Processing method of tea-leaf like sparrow tongue

A processing method and tea technology, which is applied in the processing field of sparrow tongue tea, can solve the problems of inability to effectively ensure product quality and product style characteristics, large influence of human factors, low degree of mechanization, etc., and achieve clear and bright green tea soup, strong and long-lasting chestnut aroma , The effect of cleaning processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

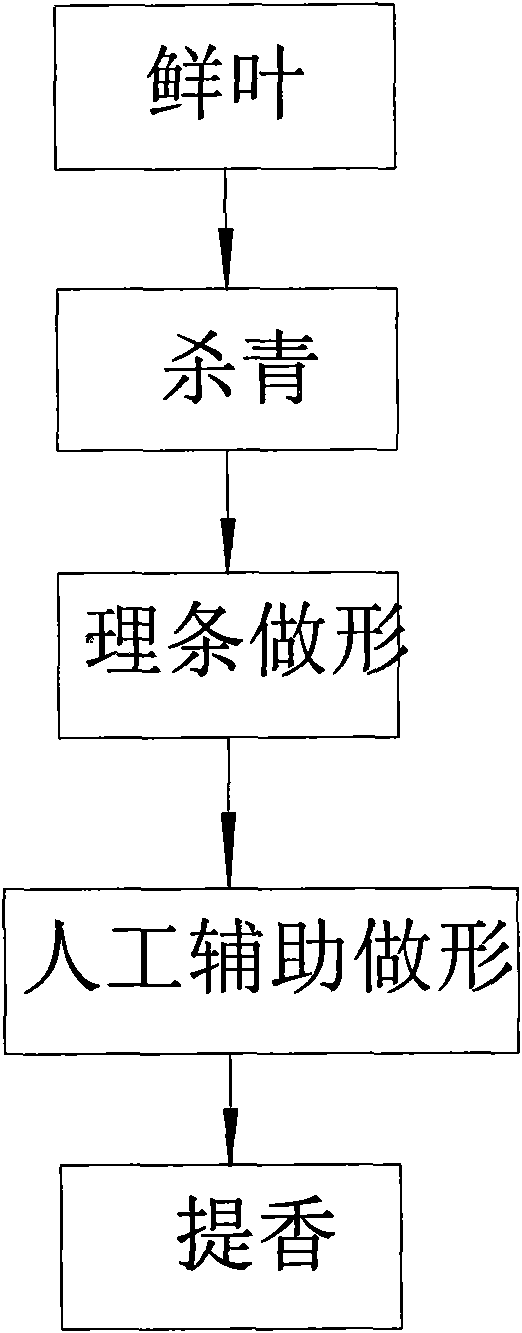

Method used

Image

Examples

Embodiment 1

[0014] a. Fresh leaves: Fresh leaves are collected from Fuding Dabaicha, Mingxuan 131, Mingxuan 311 and other fine tea trees from late February to April 20th. The cooling thickness is 3cm, the cooling time is 3 hours, and the water content of fresh leaves is controlled at 65%;

[0015] b. Finishing: Use a continuous drum cleaning machine and a microwave cleaning machine to complete the greening. The temperature is controlled at 120°C. The leaf homogenizer of the hoist is evenly loaded. The amount of leaves is adjusted according to the degree of greening. The leaves are soft, lose their luster, dark green in color, lose green air, and release the fragrance. The greening time is 4 minutes, and the water content of the greening leaves is 50%. cool down;

[0016] c. Shaping of strips: in the multi-functional strip-making machine, the amount of leaves thrown is moderate, and the temperature is controlled at 70°C during the strips. When the tea sticks are straightened in the recipr...

Embodiment 2

[0020] a. Fresh leaves: Fresh leaves are collected from Fuding Dabaicha, Mingxuan 131, Mingxuan 311 and other fine tea trees from late February to April 20th. The cooling thickness is 5cm, the cooling time is 8 hours, and the water content of fresh leaves is controlled at 70%;

[0021] b. Finishing: Use a continuous drum cleaning machine and a microwave cleaning machine to complete the greening. The temperature is controlled at 180°C. The leaf homogenizer of the hoist is evenly placed on the leaves. The amount of leaves is adjusted according to the degree of greening. The leaves are soft, lose their luster, dark green in color, lose their green air, and release the fragrance. The greening time is 8 minutes, and the water content of the greening leaves is 60%. cool down;

[0022] c. Shaping the strips: in the multi-functional strip-making machine, the amount of leaves thrown is moderate, the temperature is controlled at 110°C when the strips are stripped, and the tea sticks ar...

Embodiment 3

[0026] a. Fresh leaves: Fresh leaves are collected from Fuding Dabaicha, Mingxuan 131, Mingxuan 311 and other fine tea trees from late February to April 20th. The cooling thickness is 7cm, the cooling time is 12 hours, and the water content of fresh leaves is controlled at 75%;

[0027] b. Finishing: Use a continuous drum cleaning machine and a microwave cleaning machine to complete the greening. The temperature is controlled at 205°C. The leaf homogenizer of the hoist is evenly placed on the leaves. The amount of leaves is adjusted according to the degree of greening. The leaf quality is soft, loses luster, dark green leaf color, green air is lost, and fragrance escapes. It takes 10 minutes to kill the green leaves, and the water content of the green leaves is 65%. cool down;

[0028] c. Shaping of strips: in the multi-functional strip-making machine, the amount of leaves thrown is moderate, and the temperature is controlled at 150°C during the stripping. When the tea sticks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com