Numerical control milling and drilling machine

A technology for drilling and milling machines and beams, which is used in large fixed members, maintenance and safety accessories, feeding devices, etc., can solve problems such as large hole spacing error, large milling vibration, and uneven surface, and achieve rapid and accurate drilling and milling. The degree of automation and the effect of good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with specific drawings and embodiments.

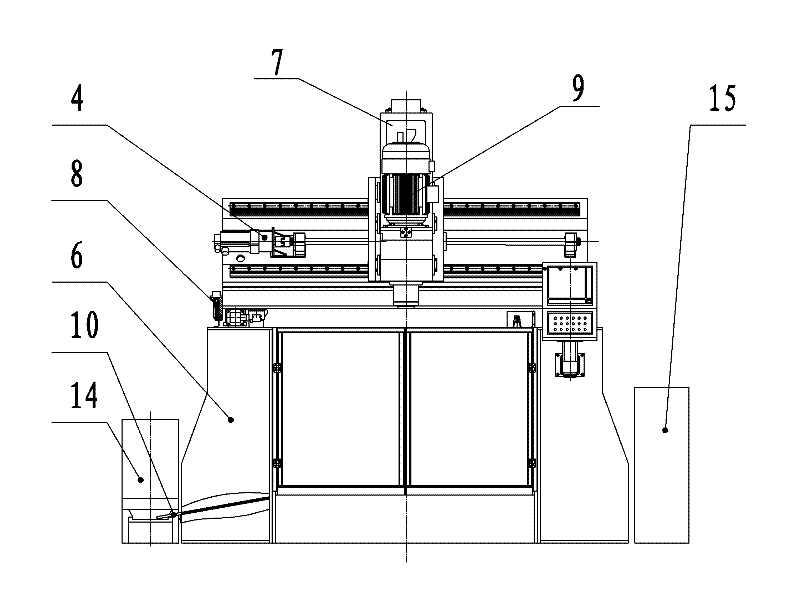

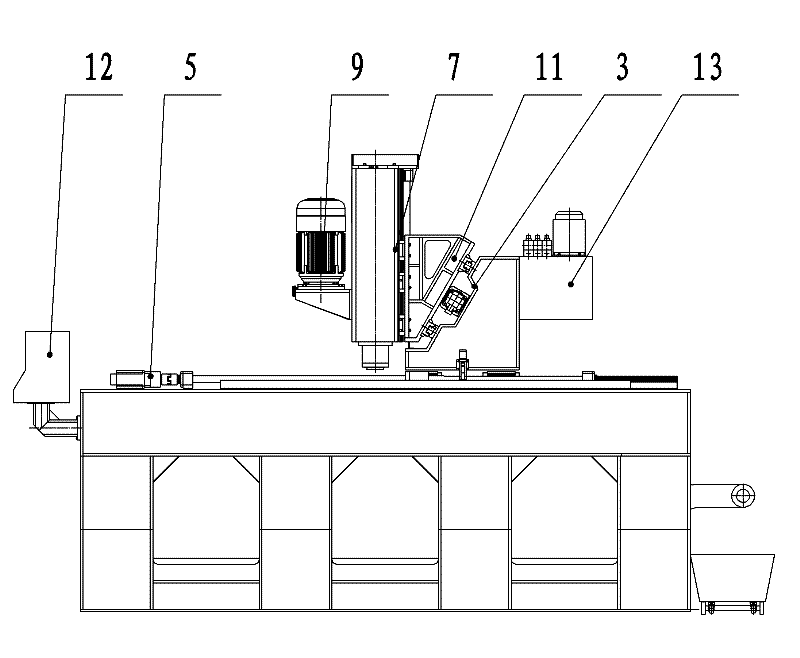

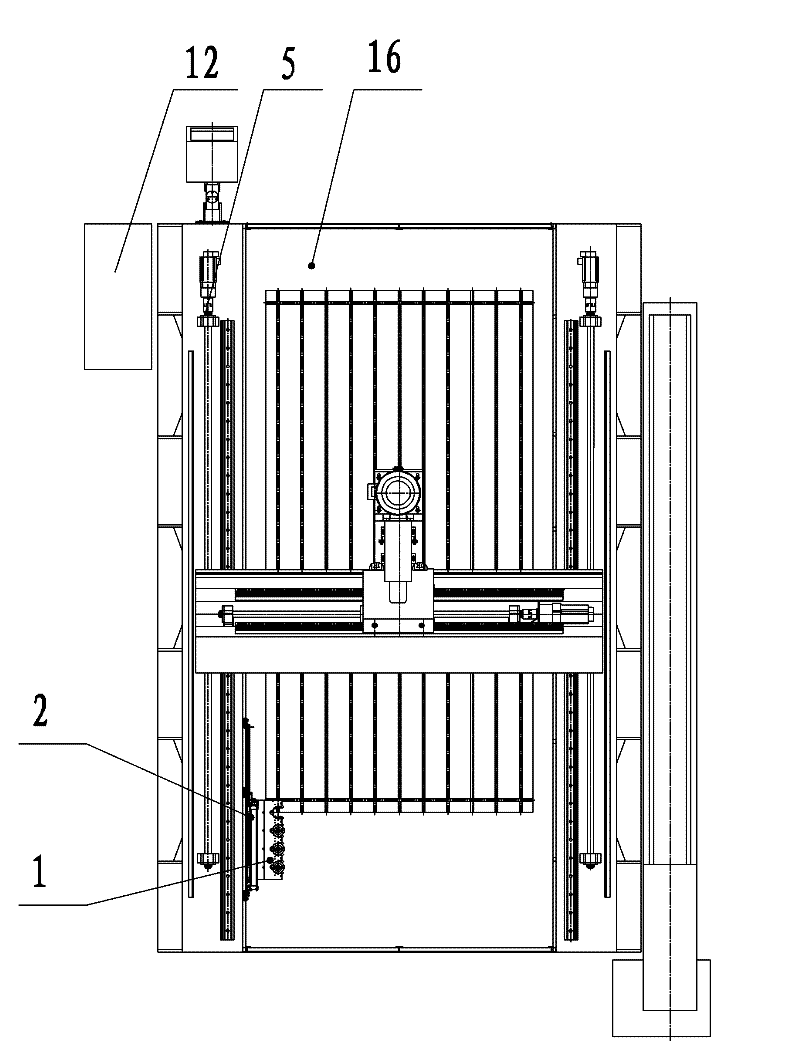

[0061] Such as figure 1 , 2 , 3, the present invention mainly consists of a tool magazine mechanism 1, a tool magazine feeding mechanism 2, a crossbeam inclined mounting surface structure 3, a transverse transmission mechanism 4, a crossbeam transmission structure 5, a welding frame structure 6, a lifting structure 7, a hydraulic lock Tightening structure 8, main shaft transmission structure 9, chip plate 10, mobile frame 11, numerical control operating system 12, hydraulic system 13, chip removal machine 14, electric control box 15, workbench 16 and locking bar 17 and other components.

[0062] Such as Figure 4 , 5 As shown, it is mainly composed of bracket 1.01, tool handle 1.02, pin shaft 1.03, cap nut 1.04, tool holder 1.05, pin shaft 1.06, hinge pin shaft 1.07, flat key 1.08, holder 1.09, edge tension spring 1.10, lining Components such as cover 1.11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com