Ball grinder for presses

A press and grinding machine technology, applied in the field of ball-end grinding machines, can solve the problems that the precision of stamping parts cannot meet the needs of high-precision processing, the surface fit is not tight, and the cost of maintenance is increased, so as to achieve high processing accuracy, Short grinding time and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

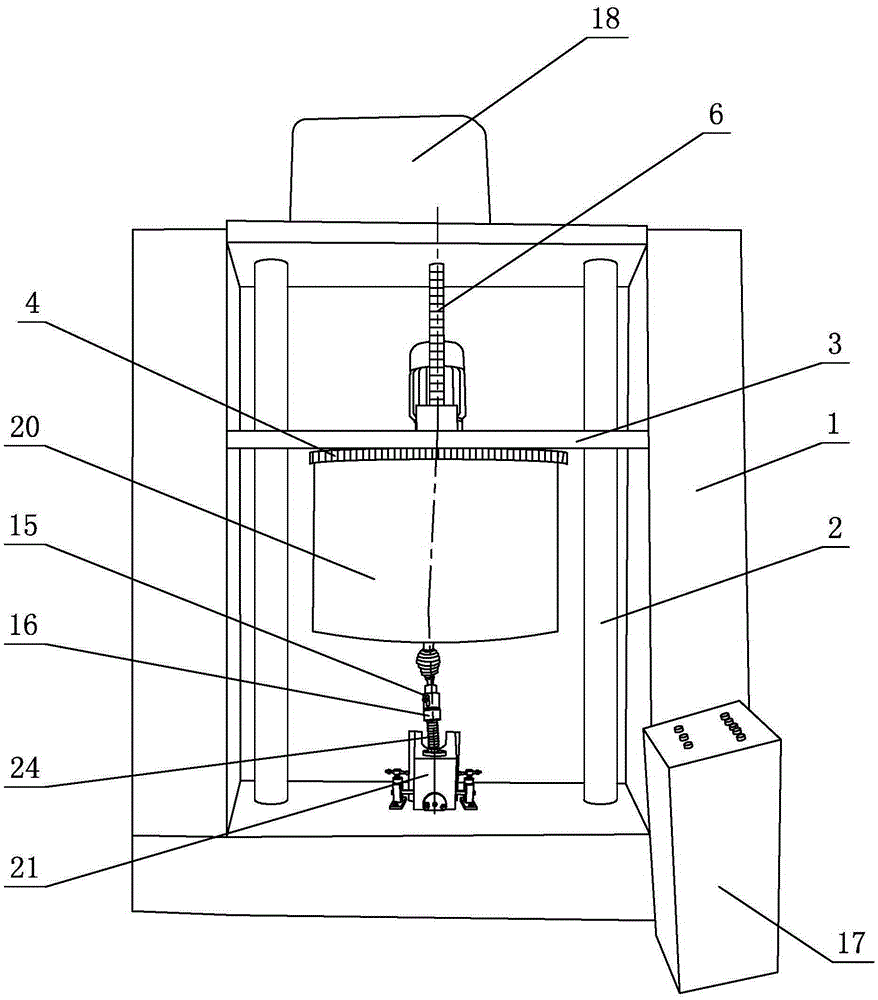

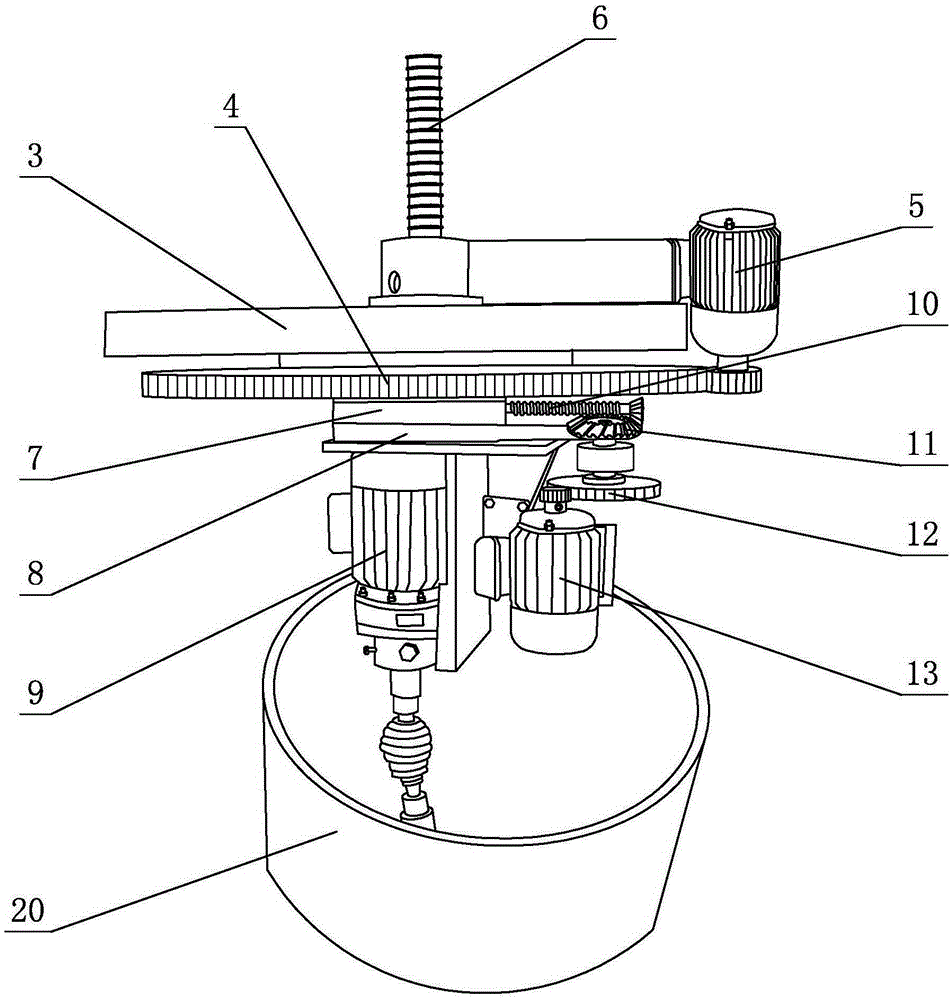

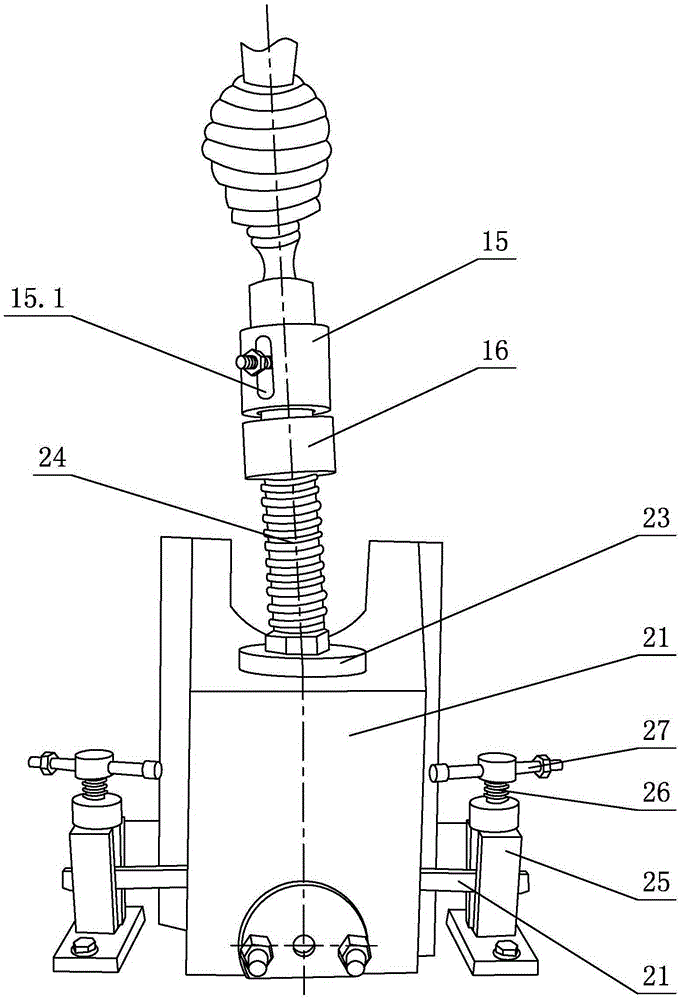

[0018] see figure 1 - Figure 4 , The ball grinder of this press machine includes a fuselage 1 column 2, a lifting screw 6, a rotating power head and a lifting mechanism. The whole of the fuselage 1 is a gantry structure, and the main motor and the lifting plate 3 are arranged on it, and the lifting screw 6 is arranged on the lifting plate 3, and the lifting screw 6 is connected with the main motor drive, so that it can be mounted on the column 2. Move; the rotating power head is provided with a grinding mechanism, and the working position of the grinding motor 9 is adjusted through the grinding mechanism; the upper part of the ball screw 24 is driven and connected with the grinding motor 9, and the lower part is set in the slider 21 and passed through the grinding motor 9. Drive the ball screw 24 to realize grinding in the slider 21; one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com