Piston reciprocating double-cylinder engine

An engine and piston technology, applied in the field of piston reciprocating twin-cylinder engine, can solve the problems of occupying equipment load and space, complicated structure of engine cylinder and crankshaft, unfavorable maintenance and repair, etc., to achieve the effect of expanding the scope of application and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

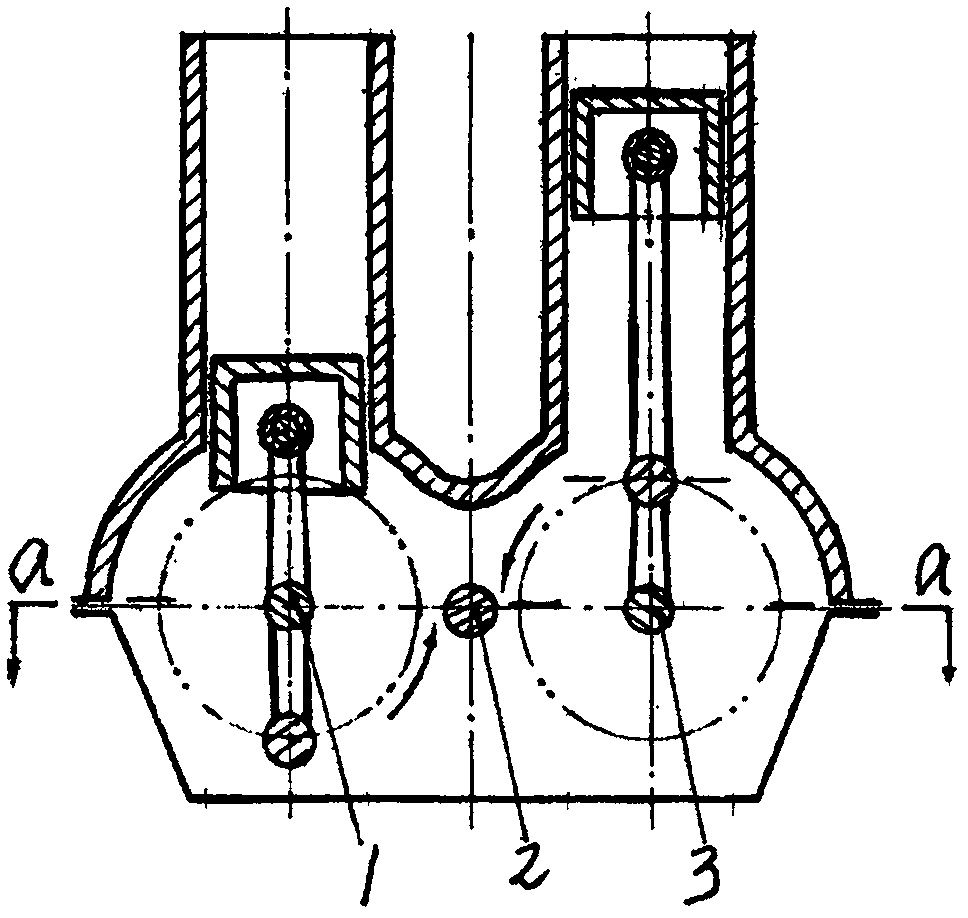

[0018] figure 1 Shown: the left and right twin cylinders of the engine are vertically connected in parallel, figure 1 The middle arrow shows the rotation direction of the crank pins of the left and right cylinders, and the double-dot dash line shows the rotation track of the crank pins.

