Sludge incineration method

A sludge incineration and sludge technology, applied in the combustion method, incinerator, combustion type and other directions, can solve the problems of complex equipment, large investment, expensive operation cost, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

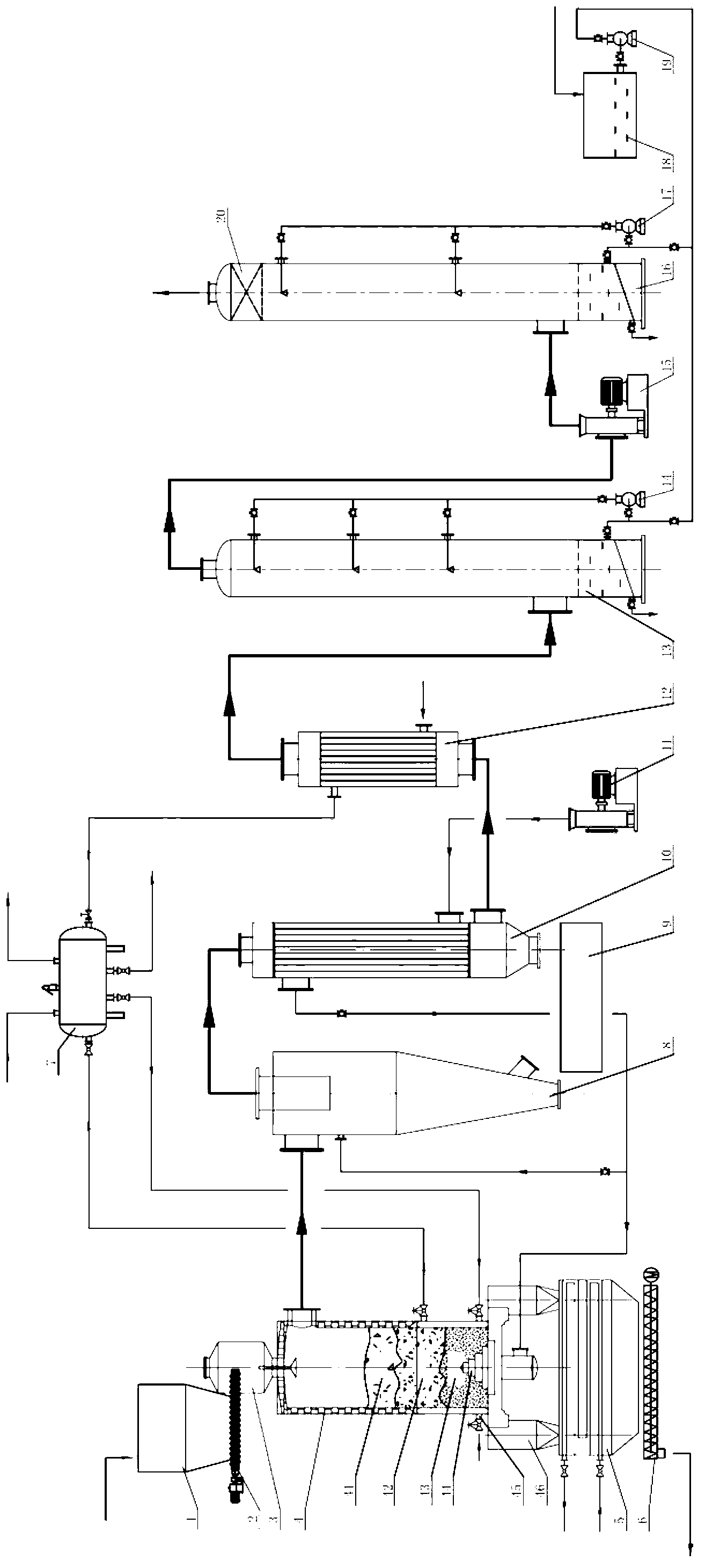

Image

Examples

Embodiment 1

[0029] After crushing the dry sludge into lump dry sludge with a diameter of 4-6cm, the sludge is transported from the sludge silo 1 to the sludge distributor 3 through the screw conveyor 2, and the sludge is distributed by the incinerator 4 Top evenly into incinerator 4.

[0030] The sludge moves from top to bottom in the incinerator 4, and under the action of bottom-up high-temperature flue gas flow and radiant heat, it completes the processes of heating, drying, pyrolysis, and combustion in sequence.

[0031] Start the grate machine 44 at the bottom of the incinerator 4 to make the mud layer move slowly, and the airflow produced by the high-pressure blower 11 disturbs the sludge from the bottom of the incinerator 4 and constantly renews the combustion surface, while controlling the residence time of the sludge in the furnace to exceed 1 hour. The sludge is fully burned, and the dry sludge is burnt with the good cooperation of the primary air inlet system.

[0032] The burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com