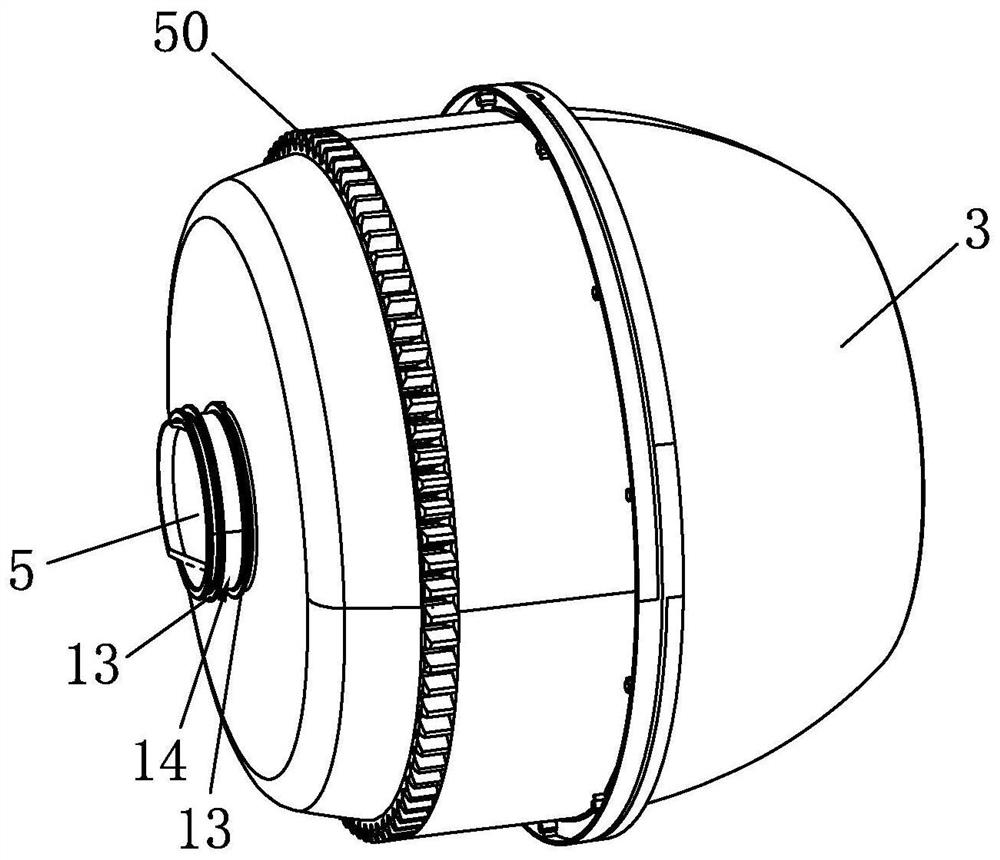

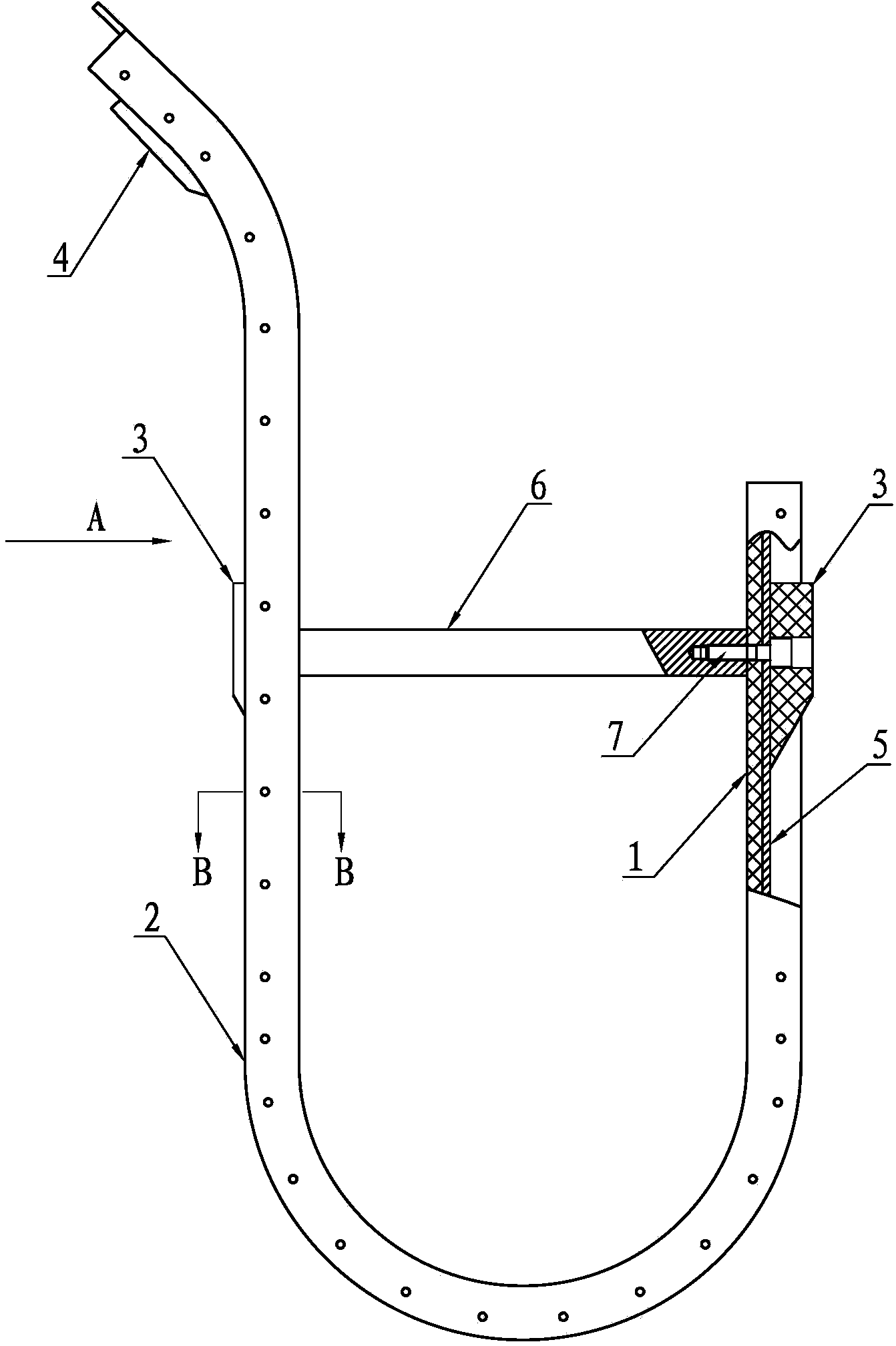

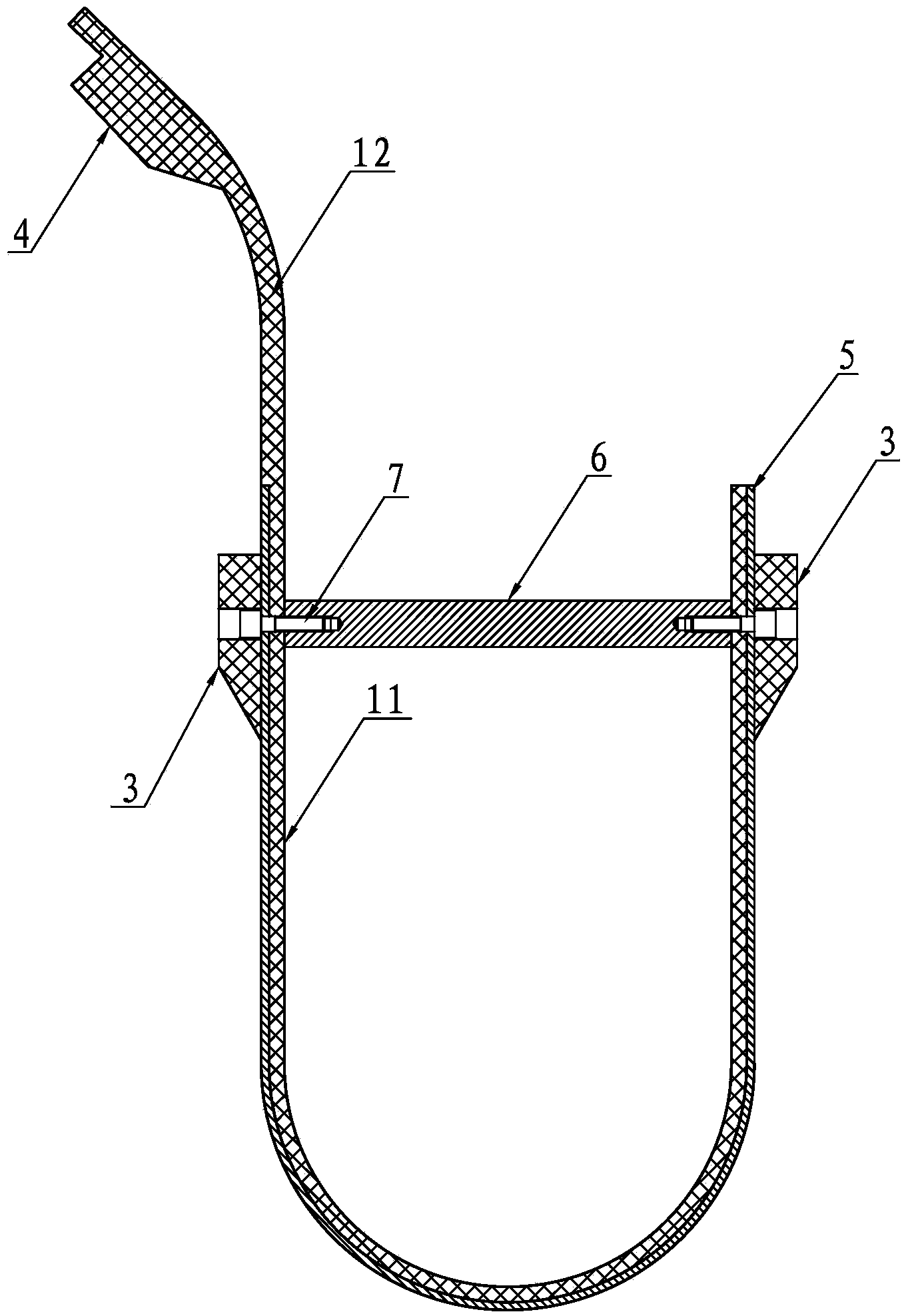

Preparation methods for soluble core mould and nonmetal-lining or no-lining fibre winding container

A preparation method of a solube core mold comprises: blank moulding of a mortar mould: a) the ingredients of the mortar die consists of quartz sand, polyvinyl alcohol and water with a weight ratio of 100:1-2:6; b) the inner sleeve of the mortar mould is sleeved in a moulding mould, then adding the uniformly stirred ingredients of the mortar mould into the moulding mould until the moulding mould is full; c) demoulding; and d) solidifying; and a mandrel is penetrated in the mortar mould, the mandrel and the mortar mould are fixed in a circumferential direction by using the inner sleeve of the mortar mould and fixed in an axial direction by using a locking ring. A preparation method of a nonmetal-lining or no-lining fibre winding container comprises: infiltrating a fibre reinforced material in a resin solution, winding the fibre reinforced material on the soluble core mould in a circumferential direction and in a longitudinal direction by using a winder, solidifying, washing with water and demoulding. By using the container, demoulding can be finished by water washing. The soluble core mould is especially suitable for preparing composite material containers with a complex-shape internal profile as well as hard to demould, is low in cost and reusable in raw materials.

Owner:北京玻钢院复合材料有限公司

Manufacturing method of embossment ceramic tableware

The invention discloses a manufacturing method of embossment ceramic tableware. The manufacturing method comprises the following steps of: (1) manufacturing blank; (2) manufacturing a mould, wherein a main mould with an embossment pattern is manufactured, and a working mould is re-printed; (3) forming, de-molding, tidying the blank, brushing the blank, biscuiting and glazing; and (4) carrying out glaze firing. By adopting the technical scheme disclosed by the invention, the manufactured embossment ceramic tableware has the advantages of being super white, good in transparency and thin, good in plasticity, more clear and exquisite in embossment, and obviously attractive.

Owner:FUJIAN DEHUA COUNTY FUJINXING CERAMIC

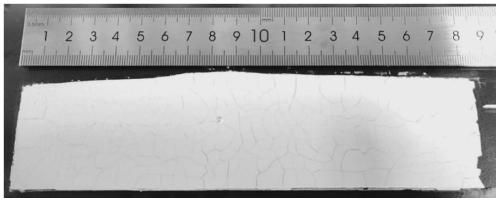

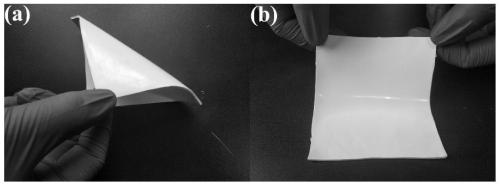

Method for preparing toughened large-size ultrathin YAG transparent ceramic biscuit based on Isobam gel system

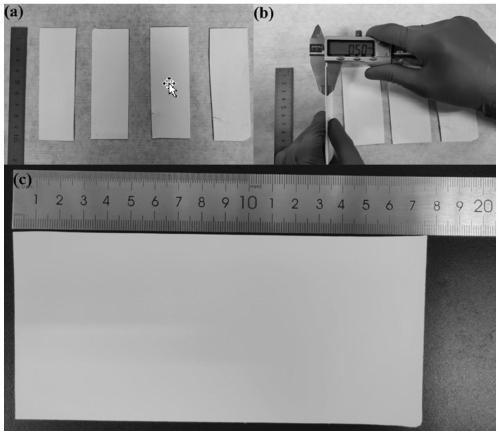

The invention discloses a method for preparing a toughened large-size ultrathin YAG transparent ceramic biscuit based on an Isobam gel system. The method comprises the following steps: respectively weighing Y2O3 powder and Al2O3 powder as ceramic powder; mixing and ball-milling the ceramic powder, a sintering aid, a dispersing agent A, grinding balls and absolute ethyl alcohol according to a certain proportion to obtain mixed slurry; drying the mixed slurry, sieving and calcining the material, and obtaining the raw material powder formed through gel casting; mixing and ball-milling deionized water, an Isobam 104 solution, a dispersing agent B, a plasticizer, grinding balls and the raw material powder according to a certain proportion, adjusting the pH value of the system to be 10-12, and preparing the ceramic slurry; and performing vacuum defoaming, pouring the defoamed slurry into a mold by adopting a pressure injection method, performing natural gel curing at room temperature, and performing drying and gel discharging to obtain the YAG ceramic biscuit. The preparation process is simple and environmentally friendly, and the prepared ultrathin ceramic biscuit is good in flatness, not prone to cracking and easy to demold.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

Aluminum die-casting alloy suitable for anodic oxidation treatment and preparation method thereof

The invention discloses an aluminum die-casting alloy suitable for anodic oxidation treatment, which comprises the following components in percentage by weight: 11-13% of Si, 0-0.1% of Cu, 0-0.1% of Mg, 0-0.1% of Zn, 0.8-1.0% of Fe, 0-0.5% of Mn and the balance of AL. The aluminum die-casting alloy suitable for anodic oxidation treatment, which is disclosed by the invention, has the advantages of simple anodic oxidation, good oxidation effect, thick film layer and uniform color and luster, and the invention can overcome the defects of the prior art.

