Automatic material distributing and vibrating system for concrete bridge deck slab and control method thereof

A technology for automatic distribution and bridge decks, which is applied in electrical program control, program control in sequence/logic controllers, bridges, etc. It can solve the problem that the pouring technology cannot meet the requirements of steel fiber and aggregate distribution uniformity, vibration, The problems such as the inability to quickly realize the maintenance of leveling and mulching, and the influence of environmental changes on the bridge deck can reduce the waiting time for construction, speed up the maintenance in the later stage, and ensure the effect of vibrating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

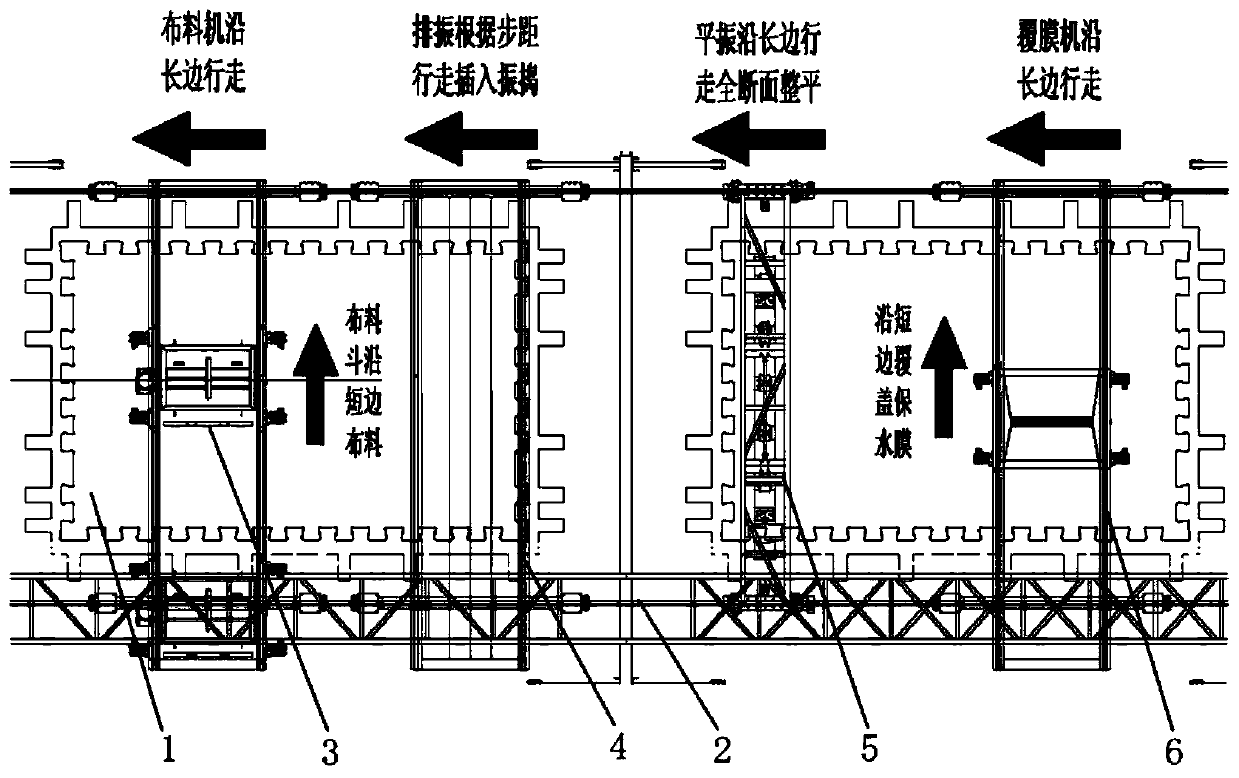

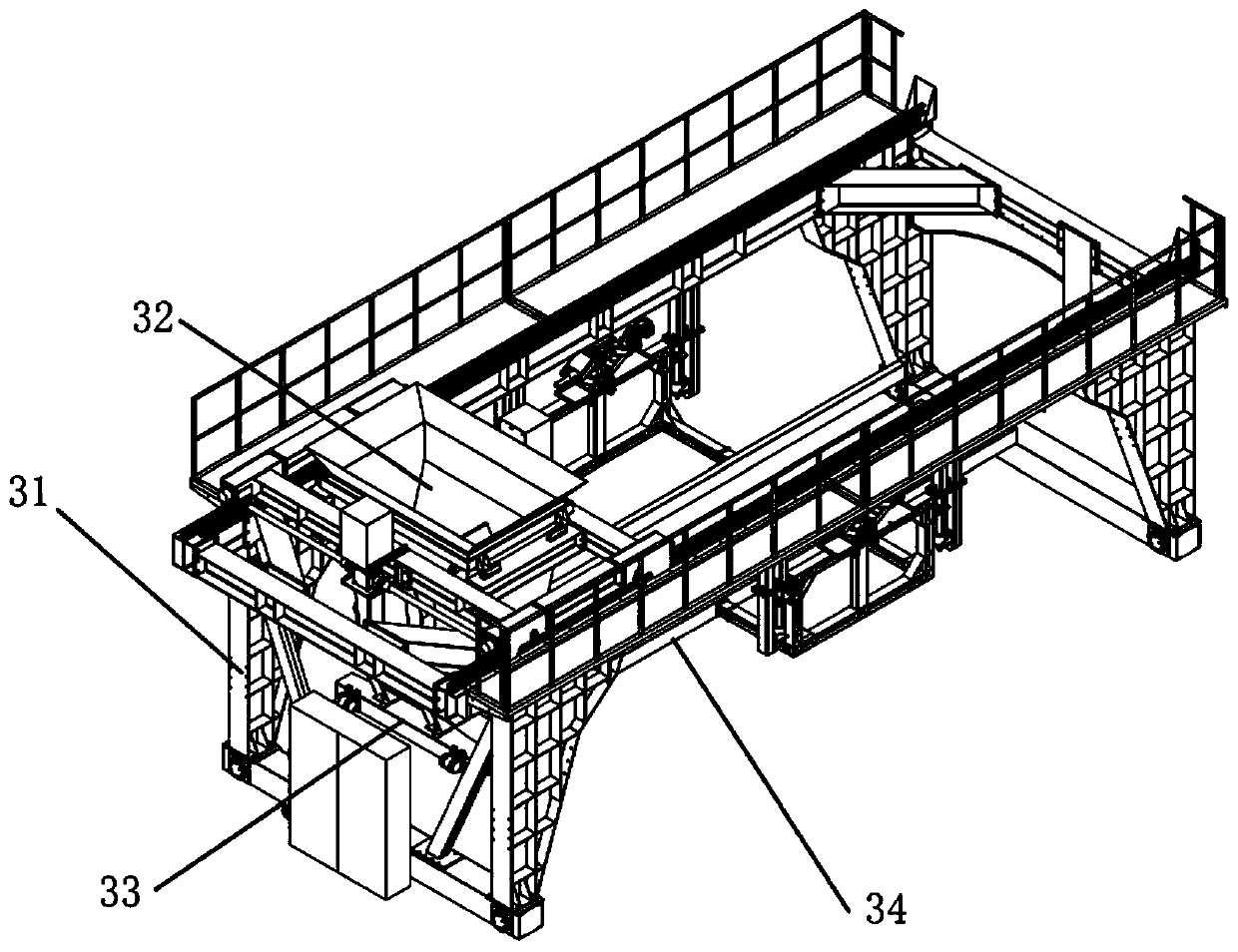

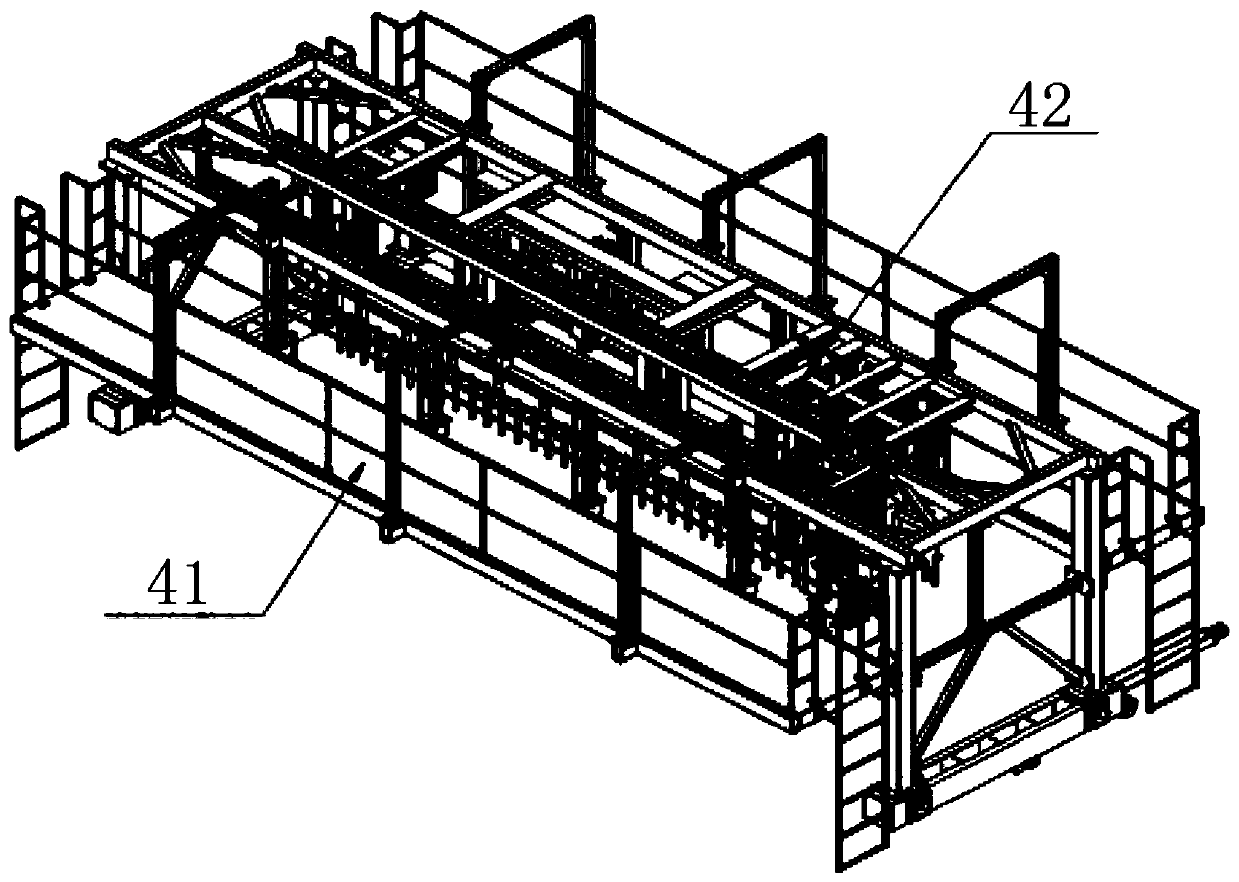

[0032] like Figure 1-6As shown, the present invention provides an automatic distribution and vibration system for a concrete bridge deck, including a track 2, a distribution machine 3, an array type vibration machine 4, a flat plate vibration and leveling machine 5, a rolling and laminating machine and a control system , the control system respectively controls the distributing machine 3, the array vibrator 4, the flat vibrator leveler 5 and the rolling and laminating machine, and the track 2 is arranged along the long side of the mold 1, located at On both sides of the mold 1, the distributing machine 3 includes a traveling vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com