Concrete centrifugal square pile and forming mold thereof

A technology for concrete and square piles, which can be applied to moulds, sheet pile walls, buildings, etc. It can solve the problems of poor sealing of tongue and groove boards, leakage of grout, and product scrapping, and achieve the effect of not easy to leak grout, not easy to damage, and easy to open the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

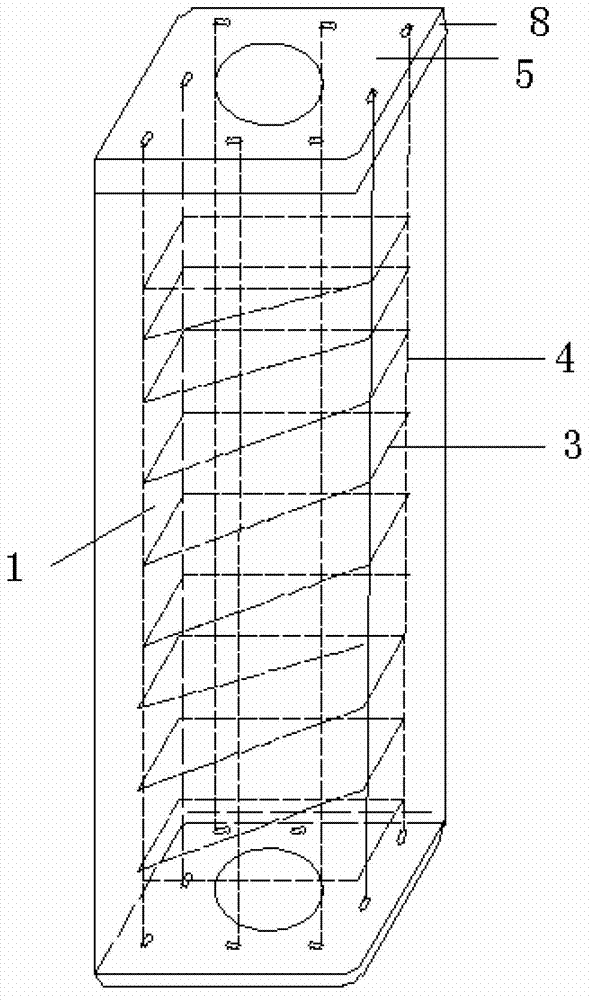

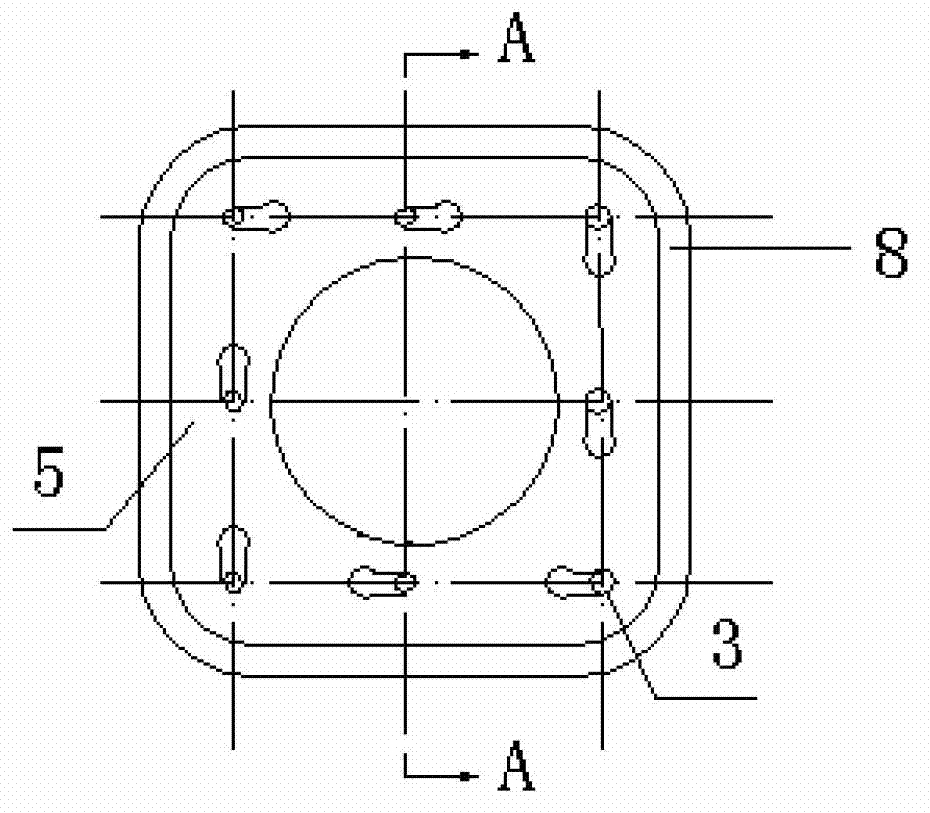

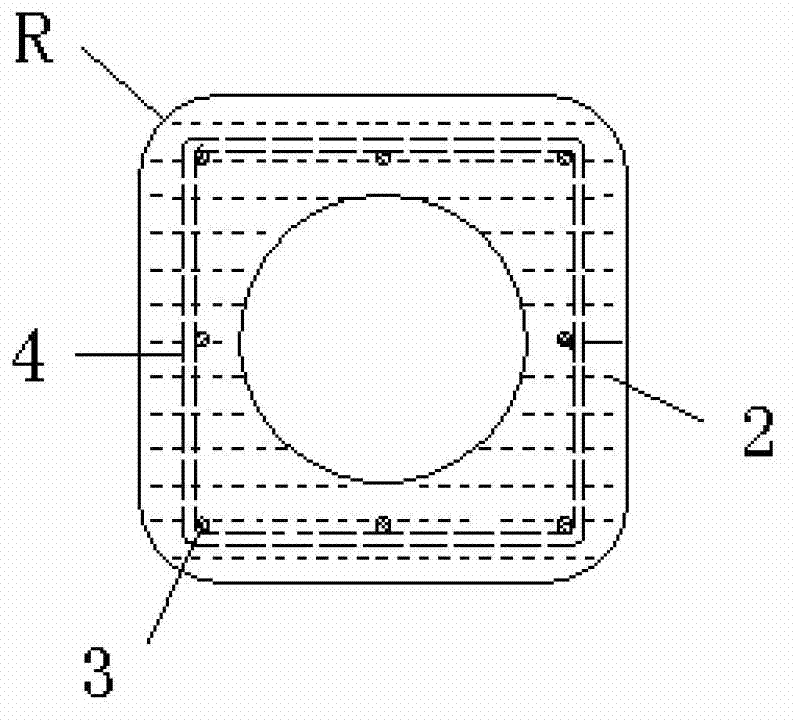

[0021] The concrete centrifugal square pile and its forming mold of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0022] The concrete centrifugal square pile structure of the present invention includes a pile body, the shape of the pile body is square, the pile core is a cylindrical central through hole, and the corners of the four sides of the pile body are in the shape of a stress-relief circular arc, and the radius of the arc is Equal, the pile body includes a reinforcement cage 1, concrete 2, and the reinforcement cage 1 includes a skeleton main reinforcement 3 and a stirrup 4, and the stirrup 4 is welded on the skeleton main reinforcement 3 continuously in a spiral shape, and the pile body Metal end plates 5 connected to the reinforcement cage 1 are provided at both ends of the steel cage; the metal end plates 5 are provided with hoops 7 at the junction of the pile body, and the arc radii R of the corners of the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com