Owner:GUIYANG GUANGHANG CASTING

Polyvinyl chloride (PVC) glove production device

ActiveCN102173017ARapid coolingGood release effectDomestic articlesCoatingsPolyvinyl chlorideEngineering

The invention belongs to the field of polyvinyl chloride (PVC) glove production and relates to a PVC glove production device. The device comprises a hand mold rail line and a glove production device, wherein the hand mold rail line is positioned above the glove production device; the glove production device comprises a PVC material groove, a PVC material dripping section, a PVC plasticizing forming device, a polyurethane (PU) material groove, a PU drying device, a PVC glove hemming device and a demolding device in turn; and the PVC plasticizing forming device and the PU drying device are connected with a heat supply boiler. The device is characterized in that: a hand mold cleaning device and a hand mold drying device are arranged in turn between the demolding device and the PVC material groove; the PVC material groove is provided with a viscosity detection adjusting device; and a PU washing device and a washing drying device are arranged in turn between the PU drying device and the PVC glove hemming device. The device has high automation degree and good effect of forming PVC gloves; moreover, the product is easy to demold, and stickness or damage hardly appears in the demolding process, so that the glove quality is ensured.

Owner:SHANDONG INTCO MEDICAL SUPPLY CO LTD

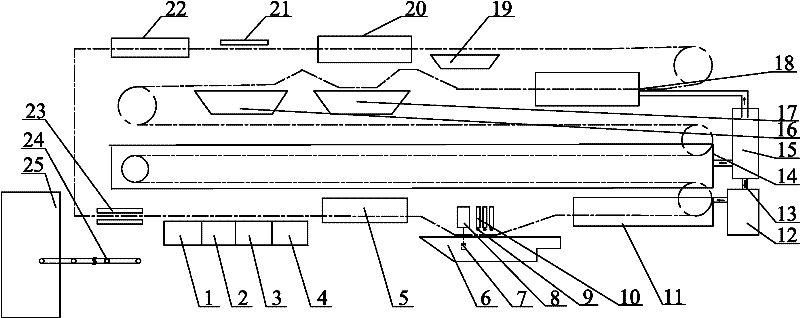

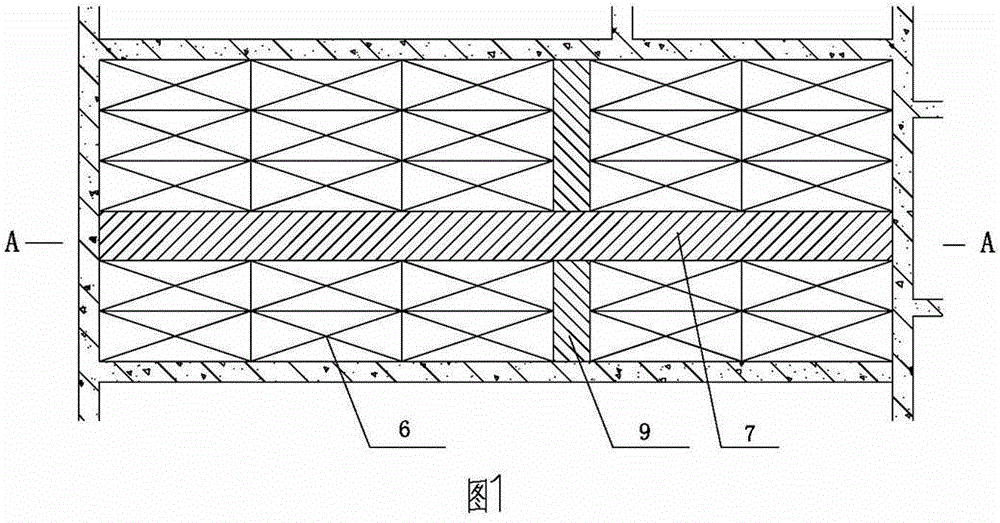

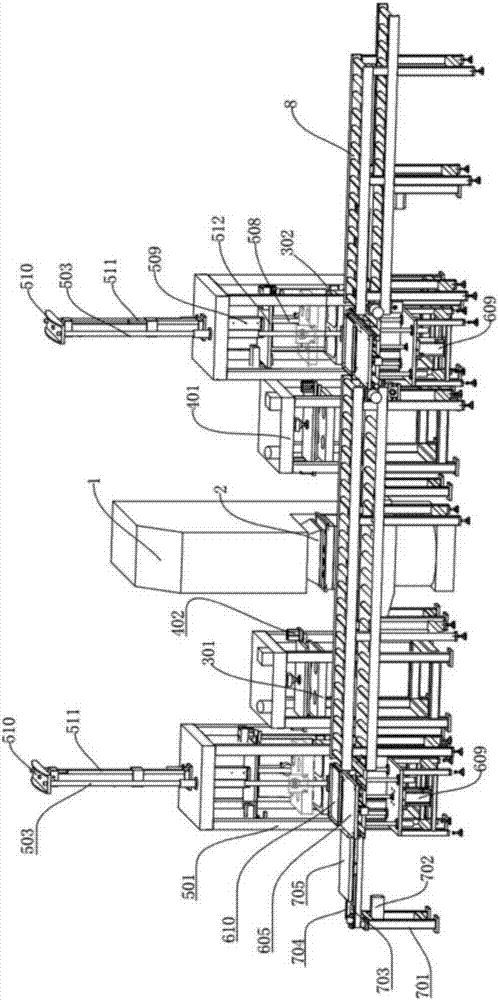

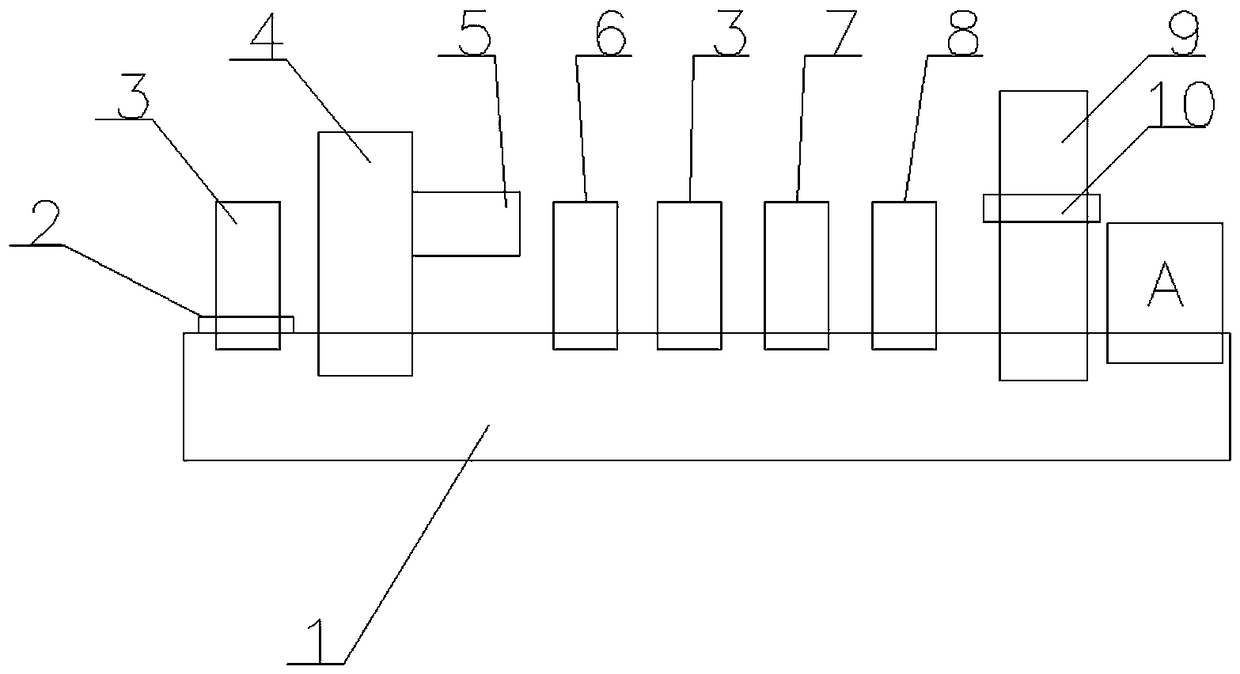

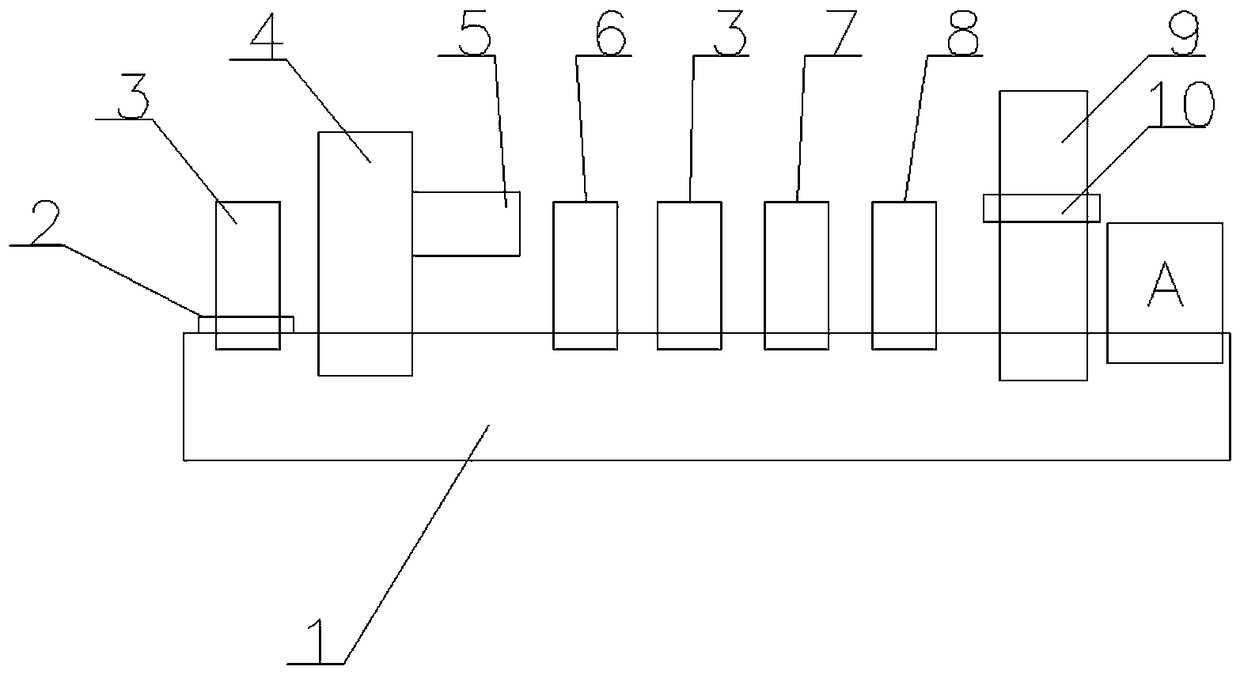

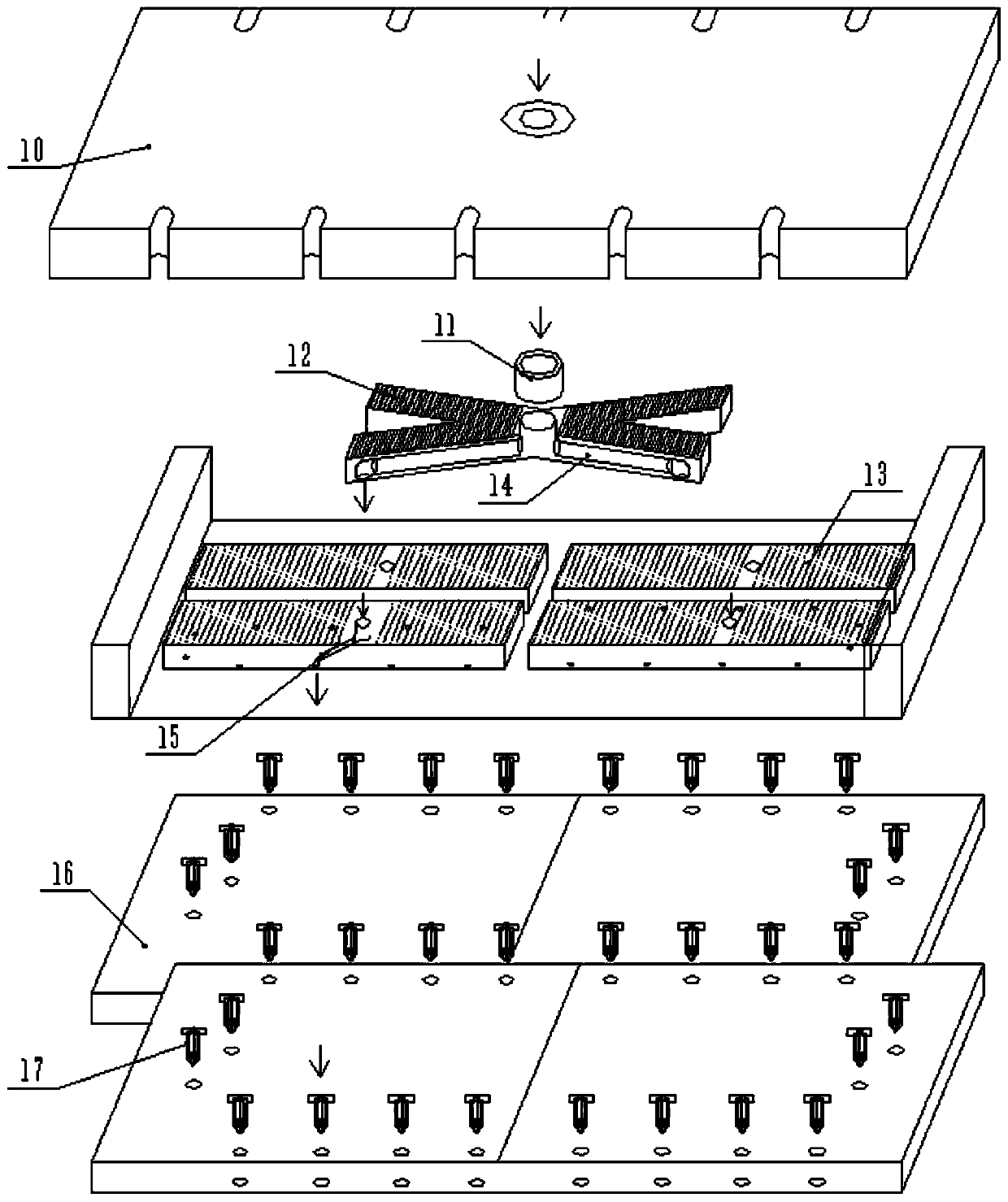

Automatic production line for high-precision grinding wheel

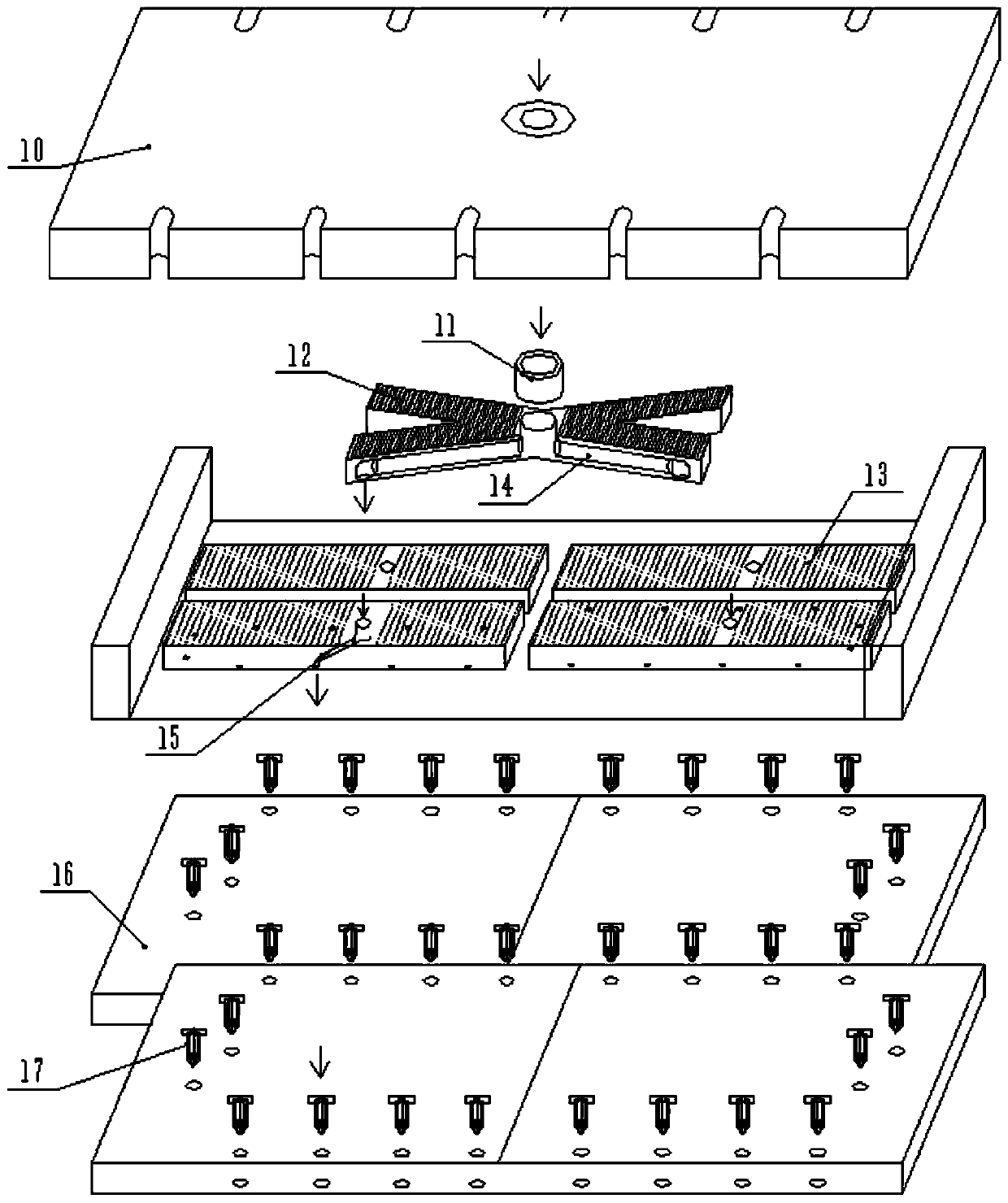

InactiveCN109048701AWell mixedAvoid overfeeding all the timeGrinding devicesProduction lineEngineering

The invention relates to an automatic production line for a high-precision grinding wheel. The automatic production line comprises a grinding wheel forming die and further comprises a lower mesh containing system, a feeding system, a charging system, a material scraping system, an upper mesh containing system, a mesh pressing system, a core ring containing system, a die pressing machine and a demoulding device, all of which are arranged on a production track. The grinding wheel forming die is arranged on the production track and conveyed, and lower mesh containing, feeding, charging, flat material scraping, upper mesh containing, mesh pressing flattening, core ring containing, die pressing forming and demoulding are sequentially finished. The automatic production line is high in automationdegree, feeding is convenient, charging is stable and uniform, meshes are flatly placed, raw materials in the die are uniform, and the grinding wheel die pressing forming quality can be better improved.

Owner:张和庆

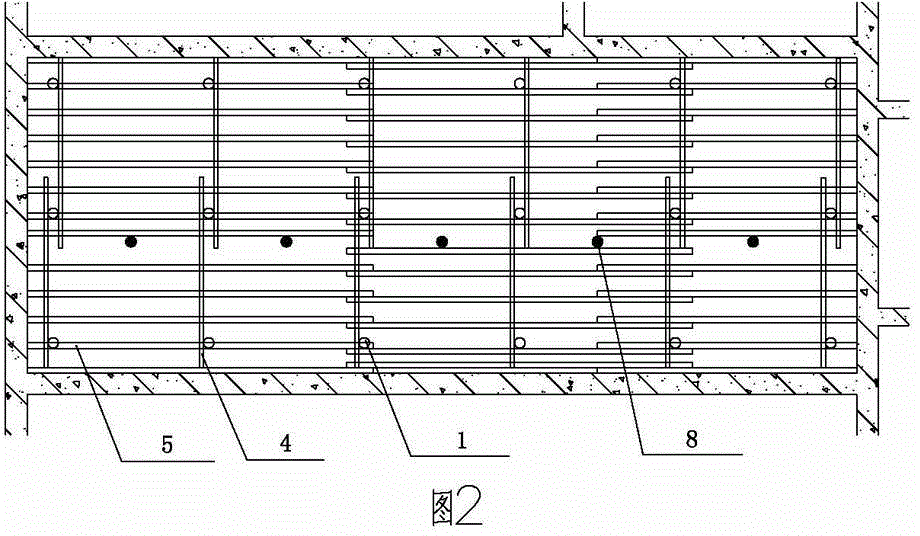

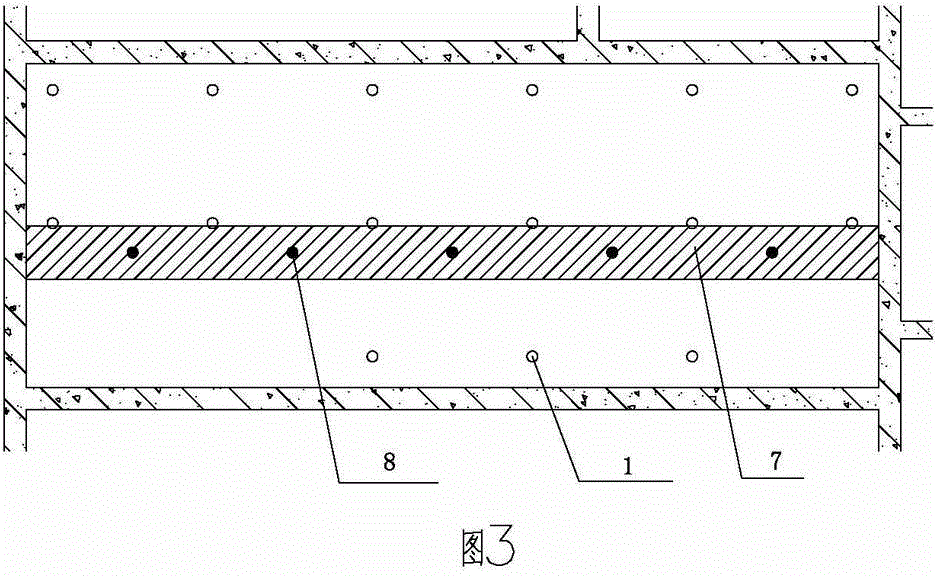

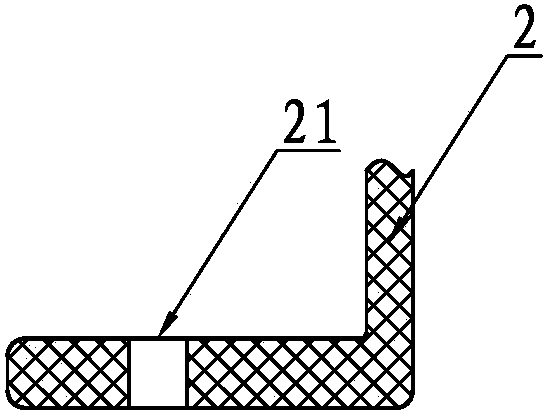

Steel beam grid floor formwork system

InactiveCN102720356AEasy to useImprove structural strengthForms/shuttering/falseworksShoresFloor slabHardness

The invention provides a steel beam grid floor formwork system, wherein a plurality of early removed steel supports and a plurality of late removed steel supports are evenly arranged on a bottom floor; the top end of an internal sleeve of each early removed steel support is provided with a jack; a plurality of rows of square steel beams are paved on the jacks in the transverse direction; and a plurality of rows of n-shaped steel beams are evenly arranged on the square steel beams in the longitudinal direction; faceplates are paved on the n-shaped steel beams; all the faceplates are arranged between collected strip clearances; late removed strips are paved in the longitudinal direction; and clearance plates are paved in the transverse direction; the bottom faces of the late removed strips are directly supported by the late removed steel supports; and longitudinal and transverse horizontal steel pull rods are buckled with the internal sleeves of all the steel supports through fasteners. Having the serialized structure sizes, the n-shaped steel beams, the square steel beams and the faceplates are convenient to use, and have great structural strength and high safety coefficient; and additionally, the n-shaped steel beams, the square steel beams and the faceplates are difficultly damaged so as to be reused for multiple times. The new type faceplates are low in toxicity and great in surface hardness, and are reused for multiple times which are three times that of the traditional faceplates. When the steel beam grid floor formwork system is used, the construction speed is high, the materials and the woods are saved, the environmental pollution level is low, less support steel is used, and the project cost is low.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

