Three-dimensional drill drilling head cross-shape travelling mechanism

A walking mechanism and drilling head technology, applied in drilling/drilling equipment, boring machine/drilling machine parts, metal processing equipment, etc., can solve the problem of inability to ensure the shape and dimensional accuracy of the drilling surface, affecting the performance and life of the machine tool, Rigidity, layout adjustment method, unreasonable manufacturability, etc., to achieve the effect of ensuring shape and size accuracy, high reliability, and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

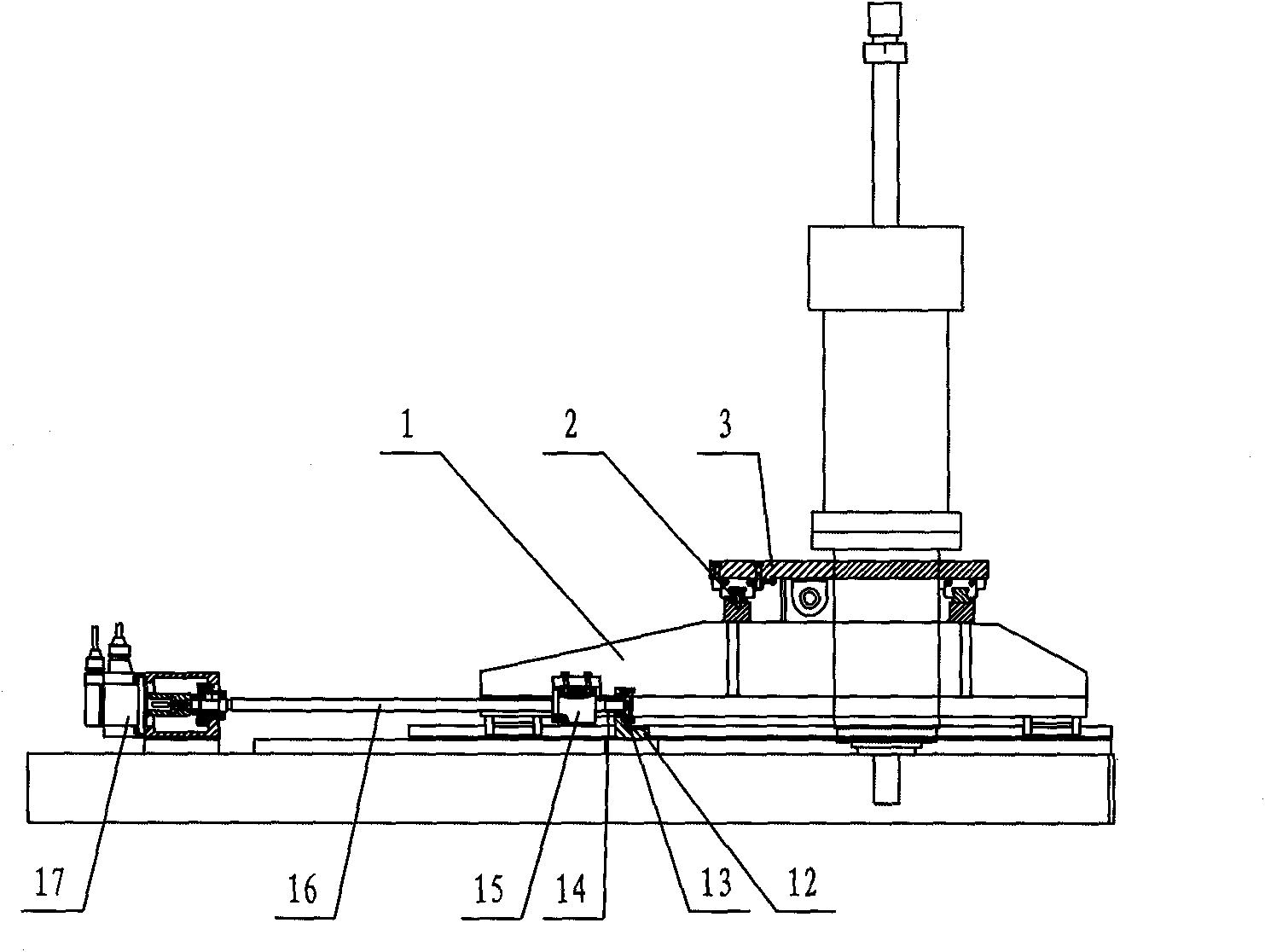

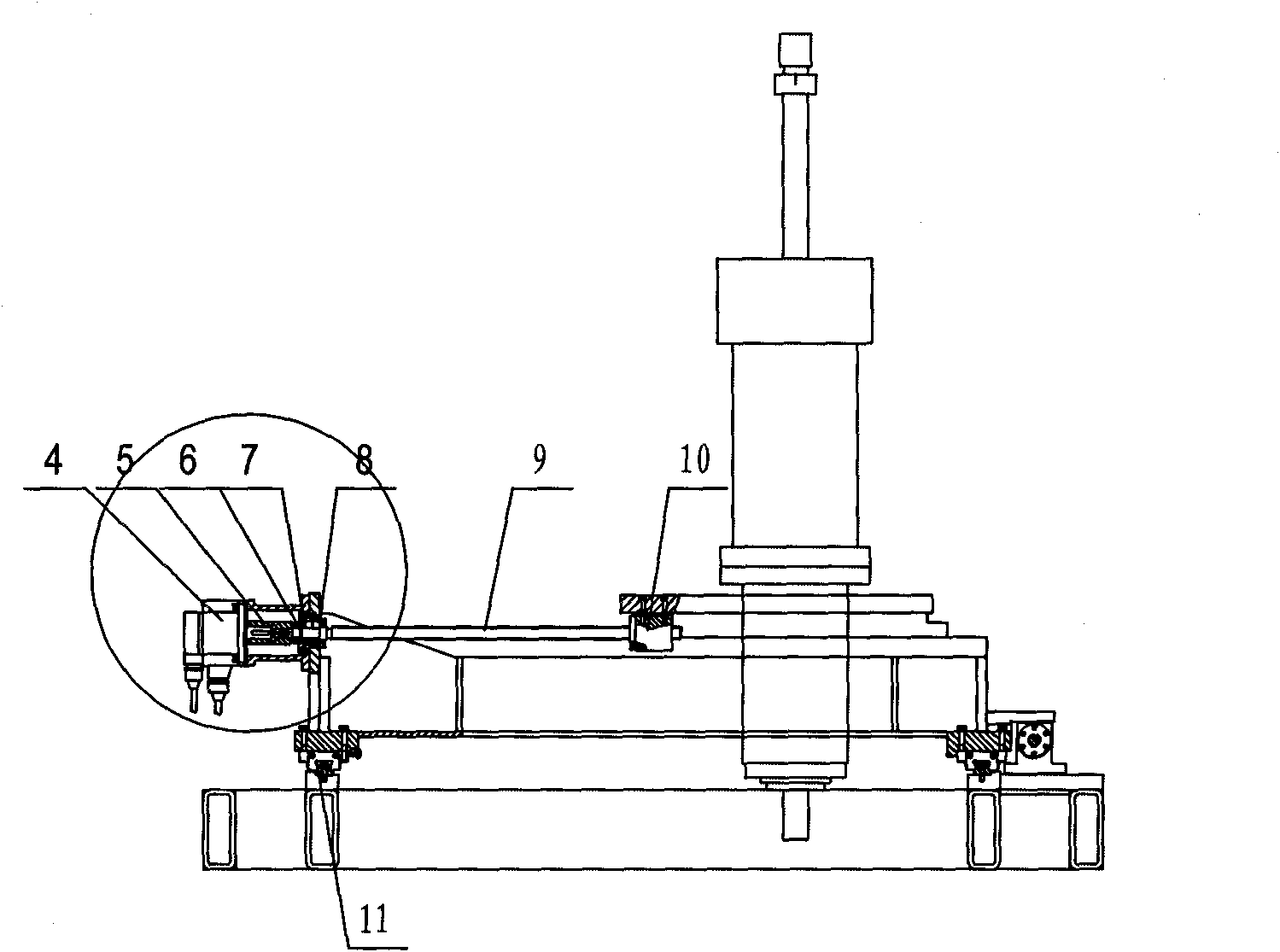

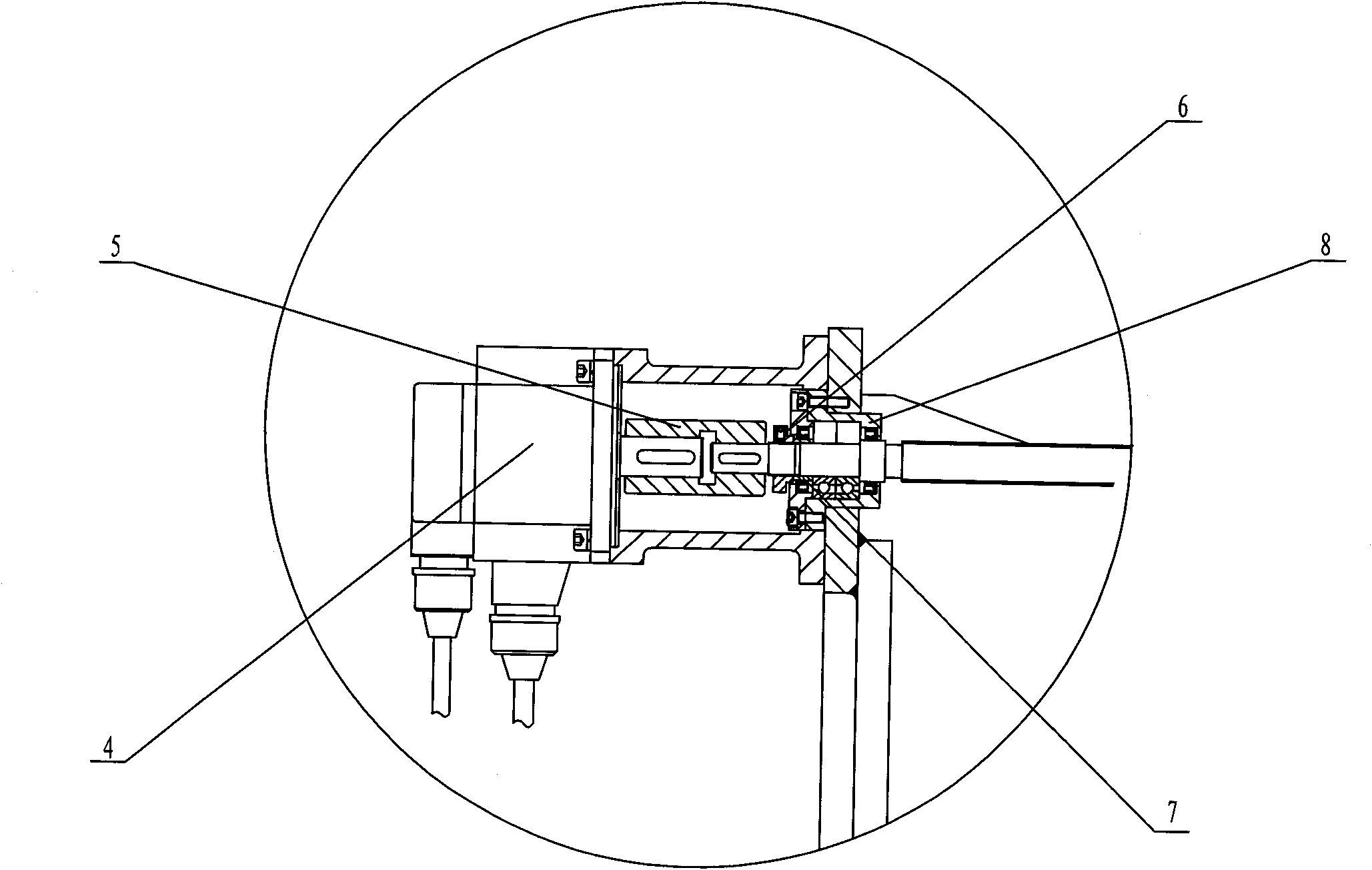

[0011] Such as Figure 1 ~ Figure 2 Shown: The cross-traveling mechanism of the three-dimensional drill upper drilling head includes a cross carriage 1, a longitudinal rolling linear guide pair 2, a main shaft seat mounting plate 3, a longitudinal servo motor 4, a coupling 5, a square nut 6, a bushing 7, and a support Unit seat 8, longitudinal ball screw pair 9, nut seat 10, transverse rolling linear guide rail pair 11, screw rear support seat 12, elastic retaining ring 13, screw rear bushing 14, transverse nut seat 15, transverse ball screw Deputy 16, horizontal servo motor 17 and so on.

[0012] The present invention includes a longitudinal rolling linear guide rail pair 2 and a lateral rolling linear guide rail pair 11. The slider and the guide rail of the longitudinal rolling linear guide rail pair 2 are installed on the main shaft seat mounting plate 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com