Face miller and use thereof

A face milling cutter and blade technology, applied in milling cutters, milling cutting inserts, cutters for milling machines, etc., can solve the problems that the cutter cannot maintain the level of cutting efficiency and tool life, milling cutter vibration, and excessive insert load, etc. Achieve good surface quality, prolong service life and reduce heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

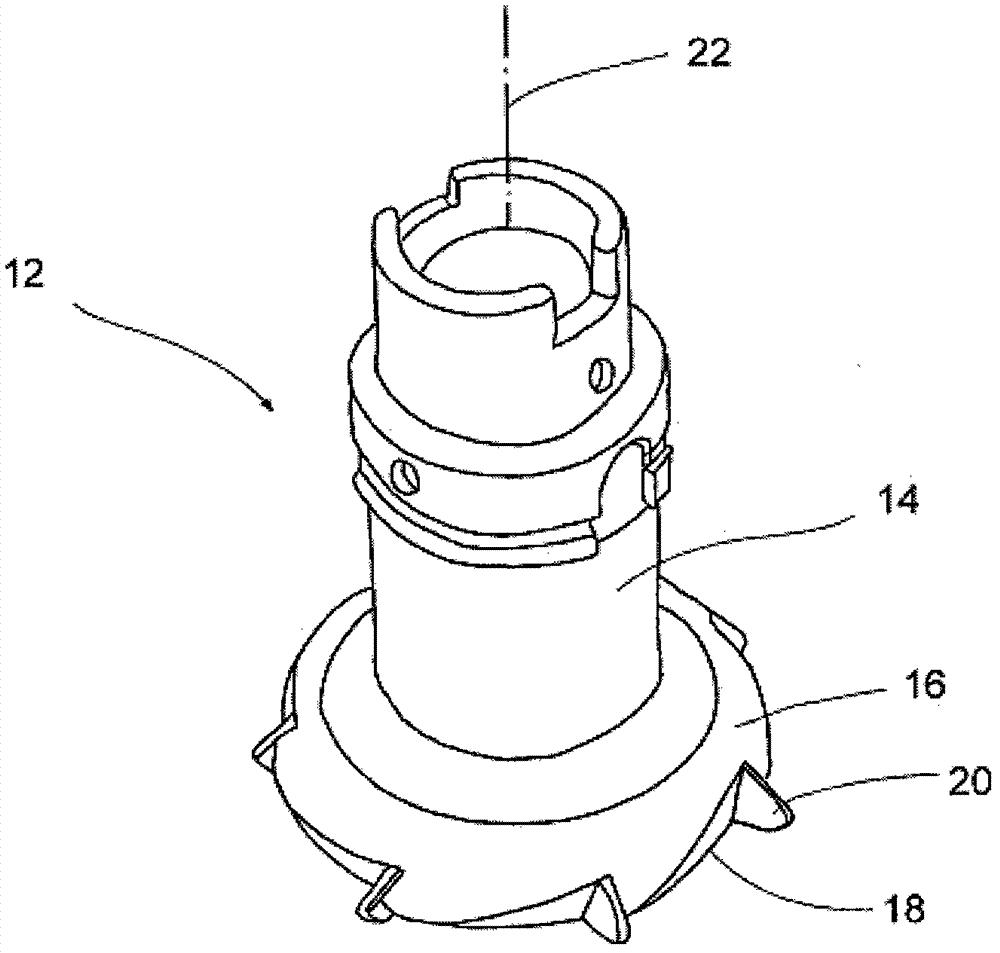

[0035] figure 1 What element symbol 12 represents in is a face milling cutter, and milling head 16 is housed on its cylindrical shank 14. Each of the grooves 18 of the milling head 16 accommodates a hard material cutting insert 20, and the specific arrangement is such that all the hard material cutting inserts 20 are located on the same indexing circle or the same edge trajectory and are spaced apart from each other by a specified distance. the circumferential distance of . Adjacent hard material cutting inserts 20 are preferably separated by different circumferential distances, that is, the milling tool adopts unequal graduations, which can reduce tool vibration caused by natural frequencies.

[0036] The above tool is a flat milling head for flat milling of end faces. The diameter of the milling head of such tools is preferably set at 1.3 times the width of the workpiece to be machined.