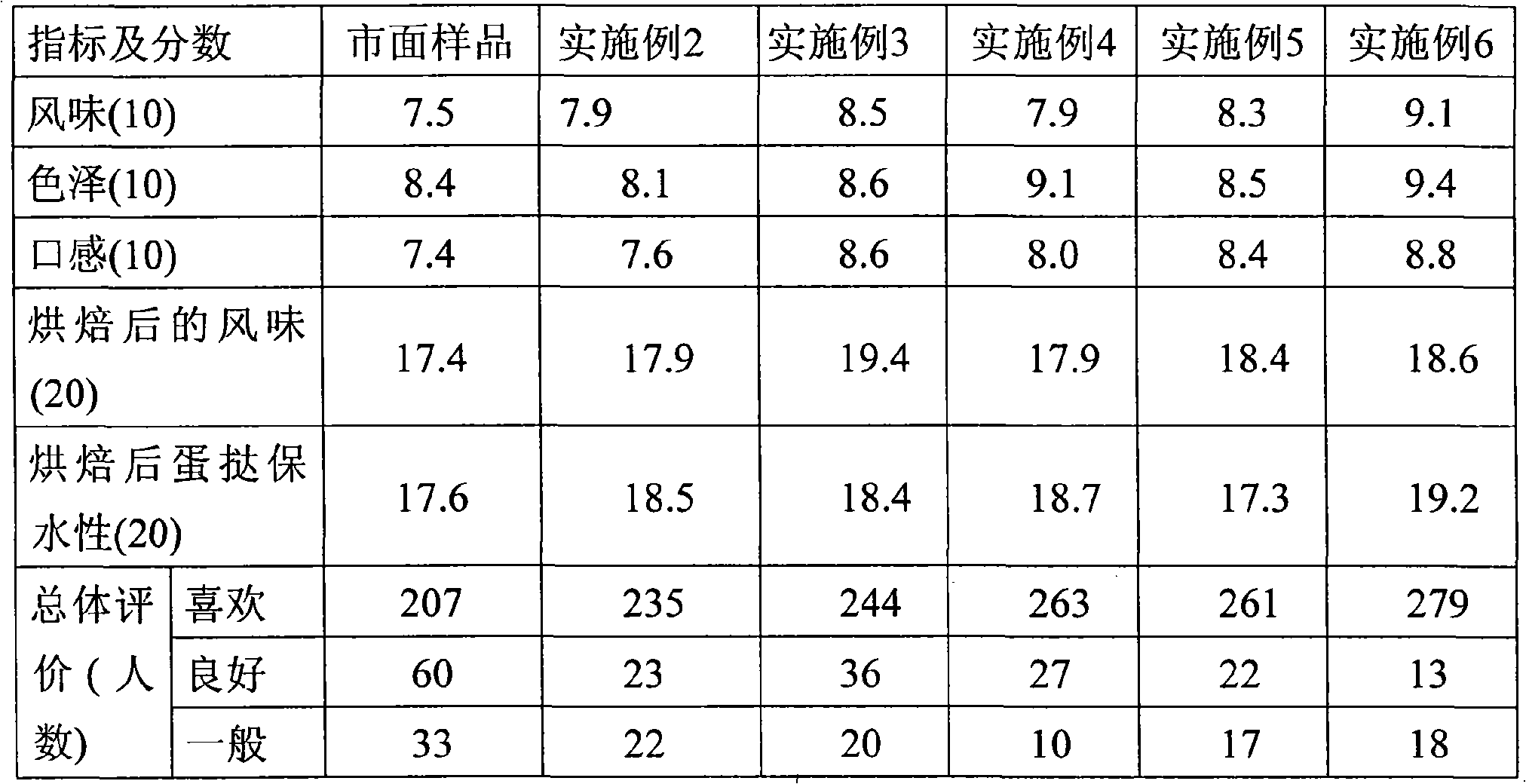

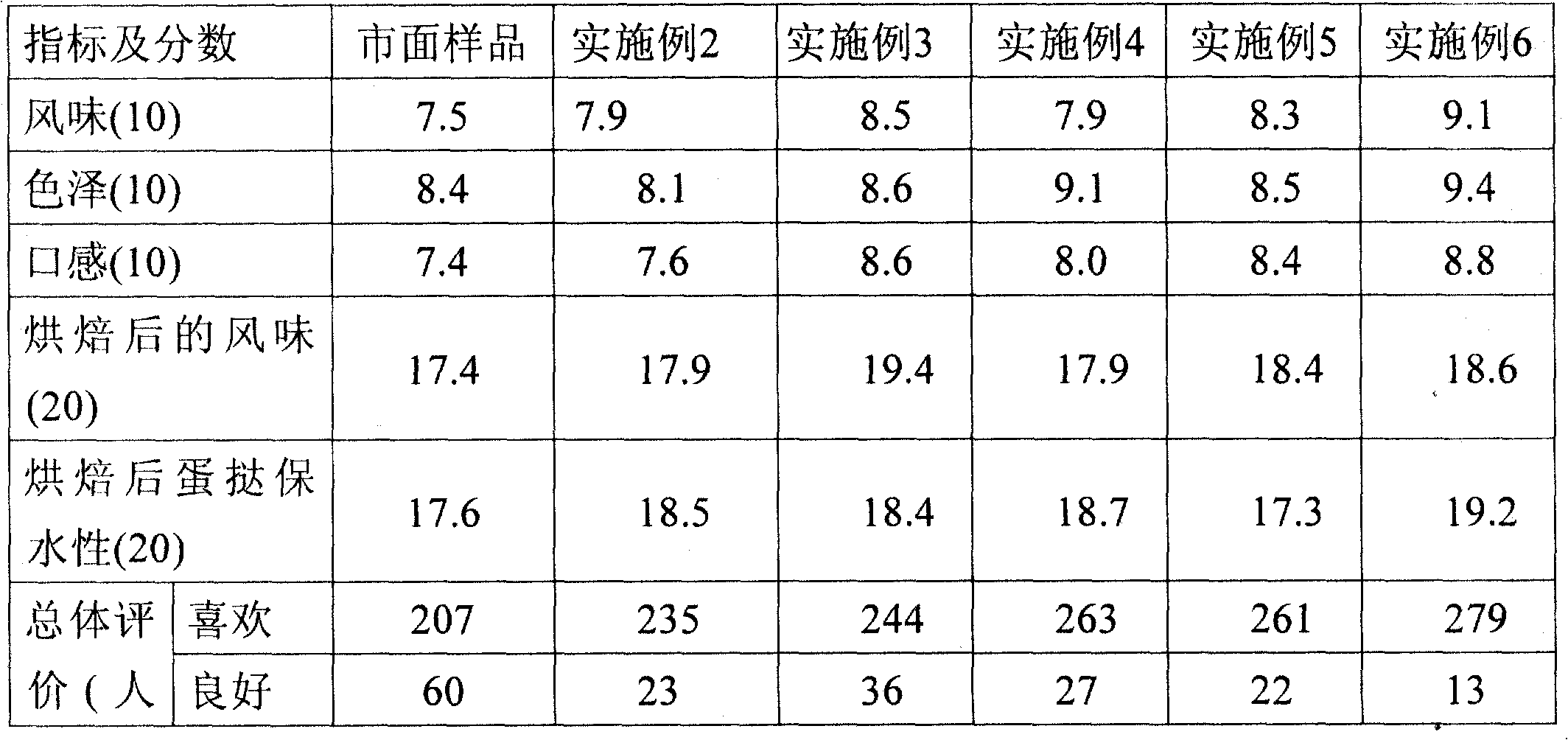

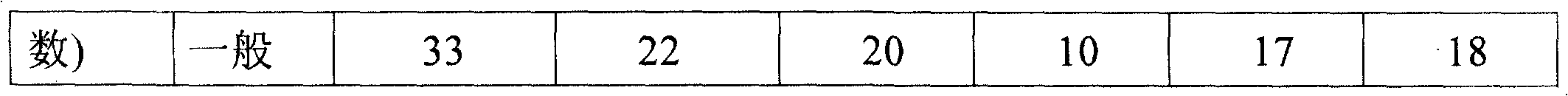

Unsalted butter special for egg tart and preparing method thereof

ActiveCN101313718AIncrease content ratioGuaranteed water retentionCream preparationBiotechnologyCow milking

The invention discloses whipping cream special for an egg tart and a production method thereof. The compositions per 100 grams of raw materials by weight of the whipping cream special for the egg tart provided by the invention are: 80 to 98 grams of the whipping cream, 0.5 to 19 grams of cow milk, 0.1 to 0.8 gram of emulsifiers, 0.1 to 0.8 gram of stabilizers, 0.0 to 0.1 gram of pigment, 0.0 to 0.05 gram of preservative, the balance being water which makes up for 100 grams. Nutrition reinforcer is also preferably added into the raw materials. The production method thereof comprises the following steps of: firstly, acceptance check of the raw material milk; secondly, separation of the whipping cream; thirdly, addition of the compositions; fourthly, pasteurization; fifthly, homogenization; sixthly, UHT sterilization; seventhly, cooling; and eighthly, package. The production of the whipping cream special for the egg tart has smooth mouthfeel and rich nutrition, and meets the roasting stability through addition of the emulsifiers and the stabilizers. Moreover, the quality guarantee period is prolonged by adoption of the UHT sterilization technology, the aseptic package technology and the online addition technology of the nutrition reinforcer.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

