Method for preparing toughened large-size ultrathin YAG transparent ceramic biscuit based on Isobam gel system

A transparent ceramic, large-scale technology, applied in the field of advanced ceramics, can solve the problems of difficult demoulding, insufficient toughness, hindering the injection of slurry into the mold, etc., achieving the effect of not easy to crack, ensuring thickness, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

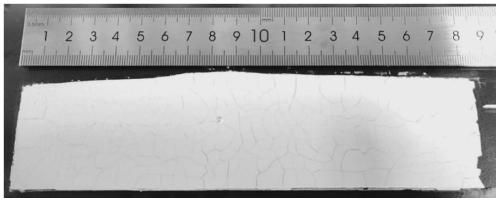

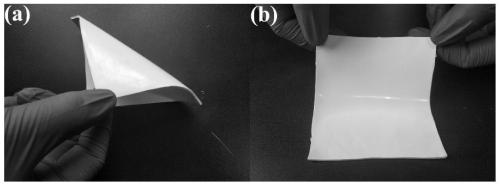

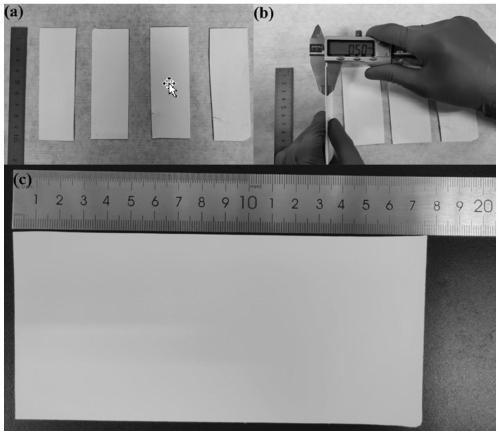

[0025] (1) According to Y 3 al 5 o 12 The stoichiometric ratio of the molecular formula weighs Y at the nanoscale, respectively 2 o 3 Powder 71.324g, Al 2 o 3 The powder is 53.676g. Put the above-mentioned oxide raw material powder into a high-purity alumina ceramic ball mill jar, add 375g of high-purity alumina balls, and add sintering aids MgO and TEOS, dispersant PEI, and absolute ethanol Prepare the slurry; mill it on a planetary ball mill at a speed of 160r / min for 15 hours; dry the obtained mixed slurry A at 60°C for 24 hours and pass it through a 100-mesh sieve for 3 times, and place the sieved powder in a Calcination in a Furnace, the calcination process is from room temperature to 700 ° C, the heating rate is 2 ° C / min, 6 hours of heat preservation, and then naturally cooled to room temperature, the prepared powder is the raw material powder for gel injection molding. Then add deionized water, Isobam104 solution, dispersant ammonium citrate, high-purity alumin...

Embodiment 2

[0030] (1) According to Y 3 al 5 o 12 The stoichiometric ratio of the molecular formula weighs Y at the nanoscale, respectively 2 o 3 Powder 71.324g, Al 2 o 3The powder is 53.676g. Put the above-mentioned oxide raw material powder into a high-purity alumina ceramic ball mill jar, add 125g of high-purity alumina balls, and add sintering aids MgO and TEOS, dispersant PEI, and absolute ethanol Prepare the slurry; mill it on a planetary ball mill at a speed of 120r / min for 24 hours; dry the obtained mixed slurry A at 50°C for 48 hours and pass it through a 100-mesh sieve for 3 times, and place the sieved powder in a Calcination in a Furnace, the calcination process is from room temperature to 900 ° C, the heating rate is 3 ° C / min, 8 hours, and then naturally cooled to 100 ° C, the prepared powder is the raw material powder for gel injection molding. Then add deionized water, Isobam104 solution in the ball mill jar, dispersant is polyethylene glycol, high-purity alumina gr...

Embodiment 3

[0034] (1) According to Y 3 al 5 o 12 The stoichiometric ratio of the molecular formula weighs Y at the nanoscale, respectively 2 o 3 Powder 71.324g, Al 2 o 3 The powder is 53.676g. Put the above-mentioned oxide raw material powder into a high-purity alumina ceramic ball mill jar, add 250g of high-purity alumina balls, and add sintering aids MgO and TEOS, dispersant PEI, and absolute ethanol Prepare the slurry; mill it on a planetary ball mill at a speed of 150r / min for 20 hours; dry the obtained mixed slurry A at 55°C for 36 hours and pass it through a 200-mesh sieve for 3 times, and place the sieved powder in a Calcination in a Furnace, the calcination process is from room temperature to 800°C, the heating rate is 2°C / min, the temperature is kept for 7h, and then the temperature is naturally lowered to 50°C. The powder obtained is the raw material powder for gel injection molding. Then add deionized water, Isobam104 solution, dispersant ammonium polyacrylate, high-puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com