Light-coloured high temperature resistant organic silicone adhesive/sealant

A technology of organic silica gel and high temperature resistance, which is applied in the direction of adhesives, other chemical processes, chemical instruments and methods, etc., and can solve problems such as decreased elasticity, decreased manufacturability, unfavorable adhesive/sealant application and construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

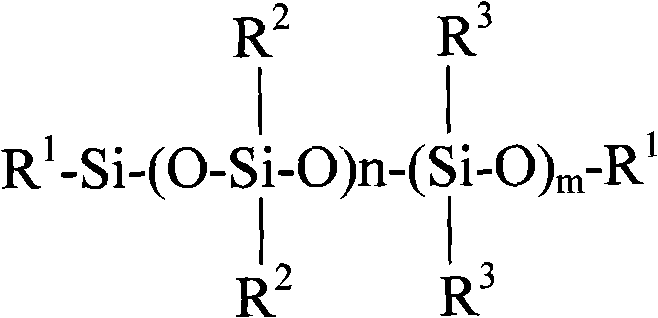

Method used

Image

Examples

Embodiment 1

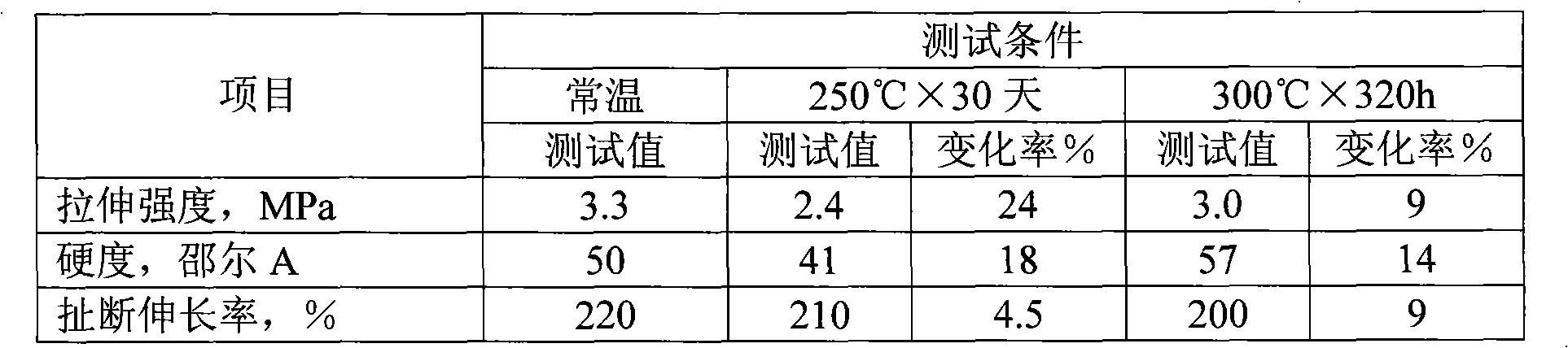

[0036] Get 100g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5,000cp, add 20g of hexamethyldisilazane-treated fumed silica, 0.5g of fumed titanium dioxide, and 100g of Al 2 o 3 , stir evenly in a stirred tank, vacuum dehydrate at 150°C, cool to 60°C, add 7g of methyltrimethoxysilane, stir for 30min, add 1.5g of isopropyl titanate, stir for 50min, and press the rubber mixture Form a test piece of 50mm×50mm×2mm, and measure its mechanical properties at room temperature and high temperature, and the results are shown in Table 2. The adhesive / sealant material skins on the surface within 1 hour at 25°C and loses its viscosity, and the curing depth reaches 3mm in 24 hours: the vulcanization speed can be increased by heating, for example, the curing depth can be achieved after 4 hours at 200°C. up to 3mm.

Embodiment 2

[0038] Get 100g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5,000cp, add 20g of hexamethyldisilazane-treated fumed silica, 2g of fumed titanium dioxide, and 100g of Al 2 o 3 , stirred evenly in a stirred tank, vacuum dehydrated at 150°C, cooled to 60°C, added 7g of phenyltrimethoxysilane, stirred for 30min, added 1.5g of isopropyl titanate, stirred for 50min, and pressed the rubber mixture Form a test piece of 50mm×50mm×2mm, and measure its mechanical properties at room temperature and high temperature, and the results are shown in Table 2. The adhesive / sealant material skins on the surface within 1 hour at 25°C, loses its viscosity, and the curing depth reaches 3mm in 24 hours; the vulcanization speed can be increased by heating, such as heating at 200°C for 4 hours, the curing depth can reach 3mm .

Embodiment 3

[0040] Get 100g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 7,000cp, add 20g of hexamethyldisilazane-treated fumed white carbon black, 1.5g of fumed titanium dioxide, 60gAl 2 o 3 , stirred evenly in a stirred tank, vacuum dehydrated at 150°C, cooled to 60°C, added 7g of phenyltrimethoxysilane, stirred for 30min, added 1.5g of isopropyl titanate, stirred for 50min, and pressed the rubber mixture Form a test piece of 50mm×50mm×2mm, and measure its mechanical properties at room temperature and high temperature, and the results are shown in Table 2. The adhesive / sealant material skins on the surface within 1 hour at 25°C, loses its viscosity, and the curing depth reaches 3mm in 24 hours; the vulcanization speed can be increased by heating, such as heating at 200°C for 4 hours, the curing depth can reach 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com