Vertical sedimentation centrifuge

A decanting centrifuge, vertical technology, applied in the field of centrifuges, can solve the problems of heavy cover plate burden, power consumption, complex structure of centrifuges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

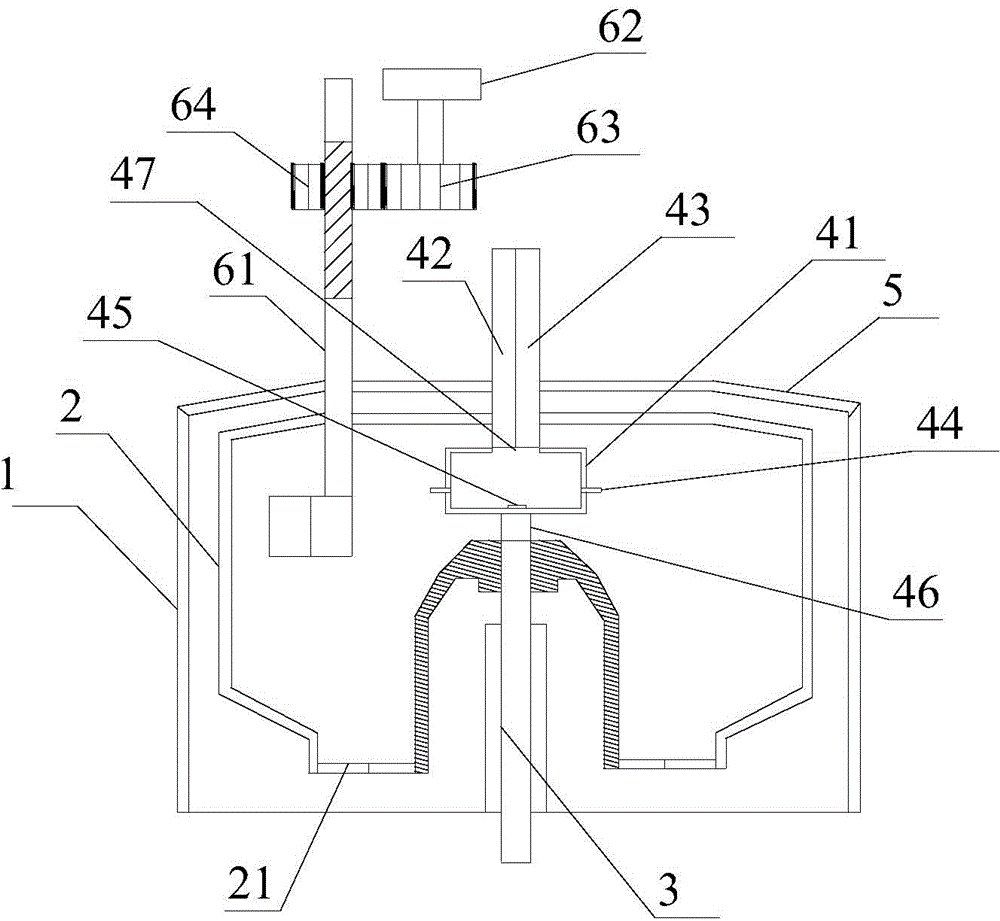

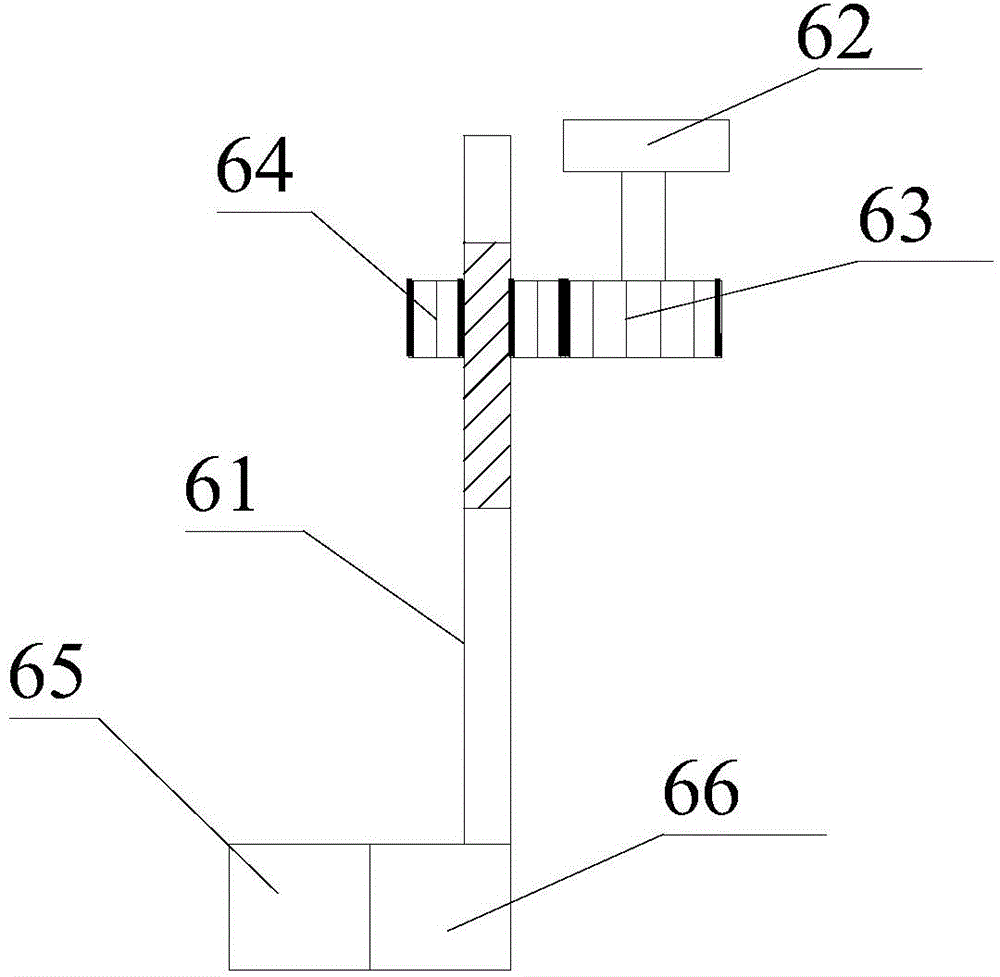

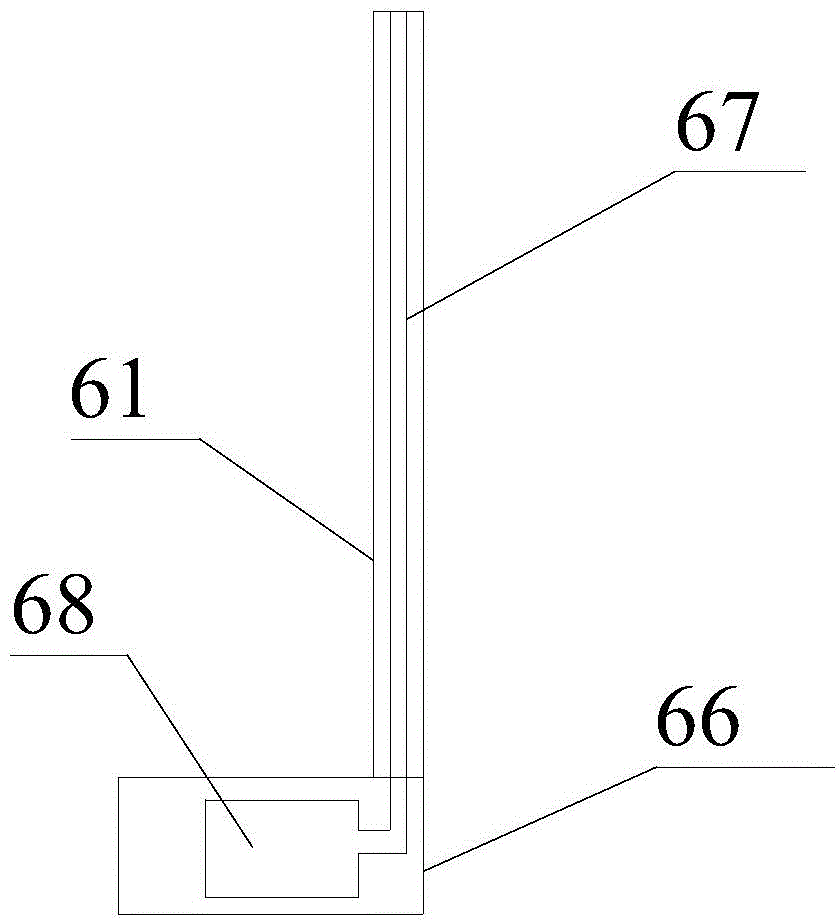

[0019] refer to figure 1 , the present invention proposes a vertical sedimentation centrifuge, comprising a casing 1, a main shaft 3, a drum 2 sleeved on the main shaft 3, a machine cover 5 fixed on the top of the casing 1, a controller, a feeding device, A scraper mechanism for removing solid-phase materials in drum 2, wherein:

[0020] The bottom of the drum 2 is provided with a discharge port, and the discharge port is provided with a split-type movable door 21, and screen holes are distributed on the movable door 21, and the movable door 21 is connected with the controller. During the rotation of the centrifuge, the residual liquid is discharged out of the drum 2 through the discharge port. The residual liquid may take away part of the solids. A movable door 21 with a sieve hole is arranged at the discharge port to remove the residual liquid. The solid mixed in the residual liquid is filtered out, and after the residual liquid is processed, the controller controls the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com