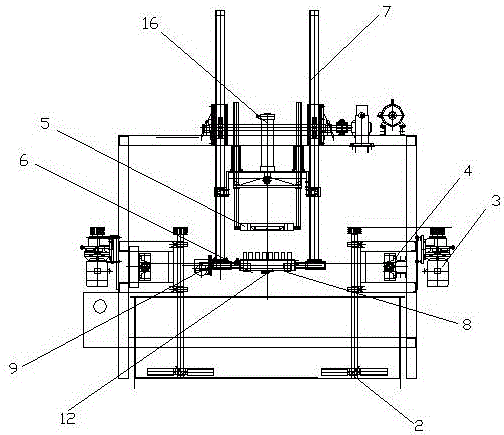

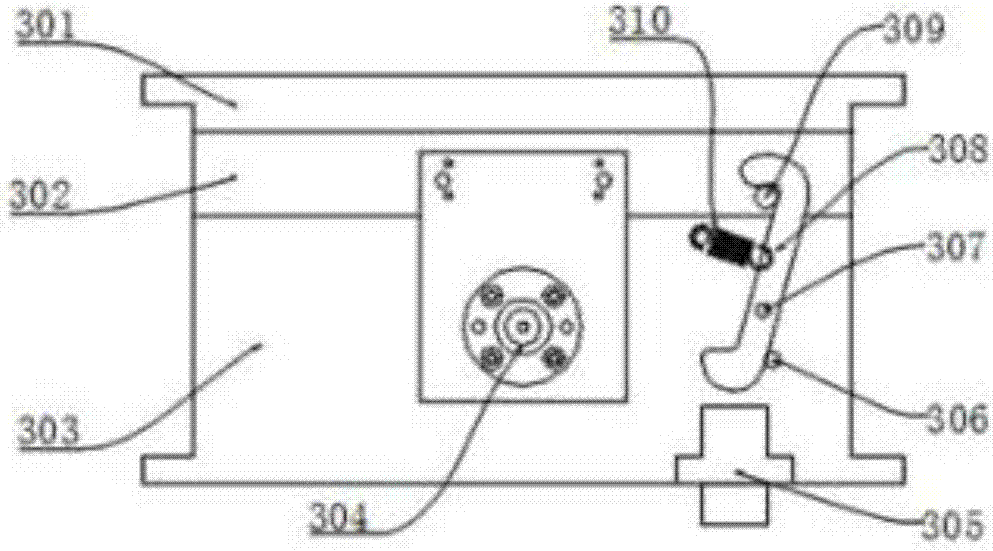

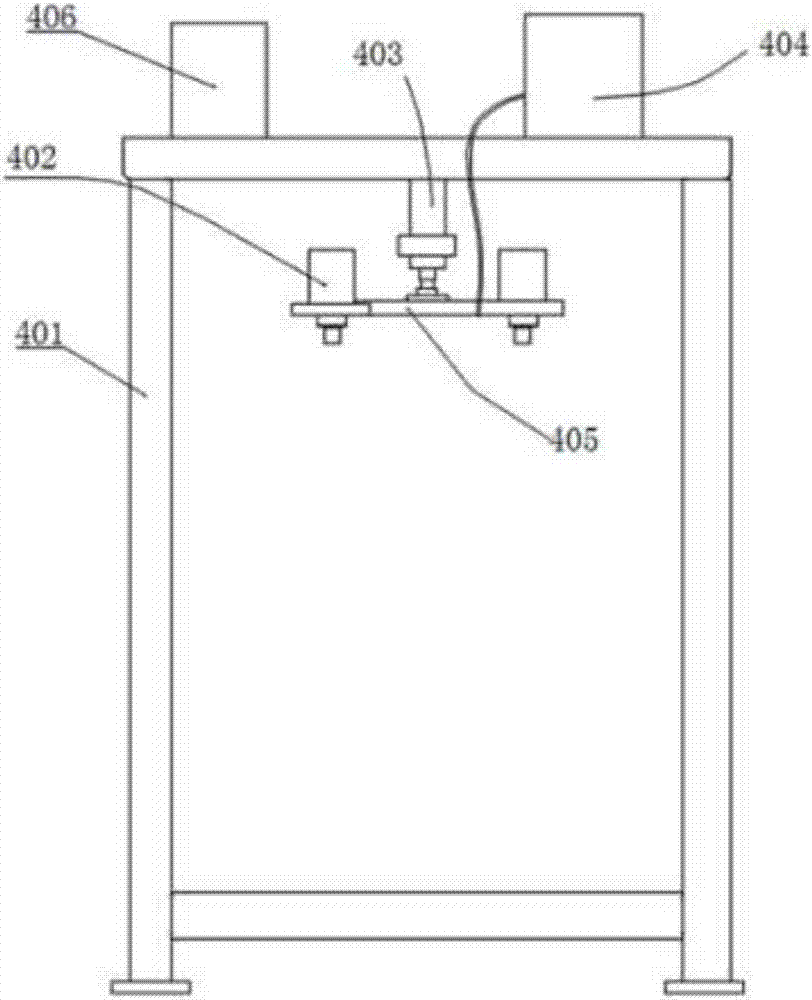

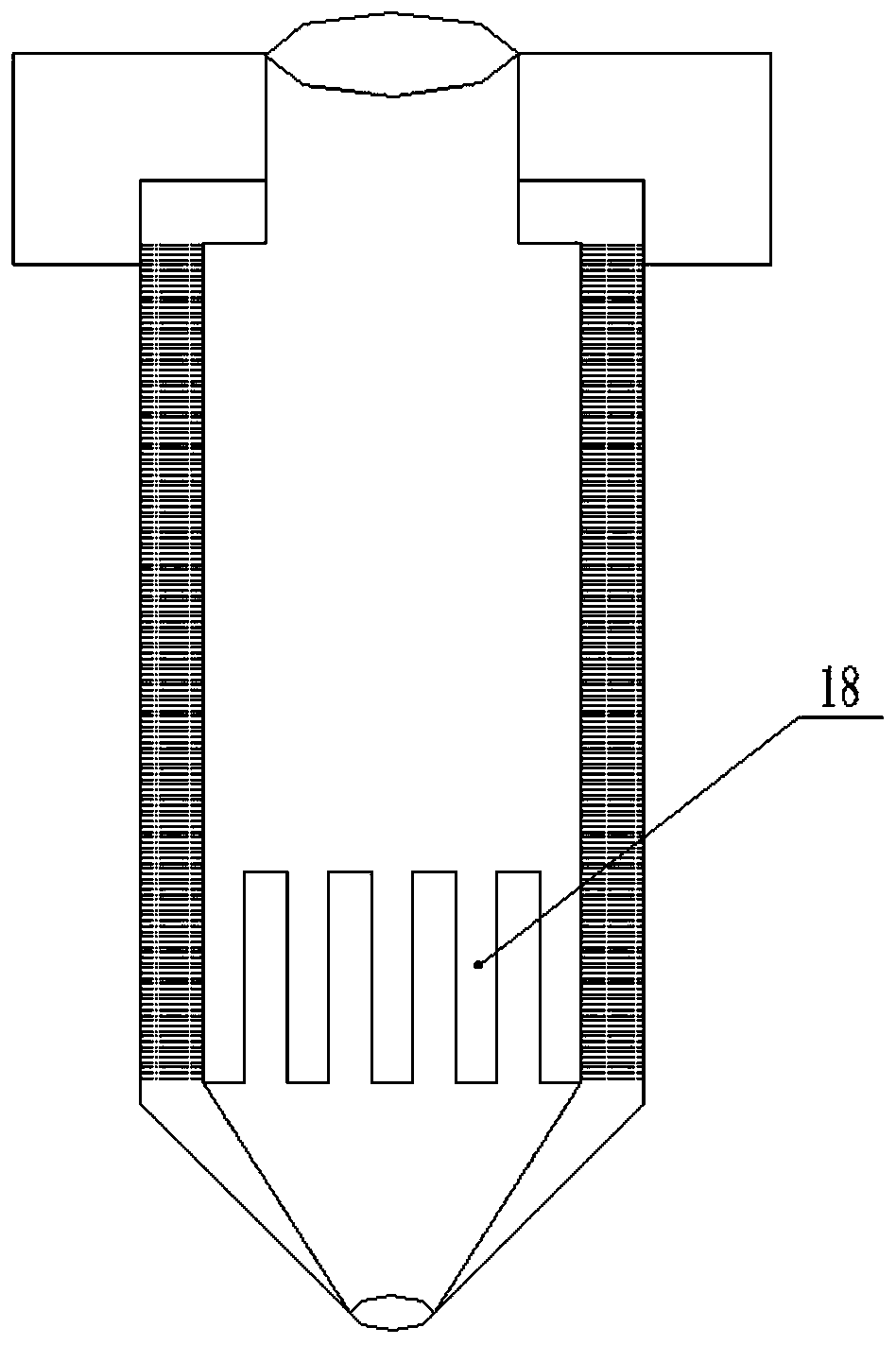

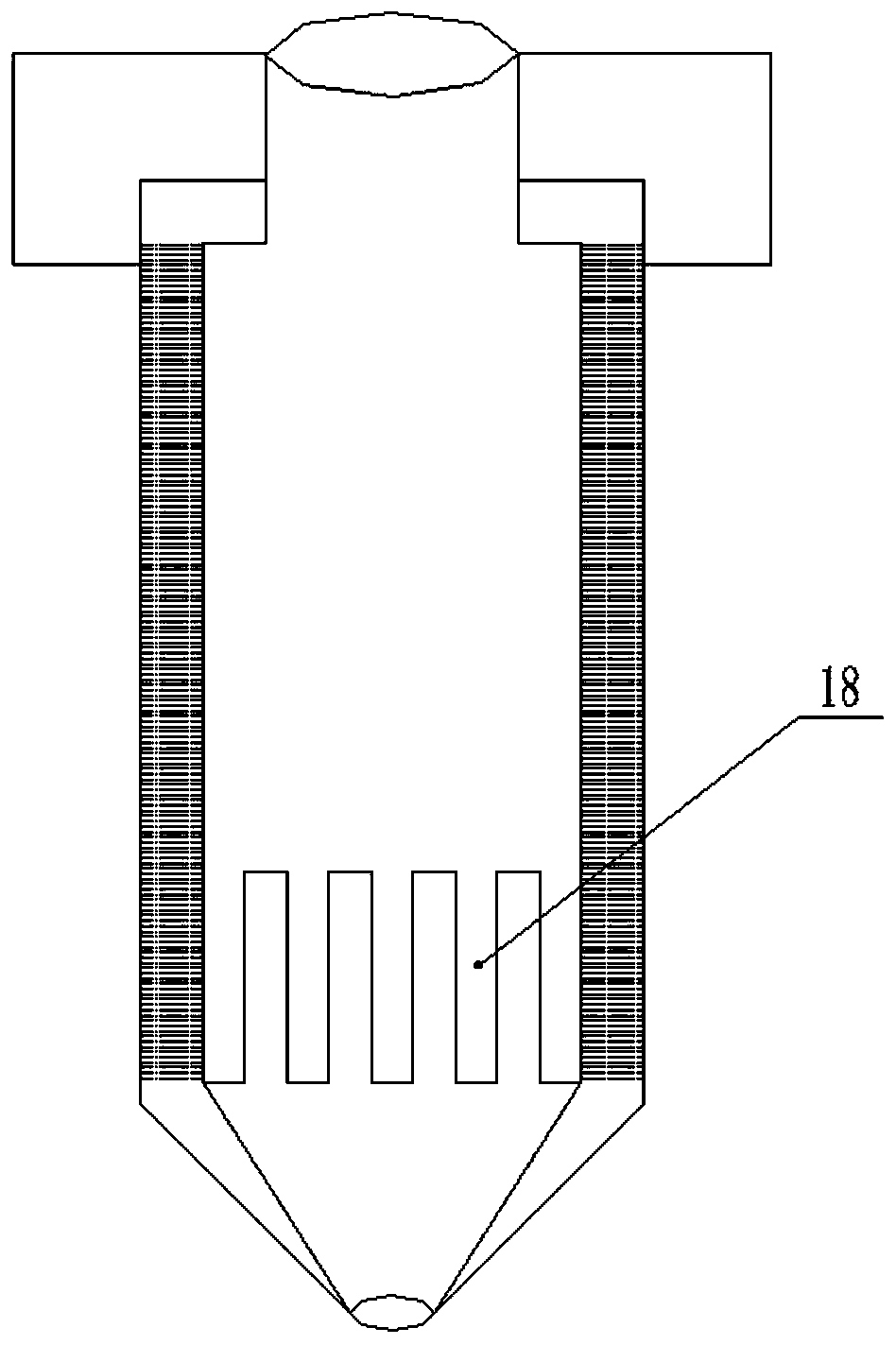

Riser forming machine

InactiveCN105798237AReduce physical laborUniform and stable outputFoundry mouldsFoundry coresEngineeringMaterial storage

The invention discloses a riser forming machine which comprises a slurry tank, a die, a scraping device and a vacuum absorbing device. Two stirring devices opposite in stirring direction are arranged in the slurry tank. The die is arranged on the upper side of the slurry tank through a rack elevating shaft and slides along the rack elevating shaft vertically. The die comprises an inner die body and an outer die body. Four hammers are arranged on the periphery of the inner die body. The die is provided with an exhausting hole. The scraping device is arranged between the slurry tank and the die and comprises a brush oil cylinder, a stainless steel roller and a brush. The vacuum absorbing device comprises a vacuum box and a vacuum settling tank. The vacuum settling tank is provided with a gas inlet hole and a sewage draining opening. The gas inlet hole is connected with the exhausting hole of the die through a hose. The riser forming machine enables whole mixed materials to be turned over upwards, so that the effects of dead-angle-free material storage and uniform mixing are achieved. By means of automatic die releasing, the defects that due to the fact that a die is hammered manually, a riser can not be released from the die easily, and manpower is wasted are overcome, the inner wall and the outer surface of the produced riser are smooth, and the quality and the working efficiency of the riser are improved.

Owner:NANJING NINGJINYAO MACHINERY CO LTD

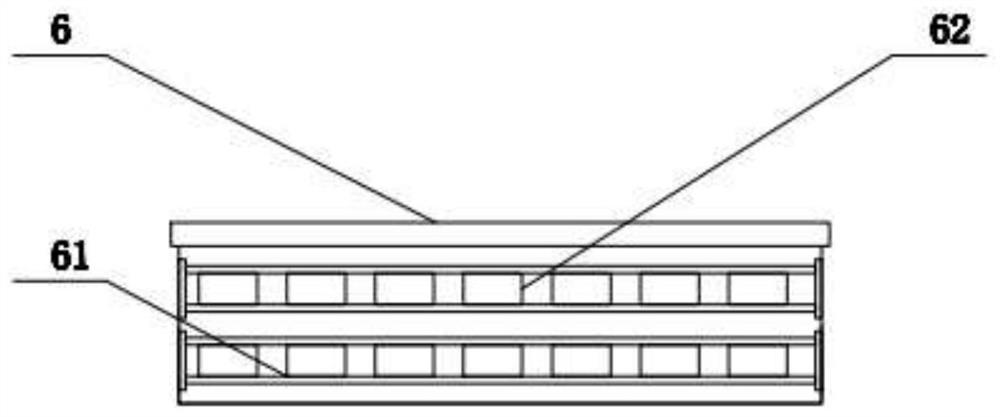

Full-automatic core shooting machine

The invention relates to a fully automatic core shooting machine, which includes a mold and a core shooting device for injecting core sand into the mold. The mold is divided into an upper mold, a middle mold and a lower mold. The locking mechanism for the opening and closing of the middle mold and the lower mold. The fully automatic core shooter also includes: a curing device, which includes a curing frame, an air blowing mechanism and a parting mechanism; a demoulding device, which includes a demoulding frame, a lifting mechanism for lifting the mold, and flipping the lifted mold The overturning mechanism and the ejection mechanism for demoulding the core in the mold; the moving device, which is driven by a servo motor, makes the mold accurately position or move back and forth horizontally in the positions of the core shooting device, curing device, and demoulding device; A material receiving device, which is used to automatically transport the core obtained from the demoulding device; a PLC control system, which controls each drive in the core shooting device, curing device, demoulding device, moving device, and material receiving device Motor and cylinder for automatic operation.

