Full-automatic core shooting machine

A core shooting machine, fully automatic technology, applied in the direction of molding machine, casting equipment, metal processing equipment, etc., can solve problems such as large demand for manual operation, poor mold clamping accuracy, affecting core quality, etc., to achieve a degree of automation High, not easy to demould, saving labor and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained and illustrated below in conjunction with the accompanying drawings.

[0025] The automatic core shooter of this embodiment, through the PLC (programmable logic controller) control system, automatically controls the drive motor of each device and the air pressure valve of the air pressure system to complete the operation of the whole machine.

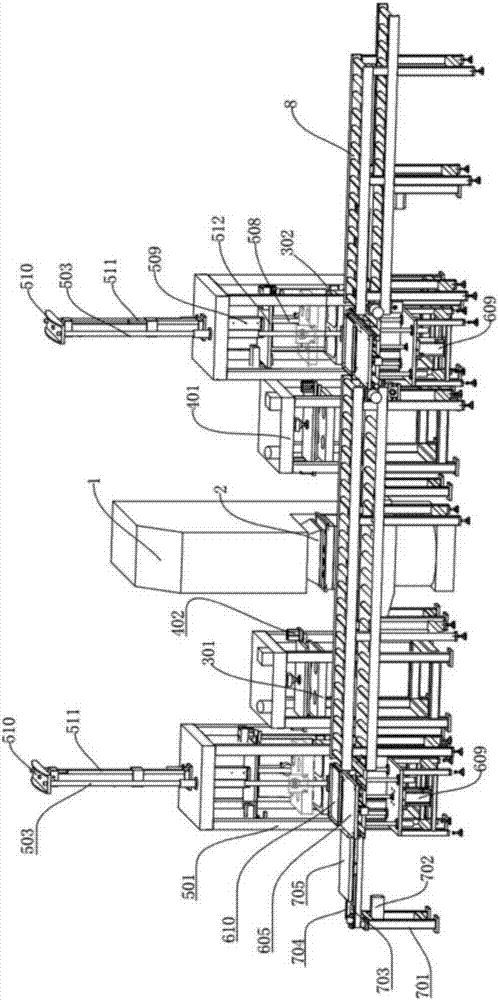

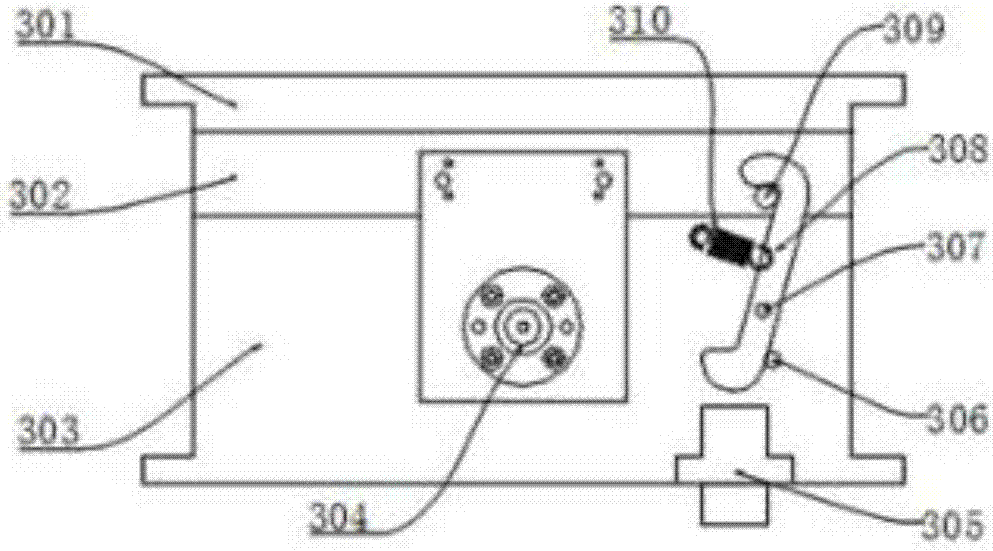

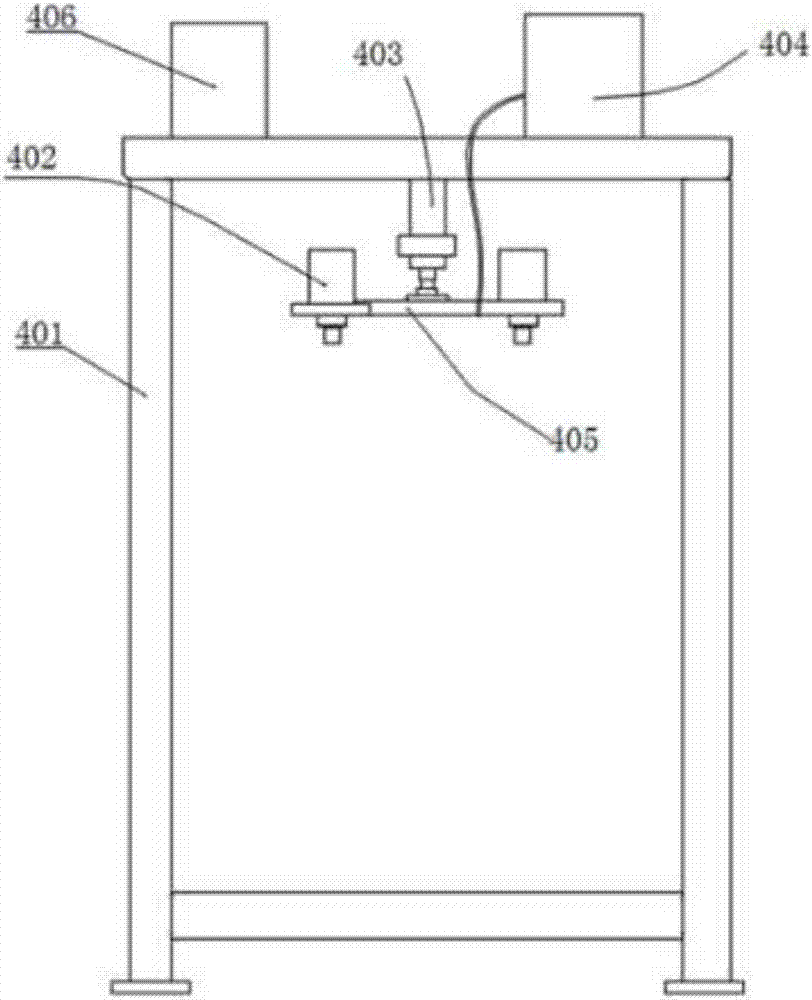

[0026] Such as Figure 1 to Figure 7 The fully automatic core shooting machine shown in this embodiment includes a hopper 11, a mold and a core shooting device 2 for injecting core sand into the mold. The mold is divided into an upper mold 301, a middle mold 302 and a lower mold 303. The mold The opposite sides are provided with a locking mechanism that controls the opening and closing of the middle mold 302 and the lower mold 303; the automatic core shooter also includes: a curing device, which includes a curing frame 401, an air blowing mechanism 404 and a mold splitting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com