Unbalanced shaft

A balance shaft and balancing technology, applied in the direction of spring/shock absorber, machine/engine, vibration suppression adjustment, etc., can solve the problems of complicated installation and cost-intensive, and achieve the effect of simple axial and/or radial fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

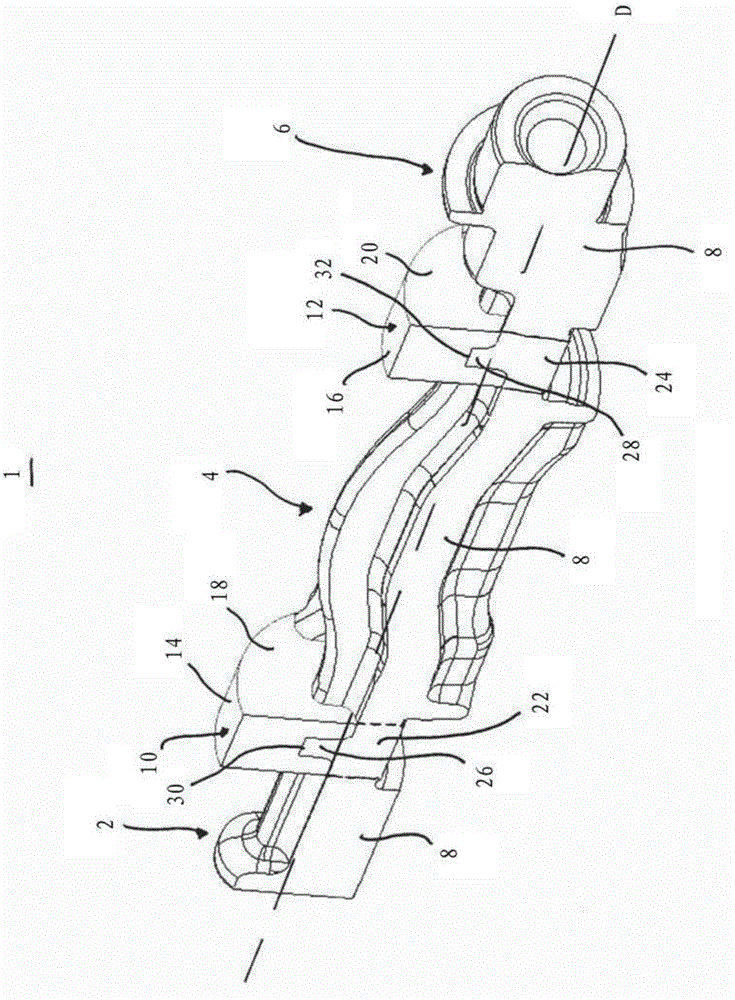

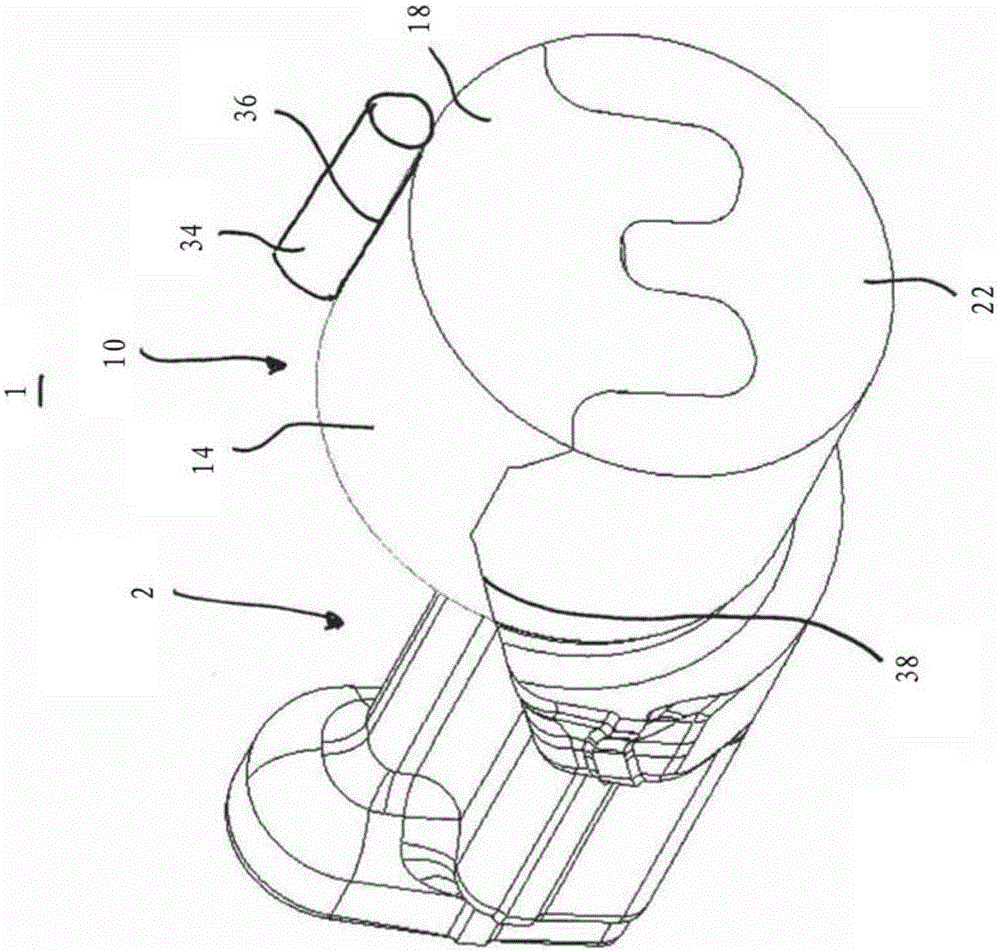

[0018] figure 1 A perspective section through an unbalanced shaft 1 is shown, which has a plurality of shaft sections 2 , 4 and 6 and is mounted rotatably along an axis of rotation D. FIG. An unbalanced mass 8 is arranged on the shaft sections 2 , 4 and 6 in each case, which ensures a center of gravity that is eccentrically formed with respect to the axis of rotation D. FIG. figure 1 It is also shown that the imbalance shaft 1 can be supported radially by means of bearing journals 10 , 12 . The bearing journals 10 , 12 thus generally serve as inner running surfaces for the rolling bodies (not shown) of rolling bearings with line contact, so that the cylindrical outer surfaces 14 , 16 of the bearing journals 10 , 12 simultaneously serve as contact surfaces for the rolling bodies. working surface. Rolling bearings with line contact are considered to be all rolling bearings of this type in which the rolling elements contact their running surfaces along a straight line. These a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com