Owner:曹淅

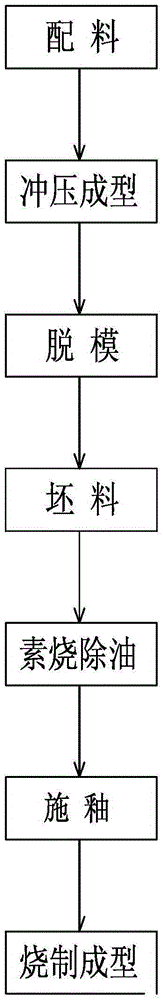

Ceramic floor drain and manufacturing method thereof

The invention belongs to the technical field of ceramic floor drain production, and particularly relates to a green body formula and manufacturing method of a ceramic floor drain. The green body formula of the ceramic floor drain comprises, by weight, 93%-98% of kaolin powder, 1%-3% of kerosene, 1%-3% of leather oil and 0.2%-0.5% of binding agents, and therefore the green body of the ceramic floor drain is stable in quality, not prone to deforming and easy to demould after punch forming. The green body of the ceramic floor drain is sequentially processed through procedures of punch forming, demoulding, oil removing through biscuit firing, glazing and firing forming to be prepared into the ceramic floor drain. The ceramic floor drain is simple in production technology, high in finished product yield and low in production cost and has the active economic and social benefits on popularization and industrialization development of the ceramic floor drain.

Owner:郭任彬

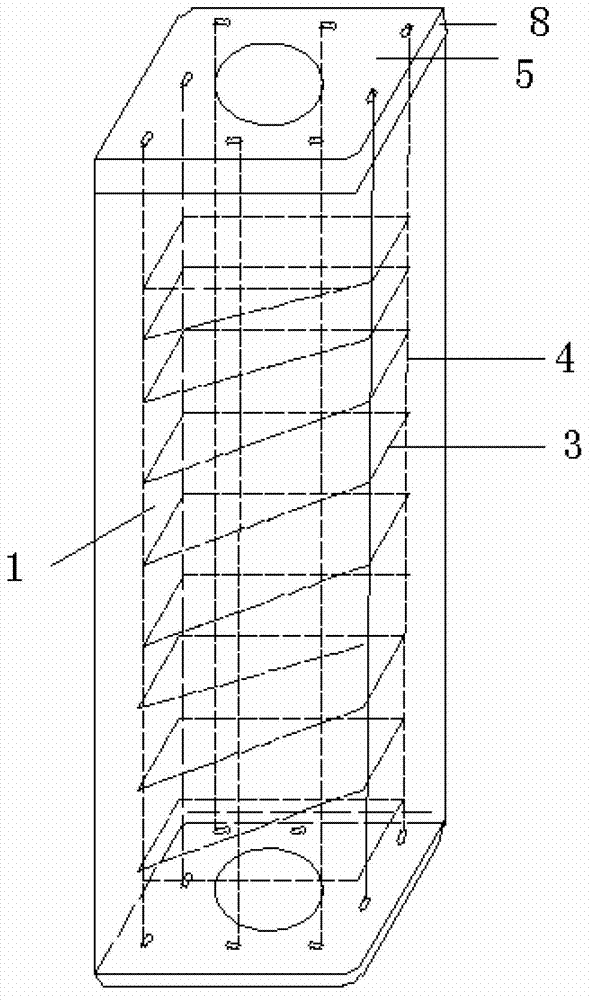

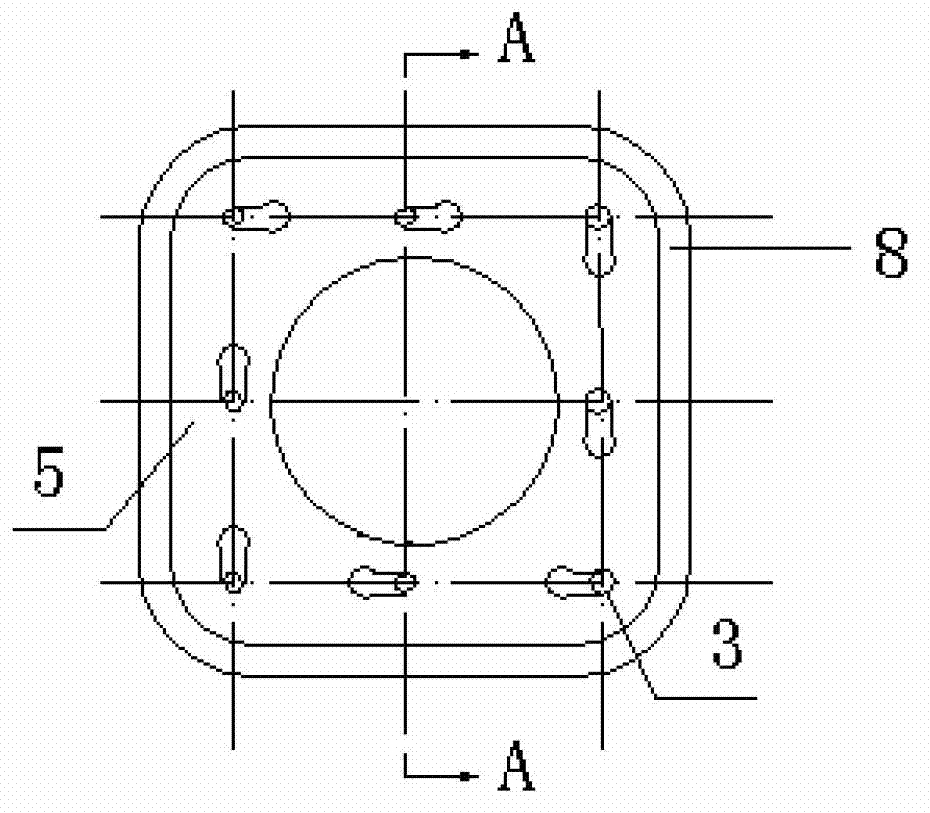

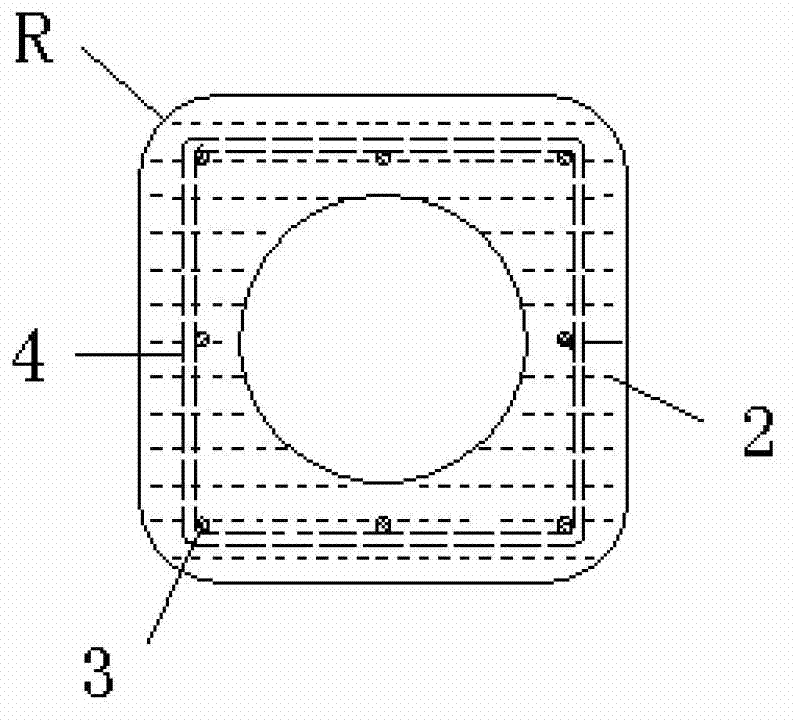

Concrete centrifugal square pile and forming mold thereof

InactiveCN102776879AImprove molding qualityGuarantee molding qualityMouldsBulkheads/pilesStress relievingEngineering

The invention provides a concrete centrifugal square pile and a forming mold thereof. A pile body is in a square shape, a pile core is a central through hole and is cylindrical, corners of four sides of the pile body are in a stress relieving arc shape, the radius of arcs is the same, the pile body comprises a steel reinforcement cage and concrete, the steel reinforcement cage comprises a main skeleton reinforcement and stirrups, the stirrups are successively welded on the main skeleton reinforcement in a spiral mode, metal end plates which are connected with the steel reinforcement cage are arranged at two ends of the pile body, sleeve hoops are arranged on the connecting portions of the metal end plates and the pile body, and the radii R of the arcs of the corners of the four sides of the pile body are respectively 18mm, 22mm, 26mm and 32mm. The square pile has the advantages that materials are saved, the self weight is light, the square pile is not easy to damage, the tensibility of the pile body is good, the bearing capacity of the pile is large, the service life is long and bending resistance and shearing resistance performances are good. The structural pile of the forming mole is easy to demold, the energy is saved and the carbon emission is reduced.

