Ceramic floor drain and manufacturing method thereof

A production method and floor drain technology, applied to clay products, other household utensils, household utensils, etc., can solve the problems of complex production process, difficult processing, high production cost, etc., and achieve simple production process, stable body quality and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0025] A ceramic floor drain, the green body formula is calculated by weight: 97.5% of kaolin powder, 1% of kerosene, 1% of leather oil, and 0.5% of binder.

specific Embodiment 2

[0026] A ceramic floor drain, the green body formula is calculated by weight: 95.7% of kaolin powder, 2% of kerosene, 2% of leather oil, and 0.3% of binder.

specific Embodiment 3

[0027] A ceramic floor drain, the green body formula is calculated by weight: 93.8% of kaolin powder, 3% of kerosene, 3% of leather oil, and 0.2% of binder.

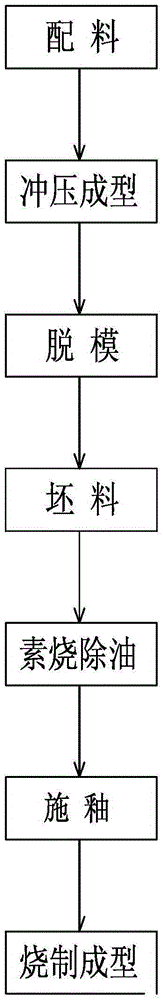

[0028] refer to figure 1 Shown, the manufacture method of the ceramic floor drain shown in specific embodiment one to three, comprises the following steps:

[0029] Step 1, batching, pulverizing and grinding the kaolin and passing through a 350-mesh sieve, kaolin powder, kerosene, leather oil, and binder are stirred in proportion to form granular powder;

[0030] Step 2, stamping molding, put the granular powder obtained in step 1 into the floor drain mold prepared in advance, and stamp it into a floor drain body through 200 tons. The preferred floor drain mold includes an upper mold and a lower mold, and the upper mold and the lower mold are both Made of copper material;

[0031] Step 3, demoulding, the base drain body is removed from the floor drain mold;

[0032] Step 4, biscuit burning to remove oil, put the floor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com