Moisture regaining method and apparatus for tobacco, Chinese herbal medicine and its products

A technology of Chinese herbal medicine and tobacco, applied in tobacco, tobacco preparation, application, etc., can solve the problems of high cost, affecting the internal quality of materials, loss of aroma, etc., and achieve the effect of soft processing intensity, reasonable design, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

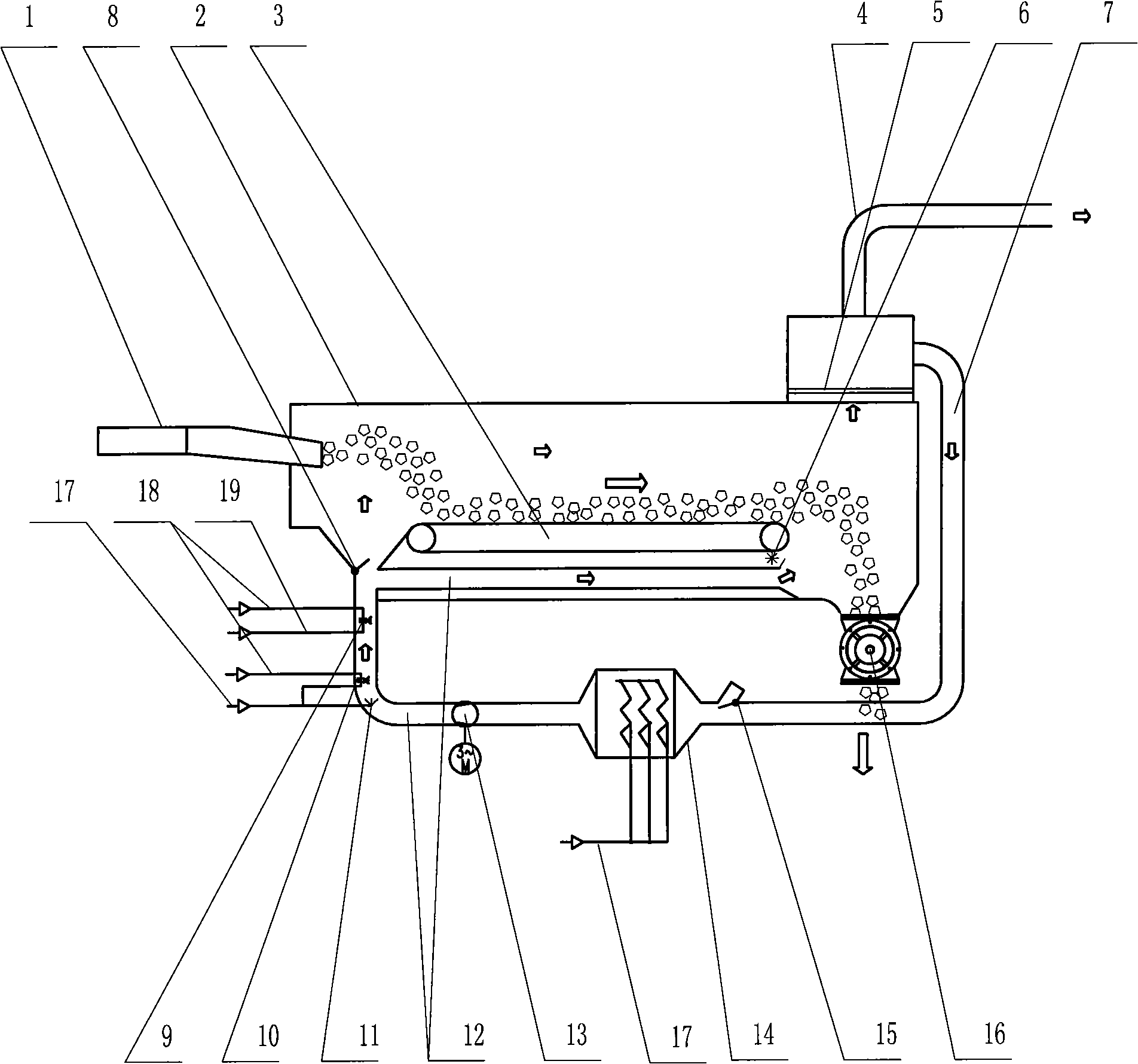

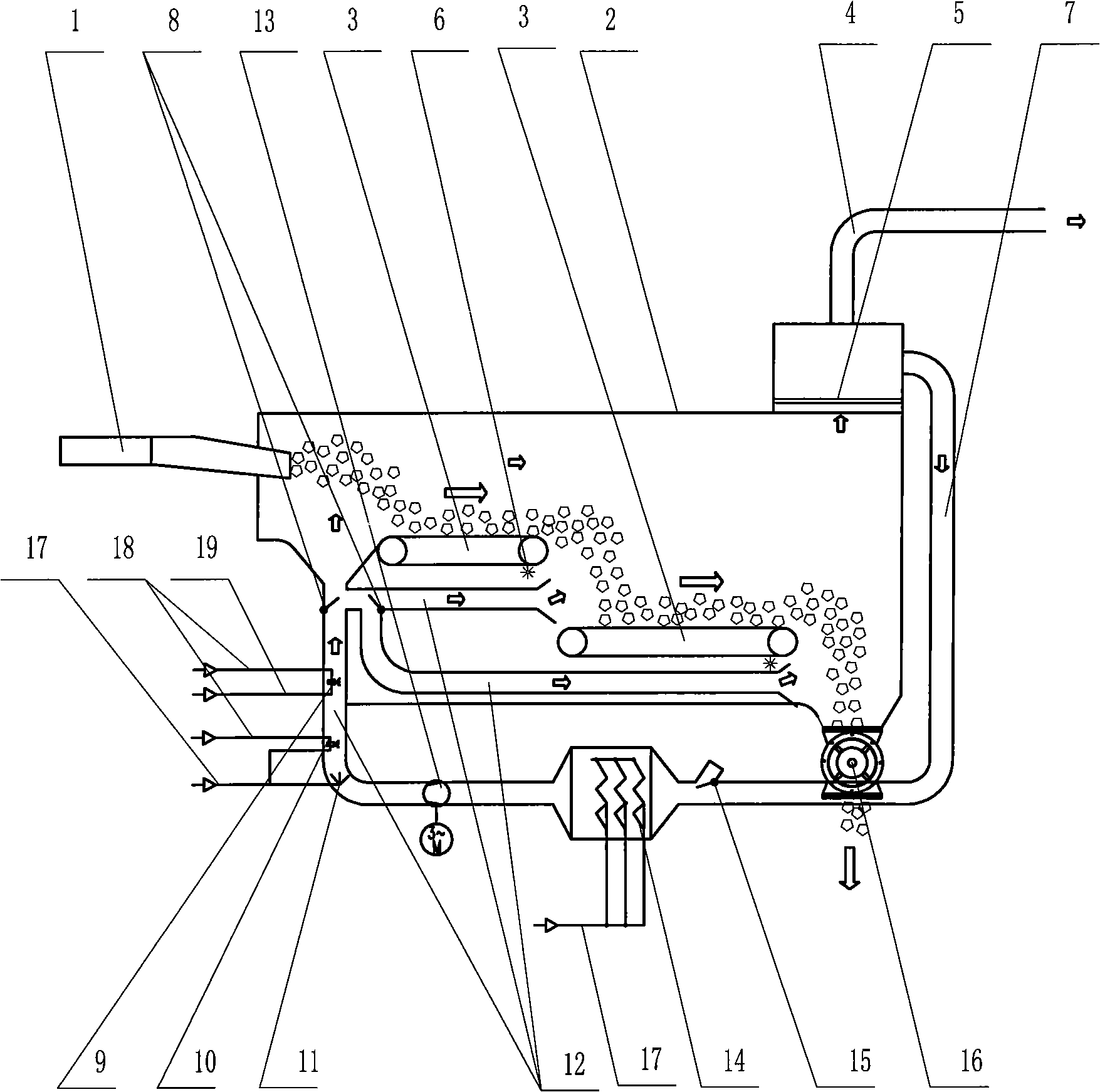

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. Tobacco, Chinese herbal medicine, and products in the present invention refer to herbal materials such as tobacco, Chinese herbal medicine, and products, etc., where "products" refer to materials in the semi-finished state of tobacco and Chinese herbal medicine raw materials processed in the production process .

[0019] The principle adopted by the method of the present invention is different from the material regaining method adopted in the prior art. It is not only suitable for the regaining of high-grade materials without causing changes in the color of the materials and the internal quality of the materials, but also suitable for small batches of single products It can also carry out continuous production of changing varieties. The method of the present invention overcomes the disadvantages of the prior art method an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com