A vertical type numerical control workbench radial drilling machine

A technology of a radial drilling machine and a workbench, applied in the field of machine tools, can solve the problems of poor drilling accuracy, limited processing range, troublesome operation, etc., and achieve the effects of improving the degree of automation, good running stability, and convenience for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

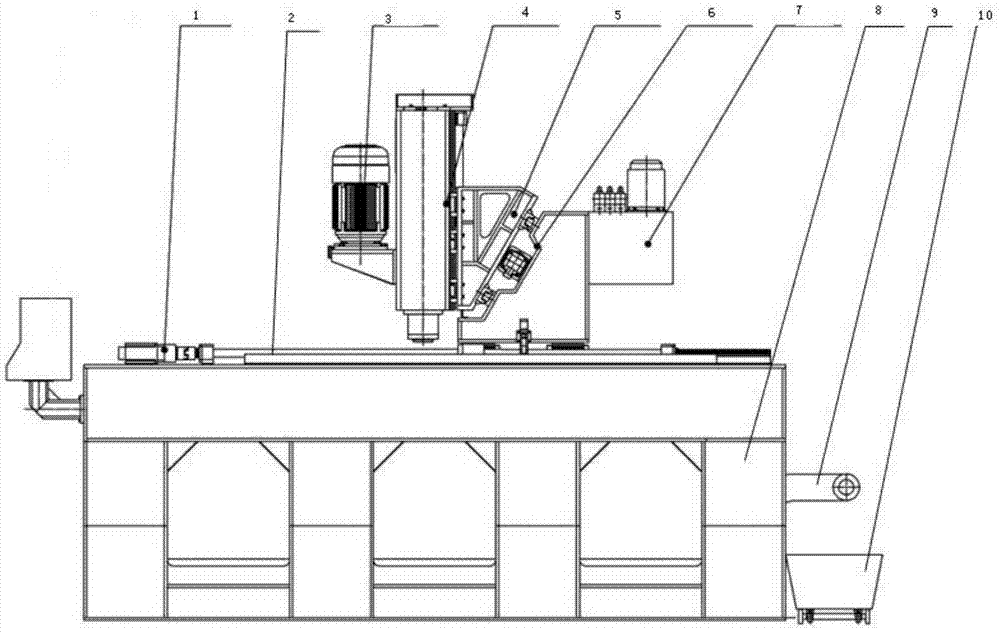

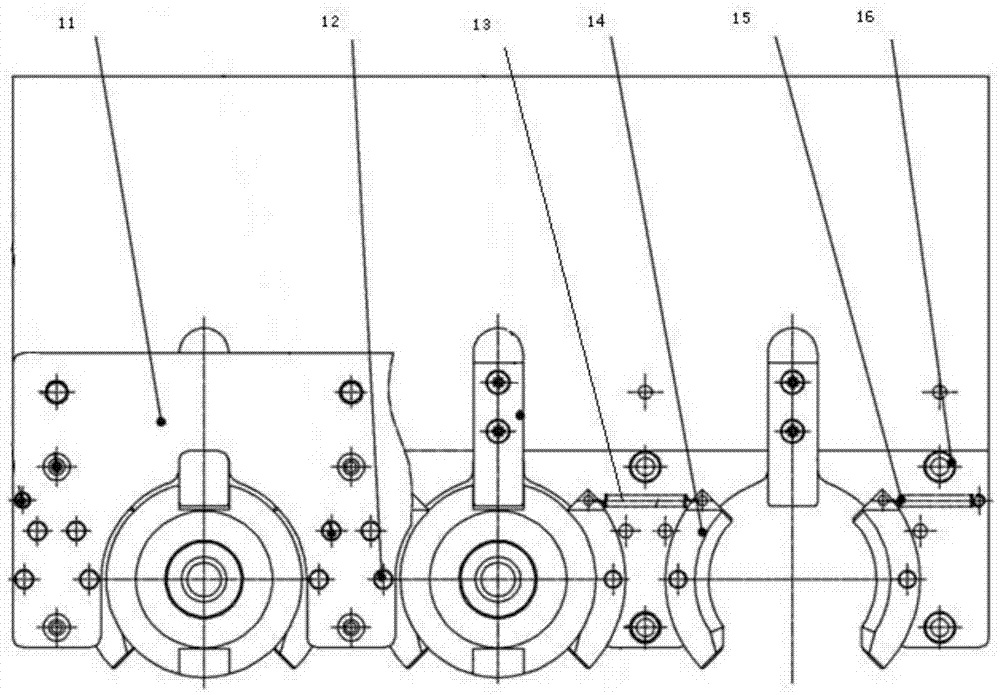

[0009] A vertical numerical control workbench radial arm drilling machine, including a workbench fixedly installed on a welding frame structure 8, and a beam transmission structure 1 arranged horizontally and longitudinally on the welding frame structure 8 on the left and right sides of the workbench , a crossbeam inclined mounting surface structure 6 is installed on the crossbeam transmission structure 1, a hydraulic system 7 is fixedly installed on the crossbeam inclined mounting surface structure 6, and a transverse transmission mechanism 2 arranged horizontally and transversely is installed on the crossbeam inclined mounting surface structure 6, On the beam inclined mounting surface structure 6, a mobile frame 5 is slidably installed, and a vertically arranged lifting structure 4 is installed on the mobile frame 5, and a main shaft transmission structure 3 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com