Probiotic preparation based on W1/O/W2 type dual emulsion structure, preparation method and application

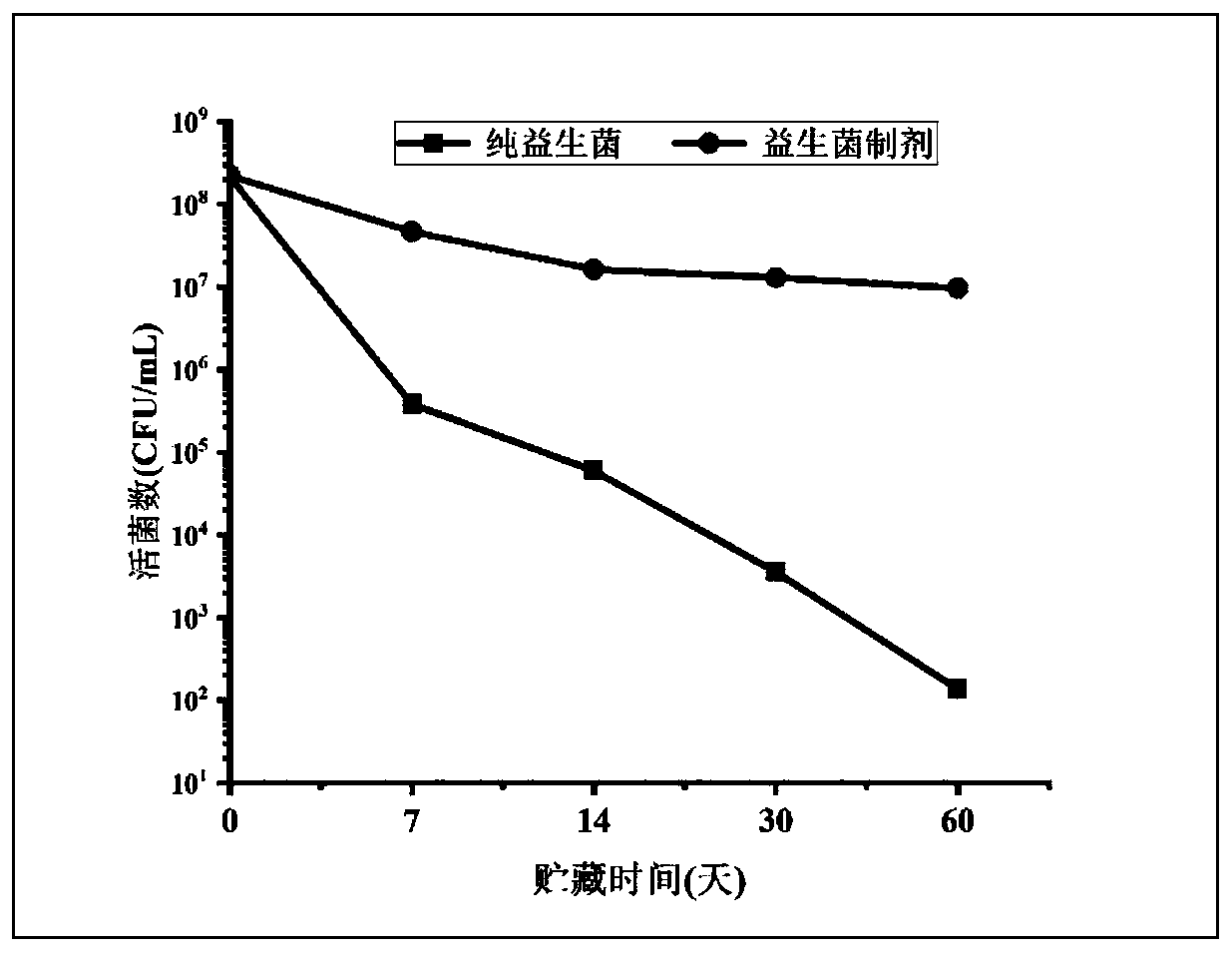

A technology of probiotic preparation and double emulsion, applied in the biological field, can solve the problems of easy inactivation of probiotics, achieve the effects of prolonging survival rate, reducing cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

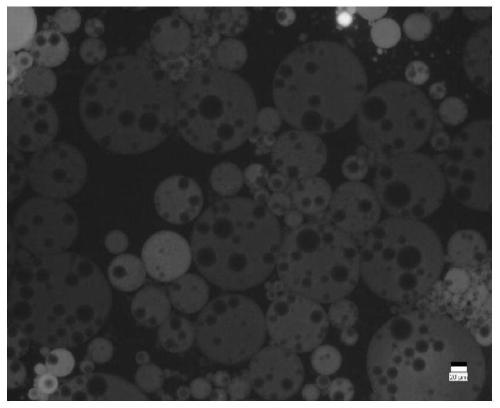

[0041] The invention discloses a W-based 1 / O / W 2 The probiotic preparation, preparation method and application of type double emulsion structure are specifically shown in the following examples. The probiotics in the present invention can be any probiotics, including but not limited to Lactobacillus plantarum, Lactobacillus acidophilus, Lactobacillus rhamnosus, Lactobacillus bulgaricus, Bifidobacterium bifidum, Bifidobacterium longum, Lactococcus lactis or For Streptococcus thermophilus, since various probiotics do not produce significant differences when adapted to the technical solution of the present invention, the following only takes some probiotics as examples for detailed description. The present invention has no special restrictions on the edible oil, as long as it can meet the relevant requirements for eating. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in this techni...

Embodiment 2

[0059] Application of embodiment 2 double emulsion probiotic preparation in ice cream

[0060] 1, the preparation method of probiotic ice cream, comprises the following steps:

[0061] (1) Raw material mixing: Weigh 10-15wt% whole milk powder, 8-12wt% white granulated sugar, 8-15wt% cream, 0.3-0.6wt% composite stabilizer and water and mix evenly.

[0062] (2) Sterilization and homogenization: pasteurize at 90°C for 20 minutes, then cool down to about 60°C for homogenization, and the homogenization pressure is 20.0MPa.

[0063] (3) Cooling and aging: After homogenization, quickly cool the material to 2-4°C, add 1-15wt% of the prepared probiotic preparation embedded in double emulsion, and keep stirring to fully expand the fat, protein and stabilizer And combined, the aging time is 4 ~ 8h.

[0064] (4) Freezing: Add the aged and mature ice cream slurry to the freezer for puffing, and through the freezing and whipping process, air is mixed into the ice cream slurry to make volu...

Embodiment 3

[0070] Embodiment 3 preparation of double emulsion probiotic preparation

[0071] 1. The preparation method mainly comprises the following steps:

[0072] (1) Preparation of bacterial suspension: the probiotic Streptococcus thermophilus was activated with MRS broth medium, cultured in a constant temperature incubator at 37° C. for 12-18 hours, and then the bacterial liquid was centrifuged to obtain bacterial cells.

[0073] (2) Inner water phase W 1 Preparation: Prepare a mixed solution of 10wt% fructose, 2wt% glycerin and 10wt% whey protein isolate, sterilize at 121°C for 15 minutes, and after cooling to room temperature, suspend the bacteria in the mixed solution to obtain the inner water phase W 1 .

[0074] (3) Preparation of oily phase O: Add Span 20 to soybean oil, and magnetically stir at 500 rpm for 20-40 min to obtain 3 wt% Span 20, which is the oily phase O.

[0075] (4) Colostrum W 1 Preparation of / O: the inner aqueous phase W 1 Drop into the oil phase O while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com