fence

A technology for guardrails and guardrails, applied in the field of guardrails, can solve the problems of high skill requirements for installers, high maintenance costs, and high cost of raw materials, and achieve the effects of reasonable manufacturability, unreliable fastening performance, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following description sufficiently illustrates specific embodiments of the invention to enable those skilled in the art to practice them.

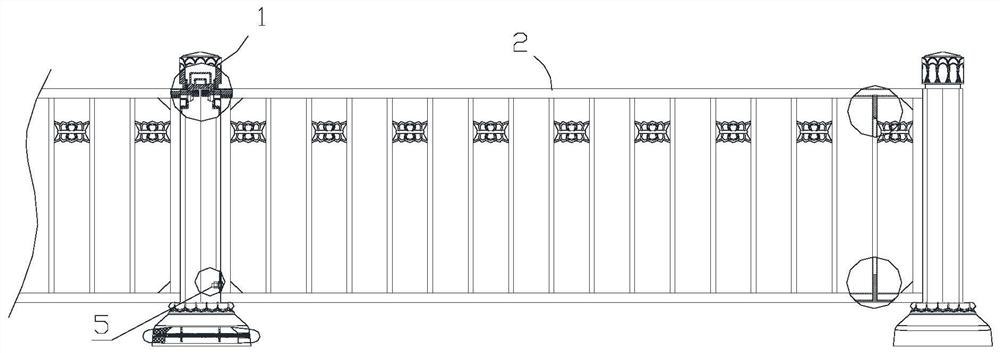

[0042] Such as figure 1 Shown, is the structural diagram of guardrail among the present invention.

[0043] The structure of the guardrail includes: a column 1 and a guardrail monomer 2, and the guardrail monomer 2 is connected between two columns 1. The steel wire cables 3 are connected to the column 1 and the guardrail monomer 2 respectively.

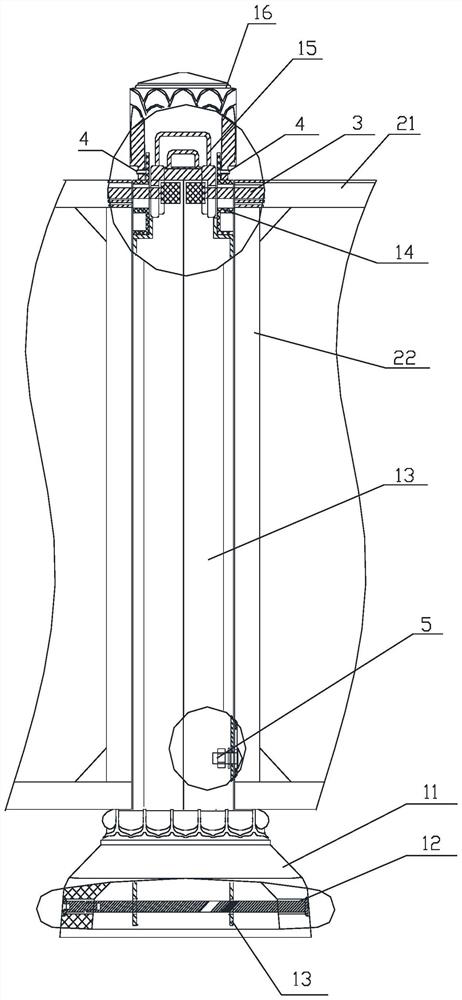

[0044] Such as figure 2 Shown is the connection diagram of the column 1 and the guardrail monomer 2 in the present invention.

[0045] The structure of the column 1 includes: a composite base 11 , a column fixing bolt 12 , a half column 13 , a protruding part 14 of a half column head, a connection latch 15 , and a column head 16 .

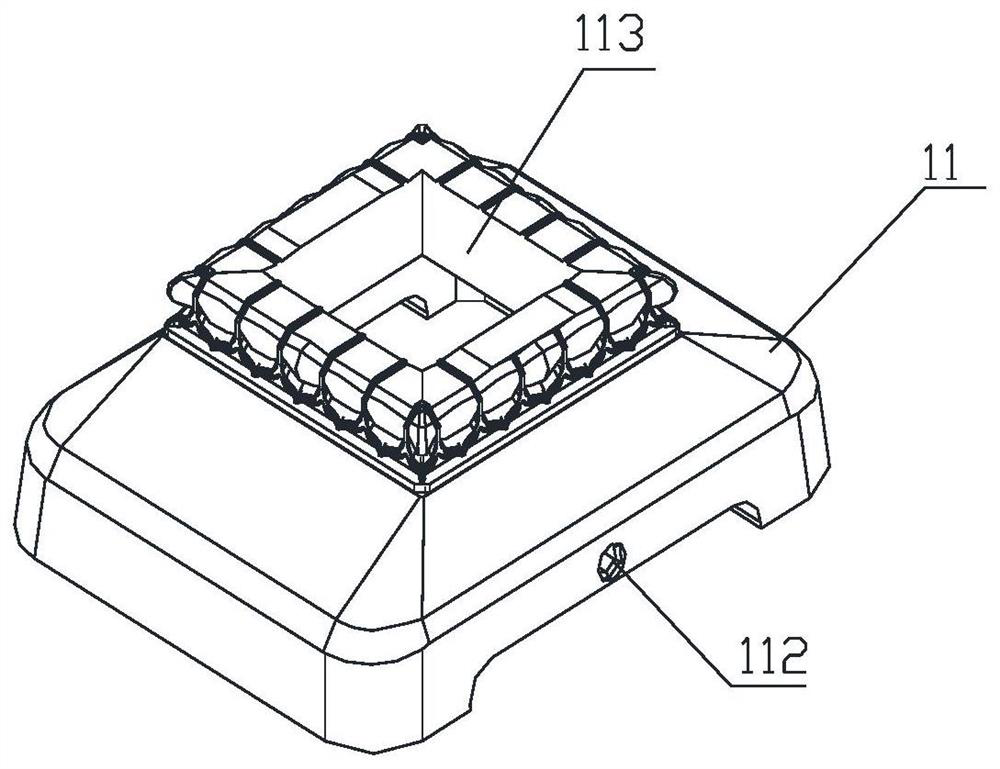

[0046] Such as image 3 As shown, it is a three-dimensional structure diagram of the composite base 11 in the present invention; Figure 4 Shown is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com