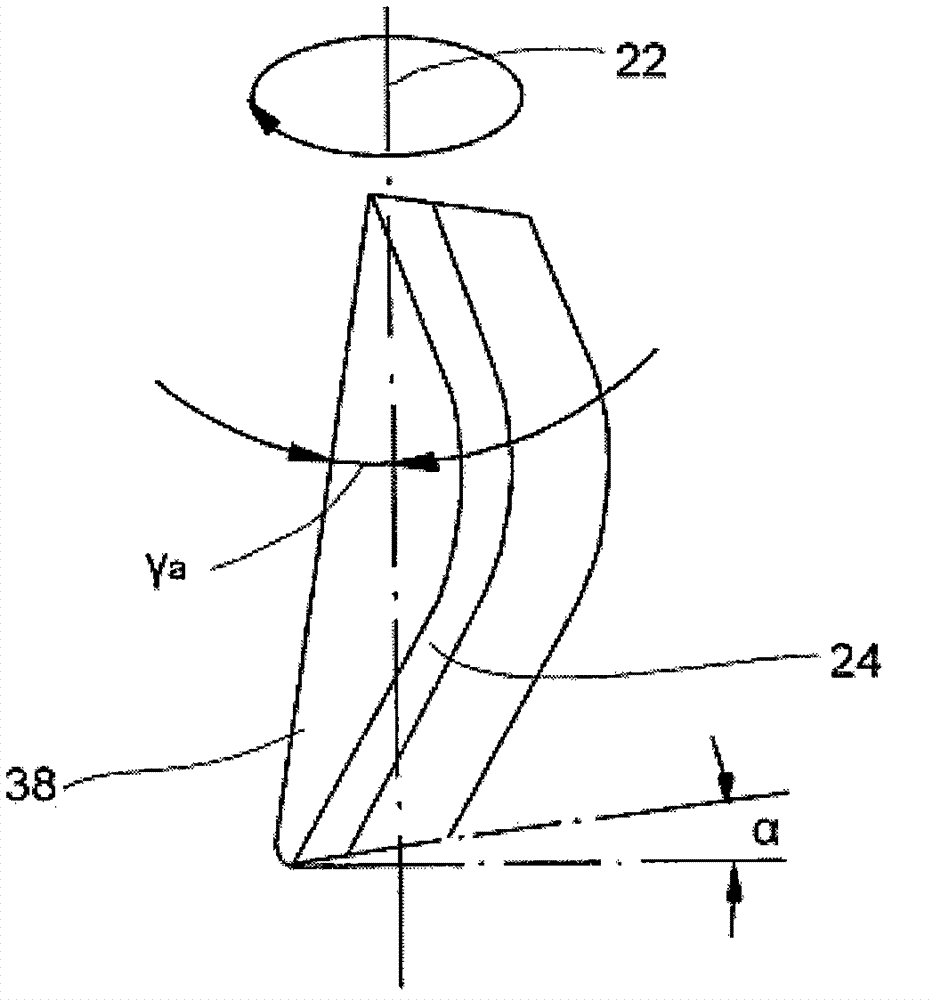

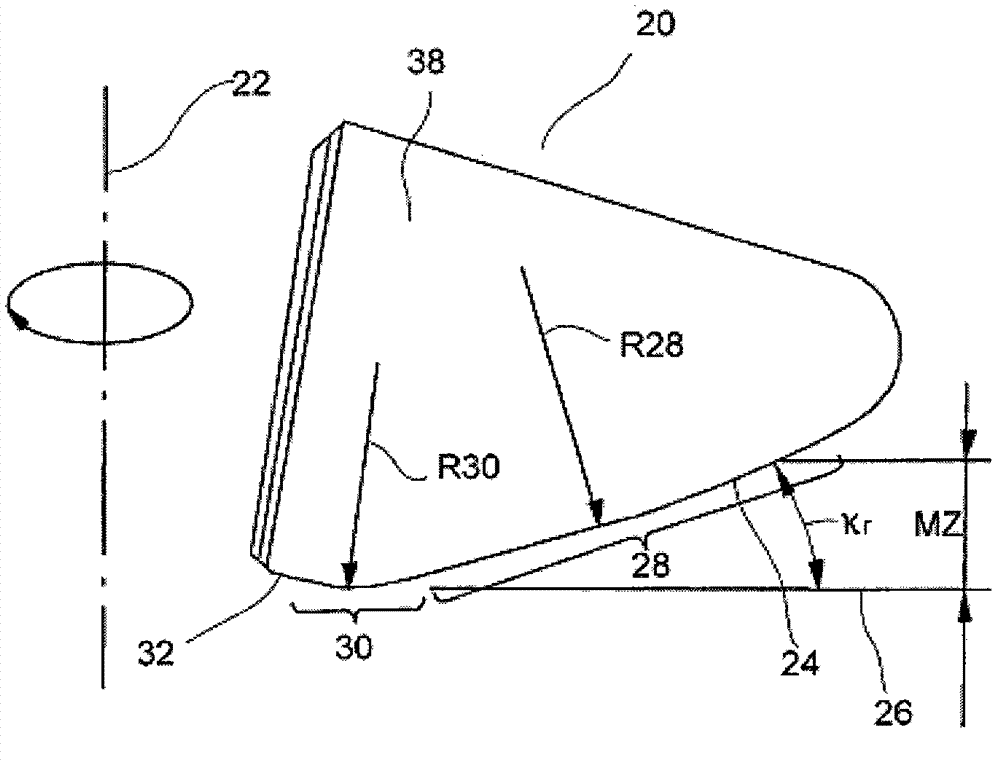

[0037]figure 1 The tool shown is characterized in that both the geometry of the hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com