Owner:TIANJIN JIANCHENGJIYE GRP

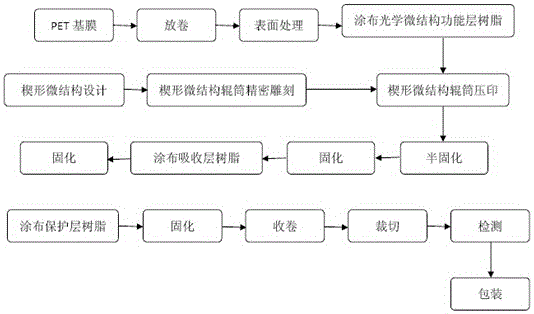

Roll-to-roll preparation method of contrast refined film

ActiveCN105807341AImprove accuracyReduce thicknessPretreated surfacesCoatingsProtection layerContrast ratio

The invention provides a roll-to-roll preparation method of a contrast refined film. The method comprises the steps of: designing and simulating a contrast refined film; carving out a wedge-shaped microstructure roller with the designed structure and size; carrying out surface processing on a PET base film coiled material, and then carrying out precise coating with optical microstructure function layer resin; carrying out semi-solidifying on the optical microstructure function layer resin, carrying out demoulding, deeply solidifying the basically-shaped optical microstructure function layer resin after demoulding, and solidifying the optical microstructure function layer resin into a film; precisely coating a optical microstructure function layer after film formation by solidifying with absorbing layer resin, and solidifying the absorbing layer resin into a film; and precisely coating an absorbing layer after film formation by solidifying with protection layer resin, and solidifying the protection layer resin into a film. The roll-to-roll preparation method of the contrast refined film has the advantages that a press roller facilitates demoulding, the size accuracy of the wedge-shaped microstructure is high, the yield is high, the operation is convenient, safety and reliability are realized, the method is economic and environmental-friendly, and large-scale batch production can be easily realized.

Owner:BEICHUAN RUIHUI SCI & TECH CO LTD

Grinding wheel partition and mesh integrated picking and releasing claw

The invention relates to a grinding wheel partition and mesh integrated picking and releasing claw. The grinding wheel partition and mesh integrated picking and releasing claw includes a vacuum chuck,wherein an upper end surface of the vacuum chuck is uniformly provided with three or more supporting claw cylinders, an inner end of each of the supporting claw cylinders is fixedly hinged with an upper end surface of the vacuum chuck, an outer end of each of the supporting claw cylinders is movably hinged with an upper end of a supporting claw, the middle portion of the supporting claw is movably hinged with the vacuum chuck, a lower end of the supporting claw rotatably rotating around a middle hinge point extends into a lower portion of the vacuum chuck, the diameter of the circumference ofthe supporting claw extending into the deepest portion below the vacuum chuck is larger than the diameter of a partition and is smaller than the diameter of a fiber mesh, the vacuum chuck is externally connected with a vacuum pump and an air compressor through a switching valve, and the air compressor is the hot air structure with a heater. The integrated picking and releasing claw has a high degree of automation, is convenient for feeding, is stable and uniform for feeding, achieves flat laying of the mesh, has uniform raw materials in the mold and facilitates to improve the quality of molding of a grinding wheel.

Owner:张和庆

Machining process for extrusion die

The invention provides a machining process for an extrusion die. The machining process is used for machining the extrusion die sleeved on a roll shaft of a granulator. A die blank with die holes is subjected to thermal treatment and finish machining, and each die hole is subjected to extrusion and grinding treatment. The thermally treated extrusion die has strong strength, cannot be cracked after being extruded for a long time, and is long in service life; the die holes are high in compressive resistance and bending resistance, and cannot be deformed by extrusion; after the finish machining, the extrusion die can rotate stably, and the yield is high; in addition, the grinding cost of the extrusion mode is low, and two die blanks can be ground by once extrusion, so that the grinding efficiency is high; and the die holes of the ground die blanks are low in roughness, and extruded products are easy to de-mold.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

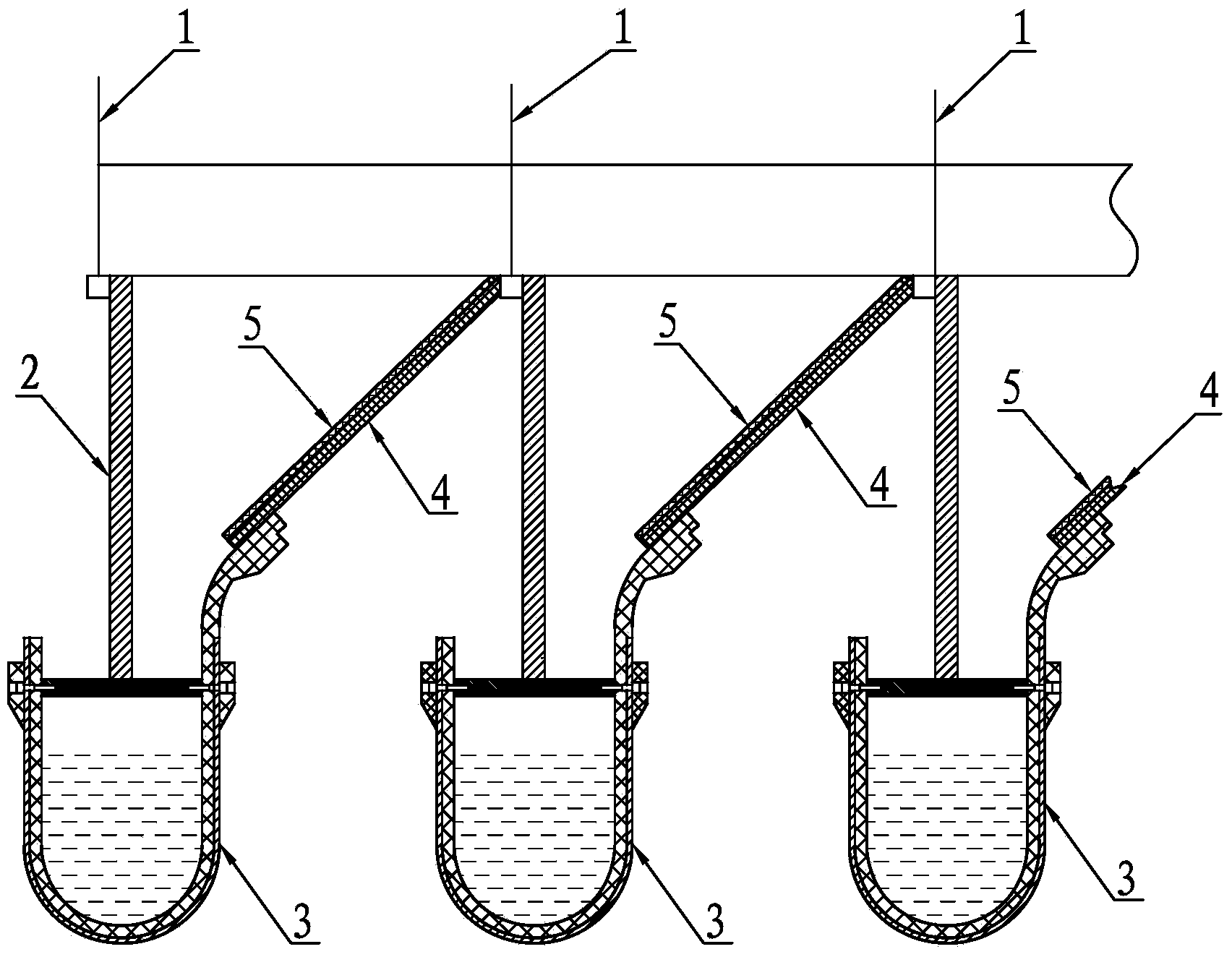

Splash-proof water-intercepting flow-guide device of high water receiving cooling tower in power plant

The invention discloses a splash-proof water-intercepting flow-guide device of a high water receiving cooling tower in a power plant. The device comprises suspension cables, transverse lifting rods, water collection tanks, water collection flow guide plates and splash-proof gratings, wherein the lower ends of the transverse lifting rods are fixedly mounted on the water collection tanks, and the upper ends of the transverse lifting rods are suspended in the tower through the suspension cables; the water collection flow guide plates are obliquely arranged above the two adjacent water collection tanks, the lower end of each water collection flow guide plate is fixed on the side edge of the previous water collection tank, the upper end of the water collection flow guide plate is fixed at the top end of the next transverse lifting rod, and the water collection flow guide plates are vertically distributed corrugated plates; the splash-proof gratings are fixedly arranged on the upper end surfaces of the water collection flow guide plates; each water collection tank comprises a water tank body, a connecting flange, a tank opening reinforcement rib, an outwards protruded reinforcement rib, a bearing and lifting steel belt and a horizontal lifting rod; the water tank body comprises a water collection tank body and an arc-shaped drainage upper side plate. The device is high in bearing strength, good in splash-proof performance, high in water receiving efficiency, low in water collection noise and long in service life.

Owner:常州金坛塑料厂

Freeze-dried grain food product

InactiveCN109105729ALong-term retention of nutrientsExtended shelf lifeFood freezingFood homogenisationCarrageenanAdditive ingredient

The invention relates to a freeze-dried grain food product. Grains are taken as the main food raw materials of the freeze-dried grain food product. A preparation method comprises following steps: material supply, crushing, slurry preparation, mould injection, freezing, and drying, or material supply, pulp grinding, mould injection, freezing, and drying. The crushed raw materials are subjected to freeze drying, so that the nutrients in grains are maintained for a long term, the self life is prolonged, it is convneeint for storage, carrying, and eating, no additive is added, the freeze-dried grain food product is natural and is good for health. Auxiliary food raw materials are added into a slurry, so that nutrient components are increased, and the mouthfeel is improved; and in addition, foodcolloids such as guar gum, xanthan gum, carrageenan, konjac glucomannan, pectin, Arabic gum, and locust bean gum are added into the slurry, so that product surface lubricity is improved, demoulding from a mould is convenient, product cohesive force is increased, and a problem in the prior art that cracking of freeze-dried food is easily caused is solved.

Owner:WINNER MEDICAL CO LTD

Nano-ceramic paper pulp abrasive disc and production method thereof

The invention discloses a nano-ceramic paper pulp abrasive disc and a production method thereof. Raw material components of the nano-ceramic paper pulp abrasive disc include nanometer corundum and nanometer fused alumina zirconia, and the disadvantages of poor toughness and low corrosion resistance are solved, the service life of pulp abrasive discs is prolonged, and production of high-end nonmagnetic paper pulp is realized. The production method of the nano-ceramic pulp abrasive disc comprises the following steps: (1) preparing the raw materials; (2) carrying out pressure forming; (3) carrying out isostatic compaction; (4) machining a blank; (5) carrying out high temperature sintering; and (6) carrying out abrasive machining. The method solves the technical problem of difficult demolding of special-shaped paper pulp abrasive discs, and opens up a new way for production of special-shaped ceramics.

Owner:HANDAN HUIQIAO COMPOSITE MATERIAL TECH CO LTD

Corrosion-proof easily-demoulded nylon-66 plastic

InactiveCN102382462AImprove the lubrication effectImprove wear resistanceActivated carbonAntioxidant

The invention relates to an organic polymer composite, in particular to corrosion-proof easily-demoulded nylon-66 plastic, which comprises, by weight, 66:65-85% of polyamide, 2-32% of powdered graphite, 0.3-2.7% of antioxidant, 0.5-3.2% of heat stabilizer, 0.4-2.9% of coupling agent, 0.1-3.2% of high-molecular-weight silicon oil and 0.5-5.5% of activated carbon. The corrosion-proof easily-demoulded nylon-66 plastic has the advantages that self-lubricating performance and corrosion-proof performance of graphite are excellent, automatic demoulding can be achieved during injection molding or extruding of finished products, demoulding agent is not needed, and prepared plastic is not easy to corrode due to the corrosion-proof graphite.

Owner:SUZHOU IND PARK XINFENGLIN PLASTIC TECH

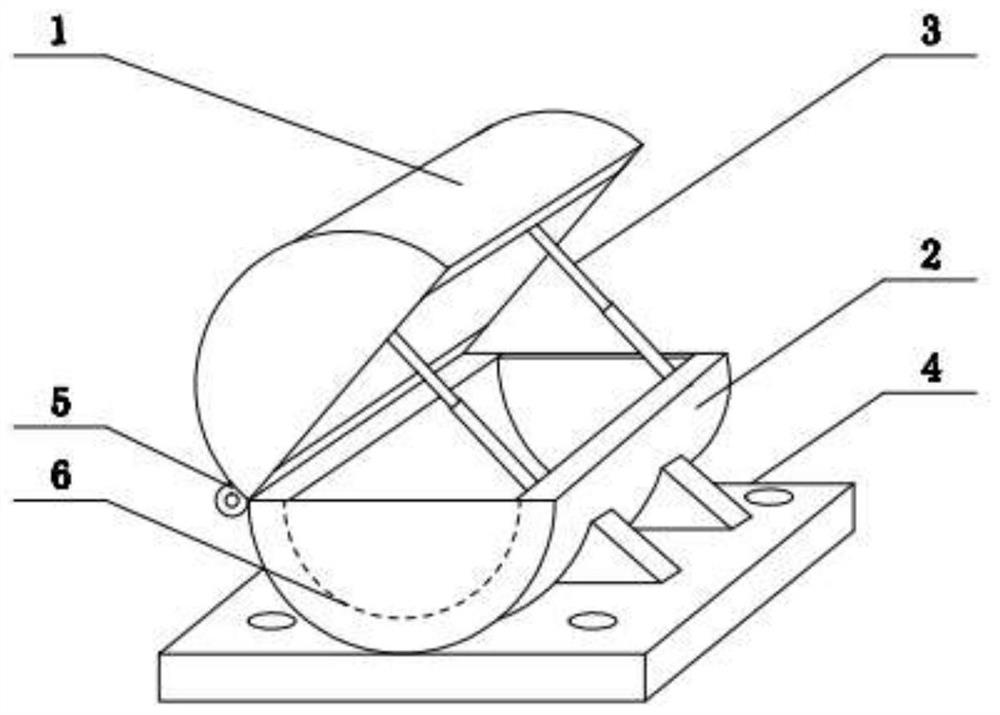

Forming tool for carbon fiber composite material landing gear strut

The invention discloses a forming tool for a carbon fiber composite material landing gear strut. The forming tool comprises an upper tank body, a lower tank body, a telescopic rod, a base, a hinged piece, a die frame and a core die. The hinged piece is connected between the upper tank body and the lower tank body, and the die frame and the core die are correspondingly arranged on the upper tank body and the lower tank body respectively. The upper end of the telescopic rod is connected into the upper tank body, and the lower end of the telescopic rod extends to the inner side of the lower tank body. A fan and an air inlet device are arranged on the surface of the base, and the fan is located on one side of the air inlet device. A heating assembly is laid on the periphery of the die frame, a cooling assembly is fixedly installed below the heating assembly, a heat preservation frame is movably installed above the heating assembly, and a lighting device is arranged at the bottom of the die frame. The forming tool has the beneficial effects that demolding is not likely to happen, popularization is made convenient, then the problems of laying, pressurizing curing and demolding of the landing gear composite material strut are solved, and molding manufacturing of a double-curvature variable-cross-section, multi-layer-number and large-thickness composite product of a special structure is achieved.

