Shoe last clamping and releasing device

A technology for shoe last and last release, applied in shoe last, footwear, application and other directions, can solve the problems of high labor intensity of workers, need manual last release, no last release function, etc., and achieves high work efficiency, high positioning accuracy, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

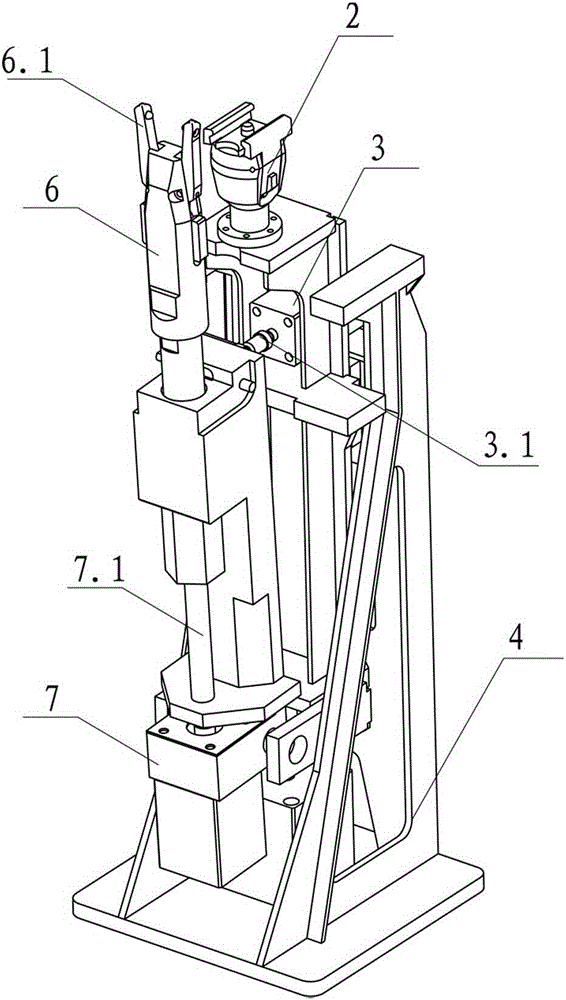

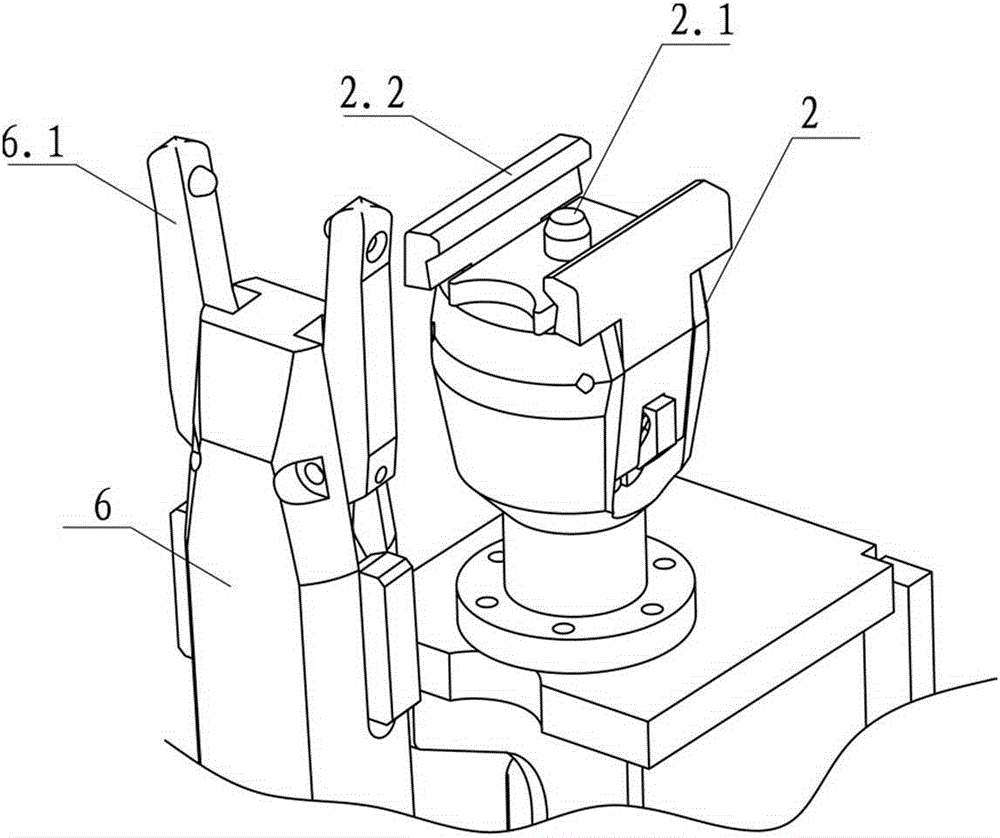

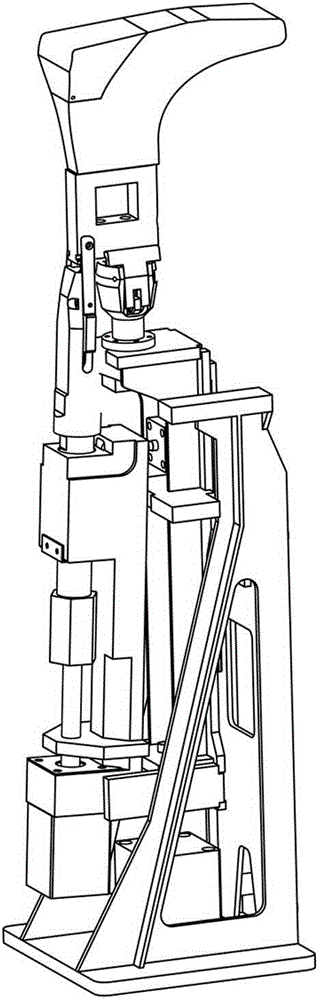

[0012] Such as figure 1 , figure 2 As shown, a shoe last pinching device in this embodiment includes a last clamping cylinder 2 with a shoe last positioning pin 2.1 and a shoe last pneumatic clamp 2.2, a last stripping cylinder 6 with a last stripping rod pneumatic clamp 6.1, and a last stripping cylinder 6 with a last stripping rod pneumatic clamp 6.1. The last cylinder 6 is a lifting cylinder 7 for lifting and moving, and a push cylinder 3 with a push rod 3.1; the clamping cylinder 2 is set opposite to the stripping cylinder 6; the push cylinder 3 is located below the clamping cylinder 2, and its push rod 3.1 is facing The lasting cylinder 6; the lifting arm 7.1 of the lifting cylinder 7 is connected with the lasting cylinder 6, and the action sequence of the above-mentioned cylinders is controlled and implemented by a PLC programmable controller.

[0013] The following is a brief description of the working procedure of this device: the operator first puts the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com