Uniform feeding device for candy ovenware

A technology of feeding device and baking pan, which is applied in the direction of transportation and packaging, conveyors, vibrating conveyors, etc., can solve the problems of laborious and time-consuming work, low work efficiency, etc., and achieve simple transmission mode, convenient connection, and good vibration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

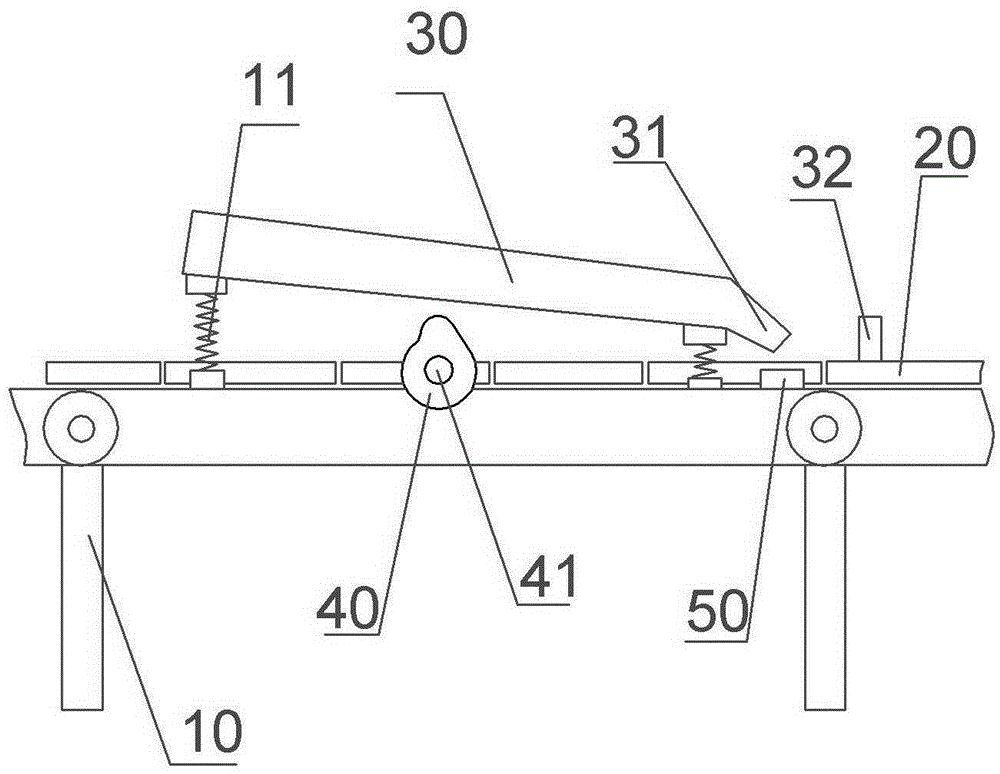

[0011] The reference numerals in the drawings of the specification include: a support 10 , a baking pan 20 , a vibrating pan 30 , an outlet 31 , a baffle 32 , a cam 40 , a vibrating motor 41 , and a weight sensor 50 .

[0012] The embodiment is basically as attached figure 1 Shown: a candy baking pan uniform feeding device, including a support 10, a vibrating plate 30, a conveyor belt, a controller, a transmission motor and a baking pan 20. The transmission motor is a servo motor that can better control the speed of the conveyor belt and can be started frequently. Compared with ordinary motors, it has a longer service life. The servo motor is connected to the conveyor belt, the conveyor belt is set on the bracket 10, the vibration motor 41 is connected to the bracket 10 by bolts, the output end of the vibration motor 41 is connected to the cam 40 through a shaft coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com