Drawing process of arc corner connecting rib of metal box shell

A technology of arc corners and metal boxes, applied in metal processing equipment, metal layered products, applications, etc., can solve the problems of difficult demoulding in the molding process, difficult convex lines, easy stretching and easy clamping of molds, etc., to achieve force-bearing The effect of improved ability, convenient demoulding, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

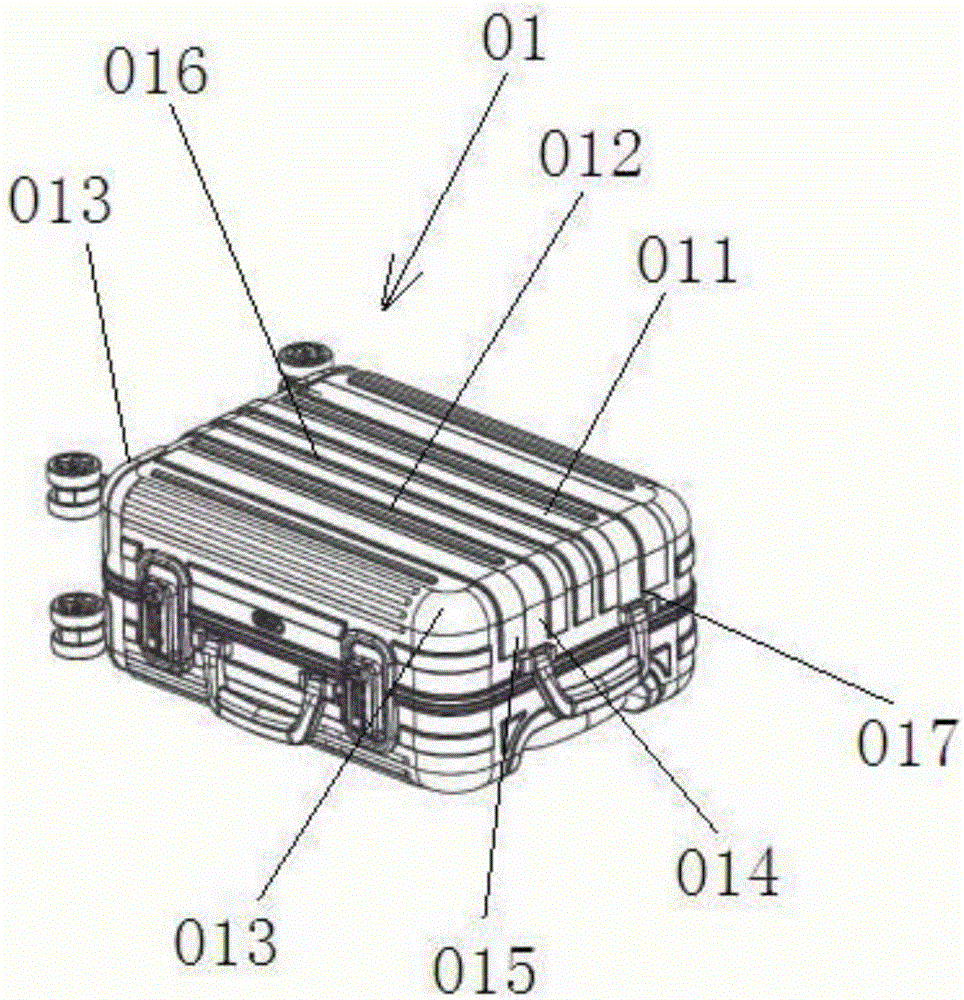

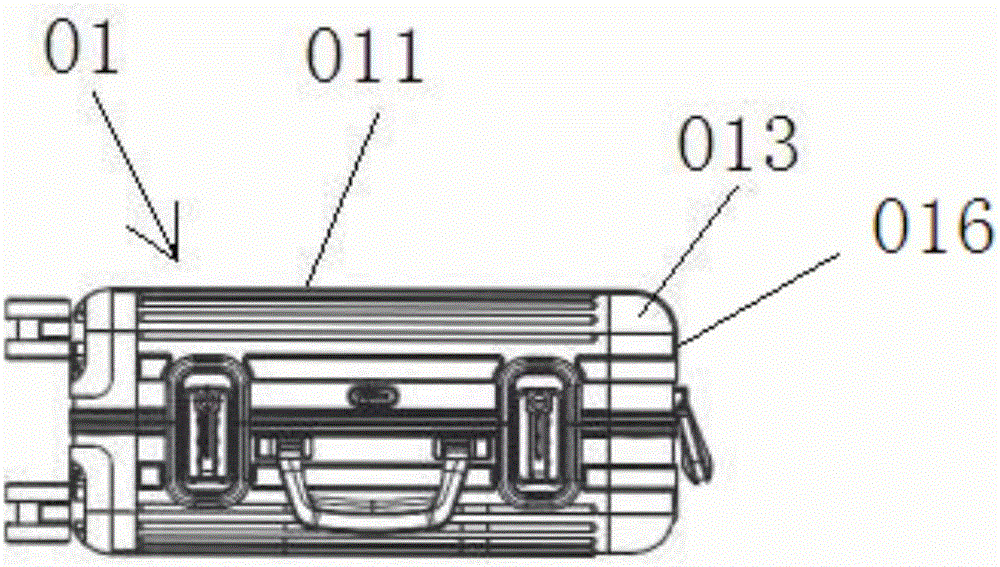

[0015] Attached below figure 1 to attach Figure 4 The present invention is further described.

[0016] refer to Figure 1 to Figure 4 , the stretching process of the arc corner jointing of the metal box shell, including the following steps:

