Earthworm bioreactor and organic waste treatment method

A bioreactor and organic waste technology, applied in the direction of organic fertilizer, solid waste removal, application, etc., can solve the problems of not being able to effectively simulate the optimal production and multiplication mode of earthworms, and not setting pH and gas detailed control devices, etc., to achieve The effect of high efficiency of earthworm production and multiplication and uniform cloth distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

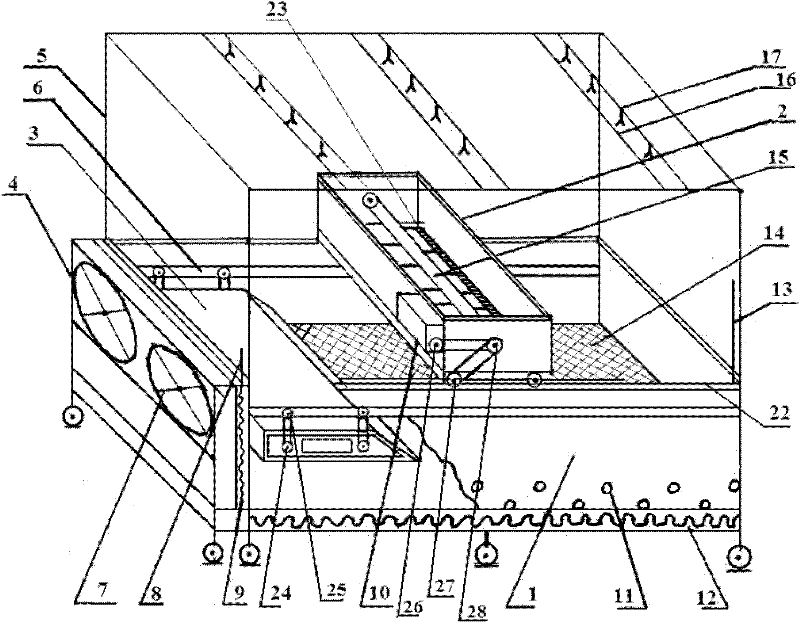

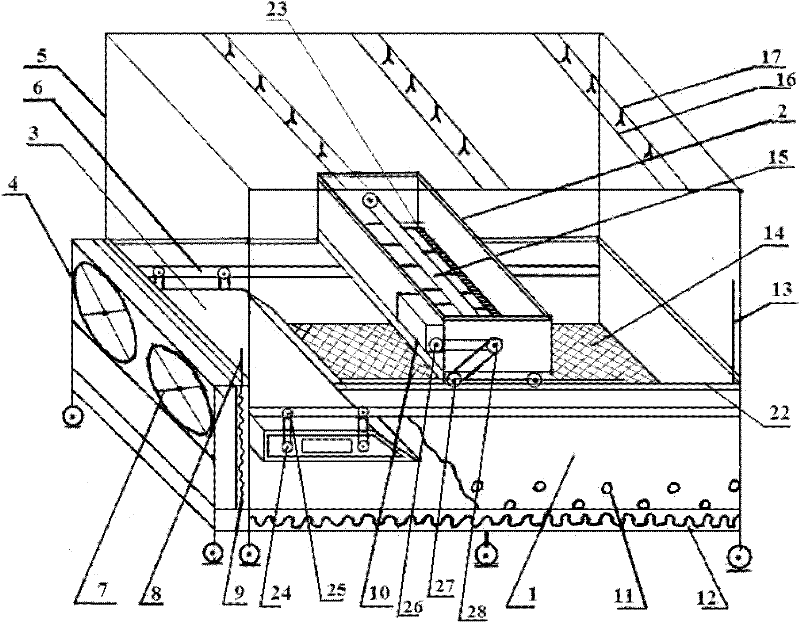

[0032] Such as figure 1 As shown, the earthworm bioreactor includes a reactor box 1 with an upper opening, an organic waste distributing device, a vermicompost output device, a forced ventilation system 4, a telescopic frame 5 and a lighting device 17, and the reactor box 1 is opened upwards. The casing; the telescopic frame 5 is connected above the reactor casing 1, the lighting device 17 is arranged above the reactor casing 1, and is fixed on the telescopic frame 5; the reactor casing 1 both sides Two distributing wheel rails 22 are respectively connected to the upper edge, and the organic waste distributing device is slidably connected to the distributing wheel rails 22; two vermicompost output wheel rails 6 are arranged inside the reactor box 1, each vermicompost The two ends of the output wheel rail 6 are fixed on the inner wall of the reactor box 1, and the vermicompost output device is slidably connected with the vermicompost output wheel rail 6, and the side of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com