Optimum design method for staged fracturing perforation cluster parameters of horizontal well of shale reservoir

A staged fracturing and shale reservoir technology, applied in calculation, earthwork drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the drawings, but the protection scope of the present invention is not limited to the following.

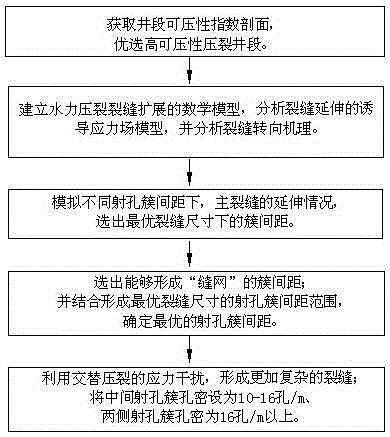

[0053] Such as figure 1 As shown, a shale reservoir horizontal well staged fracturing perforation cluster parameter optimization design method, which includes the following steps:

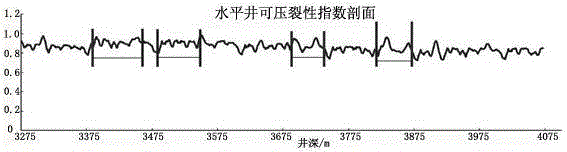

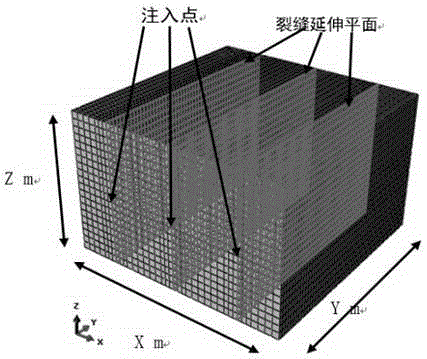

[0054] S1. Use reservoir rock mechanics parameters and mineral composition parameters to calculate reservoir compressibility index, obtain well section compressibility index profile, and select high compressibility fractured well sections. The geological structure of shale reservoirs is complex, and the internal physical properties and heterogeneity of the reservoirs are very different. The fracturability of the reservoir has an important influence on the volume of the fracture network formed by fracturing. How to screen out the reservoirs with high fracturability is Volume fracturing is a prerequisite for more complex fractu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com