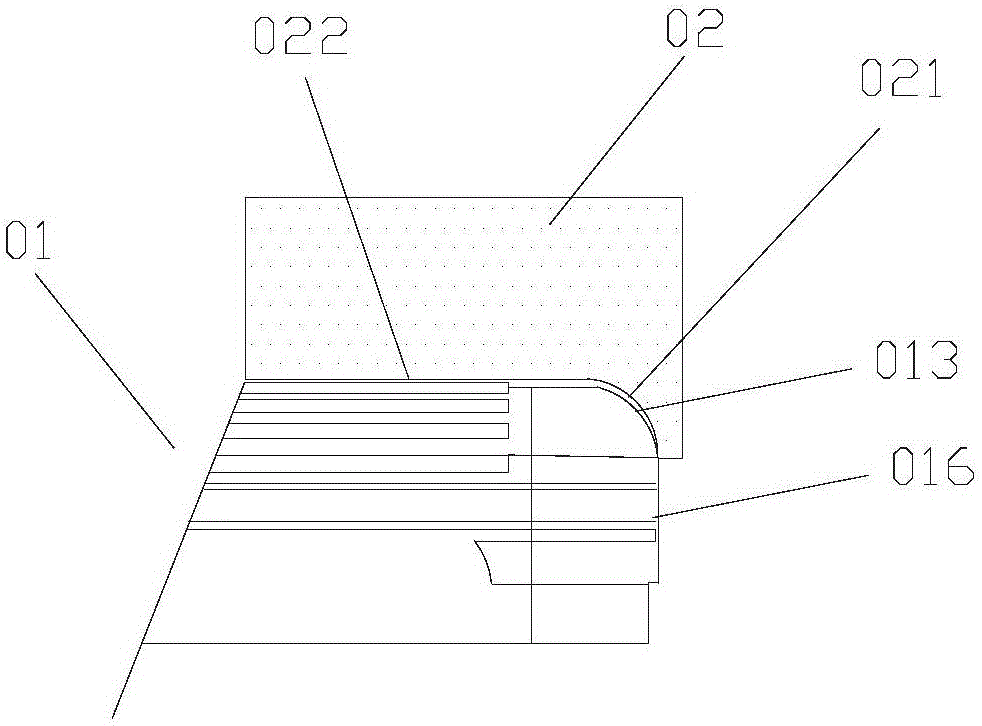

[0017] Prepare the metal rectangular shell 01, the top corner of the metal rectangular shell 01 is the arc corner transition part 013, use the first metal drawing die 02 to stretch the top panel 011 of the metal rectangular shell 01 for the first time, the metal The rectangular shell 01 is copper, copper alloy, aluminum or aluminum alloy shell. Among them, refer to image 3 , the first metal drawing die 02 includes a first arc-shaped groove 021 and a top surface groove 022 connected to the first arc-shaped groove 021, the top panel 011 of the metal rectangular shell 01 is placed at the top surface groove 022, and the side panel A part of 017 is placed at the first arc-shaped groove 021, and the top surface groove 022 is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com