Method for pressing porous brick by using porous brick mould and porous brick mould

A technique for porous bricks and molds, which is applied in the field of porous brick molds for pressing porous bricks and porous brick molds. It can solve the problems of brick adobe stability cannot be guaranteed, mold operation is difficult to run smoothly, and brick adobe quality is unstable, so as to achieve high density and improve use. Lifespan, the effect of eliminating jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for pressing porous bricks with a porous brick mold, the specific steps are: 1. Ready state: the upper mold of the porous brick mold is raised to the upper limit point, and the middle frame is lowered to be flush with the lower mold core. 2. The middle frame is raised to a height of 80mm, and the feeding cart advances to fabricate, and the vibration motor starts to work at the same time. 3. The middle frame continues to lift to the set height of the material, the vibration motor stops working, the material is finished, and the material cart moves back to the rear limit point. 4. The upper mold descends. When the upper mold limit rod touches the middle frame, the middle frame uses the upper mold limit rod to descend together with the upper mold to produce a follow-up movement. 5. The upper mold continues to descend to the set point, and the brick is pressed and ready to be demoulded. 6. The middle frame descends to the pre-stripping point. At this time, the upp...

Embodiment 2

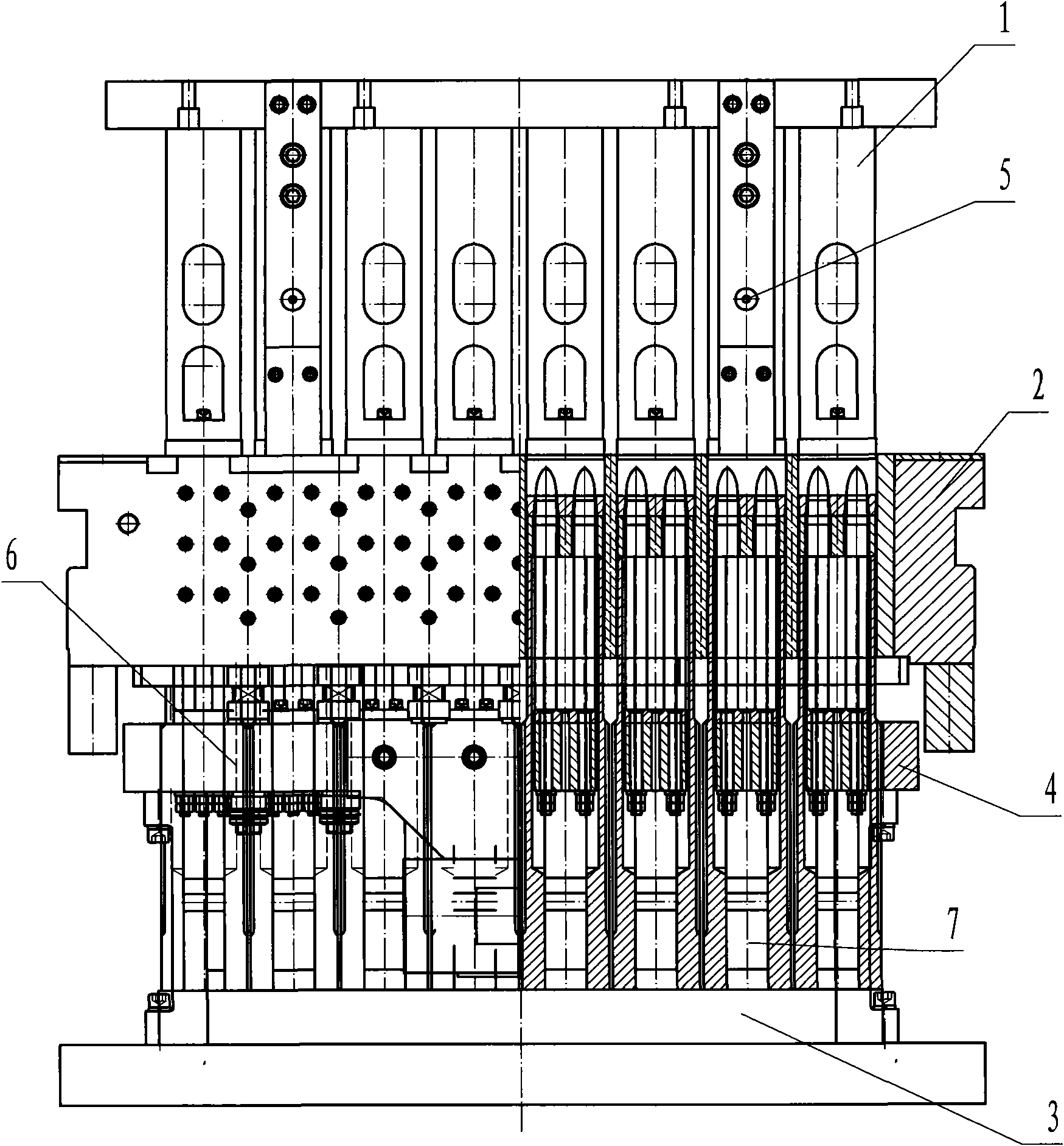

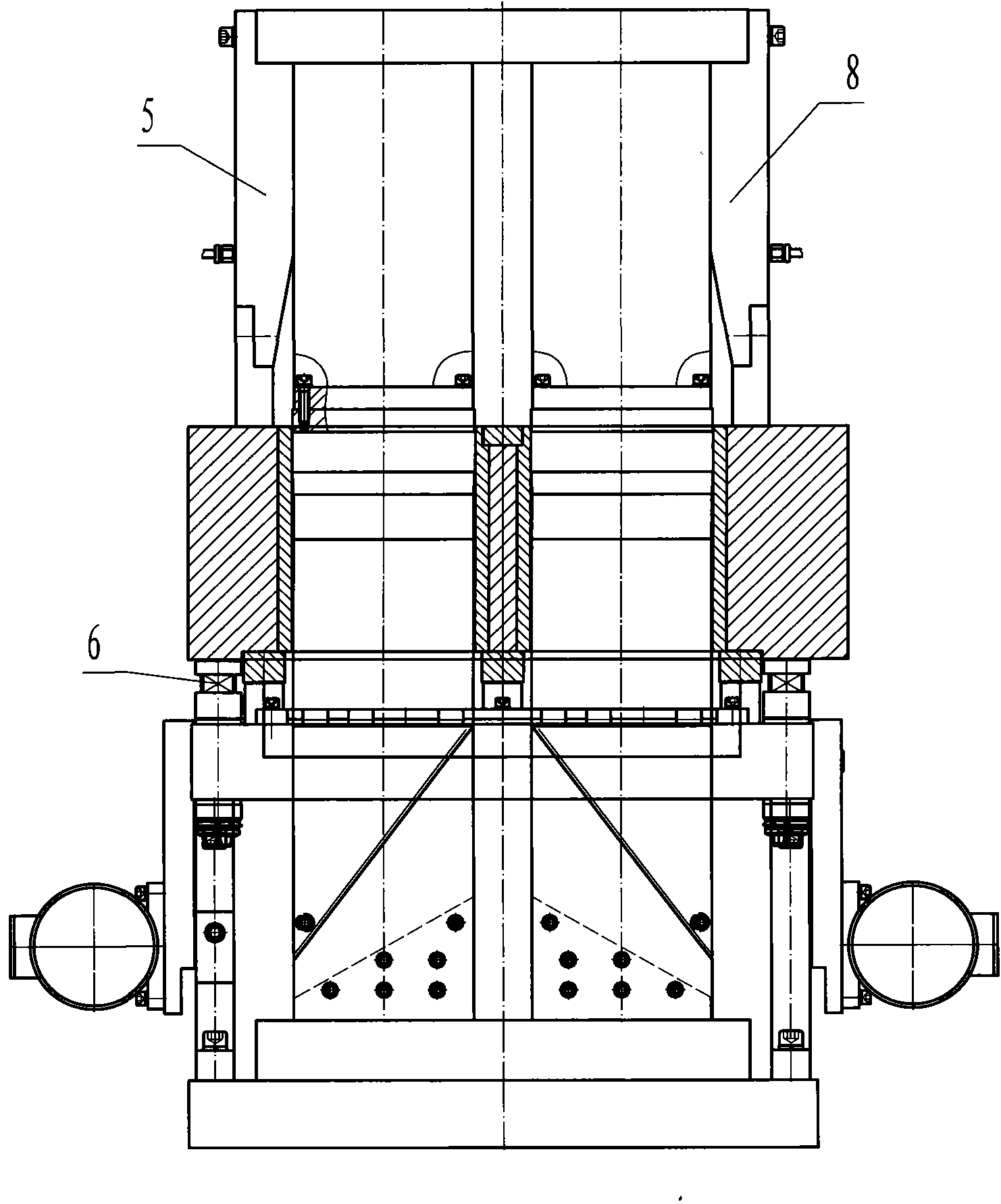

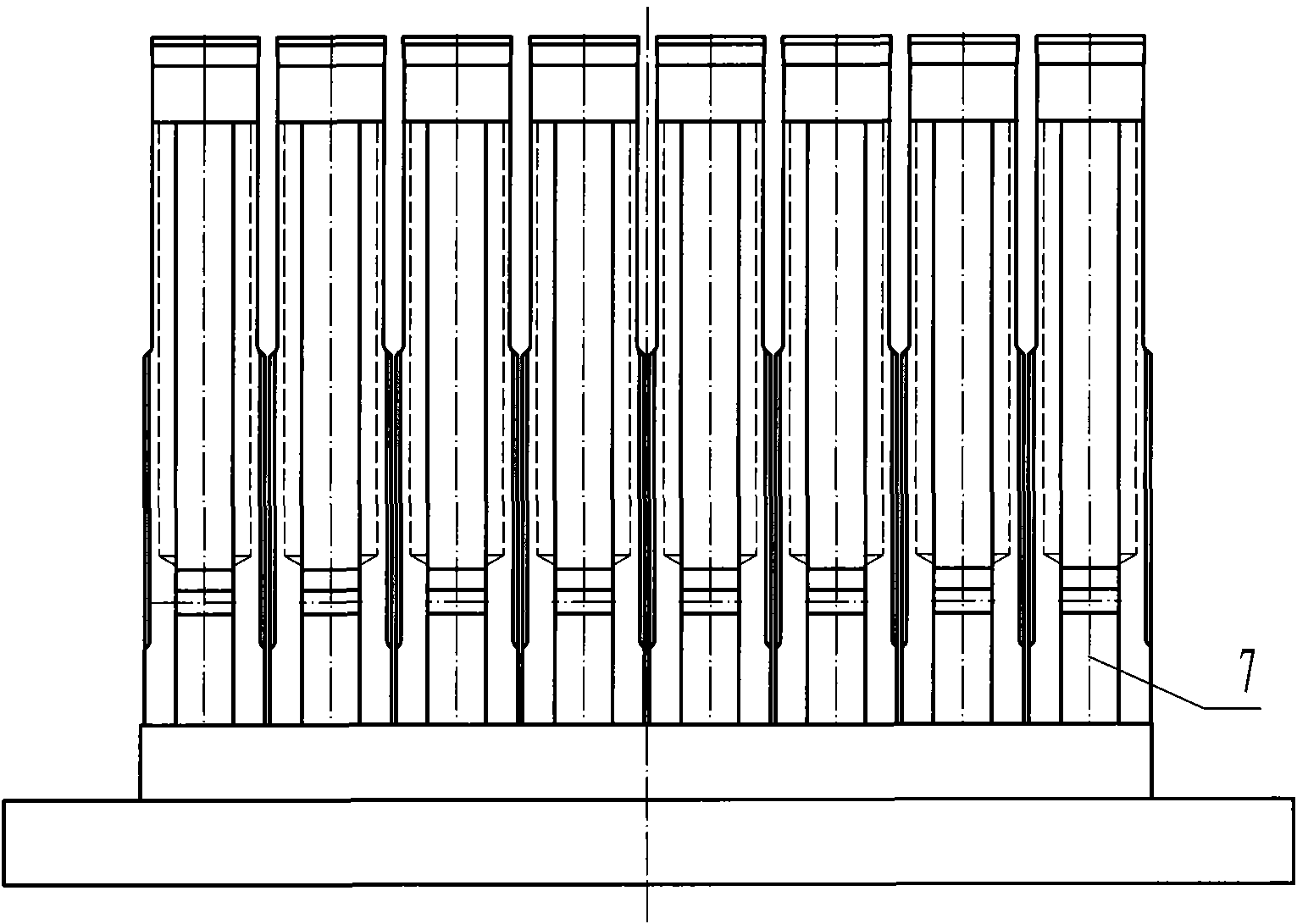

[0039] a kind of like Figure 1-4 The porous brick mold shown includes an upper mold 1 , a middle frame 2 , a lower mold 3 , a core rod part 4 and a linkage device 5 . The core rod part includes a core rod and a cantilever beam. The middle frame is connected with the core rod part through the connecting rod 6 . The connecting rod is arranged between the middle frame and the cantilever beam. The linkage device is a limit rod. Four sidewalls of patrix are all provided with limit rods 8, and each side is provided with two limit rods, and the limit rods on the opposite sides of patrix are relatively arranged. Described limit bar protrudes from the side of upper die, and the distance between the upper die side and the upper die is greater than the gap between the upper die side and the middle frame on the limit bar. The connection between the limit rod and the upper die is a detachable threaded movable connection. The whole limit rod is stepped. The rib plate 7 at the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com