Frame structure of trailer for collecting coal mines

A frame structure, trailer technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of trailer body damage, no overload protection, reduced service life of the trailer, etc., to achieve low cost , simple structure, and the effect of improving the force bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

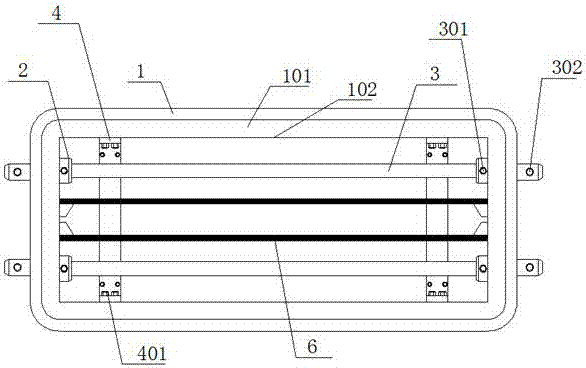

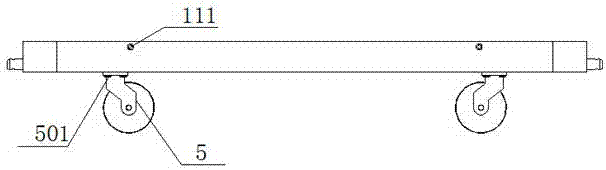

[0016] refer to figure 1 and figure 2 The shown frame structure of a trailer for coal mine collection includes a frame body 1, a vehicle body installation groove 101 is provided on the top of the vehicle frame body 1, and a vehicle body installation groove 101 is provided at the bottom of the vehicle body installation groove 101. Hollow groove 102, four end portions 2 are arranged symmetrically in the hollow groove 102, a traction rod 3 is fitted between the two oppositely disposed end portions 2, and the two ends of the traction rod 3 pass through the The end 2 and the frame body 1, a screw 301 is fitted between the draw bar 3 and the end 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com