Tool storage mechanism of numerically controlled drilling and milling machine

A technology for drilling and milling machines and tool magazines, which is applied in the direction of metal processing machinery parts, clamping, supporting, etc. It can solve the problems of high labor intensity for workers, long auxiliary time for tool changing, and low production efficiency, so as to achieve good operation stability and ensure Accuracy, stability, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

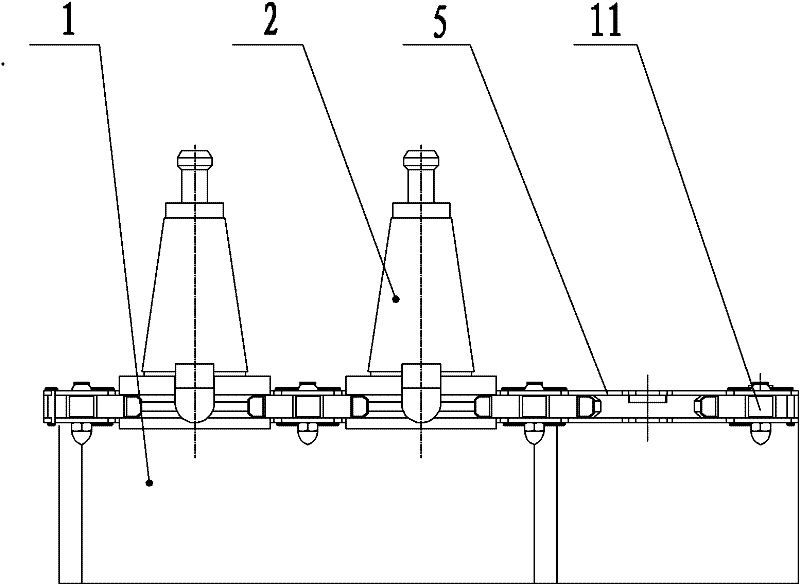

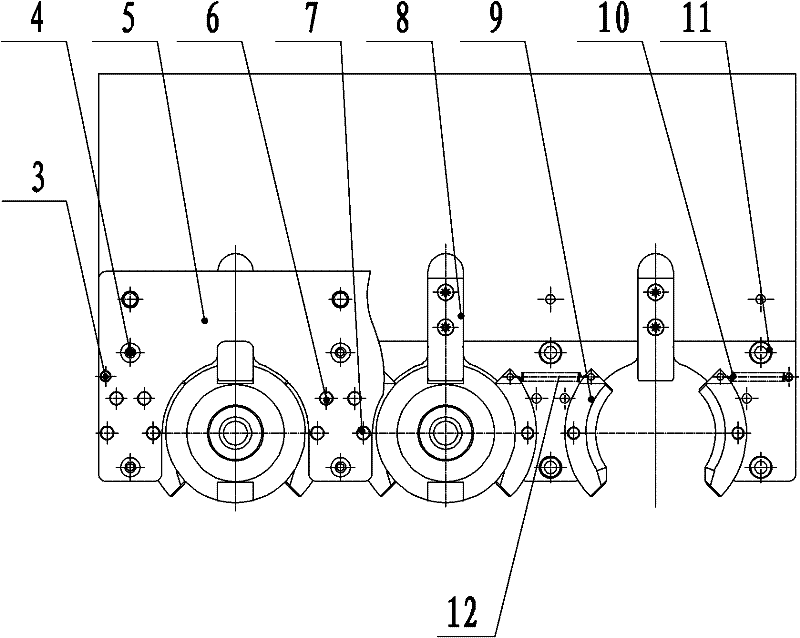

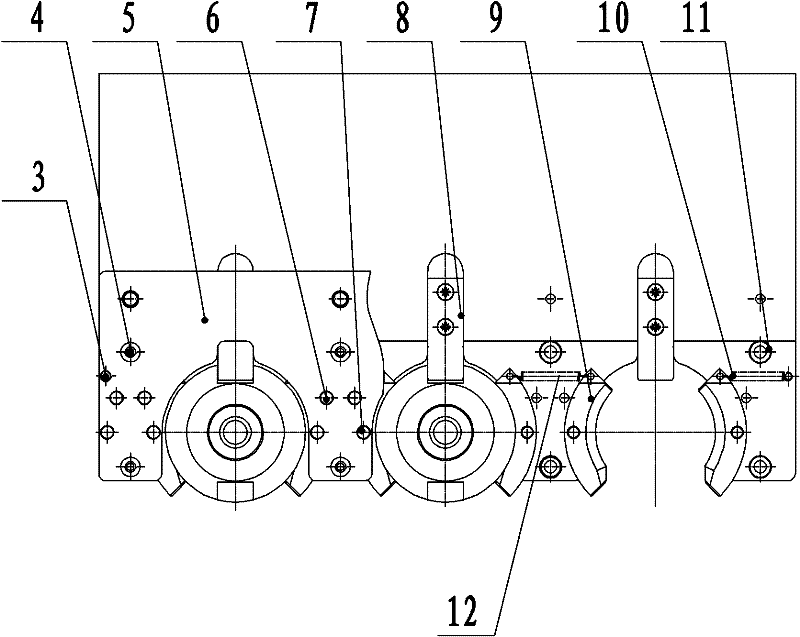

[0010] As shown in the figure, the present invention mainly consists of a bracket 1, a knife handle 2, a pin shaft 3, a cap nut 4, a knife seat 5, a pin shaft 6, a hinge pin shaft 7, a flat key 8, a holder 9, and an edge stretcher. Spring 10, bushing 11 and middle part extension spring 12 etc. parts constitute.

[0011] The tool magazine mechanism of the CNC drilling and milling machine includes tool holders 5 fixedly installed on the upper and lower mounting surfaces of the bracket 1, a bushing 11 is arranged between the upper and lower tool holders 5, and a bushing 11 is arranged between the upper and lower tool holders 5. There are several sets of grippers arranged side by side, and each set of grippers is formed by combining two gripper monomers 9, and the middle part of each gripper monomer 9 is hinged to the upper and lower two knives through the hinge pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com