Roll-to-roll preparation method of contrast refined film

A bright-room contrast and functional film technology, which is applied to devices, optics, instruments, etc. for coating liquid on the surface, can solve the problems of unsuitable flexible display, high cost of film layers, and difficulty in forming, and achieves easy mass production on a large scale. , Easy to operate, high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

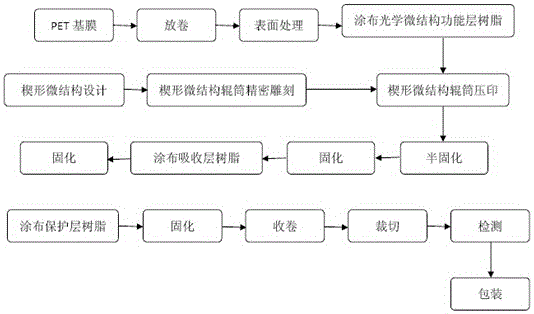

[0018] Such as figure 1 as shown, figure 1 It is a flow chart of the roll-to-roll preparation method of the bright room contrast-enhancing functional film of the present invention. Take the following steps:

[0019] (1) The microstructure is designed and simulated by ray tracing method, the size parameters of the microstructure and the optical characteristic parameters of the material are determined, and a wedge-shaped microstructure arranged in parallel is designed, which is composed of four layers, and the substrate is PET film, sequentially from the substrate upward It is the optical microstructure functional layer, absorbing layer and protective layer;

[0020] ⑵Using precision diamond machining equipment to carve wedge-shaped microstructure rollers with designed structure and size;

[0021] (3) Surface treatment is carried out on the PET base film coil, and then the optical microstructure functional layer resin is precisely coated, and the designed wedge-shaped microst...

Embodiment 1

[0028] ⑴Using the ray tracing method, a new type of bright room contrast-enhancing functional film with a wedge-shaped microstructure is designed, which consists of four layers. The base material is PET film. .

[0029] ⑵ Using precision diamond machining equipment to carve wedge-shaped microstructure rollers.

[0030] (3) The PET base film (thickness 100 μm, light transmittance 91%) is surface-treated, and then precisely coated with 15 μm thick optical microstructure functional layer resin (refractive index 1.35, light transmittance 93%), with a wedge-shaped microstructure The roller imprints the designed parallel wedge-shaped microstructures.

[0031] ⑷First control the light distance to 20cm and the intensity to 200mV / cm 2 , The curing time is 5s, so that the optical microstructure functional layer resin is semi-cured; for the optical microstructure functional layer resin that has been basically formed after demoulding, control the light distance to 20cm and the intensity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com