Variable-speed conveying equipment for flexible materials

A variable-speed conveying and flexible material technology, which is applied in the direction of thin material processing, coiling, transportation and packaging, etc., can solve the problems of high precision requirements of servo motors, restrictions on maximum rotation speed, large misalignment, etc., and achieve stable operation Good performance, adjustment and elimination, and the effect of reducing the amount of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below by specific embodiments.

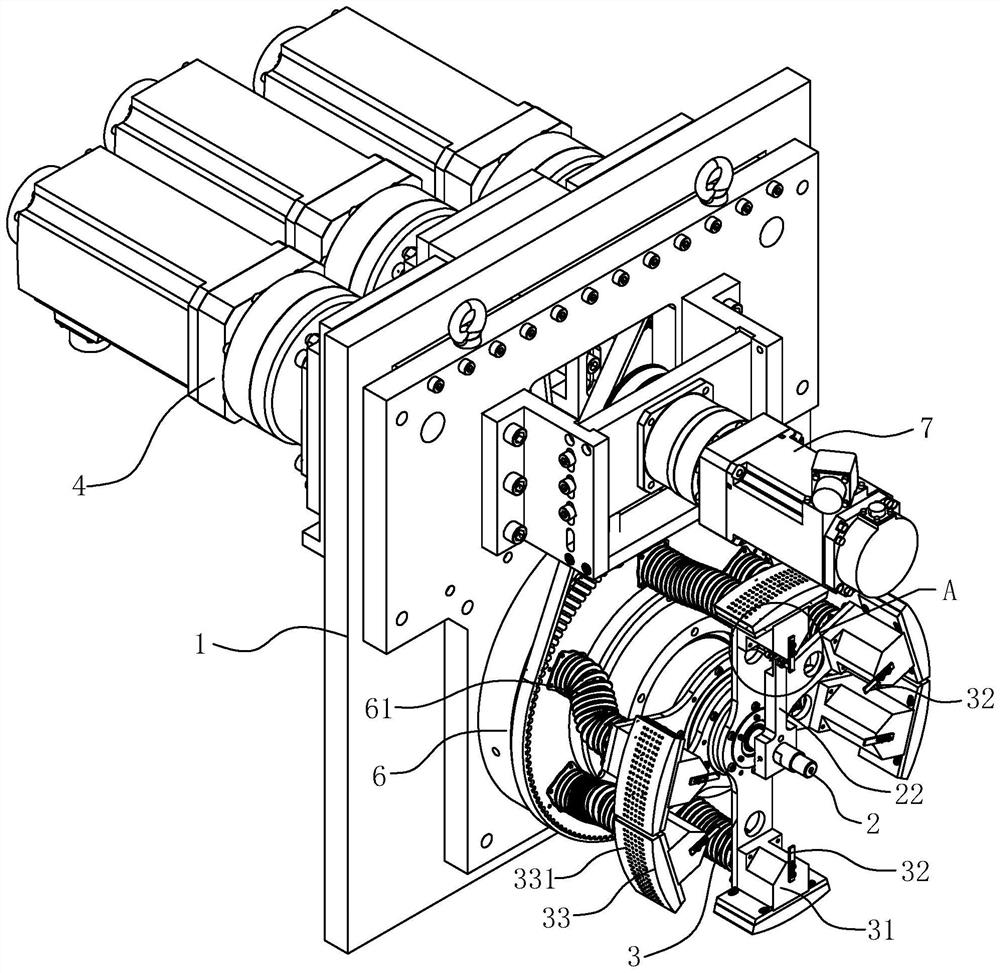

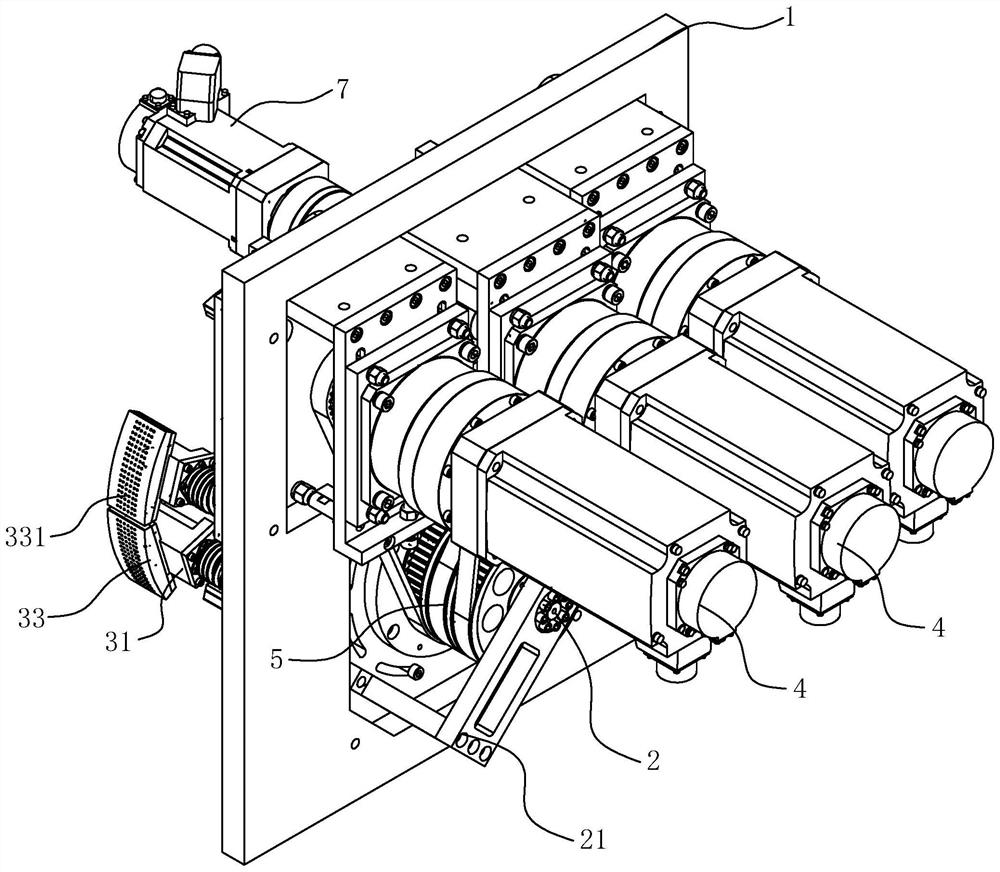

[0022] Reference Figures 1 through 5 As shown, a flexible material variable speed conveying equipment, including the main support plate 1, fixed shaft 2, rotating plate 3, servo motor 4, bushing transmission mechanism 5, negative pressure turntable 6, constant speed motor 7, controller.

