Method for preparing magnetic porous microsphere adsorbing material by utilizing O/W/O double emulsion template

A technology of porous microspheres and adsorption materials, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

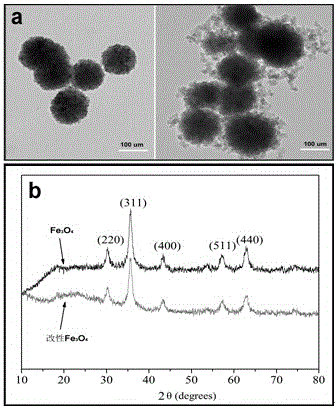

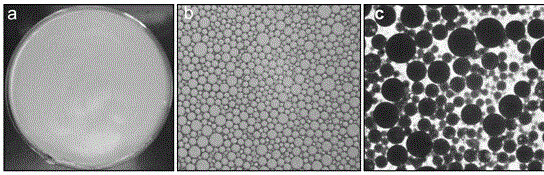

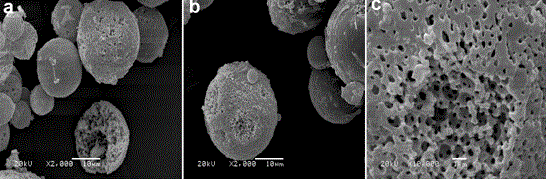

Method used

Image

Examples

Embodiment 1

[0049] Mix 0.1g hydroxypropyl cellulose, 2.0g hydroxyethyl methacrylate, 1.5g itaconic acid, 3.0g ethylene glycol dimethacrylate, 0.2g modified Fe under stirring at 200rpm 3 o 4 , 1.0g of polyoxyethylene alkyl acylation amine surfactant was dispersed in 5mL of water; after each component was dissolved, 10mL of toluene was added to the mixed solution and stirred for 4h, and then 0.5g of initiator benzoyl peroxide was added. Stir at 100rpm for 2min to obtain Pickering-emulsion;

[0050] Add the Pickering-emulsion to 25mL p-xylene (containing 2.5g of polyoxyethylene alkyl acylinolamine surfactant), stir and disperse at 8000rpm for 1min; then put it into a test tube and polymerize at 70°C for 4h; After extraction for 48 hours, vacuum-dry to obtain magnetic porous microsphere adsorption material.

[0051] The adsorption material for heavy metal Cu 2+ and Pb 2+ The desorption amounts of the desorbents were 125mg / g and 203mg / g, respectively.

Embodiment 2

[0053] 0.6g hydroxypropyl cellulose, 1.5g 2-acrylamide-2-methyl-propanesulfonic acid, 2.0g maleic acid, 2.0g N,N' - Methylenebisacrylamide, 0.1g modified Fe 3 o 4 , 1.0 g of alkylphenol polyethylene oxide ether surfactants were dispersed in 3 mL of water; after each component was dissolved, 6 mL of cyclohexane was added to the mixed solution and stirred for 2 h, and then 0.2 g of initiator ammonium persulfate was added, Stir at 100rpm for 1min to obtain Pickering-emulsion;

[0054] Add Pickering-emulsion to 9mL liquid paraffin (containing 0.45g polyoxyethylene polyoxypropylene block copolymer surfactant), stir and disperse at 3000rpm for 2min, then put it into a test tube and polymerize at 40°C for 12h; the obtained polymer acetone Soxhlet extraction for 48 hours, vacuum drying to obtain magnetic porous microsphere adsorption material.

[0055] The adsorption material for heavy metal Cu 2+ and Pb 2+ The desorption amounts of the desorbents were 153mg / g and 388mg / g, respec...

Embodiment 3

[0057] Mix 0.3g hydroxypropyl cellulose, 2.0g methacrylic acid, 1.0g acrylic acid, 0.3g modified Fe under stirring at 800rpm 3 o 4 , 0.15g of fatty alcohol polyoxyethylene ether surfactant was dispersed in 4mL of water; after each component was dissolved, 6mL of p-xylene was added to the mixed solution and stirred for 2h, and 0.3g of initiator azobisisobutyronitrile was added, and Stir for 4 minutes at 100 rpm to obtain Pickering-emulsion;

[0058] Add the Pickering-emulsion to 30mL cyclohexane (containing 6g fatty acid polycycloethylene alkyl ester surfactant), and then stir and disperse at 5000rpm for 2min; then put it into a test tube and polymerize at 70°C for 4h; the obtained polymer n-hexane Soxhlet After extracting for 24 hours and dehydrating with industrial ethanol, the magnetic porous microsphere adsorption material is obtained.

[0059] The adsorption material for heavy metal Cu 2+ and Pb 2+ The desorption amounts of the desorbents were 282mg / g and 378mg / g, resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com