Nickel inner electrode slurry

A technology of internal electrodes and pastes, applied to fixed capacitor electrodes, conductive materials dispersed in non-conductive inorganic materials, laminated capacitors, etc., can solve problems such as cracking, difficult matching, and poor matching of dielectric layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

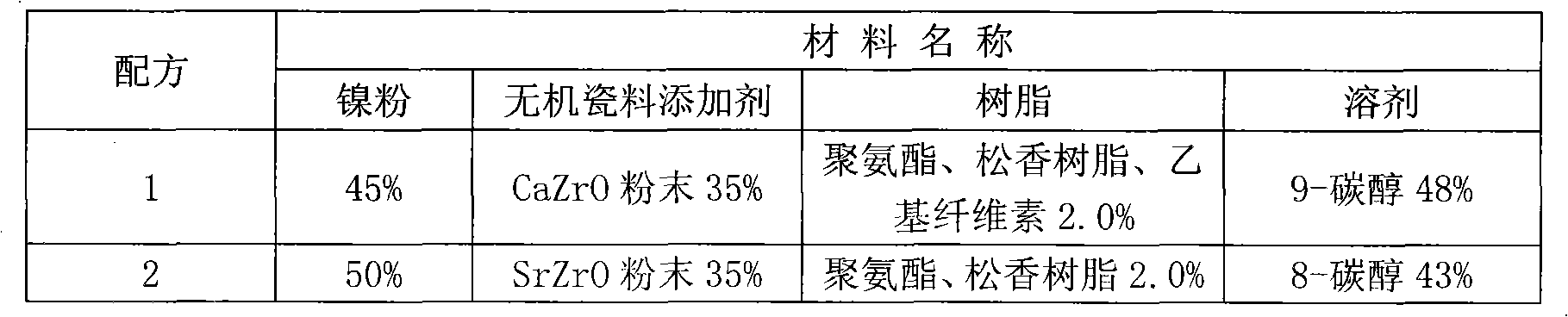

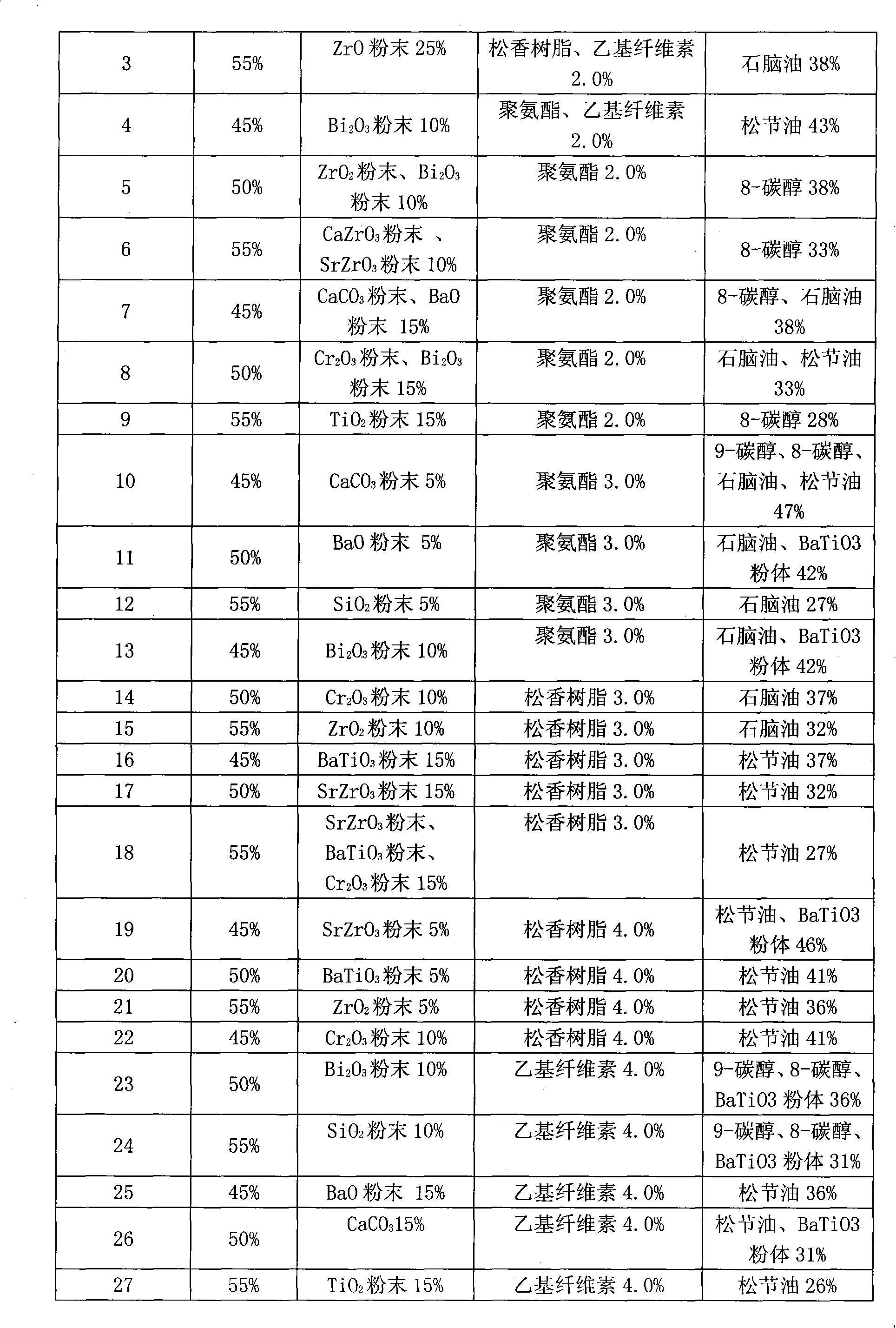

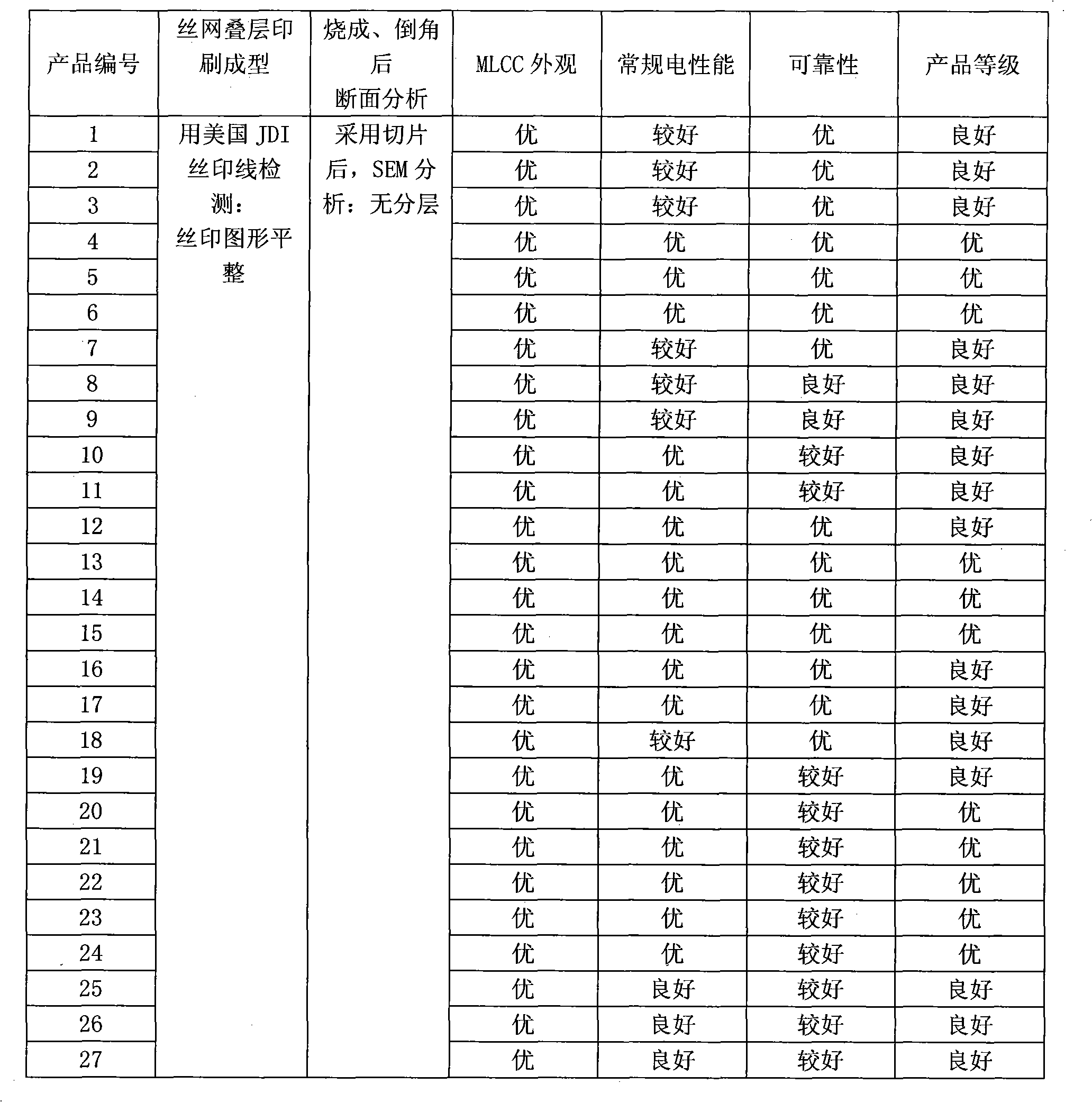

[0009] A kind of nickel internal electrode slurry, its weight percent composition is as the No. 1~27 slurry formula of table 1, according to the usual method of slurry, such as weighing each formula in proportion to carry out batching→stirring→dispersion→rolling→semi-finished product Inspection→slurry mixing→finished product inspection→packing to prepare nickel internal electrode slurry for MLCC, and the particle size of the ultrafine nickel powder is below 1 μm. Described inorganic porcelain material additive is TiO 2 , CaCO 3 , BaO, SiO 2 、 Bi 2 o 3 、Cr 2 o 3 , ZrO 2 , BaTiO 3 , SrZrO 3 , CaZrO 3 One or more of these substances in powder, or all of these substances. The polymer resin is one or two of polyurethane, rosin resin, ethyl cellulose, or all of these substances. The organic solvent is one or more of 9-carbon alcohol, 8-carbon alcohol, naphtha, turpentine or all of these solvents. Also add barium titanate BaTiO as a dispersant in the organic solvent 3 Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com