Owner:NANJING XIAOZHUANG UNIV

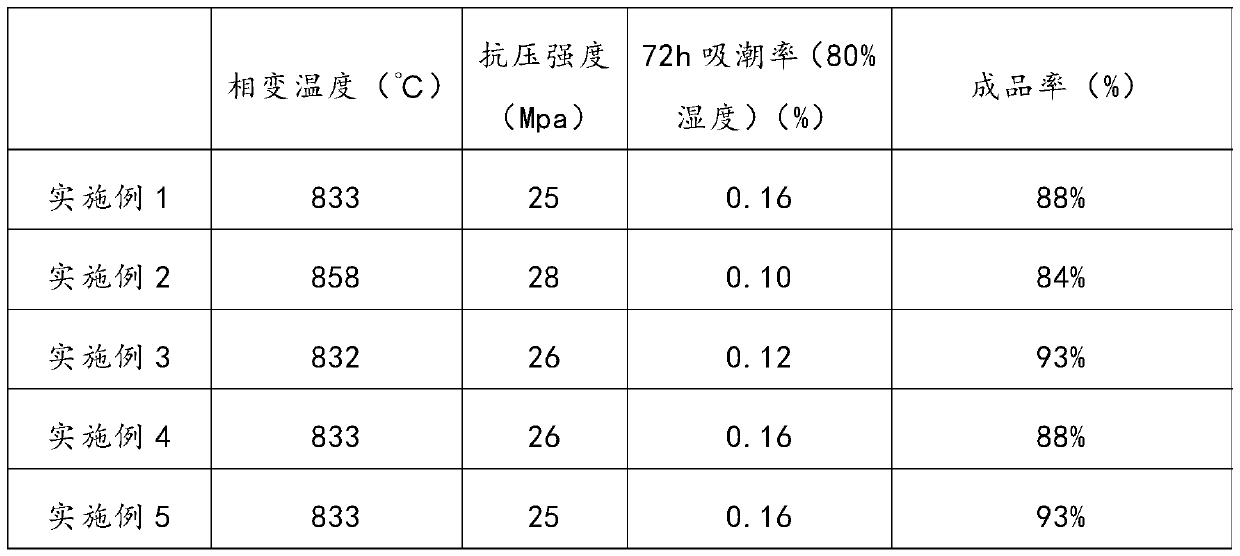

High-temperature phase-change heat storage material, heat storage brick and preparation method of heat storage brick

ActiveCN111004018AImprove surface activitySmall coefficient of thermal expansionHeat-exchange elementsThermal dilatationBrick

The invention provides a high-temperature phase-change heat storage material, a heat storage brick and a preparation method of the heat storage brick. The high-temperature phase-change heat storage material comprises a base material, a phase-change material, an adhesive and a sintering aid, and the base material comprises fused magnesium oxide. The high-temperature phase change heat storage material comprises the fused magnesium oxide. The fused magnesium oxide has relatively high surface activity and relatively low thermal expansion coefficient; the surface tension of particles in the sintering process can be reduced, so that the raw material particles can be fully contacted and fused in the sintering process, the cohesiveness among the particles is better, the sintering is facilitated, and the phenomena of serious cracking, deformation or insufficient strength cannot occur when the heat storage brick, especially a large-size heat storage brick, is prepared.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

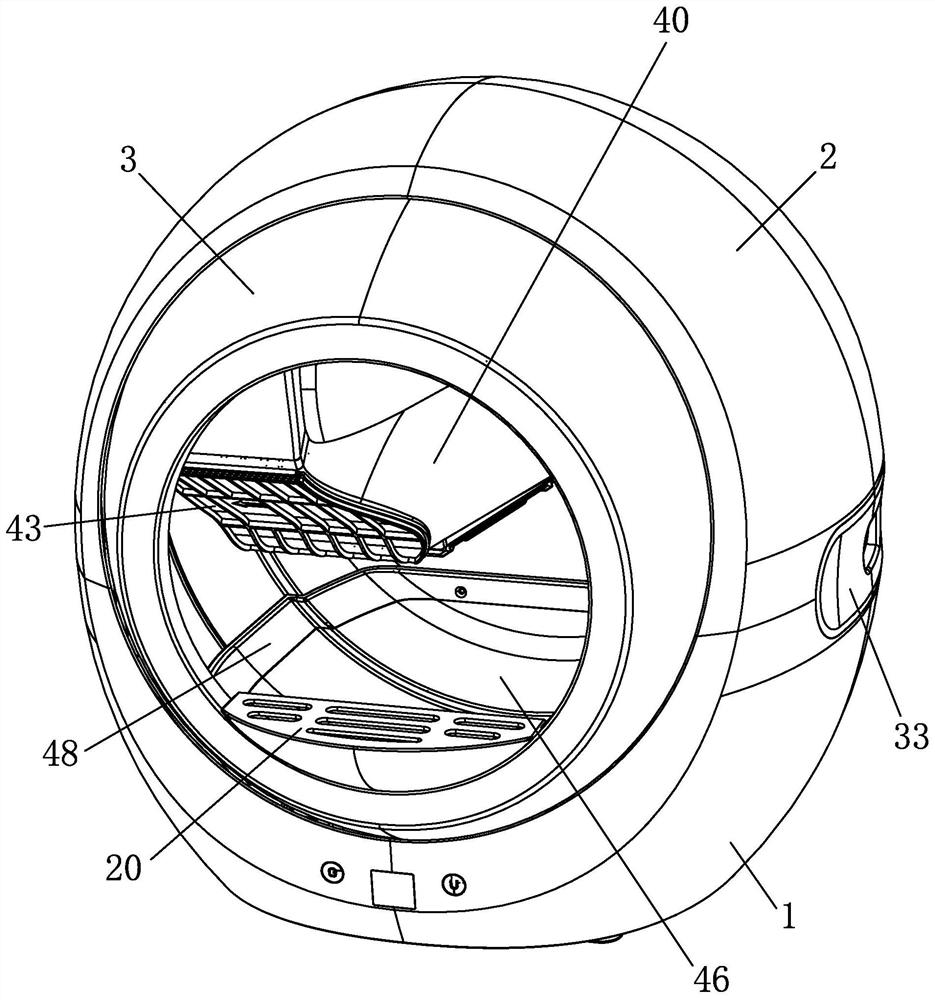

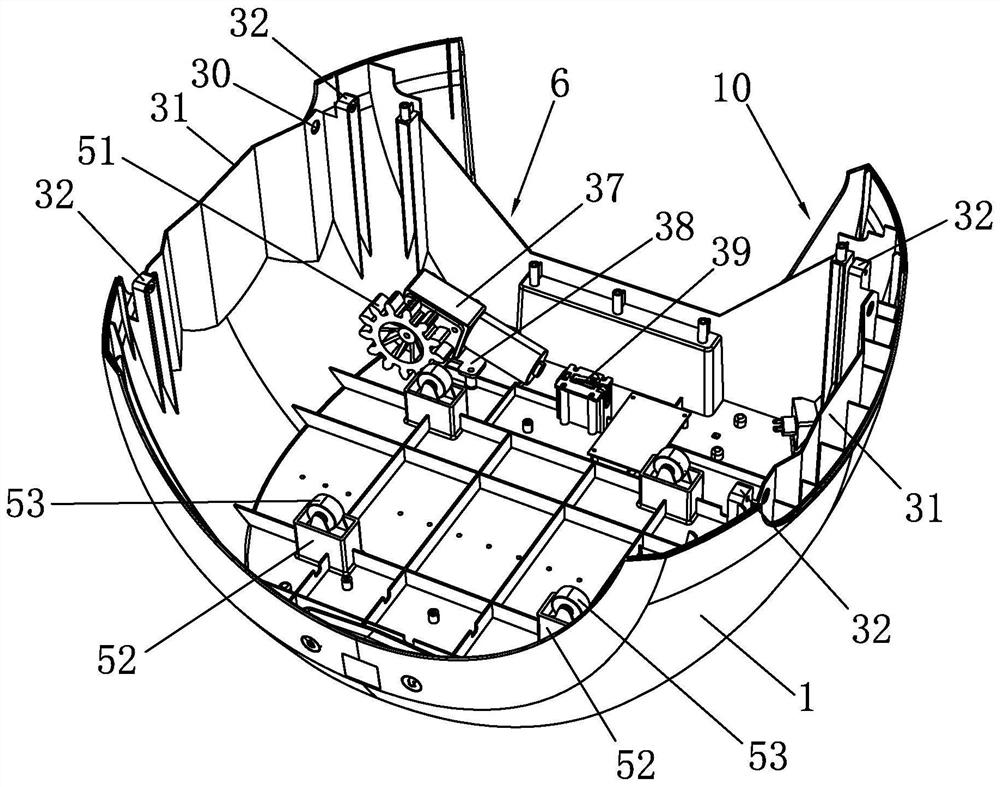

Self-cleaning intelligent cat litter basin and cleaning method thereof

PendingCN112753590APlay a supporting roleThe overall thickness is thinAnimal housingMechanical engineeringLitter

The invention discloses a self-cleaning intelligent cat litter basin and a cleaning method thereof. The self-cleaning intelligent cat litter basin comprises a base, an upper cover, a separation barrel and a combined supporting structure. The combined supporting structure limits an excrement outlet of the separation barrel, the upper cover and the base are each provided with a first embedding groove, the combined supporting structure is embedded into the first embedding grooves, so that the combined supporting structure and the upper cover are hermetically connected, and the combined supporting structure and the base are hermetically connected. The cleaning method comprises the following steps that a, cat excrement is put into a cat excrement collecting box; b, cat litter is separated from excrement blocks; c, cat litter is discharged; d, the separation barrel is cleaned; and e, drying is carried out. The bearing capacity of the whole device is improved, deformation of the upper cover and the base is avoided, the combined supporting structure and the upper cover are hermetically connected, the combined supporting structure and the base are hermetically connected, self-cleaning operation on the separation barrel in the later period is facilitated, sewage discharged from the separation barrel is not prone to entering the base, cleaning is convenient, the speed is high, and the self structure of the separation barrel cannot be damaged.

Owner:林琳

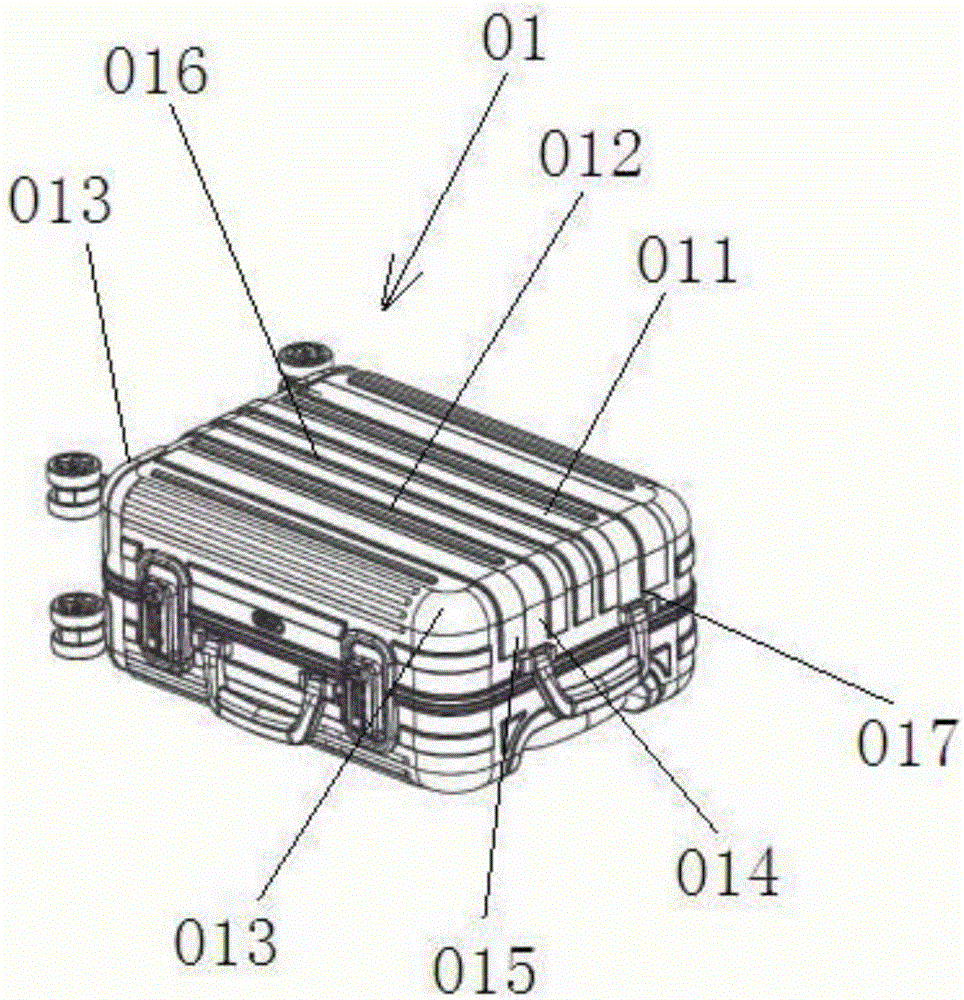

Grinding wheel forming die demoulding device

InactiveCN109048700AImprove molding qualityImprove qualityGrinding devicesVertical vibrationEngineering

The invention relates to a grinding wheel forming die demoulding device. The demoulding device is arranged on a production track. The production track is provided with a demoulding positioning sensor.The production track is provided with a circle of demoulding ring corresponding to the demoulding positioning sensor and the position above a demoulding vertical vibration hammer, and a plurality ofdemoulding positioning holes which are located in the outer side of the demoulding ring and correspond to demoulding lifting suction heads. A demoulding rotation base is driven through a demoulding motor and connected with one or more demoulding vertical vibration hammers. The two sides of the production track correspond to two demoulding horizontal vibration hammers on the outer circumference ofa grinding wheel forming die. The demoulding lifting suction heads are arranged below the production track and fixed to be in a state that the demoulding lifting suction heads can ascend and descend to penetrate through the demoulding positioning holes to actuate the bottom end face of the grinding wheel forming die. The grinding wheel forming die demoulding device is high in automation degree, feeding is convenient, charging is stable and uniform, meshes are flatly placed, raw materials in the die are uniform, and the grinding wheel die pressing forming quality can be better improved.

