Multifunctional water collection tank of high-order water-saving cooling tower

A high-level water collection and water collection tank technology, applied in the direction of water shower coolers, lighting and heating equipment, heat exchanger types, etc., can solve the problems of unfavorable stripping, cracking, and difficult processing, so as to improve the overall strength and Effects of rigidity, enhanced resistance strength, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

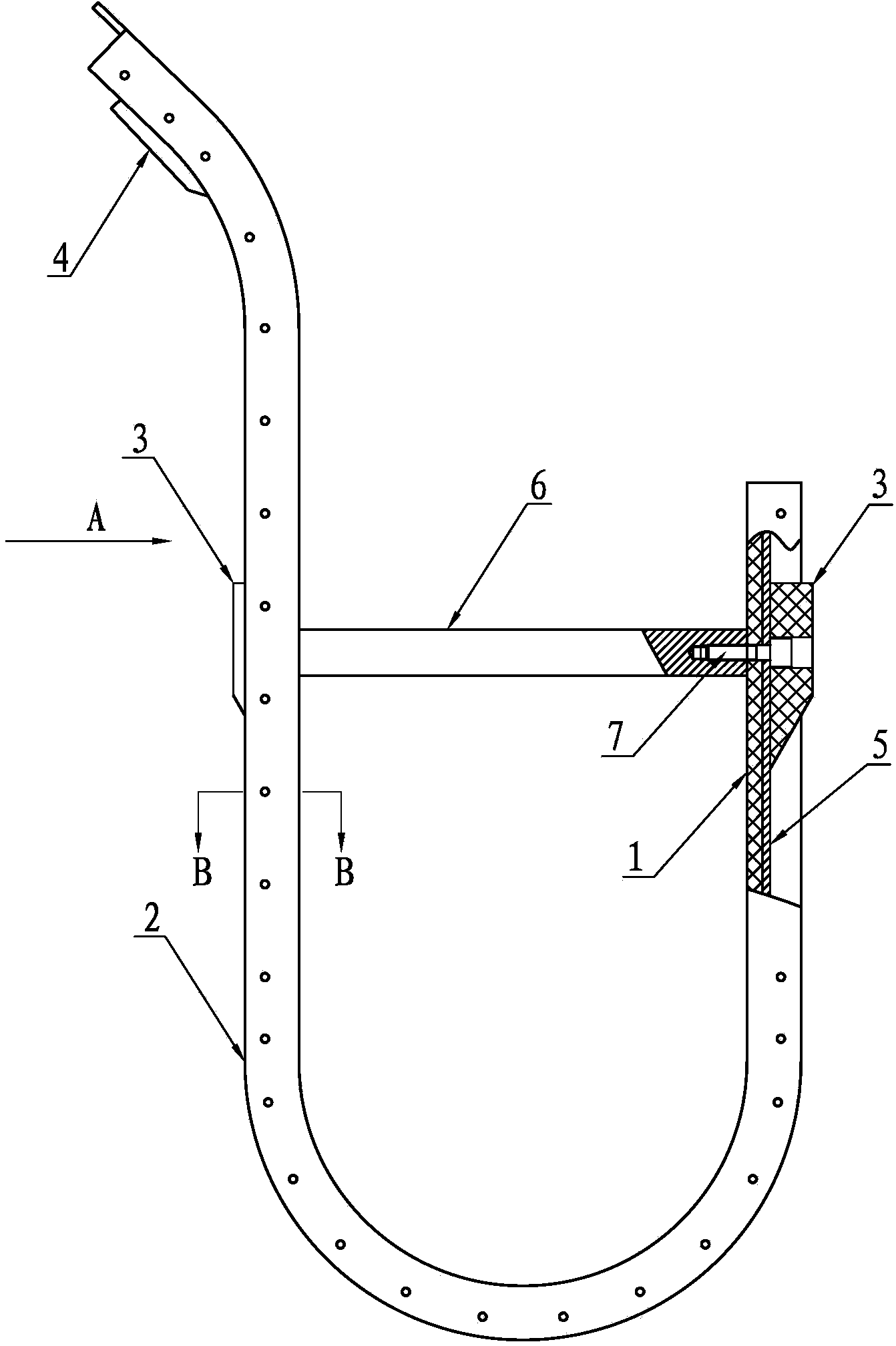

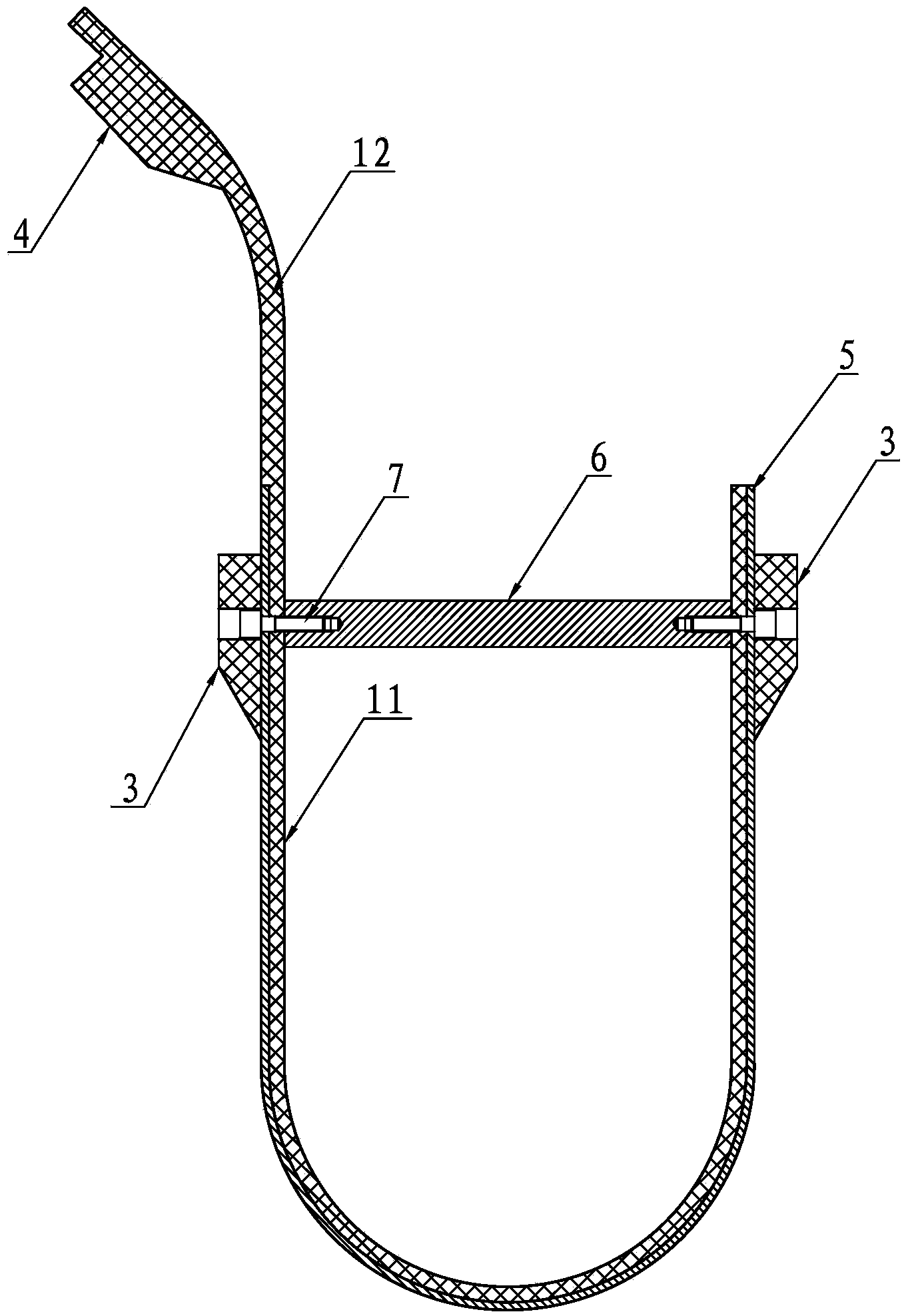

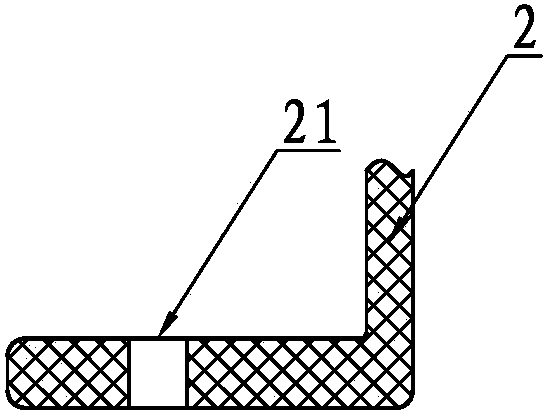

[0021] A kind of multi-functional sump of high water collection cooling tower, such as Figure 1~3 As shown: it is composed of tank body 1, connecting flange 2, notch reinforcing rib 3, protruding reinforcing rib 4, hanging steel belt 5 and transverse suspender 6, and connecting flange 2 is set on the outside of both ends of the tank body 1 There are connecting holes 21 evenly distributed on the connecting flange 2 around the periphery, and the two adjacent water tank bodies 1 are sealed and fixedly connected through the connecting flange 2. The water tank body 1 includes a water collection tank body 11 and an arc-shaped drainage upper side. Plate 12, the water collection tank body 11 is a groove-shaped body with an upper end opening, and its transverse area is U-shaped. The upper end of the side is provided with protruding reinforcing ribs 4 on the outer surface of the arc-shaped drainage upper side plate 12, and horizontally distributed notch reinforcing ribs 3 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com