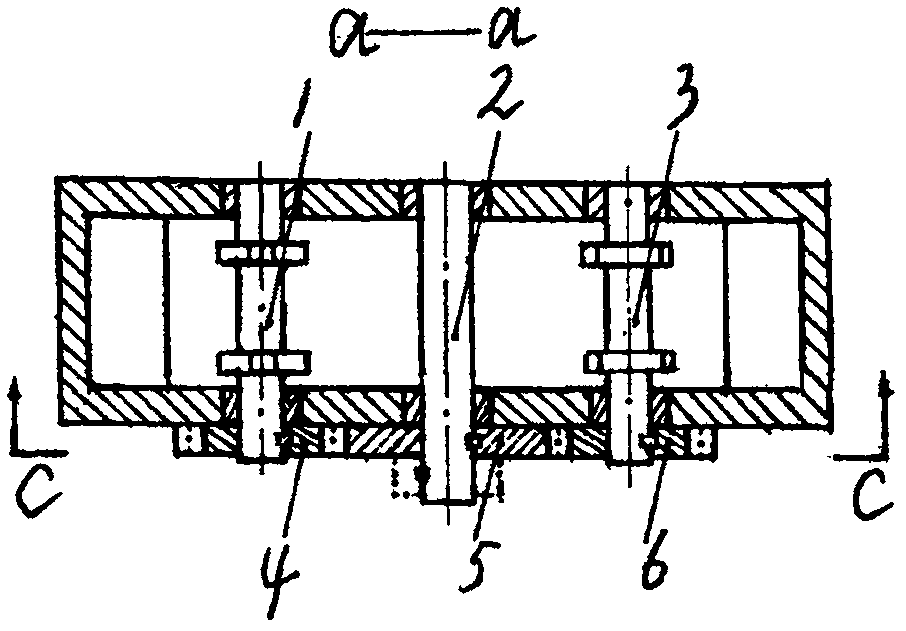

[0019] figure 1 and figure 2 Shown: the left and right crankshafts (1, 3) are parallel to one plane, and the output shaft (2) is arranged in the middle between the left and right crankshafts.

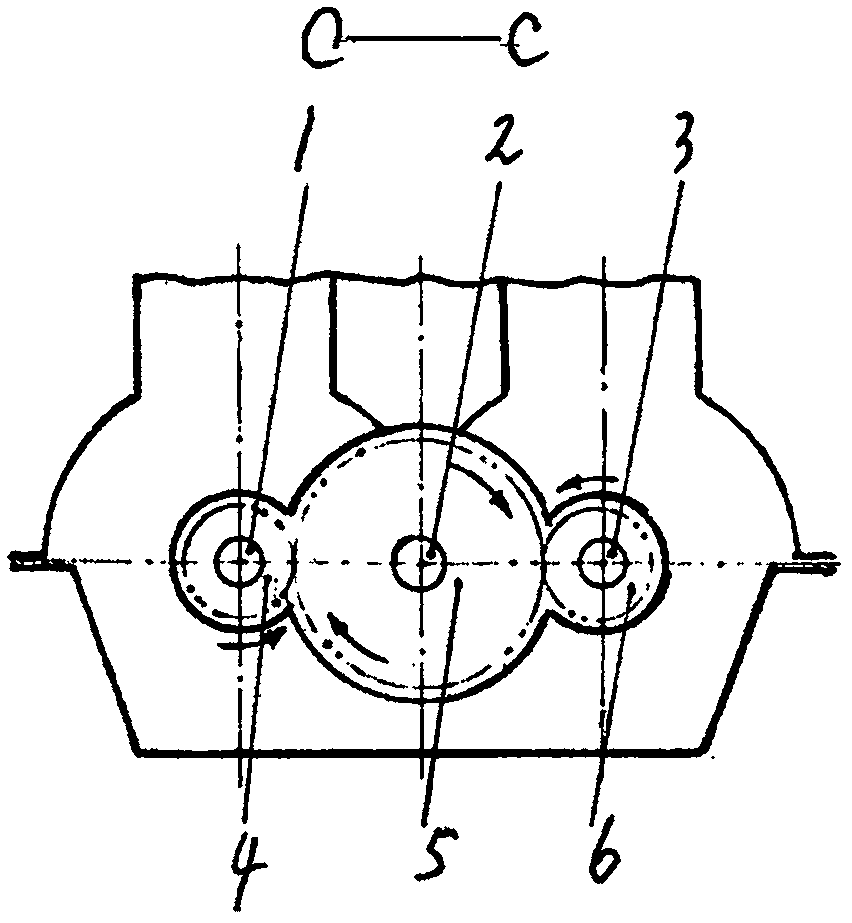

[0020] figure 2 show binding image 3 In the transmission system, the left and right crankshafts (1, 3) and the front ends of the output shaft (2) are respectively assembled with the left and right crankshaft gears (4, 6) and the output shaft gear (5), and the left and right crankshaft gears (4, 6) are respectively connected to the output Shaft gears (5) mesh to form a gear set.

[0021] figure 2 and image 3 Shown: in the gear set, if the pitch circle diameters of the left and right cranksh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com