Owner:张和庆

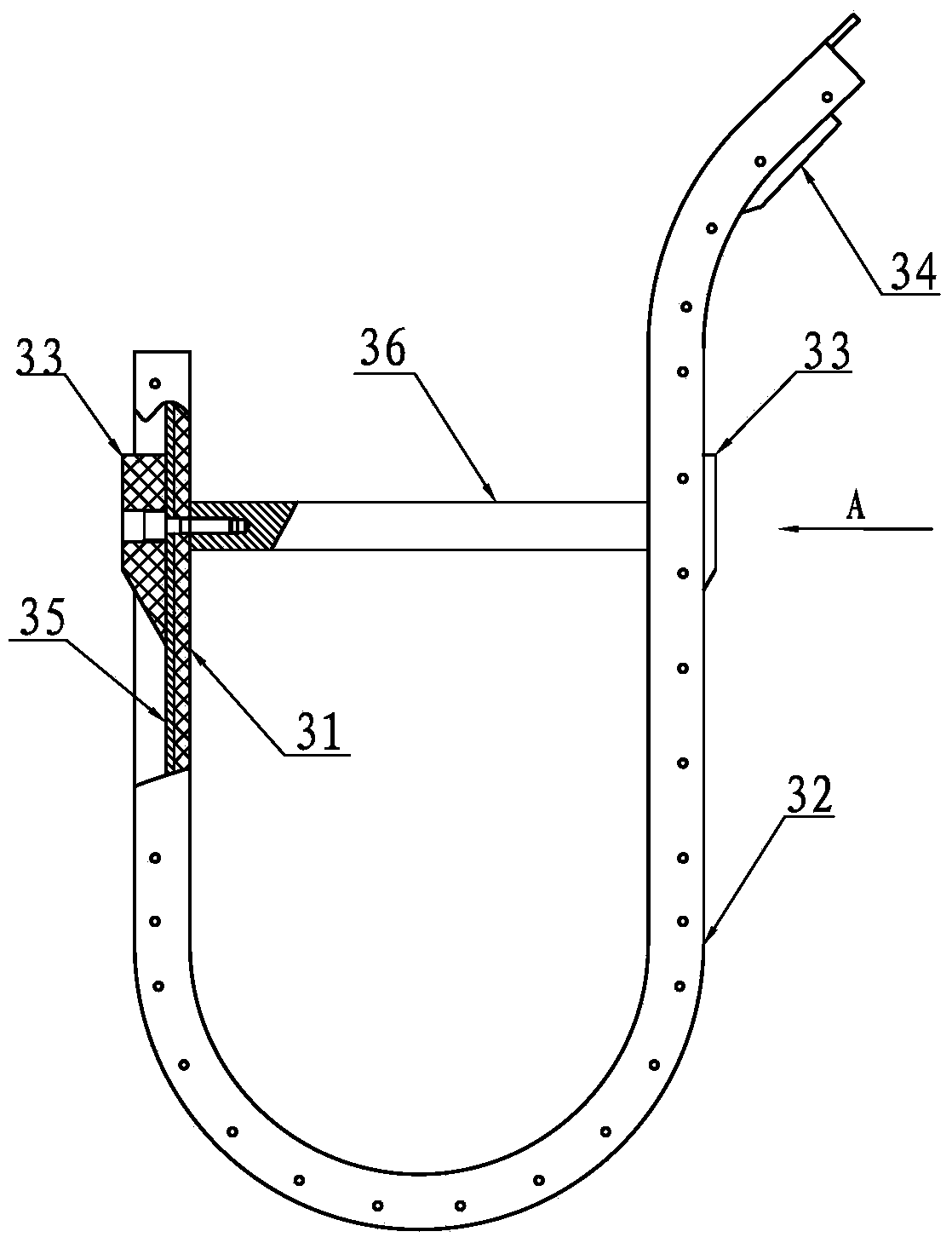

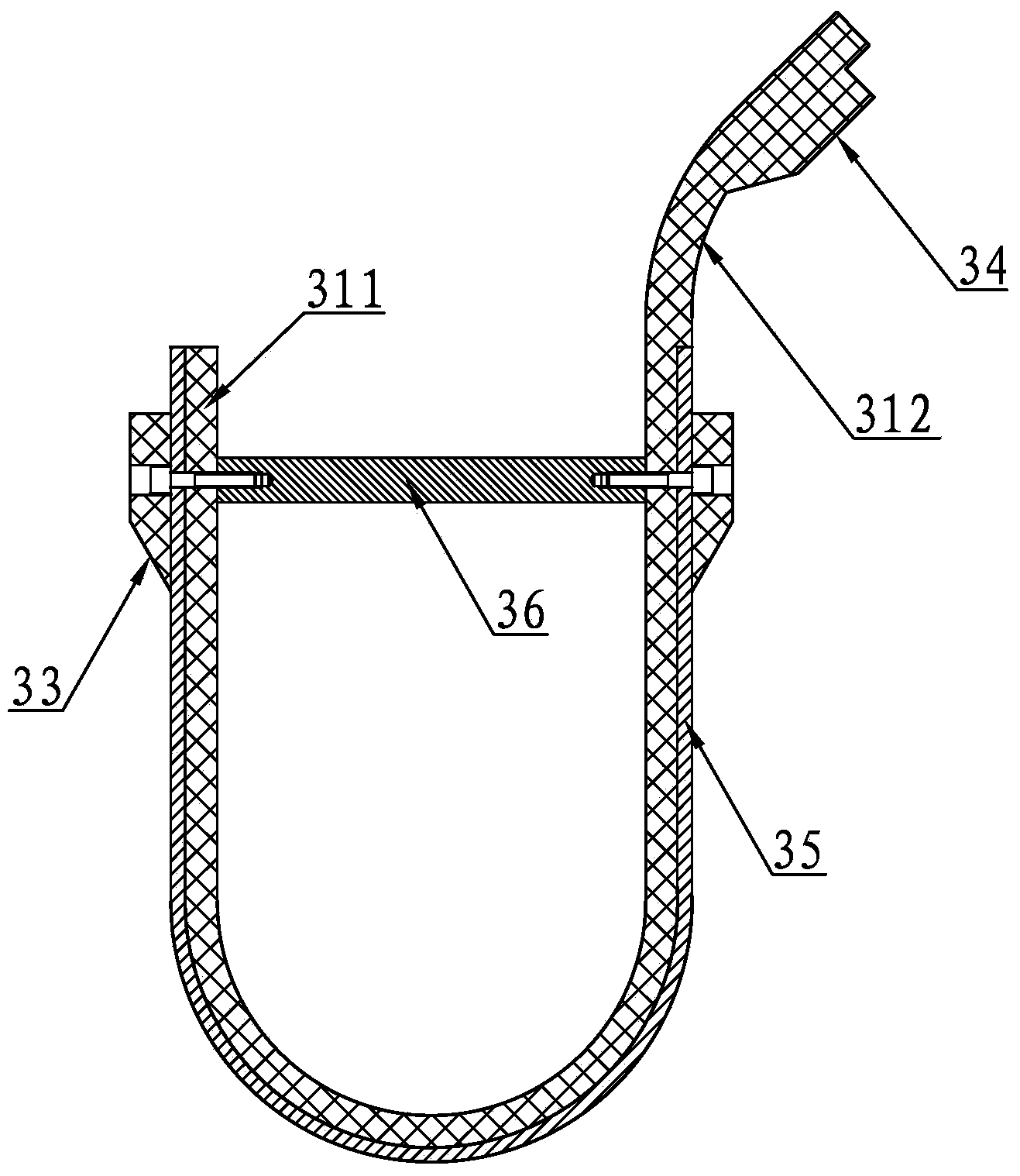

Multifunctional water collection tank of high-order water-saving cooling tower

ActiveCN103954166ALittle influence of side wallImprove the strength of resistanceTrickle coolersWater savingCooling tower

The invention discloses a multifunctional water collection tank of a high-order water-saving cooling tower. The multifunctional water collection tank comprises a water tank body, a connection flange, notch reinforcement ribs, an outwards protruded reinforcement rib, a bearing and lifting steel band and a transverse lifting rod, wherein the water tank body comprises a water collection tank body and an upper arc drainage side plate; the upper arc drainage side plate is arranged above one side wall of the water collection tank body; the bearing and lifting steel band covers the outer surface of the water collection tank body and is fixed by and covered with the notch reinforcement ribs; two ends of the transverse lifting rod are fixedly mounted at combination parts of the notch reinforcement ribs and the bearing and lifting steel band. The notch reinforcement ribs and the outwards protruded reinforcement rib are arranged on the outer side surface of the water tank body, so that demolding is facilitated, and the overall strength of the water tank body is improved; the bearing and lifting steel band and the notch reinforcement ribs are additionally arranged at the lifting position, so that the weight of the water collection tank is concentrated on the bearing and lifting steel band and the notch reinforcement ribs; the inner side surface of the upper arc drainage side plate is smooth, so that smoothing of air flow is guaranteed, and the problems in the prior art are ideally solved.

Owner:常州金坛塑料厂

Production method of floors capable of being quickly installed in side sliding mode

ActiveCN111005524AHigh locking precisionPrevent overflowDomestic articlesCoatingsVegetable oilStructural engineering

The invention discloses a production method of floors capable of being quickly installed in a side sliding mode, and belongs to the technical field of floor production. The production method includesthe following steps that step 1, floor blanks are sorted; step 2, the floor blanks are subjected to curing; step 3, the floor blanks are subjected to sanding; step 4, the floor blanks are subjected tothickness setting; step 5, the floor blanks are subjected to surface treatment; step 6, the floor blanks are subjected to length setting and molding processing; step 7, the floor blanks are sprayed with anti-cracking oil; step 8, the floor blanks are plastic-packaged; step 9, the floor blanks are painted with back paint; and step 10, the floor blanks are painted or painted with vegetable oil. After injection molding, lock catch frames are hidden under bosses of the floor blanks, and lock catches are high in dimensional accuracy and firmly assembled.

Owner:ANHUI YANGZI FLOORING

Mechanical pneumatic type plastic bowl easy-demolding injection mold

The invention relates to the technical field of injection molds, and discloses a mechanical pneumatic type plastic bowl easy-demolding injection mold. The mechanical pneumatic type plastic bowl easy-demolding injection mold comprises a workpiece table, a heat insulation cover is fixedly connected to the top of the workpiece table, a movable groove is formed in the inner wall of the middle of the heat insulation cover, a T-shaped groove is formed in the top of the workpiece table, a lifting column is fixedly connected to the top of the workpiece table, a fixing table is fixedly connected to the top of the lifting column, a pneumatic push rod is fixedly connected to the outer side of the fixing table, and an injection molding gun is movably connected to the inner wall of the middle of the fixing table. According to the mechanical pneumatic type plastic bowl easy-demolding injection mold, a pneumatic lifting table drives a movable block to move, the movable block drives a supporting table to move, an electromagnet drives a first magnetic block to move, and then a rubber suction cup and a piston are used in cooperation, so that the effect that negative pressure adsorption demolding is automatically pushed, damage caused by manual operation is avoided is achieved, compared with a traditional mold, the mold can effectively guarantee that a finished plastic bowl is not prone to being damaged, and meanwhile the demolding efficiency is guaranteed.

Owner:黄绍钧

Drawing process of arc corner connecting rib of metal box shell

ActiveCN105013917AArc corner neatImprove the bearing capacityMetal-working apparatusMetal layered productsEngineeringSurface plate

The invention discloses a drawing process of an arc corner connecting rib of a metal box shell. The drawing process comprises the following steps that the metal rectangular shell is prepared, and arc corner transition portions are arranged at the vertex corners of the metal rectangular shell; a first metal drawing die is used for drawing a top face plate of the metal rectangular shell for the first time, so that a plurality of first convex strips are formed in the first area between the two arc corner transition portions of the top face plate; and a second metal drawing die is used for drawing a side face plate and arc corner transition portions of the metal rectangular shell obtained after first-time drawing molding for the second time, so that a plurality of second convex strips are formed in the second area between the two arc corner transition portions of the side face plate. The drawing process has the beneficial effects that through two times of drawing, arc corners can be orderly, and the stress capacity of the arc corners is improved; meanwhile, convex grain can be formed on the shell, especially on the arc corners, and attractiveness and durability are achieved; especially, die stripping is facilitated in the whole manufacturing process, the production process is simplified, and the occurrence rate of defective goods is lowered.

Owner:费晓明

Unsalted butter special for egg tart and preparing method thereof

ActiveCN101313718BRich pure frankincenseUniform and delicate tissue stateCream preparationCow milkingBlack spot

The invention relates to whipping cream special for an egg tart. The compositions per 100g of raw materials by weight are: 80 to 98 g of the whipping cream, 0.5 to 19 g of cow milk, 0.2 to 0.6 g of emulsifiers, 0.2 to 0.5 g of stabilizers, 0.0 to 0.1 g of pigment, 0.0 to 0.05 g of preservative. The whipping cream special for the egg tart not only enables the egg tart and tart piece to have a pure frankincense during an egg tart bake process, but also enables the baked egg tart to have the characters of little black spot and good glossiness of the egg tart surface, thereby ensuring water retention for the egg tart during the bake, preventing water seepage of the tart shell so that the egg tart does not easily demould. The invention also relates to a production method of the whipping cream special for the egg tart.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Production method of rapid sideslip mounting floor

InactiveCN110067358AHigh locking precisionPrevent overflowDomestic articlesCoatingsPlastic packagingEngineering

The invention discloses a production method of a rapid sideslip mounting floor, and belongs to the technical field of floor production. The manufacturing method comprises the following steps that stepone, floor blanks are sorted; step two, the floor blanks are conserved; step three, the floor blanks are sanded; step four, the floor blanks are subjected to thickness fixing; step five, the surfacesof the floor blanks are treated; step six, the floor blanks are subjected to fixed-length forming processing; step seven, anti-cracking oil is sprayed to the floor blanks; step eight, the floor blanks are subjected to plastic packaging; step nine, the floor blanks are coated with back paint; and step ten, the floor blanks are coated with oil paint or plant oil. After injection molding, a lock catch frame is hidden under a boss of each floor blank, the precision of the size of a lock catch is high, and the assembly is firm.

Owner:ANHUI YANGZI FLOORING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com