Method for preparing faveolate polymer microsphere on basis of micro-fluidic chip

A microfluidic chip and polymer technology, applied in chemical instruments and methods, educts, laboratory containers, etc., can solve the problems of unsatisfactory synthesis requirements, poor shape controllability, poor monodispersity, etc., to achieve The shape and size are controllable, the process is simple and fast, and the effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

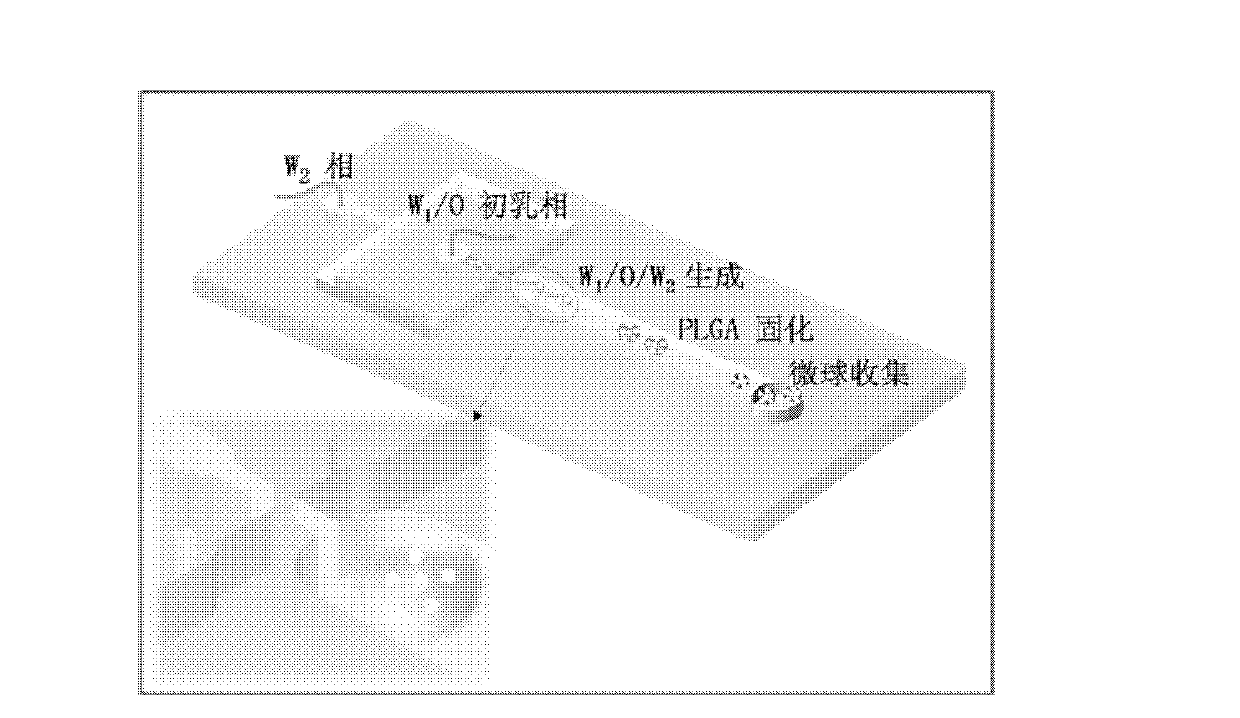

[0026] Preparation and modification of microfluidic chip: Based on soft lithography technology, a PDMS layer containing microchannel patterns is prepared, and the microfluidic chip is obtained by irreversible sealing with the glass substrate. Pour polyvinyl alcohol-glycerol mixed solution into the chip, after a period of molecular adsorption, the surface of the channel is modified with hydrophilic groups, so as to ensure the double emulsion phase (W 1 / O / W 2 ) droplet formation.

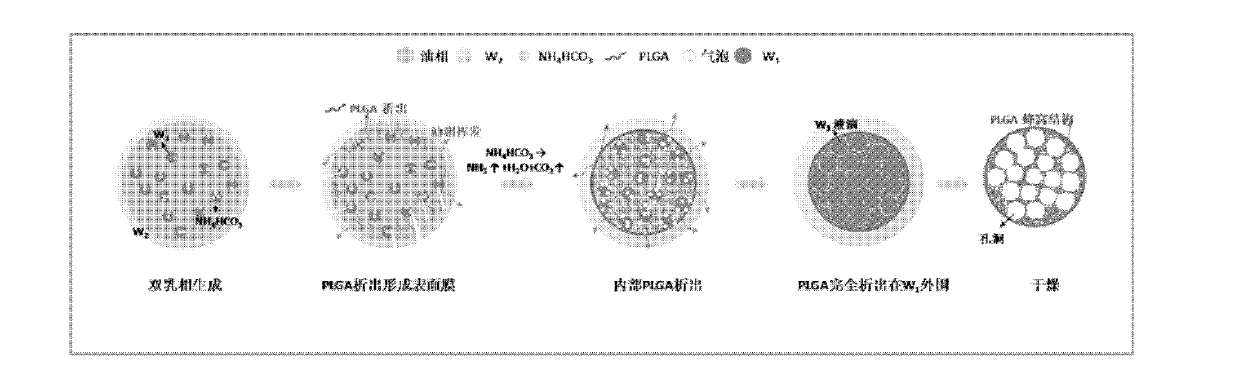

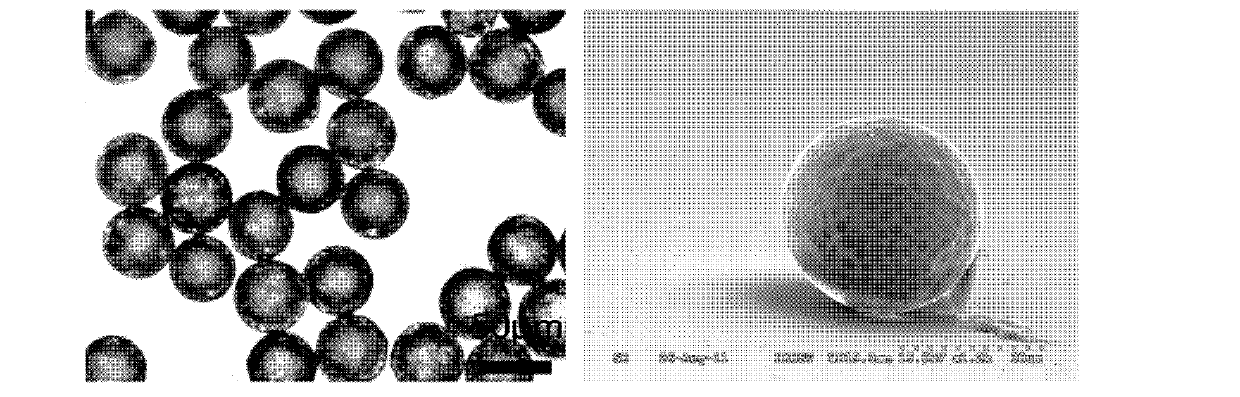

[0027] The preparation of reaction precursor liquid: effervescent agent ammonium bicarbonate inorganic salt is dissolved in water as internal water phase (W 1 ) (10%, 5%, 1%, wt%), the polymer polylactic acid-glycolic acid is dissolved in the organic solvent dimethyl carbonate as the oil phase (O) (PLGA viscosity is 1.64dL / g, 1.6%, wt %), ice-bath ultrasonic dispersion to obtain water-in-oil colostrum phase (W 1 / O); external water phase (W 2 ) is an aqueous solution (2%, wt%) containing surfacta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com