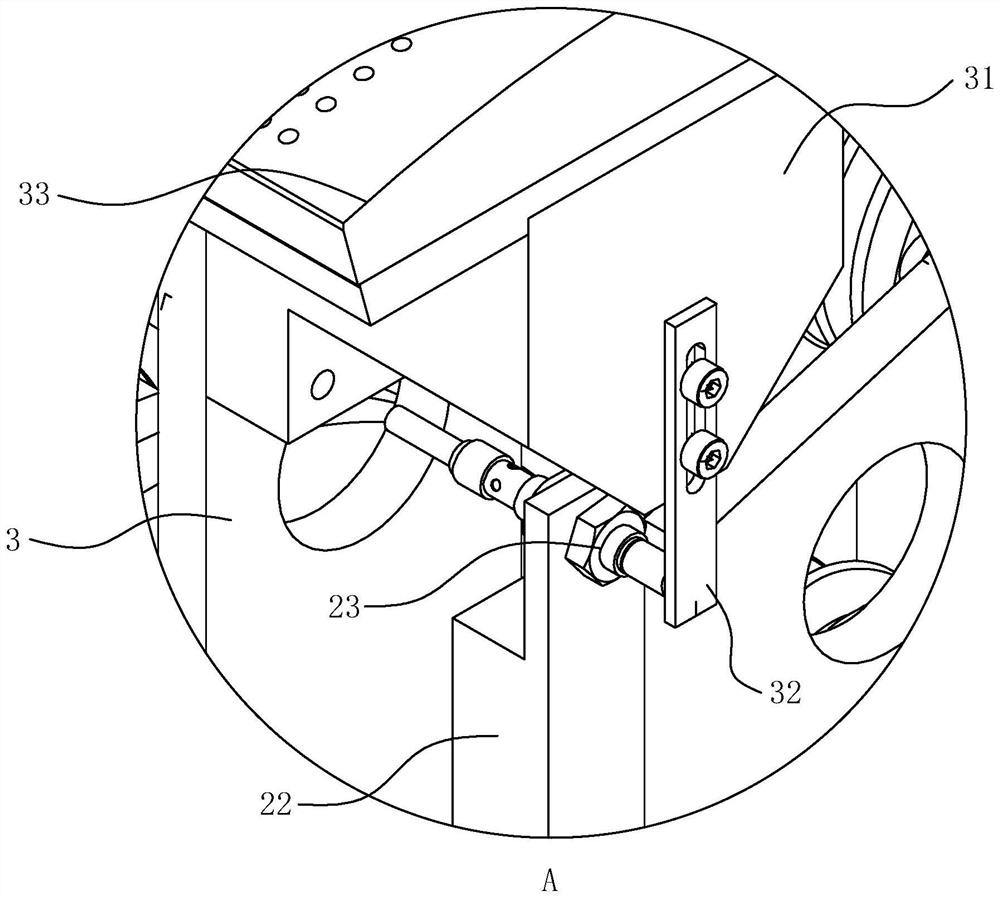

[0023] Fixed shaft 2 end is connected to the main support plate 1 through the positioning frame 21, the rotating plate 3 has several groups, each rotating plate 3 central position can be rotated outside the fixed axis 2, a rotating plate 3 at both ends are provided with a negative pressure box 31, the same rotating plate 3 of the two negative pressure boxes 31 are symmetrically distributed, the negative pressure box 31 on each rotating plate 31 extends to the same side, so that the inner side of each negative pressure box 31 has a concession space, the negative pressure box 31 is provided with an induction plate 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com